Environmental guidelines for access roads and water crossings

Direction on the construction and maintenance of access roads and water crossings in a forest environment.

©1990, Queen’s Printer for Ontario

Printed in Ontario, Canada

Single copies of this publication are available for $5.25 from the address noted below.

Current publications of the Ontario Ministry of Natural Resources, and price lists, are obtainable through the Ministry of Natural Resources Public Information Centre, Room 1640, Whitney Block, 99 Wellesley St. West, Toronto, Ontario M7A 1W3 (personal shopping and mail orders).

Telephone inquiries about ministry programs and services should be directed to the Public Information Centres:

Fisheries/Fishing Licence Sales –

Wildlife/Hunting Licence Sales –

Provincial Parks –

Forestry/Lands –

Aerial Photographs –

Maps –

Minerals –

Cheques or money orders should be made payable to the Treasurer of Ontario, and payment must accompany order.

Other government publications are available from Publications Ontario, Main Floor,

880 Bay St., Toronto. For mail orders write MGS Publications Services Section, 5th Floor, 880 Bay St., Toronto, Ontario M7A 1N8.

1.0 Preface

This manual provides a collection of guidelines for those involved with access roads on Crown land in Ontario. It will assist them in carrying out their projects with a minimum of disturbance to the natural environment.

These guidelines were prepared following an extensive review of guidelines used for similar purposes in other jurisdictions. Section 9 contains a partial list of these other publications.

A technical advisory group assisted in developing the manual’s final text.

Organizations represented within the advisory group included various disciplines within the Ministry, the Ontario Forest Industries Association, the Ontario Lumber Manufacturers Association and the Ontario Ministry of the Environment.

The group’s participation ensured the publication reflects the knowledge and field observations of experienced people from a cross-section of public and private sector organizations that have an interest in access roads and water crossings in Ontario.

The Ministry of Natural Resources gratefully acknowledges the following people for their participation within the technical advisory group.

Ministry of Natural Resources:

Bruce Adamson, Chairman

Regional Engineer

North Central Region

Thunder Bay

Cam Clark

Policy Officer

Assistant Deputy Minister’s Office

Thunder Bay

Linda Jackson

Policy Officer

Land Management Branch

Toronto

Brian Martyniuk

Engineering Services Technician

Thunder Bay District

Thunder Bay

Alan Parkinson

Environmental Planner

Planning and Environmental Assessment Branch

Toronto

Don Stillar

Timber Management Supervisor

Cochrane District

Greg Vaughan

Senior Lands Technician

Bracebridge District

Neville Ward

Regional Fisheries Biologist

Northwestern Region Kenora

Outside Participants:

Paul Abbott

Communications Consultant

The Abbott Jenkins Design Group

Toronto

George Blight

Consultant to Forest Industry

Amisk Forest Services Limited Hearst

Bill Creighton

Manager, Technical Support

Ministry of the Environment

Thunder Bay

Larry Hicock

Principal Writer

The Abbott Jenkins Design Group

Toronto

Ray Townsend

Operations Superintendent

The Algonquin Forestry Authority

Huntsville

Rudy Zorn

Construction Superintendent

Canadian Pacific Forest Products Limited

Thunder Bay

2.0 Introduction

2.1 Why guidelines?

It is expected that most planners, developers, operators and others involved in road development projects share a concern for the well-being of the natural environment. The potentially harmful effects of access road activities can be eliminated or minimized by decision makers who have an understanding of good environmental practices and use that knowledge effectively.

Various environmental values should be considered during the planning, construction, maintenance and abandonment of access roads and water crossings. These include:

- aquatic (water quality and fisheries)

- terrestrial (plants and animals)

- recreation, cottaging and tourism

- historical and archaeological

- aesthetics (at some locations)

- air quality (dust abatement, pollution control)

- noise levels

- worker and public safety

- economic considerations

The purpose of this manual is to establish standards and provide practical advice for ensuring minimum disturbance to the natural environment (aquatic, terrestrial). Other values outside the scope of these guidelines, for example tourism or archaeological, may require the implementation of specific mitigation techniques to minimize the effects of access roads on that value. These would normally be identified and prescriptions developed at the planning stage of the project, possibly referring to other guideline documents that are available.

