Wells Regulation – Well Abandonment: How to Plug and Seal a Well (technical bulletin)

This technical bulletin 1 of 11 on well issues created for a person who currently owns a water supply well.

The purpose of this technical bulletin is to summarize the information on how to abandon a well found in the Water Supply Wells Requirements and Best Management Practices manual published by the Ministry of the Environment and Climate Change.

To determine if a well needs to be abandoned, well owners should refer to Regulation 903 (Wells Regulation), as amended made under the Ontario Water Resources Act and the Wells Regulation Well Abandonment: When to Plug & Seal a Well technical bulletin.

Requirements to hire a licensed well contractor

Unless exempt, the person abandoning the well, often the well owner, must:

- hire a licensed well contractor, and

- ensure that the contract between them requires that a well technician licensed to construct the type of well that is being abandoned be used to abandon the well.

The person abandoning the well, often the well owner, does not need to hire a licensed well contractor to plug and seal the well if the person who works on the abandonment of the well:

- is the owner of the land or is a member of the owner’s household,

- is working without remuneration (i.e. no fees or other forms of compensation) for another person on land owned by the other person or by a member of the other person’s household, or

- holds a valid well technician licence class 1 drilling.

Considerations before starting to plug and seal a well

There are many serious dangers that must be considered when assessing and working on abandoned wells. Some dangers include the following:

- When inspecting a well, the power supply to the pump should be shut off to minimize the risk of shock or electrocution.

- Many older wells especially dug wells have structural integrity problems and could collapse. As such, it is important to wear appropriate safety gear and to guard against falling into the well. Falling into the well could result in serious injury or death.

- An abandoned well could contain contamination or explosive or poisonous gases that could affect a person’s health and safety. As such, it is important to use proper field gas detection equipment and personal protective gear.

Although the Wells Regulation allows an individual land owner to abandon his/her own well without a licence, the equipment, materials and expertise needed to comply with the requirements under the Wells Regulation generally exceed the average well owner’s abilities and resources. Well owners need to understand how to measure water levels, well depths and be able to calculate volumes of well water, chemical mixtures and material mixtures. Risks of improper well abandonment include affecting the health and safety of family members, impairing the groundwater and being open to enforcement action.

It is highly recommended that a skilled well technician with a valid well technician licence of the correct class, or classes, and who holds a valid well contractor licence or works for a licensed well contractor, be retained to construct or abandon any well.

How to abandon a well nine (9) steps

The person abandoning the well, often the well owner, must ensure the following nine (9) steps are taken in this sequence, unless otherwise specified in the Wells Regulation:

- If the well has a well tag, it must be removed and returned to the Director under the Act c/o Wells Help Desk; Ministry of the Environment, 125 Resources Road, Toronto Ontario M9P 3V6 within 30 days of its removal.

- If the casing or well screen has collapsed, reasonable efforts must be made to remove the well screen or well casing. All other equipment and debris in the well must be removed.

- The well, including any annular space (i.e. any open space beside the casing or between casings), must be plugged with abandonment barrier material from the bottom of the well upward to approximately 2 metres (6.6') below the ground surface. This does not prevent the placement of clean, washed sand or gravel adjacent to water producing zones or bedrock fractures. The abandonment barrier must be placed in a manner that prevents any movement of water, natural gas, contaminants or other material between subsurface formations, which include aquifers, or between a subsurface formation and the top of the abandonment barrier material.

For step 3, an alternative method of abandonment for wells with a diameter greater than 65 centimetres (2.1 feet) is shown in Figure 3 at the end of this technical bulletin. For further information, see the Wells Regulation and Chapter 15: Abandonment: How to Plug & Seal Wells of the Water Supply Wells Requirements and Best Management Practices manual. - After or during the placement of the abandonment barrier, the well casing or well screen must be removed, if reasonably possible. During the removal of the well screen or well casing, the bottom of the casing must remain immersed in the abandonment barrier material until the required level has been reached.

- If all of the casing and well screen cannot be reasonably removed as above, then at least 2 metres (6.6 feet) of casing below the ground surface must be removed, if reasonably possible.

Requirements for the removal of casing and well screen in sequence (i.e. steps 2, 4 and 5 previously) do not apply if a person overdrills (reams) the entire well before filling the well with abandonment barrier. - If the abandonment barrier contains cement, it must set until firm and, if necessary, it must be topped up to approximately 2 metres (6,6 feet) below the ground surface.

- At any time before the upper 2 metres (6.6 feet) of the well are sealed to the ground surface (see step 8), any below ground concrete structures, foundations, and slabs must be removed unless the removal may cause the remaining structures to become destabilized, damaged or unsafe. The structures have to be removed to a depth adequate to accommodate the sealing measures described below in step 8. For clarification, the removal of the structures can occur at anytime before or during steps 1 to 7.