The specific objectives of this manual are:

- To provide up to date environmental guidelines appropriate for the construction, maintenance and abandonment of access roads and water crossings.

- To establish mandatory standards to be followed when constructing, maintaining and abandoning access roads and water crossings on Crown land to ensure a minimum level of environmental protection.

- To record and disseminate information about good practices being used in Ontario which have proven effective in minimizing the impact on the environment.

- To provide design information about special mitigation techniques that may be used to eliminate or reduce potential negative environmental impacts.

The decisions and actions of those involved in planning, constructing and maintaining access roads and water crossings have a significant influence on how much impact those activities have on the natural environment. By using this publication access objectives can be met while the extent and duration of environmental impacts are minimized.

In many cases implementation of the recommendations does not require any additional expenditure of money. In fact, doing it right the first time is often more economical in the long run because it avoids costly mistakes that may have to be rectified. Good practices lead to efficient, cost-effective construction projects. They will ensure that access roads and water crossings will continue to function with a minimum of maintenance problems and a minimum of adverse environmental impacts.

Adherence to the manual’s guidelines will help to assure compliance with relevant legislation. As a result, technical or legal irregularities can be avoided before they arise.

2.2 Application of this manual

This manual applies to the planning, construction, maintenance and abandonment of access roads on Crown land in Ontario. These activities are subject to the Environmental Assessment Act and to the Lakes and Rivers Improvement Act. The guidelines complement other pertinent guidelines and procedures such as the Guidelines and Criteria for Approval Under the Lakes and Rivers Improvement Act, Access Road Strategies and Guidelines, Fish Habitat Guidelines, Moose Habitat Guidelines, and Tourism Guidelines.

It is a requirement of the Class Environment Assessment for Timber Management in Ontario that this manual be followed for road access activities undertaken as part of timber management. The Ministry of Natural Resources will be responsible for monitoring compliance of the private sector, as well as its own staff, with these guidelines. Where necessary, the Ministry of Natural Resources or the Ministry of the Environment will undertake enforcement related to the statutes under their administration.

Although developed for use as support to the Class EA for Timber Management, the good environmental principles and guidelines set out in the manual have application to all access roads, regardless of their purpose. This publication supercedes portions of the Construction and Mitigation Handbook dealing with access roads.

There are a wide variety of access road types and standards constructed in Ontario. The potential harmful effects on the natural environment are influenced by the physical site conditions, the activity being undertaken, the road standard, the life of the road and abandonment procedures. The potentially negative effect of a poorly installed water crossing on an important spawning bed is not lessened because it is located on a tertiary road and not a primary road. For this reason it is intended the manual will apply to all access roads on Crown land regardless of type, standard or duration of use. It is not intended to apply to roads on dedicated rights-of-way such as those under the jurisdiction of the Ministry of Transportation, Municipalities or Ontario Hydro.

2.3 Using this manual

The manual is a comprehensive collection of mandatory standards, good practice guidelines and mitigation techniques. There will be variation in practice from area to area and some of the operations described may not apply to some roads. The guideline should be applied where necessary and appropriate to prevent or minimize a potentially harmful effect on the environment. The manual is a source of information for decision-makers to draw upon to accomplish this objective.

This manual is divided into several sections. It is important to understand the manner in which these relate to each other.

Legislation and mandatory standards set out the minimum criteria that must be followed to prevent unnecessary or unacceptable environmental changes. It is expected they will be followed in all circumstances.

Adherence to the mandatory standards does not guarantee automatic compliance with applicable legislation. In situations where mandatory standards are inadequate to protect fisheries habitat, water quality or other values, appropriate good practice and mitigation techniques must be selected and used to ensure legislative standards and requirements are met. For example, if a specific objective such as protection of a fish spawning bed, is not met by following the mandatory standards then additional site specific measures may become necessary to ensure compliance with the Fisheries Act.

Good practice guidelines are provided for each component of planning, constructing, maintaining and abandoning access roads and water crossings. Most are based on simple common sense principles. Adherence to them will minimize potential harmful effects on the natural environment. As with all guidelines, flexibility is expected in their application, however they should be followed to the extent reasonably possible throughout the entire road length.

Mitigation techniques are the means by which construction activities can be modified to minimize or eliminate potential negative impacts at specific locations where important values must be protected. The techniques described in the manual are primarily focussed on erosion and sediment control at water crossings.

In areas of unique or special values, identified prior to or during construction, it may be appropriate to specify some of the good practice guidelines or mitigation techniques as mandatory requirements to mitigate possible negative impacts. In this way managers involved in road construction can draw on the information contained in the guidelines to utilize appropriate construction techniques in the protection of identified values along the route of the road.

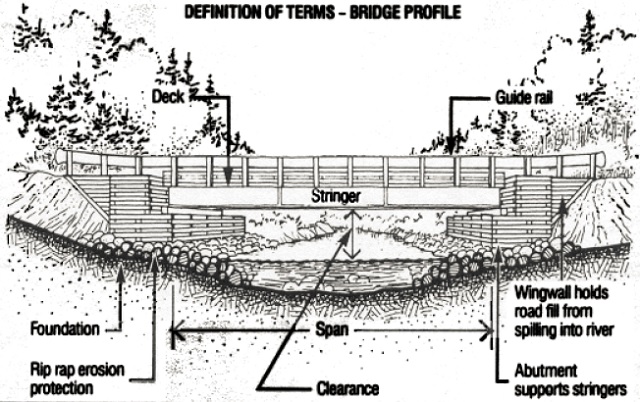

A section containing a glossary of terms is provided to define technical and construction terminology as it is used in the manual. A list of publications used as a source of information during development of the manual is provided.

It may be useful to readers who wish further details on specific areas of interest.

The guidelines contained in this manual apply to all types of access roads, including this tertiary road.

The guidelines contained in this manual apply to all types of access roads, including this tertiary road.3.0 Applicable legislation

3.1 Introduction

This section summarizes most of the special Federal and Provincial legislation applicable to the construction of access roads and water crossings on Crown land.

Included is a brief description of each of the Acts which require a permit or application for approval. Activities associated with access road and water crossing construction on Crown land that require such approvals and/or permits include the following:

- Cutting of timber on Crown land.

- Construction of a water crossing

- Any activity on Crown land during the forest fire season.

- Construction near a water body that could have a detrimental effect on fish habitat or water quality.

- Development and operation of a borrow pit or gravel pit.

- Any activity associated with timber management on Crown land.

3.2 Federal legislation

The Fisheries Act - This Act requires the protection of fish habitat; administered in Ontario by the Ministry of Natural Resources.

Navigable Water Protection Act - Under this Act, any construction in or over a navigable water body requires an application and approval; administered by the Ministry of Transport, Canadian Coast Guard.

The Railway Act - Construction and regulation of matters related to railways come under this legislation, including railway crossings; administered by the National Transportation Agency of Canada.

3.3 Provincial legislation

Crown Timber Act - Authority to cut wood on Crown land, including right-of-way clearing. It has penalties to deal with wasteful practices and the destruction of timber; administered by the Ministry of Natural Resources.

Environmental Assessment Act - Activities of the Government of Ontario, including the construction of roads, fall under this legislation. Timber management in Ontario, including the construction of roads by the forest industry, is subject to the provisions of this legislation; administered by the Ministry of the Environment.