- To prevent inadvertent or unauthorized access to the well, the well and the well opening (including any excavation) must be sealed up to the ground surface by placing:

- 50 cm (20") to 150 cm (59") of bentonite (manufactured swelling clay product) chips, pellets, granules or powder in accordance with the manufacturer’s specifications; and

- Soil cover, or other material that is more in keeping with the material immediately adjacent to the well opening, over the bentonite and up to the ground surface.

- The disturbed area must be stabilized to prevent erosion.

Abandonment barrier requirements

Depending on the well diameter size, the abandonment barrier can be different combinations of cement or bentonite products. For further information on the types of abandonment barriers see Chapter 15: Abandonment: How to Plug & Seal Wells of the Water Supply Wells Requirements and Best Management Practices manual and the Wells Regulation.

The abandonment barrier must:

- be compatible with the quality of the water found in the well,

- not contain any materials that may impair the integrity of the abandonment barrier, including soil or drill cuttings, and

- be stable in the presence of any contaminants, if the well is in contact with contaminants.

Diagrams

Figures 1 to 3 provide examples of various well types that have been plugged and sealed based on the nine step sequential process.

Well pits

Where a well pit is abandoned, it must be abandoned like a well, with necessary modifications. For additional information see Chapter 11: Maintenance & Repair of the Water Supply Wells Requirements and Best Management Practices manual and the Wells Regulation - Repairs and Other Alterations technical bulletin.

Well records

The person abandoning the well, often the well owner, must complete a well record and deliver the well record to the owner of the land on which the well is situated within 14 days after the date on which the well construction equipment used to abandon the well is removed from the site. A completed well record must be forwarded by the person abandoning the well, often the well owner, to the ministry at the Wells Help Desk; Ministry of the Environment, 125 Resources Road, Toronto Ontario M9P 3V6 within 30 days after the well construction equipment is removed from the site.

Additional information sources

This technical bulletin on well issues is one in a series of 11 created for owners of water supply wells which are available on the Water Supply wells: technical bulletin page.

Further information on well abandonment can be found in Chapter 14: Well Abandonment: When to Plug & Seal Wells and Chapter 15: Abandonment: How to Plug & Seal Wells of the Water Supply Wells Requirements and Best Management Practices manual.

A copy of the Water Supply Wells Requirements and Best Management Practices manual can be obtained from the ministry’s website.

For all of the requirements and exemption for non water supply wells (e.g. test holes or dewatering wells) see the Wells Regulation.

A copy of Regulation 903(Wells Regulation), as amended, made under the Ontario Water Resources Act and other regulations can be obtained from the e-Laws web site.

The publications are also available by calling the Publications Information Centre at

For further information about wells, contact the Wells Help Desk at

Notice: This bulletin is being provided for information purposes only and is not intended, nor should it be construed as providing legal advice in any circumstances. The applicable legislation including the Ontario Water Resources Act and Regulation 903, as amended and made under that Act, should be consulted. Legislation and regulations change from time to time so it is essential that the most current versions be used.

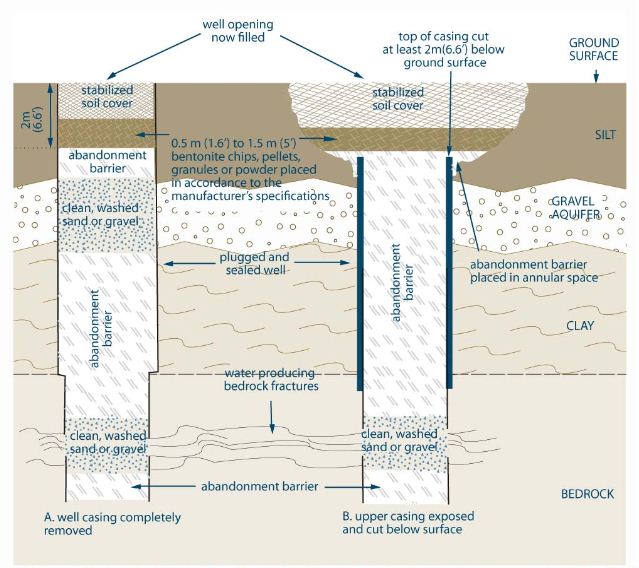

Figure 1: Plugging and sealing wells > 6.5 cm (2.5") in diameter

Download Figure 1: Plugging and sealing wells > 6.5 cm (2.5") in diameter (JPEG).

- This is typically done for drilled wells and is permitted for any type of well with a diameter greater than 6.5 cm (2.5").

- Abandonment barrier slurries must be placed using a tremie pipe.