Environmental Protection Act - Contains regulatory requirements pertaining to air, water, land and noise pollution; covers the required approval of sewage and solid waste disposal sites; administered by the Ministry of the Environment.

Forest Fire Prevention Act - A Work Permit, to authorize any work on Crown land and to ensure that adequate forest fire precautions and equipment are in place, is required; administered by the Ministry of Natural Resources.

The Lakes and Rivers Improvement Act - Approval is required for the construction of a dam

across a watercourse. A bridge or culvert may act as a dam in certain circumstances. A technical review is necessary to determine if an application is required; administered by the Ministry of Natural Resources.

The Mining Act - a Quarry Permit is required to develop and operate a borrow or gravel pit in areas of the Province excluded from the Pits and Quarries Control Act; administered by the Ministry of Natural Resources.

Occupational Health and Safety Act - Regulation 692 contains provisions applying to timber haul roads, such as road signs and the structural capacity of bridges. The Act also covers safety on construction sites; administered by the Ministry of Labour.

Ontario Heritage Act - Permits are required for excavation or alteration of archeological and historical sites; administered by the Ministry of Culture and Communications.

Ontario Water Resources Act - The Act prohibits the discharge or deposit of any material into any waterbody which may impair the water quality or may cause injuries to any person or living thing; administered by the Ministry of the Environment.

Pesticides Act - Regulates the availability, sale, use, transportation, storage and display of all pesticides. The use of herbicides on access roads requires that the pesticide be federally registered, provincially classified and applied by a licensed applicator. The use of certain pesticides requires a special use permit; administered by the Ministry of the Environment.

The Pits and Quarries Control Act - a Quarry Permit is required to develop and operate a borrow or gravel pit in areas of the Province where this Act applies; administered by the Ministry of Natural Resources. New legislation is proposed to replace this Act with the Aggregates Act which will apply to the whole Province.

Public Lands Act - Authority to construct roads on Crown land; authority for Crown cost-sharing of company roads; sets out limitations on liability, tenure for private forest roads, camp areas, defines applicability of the Highway Traffic Act on access roads; authority for use restrictions; administered by the Ministry of Natural Resources.

The Public Transportation and Highway Improvement Act, and associated Cabinet Approved Policy Statements - These address Provincial Highways, District, County and Municipal roads. Since some roads fall under the Controlled Access Criteria

, entrance permits will be necessary and applications must be made to the appropriate government agency controlling such roadways; administered by the Ministry of Transportation.

4.0 Mandatory standards

The following list sets out standards that are considered mandatory to protect the natural environment within which access roads and water crossings are built. These standards must be adhered to by anyone planning, constructing, maintaining and abandoning access roads or water crossings as part of timber management on Crown land in Ontario. Their use is encouraged on access roads for purposes other than timber management.

- All applicable legislation, as identified in Section 3, must be complied with. Those persons responsible for construction must ensure the necessary approvals and permits are in place before physical site work begins. Conditions of those approvals and permits must be met.

- A use management strategy for each primary and secondary road or for each timber management unit must be developed; this is to include consideration of other uses and abandonment when the road is no longer needed for its original purpose.

- Areas of concern identified during the planning process must be adequately addressed. Areas of concern include locations where particular values are to be protected and environmentally sensitive areas which require special attention. Appropriate mitigation techniques must be followed throughout the planning, design, construction, maintenance and abandonment of the road.

- Other uses of Crown land identified in advance (e.g. staked corner posts for mining, trenches, grid markers, trapper’s cabins, boat caches) must not be disturbed unless approval to do so has been given by the lessor and by the Ministry of Natural Resources.

- Water crossing proposals must be reviewed by the Ministry following the Guidelines and Procedures for Approval Under the Lakes and Rivers Improvement Act. This review may lead to a determination of: construction time restrictions; a minimum waterway opening size; special mitigation requirements for preventing flooding and/or minimizing detrimental impacts on fish habitat and water quality. To avoid delays, this review should occur well ahead of the proposed road construction.

- During the construction and maintenance of access roads and water crossings, appropriate measures must be taken to prevent contamination of water bodies by foreign materials such as lumber, nails, logs, brush, fuel, oil, lime, cement, asphalt, calcium chloride, sodium chloride, oil base wood preservatives and herbicides. No herbicides are to be sprayed within 10 metres of a water crossing.

- Clearing operations in rights-of-way must conform with the requirements of the Crown Timber Act, including the harvesting and utilization of salvageable wood.

- Materials moved during construction, such as grubbing, earth fills and earth cut materials must not be piled where they block drainage courses.

- The use of heavy construction machinery on streambeds is not permitted during spawning and incubation periods and must be kept to an absolute minimum at other times.

- Waterways must not be blocked so as to impede the free movement of water and fish.

- Clearing and grubbing of low vegetative cover within 100 m (350 feet) of a water crossing, or other water body identified as being sensitive by the Ministry, must be kept to the absolute minimum necessary for constructing the project.

- Exposed mineral soil within 100 metres (350 feet) of a water body must be graded to a stable angle of repose to prevent erosion.

- Appropriate erosion control and/or sedimentation control measures are to be undertaken to protect water quality.

- Access routes to lakes and streams outside the road right-of-way limits must not be constructed without the approval of the Ministry.

- Permanent diversion or channelization of an existing water course is generally inadvisable and, if undertaken, must not create any more disturbance of the natural environment than absolutely necessary. Waterway size and erosion resistance of the new channel must be comparable to those of the natural channel unless a special engineering analysis and design justifies an alternative approach. The new channel must be constructed in the dry to the maximum extent possible.

- Fill material placed below high water level within the floodplain of water bodies must be erosion resistant.

- Construction techniques used at water crossings must be selected to protect water quality. This may require the selection and use of special mitigation techniques.

- Fill slopes and waterway banks disturbed during construction must be trimmed to a stable angle of repose. Upon completion of a water crossing, any temporary fill, culverts, refuse, etc. must be removed from the construction area and disposed of in a satisfactory manner.

- Staff, as part of their normal field duties are expected to observe, on an annual basis, the condition of water crossings on maintained roads, particularly with respect to the potential for washouts or blockages of culverts. Problems are to be reported to the appropriate road authority.

Naturally abandoned roads

will be inspected at least once every three years and more frequently where circumstances, such as abnormal rainfall, warrant.- When a road is

physically abandoned

footnote 1 appropriate measures are to be taken to prevent significant erosion and sedimentation of water bodies. These measures may include the removal of culverts and bridges and grading of slopes to stable angles of repose.

5.0 Access roads – good practices

5.1 Introduction

The construction of access roads can cause significant disturbance to the natural environment. The seriousness of the impact depends on many factors, including:

- type of natural environment

- terrain difficulty

- soil types along the route

- construction materials used

- geometric road standard

- construction and maintenance practices

- a mitigation techniques implemented

- road abandonment practices

The good practices described in this section apply to all types of roads. It is recognized that not all guidelines may be relevant to all roads, however even low standard tertiary roads have the potential for causing significant harmful effects. The practices described should be consulted as a matter of course prior to and during the management of access road projects.

Access road activities can be subdivided into a series of operations that take place in a chronological sequence. Using this sequence, the good practices have been grouped into the following components:

- road planning and location

- a clearing

- grubbing

- earth grading

- a rock grading

- drainage ditches and culverts

- swamp treatments

- graveling

- road maintenance

- road abandonment

5.2 Road planning and location

This phase comprises the preconstruction components of the corridor study, road location and road design.

The level of technical evaluation, layout and design required on a particular road depends on the geometric standard, the terrain through which the road will be built and the method of construction. At this stage, the final alignment of the road is selected. Decisions about the location of a particular road have an important influence on the impact the road will have on the natural environment.