- Abandonment barrier must prevent any movement of water, natural gas, contaminants or other materials between subsurface formations (including aquifers) and between a subsurface formation (including an aquifer) and the top of the abandonment barrier.

- Water should be added to the bentonite chips, pellets, granules or powder to start hydration.

- Soil cover can be other material in keeping with existing adjacent surface material. The soil cover must prevent inadvertent and unauthorized access to the well.

- Well opening is typically excavated to remove the top portion of the well casing.

The diagram above is not to scale, is for illustrative purposes only and does not necessarily represent full compliance with other requirements found in the Wells Regulation.

Figure 2: Plugging and sealing narrow diameter wells

Download Figure 2: Plugging and sealing narrow diameter wells (JPEG).

- This is for situations where well casing and well screen are being removed or are absent.

- This is typically for narrow diameter drilled, jetted and driven point wells

- Abandonment barrier must prevent any movement of water, natural gas, contaminants or other materials between subsurface formations (including aquifers), and between a subsurface formations (including an aquifer), and the top of the abandonment barrier

- Water should be added to the bentonite chips, pellets, granules or powder to start hydration

- If well casing and screen are not being removed, the abandonment barrier must be:

- a slurry of clean water and Portland cement + up to 5% bentonite solids by weight, or

- bentonite chips or pellets that have been screened and placed in accordance with manufacturer’s specifciations.

- The well opening is typically excavated to remove the top portion of the well casing.

The diagram above is not to scale, is for illustrative purposes only and does not necessarily represent full compliance with other requirements found in the Wells Regulation.

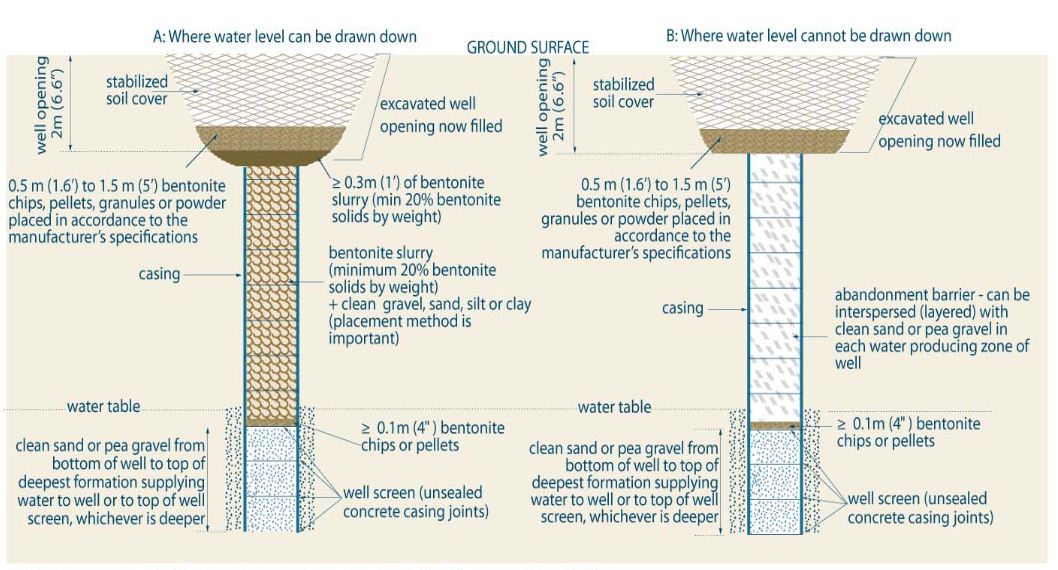

Figure 3: Plugging and sealing large diameter wells > 65 cm (2.1') - Alternate methods

- This alternative method is for large diameter dug or bored wells [i.e. diameter > 65 cm (2.1')].

- Abandonment barrier slurries must be placed using a tremie pipe.

- Soil cover can be other material in keeping with existing adjacent surface material. The soil cover must prevent inadvertent and unauthorized access to the well.

- Abandonment barrier must prevent any movement of water, natural gas, contaminants or other materials between subsurface formations (including aquifers), and between a subsurface formation (including an aquifer), and the top of the abandonment barrier.

- Water should be added to the bentonite chips, pellets, granules or powder to start hydration.

- The well opening is typically excavated to remove the top portion of the well casing.

The well in Diagram 'A' of Figure 3, above, is filled with a bentonite slurry (minimum 20% bentonite solids by weight) plus clean gravel, sand, silt or clay. Here the placement method is important. See Chapter 15: How Abandonment: How to Plug & Seal Wells of the Water Supply Wells Requirements and Best Management Practices manual for further information.

The diagram above is not to scale, is for illustrative purposes only and does not necessarily represent full compliance with other requirements found in the Wells Regulation.

PIBS 7940e