Good practices - location:

- Ensure areas of concern in the planning stage have been identified and dealt with. This may require special mitigation techniques such as protection of canoe routes, erosion control at water crossings, building neat push-outs for aesthetics, avoidance of osprey nests.

- Select the location of water crossings well in advance of construction, particularly those identified in Timber Management Plans.

- Avoid unfavourable construction areas as much as possible. These include hilly terrain with steep grades (10% or more); areas with insufficient gravel; deep swamps; bedrock; erodible soils; and shallow soils areas.

- For environmental as well as practical considerations, road alignments should follow the contours of the land.

- Gentle grades (1-4%) are desirable for proper drainage and economical construction.

- Long, sustained grades should be avoided since they allow excessive runoff buildup in ditches and can lead to erosion.

- Keep roads away from recreational areas, water bodies and wetlands, except where water access or aesthetic viewing is an objective of the road.

- Buffer zones of undisturbed vegetation between access roads and water bodies should be maintained and should increase in width proportionally to the increase in slope of land entering the waterway.

- Minimize the number of water crossings.

- Geometric road standard should be appropriate for the intended use and for the duration of use of the road. Construction to a higher standard than necessary increases costs and has the potential for more environmental damage.

- Identify sources of material for road construction, and consider locating the road near these sources, in order to minimize haul distances and provide better materials to work with.

- Landings, loading areas and turnarounds should be located when the road is being laid out. Landings should be on high ground to avoid rutting and blocking of drainage paths.

5.3 Clearing

Clearing consists of cutting and removing standing trees to make room for construction of the road. It is normal practice to specify a minimum width of clearing. This is done for several reasons: to allow space for construction equipment to operate without knocking down standing trees; to provide safe sight lines around curves; and, to allow drying of the roadway in wet weather and spring break-up. Maximum widths should also be specified to minimize the areal extent of disturbance caused by road construction.

The equipment normally used for clearing includes chainsaws, bulldozers, wheeled skidders and other loading, slashing and haulage equipment for wood handling.

Good practices - clearing

- Do not clear an area larger than necessary to meet the geometric standard for the road; control clearing width using marked sidelines.

- Reduce clearing width to the minimum needed for construction within 100 metres (350 feet) of a water crossing, or a water body identified by the Ministry as being sensitive.

- Away from water crossings, a minimum width of 20 metres (66 feet) should be cleared to ensure the road will dry out, and to provide sight lines for safety.

- Trees should be felled away from standing bush and water bodies.

- Push-outs should be pre-cut. Locate them on the low side of the road, but without blocking drainage.

- Landings should be pre-cut, on high ground, off the right-of-way, and in scrub brush areas if possible.

- Salvage merchantable timber from right-of-way clearing.

- Clear in winter months to reduce rutting.

- Slash debris should be disposed of as part of the grubbing operation.

5.4 Grubbing

Grubbing, or stripping, consists of the removal and disposal of stumps, roots, brush, small trees, embedded logs and organic material overlying the mineral soil.

Grubbing is done to expose the mineral soil for three reasons:

- To prepare for earth grading operations.

- To improve roadway performance by eliminating weak organic material in the zone carrying wheel loads; and

- To minimize future sight distance problems that roadside vegetation could cause.

Full width grubbing is done where road-building materials are expected to come from the right-of-way area. Occasionally, in certain soil conditions and on low standard roads, the grubbing material is pulled to the centre and trampled down to form part of the roadbed. On some roads, especially in deep fill areas, it is acceptable to not grub; this will minimize impact on natural environment. It should be kept in mind that it is the grubbing operation which exposes mineral soil to erosion and compaction.

The equipment usually used in the grubbing operation are bulldozers and backhoes. Special blades have been developed for bulldozers, featuring rake-like teeth or small shoes that elevate the blade to allow collection of the brush and stumps while leaving the organic topsoil on the right-of-way. It is useful to use this equipment to retain low vegetation and to minimize erosion problems.

Good practices - grubbing:

- To ensure that trees on the bush line are not under-cut, a cleared but not grubbed buffer should be left along the edge of the right-of-way.

- Grubbing should not proceed too far ahead of construction. This will limit the time that the mineral soil is exposed to erosion.

- Grubbing material should not be piled where it will block drainage courses.

- If windrows are used, they should be kept behind roadside ditches and breaks should be provided so animals can move across the right-of-way, say 5 metres every 65 metres (16 feet every 200 feet).

- If push-outs are used, they should be pre-cut to a large enough size to avoid knockdown of standing trees.

- Swamps should not be grubbed.

- The stumps in swamp areas should be shear bladed in winter if possible.

- If some organic material is left in place, it will make nutrients available to ensure rapid re-vegetation of the right-of-way. This can be done by using special blades or attachments on a bulldozer and by grubbing in winter when the blade can ride on the frost.

- In areas of fine grained soils (clays, silts and fine sands) which are subject to erosion, the area to be grubbed should be minimized.

- Grubbing in fine grained soil should be avoided during wet weather. This will prevent severe rutting and unnecessary disturbance of the clay or silt soil. Postpone the grubbing operation until drier conditions prevail, or close-cut the trees and do not grub.

5.5 Earth grading

Earth grading reshapes the original ground contours to the shape of the road, in profile and cross-section.

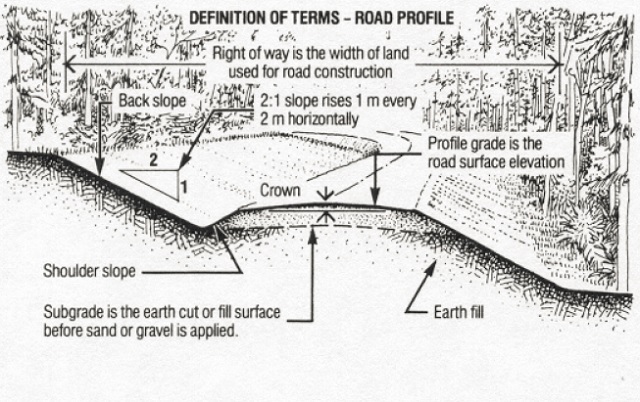

The operation includes the excavation of earth cuts and the construction of earth fills. Lower standard roads tend to follow the original ground contours more closely, because their geometric requirements are less critical; this means that cut and fill depths will be less than those for a higher-standard road constructed along the same route.

The equipment normally used includes bulldozers, front-end loaders, backhoes, dump trucks and scrapers. In poor soil areas, the use of backhoes for building fills - by pulling in material from within the right-of-way - is a preferred method. It allows for better material selection and creates less disturbance. Rather than having the material pushed into position, a backhoe picks the material up, moves it, then places it where needed; this gives the fill a chance to dry out and consolidate before it has to carry heavy traffic.

The use of well-drained, granular soils produces strong roadbeds that are easier to construct, and that will be erosion resistant. By paying close attention to the shaping of the earth cross-section and the selection of materials, and by providing for good drainage, initial costs will be minimized, maintenance costs will be reduced and potential detrimental impacts on the environment will be prevented.

Good practices - earth grading:

- Soil instability due to soft clay, springs or erosion can result in road failure. Treat soil instability by reducing the loading (fill height) or with counterbalancing side berms. Treat persistent springs with sub-surface drainage.

- Where there are potential serious consequences of soil instability or erosion, erosion control techniques should be used promptly.

- Retain natural vegetation near water crossings as long as possible, to reduce the time that the soil is exposed; i.e., delay cut excavations under the road-bed until the last moment.

- Do not dump waste material in areas that may block the flow of water.

- Fill in or around water bodies should be constructed with earth-free rock or clean, well-graded, granular material; this will help reduce the impact on fish habitat and water quality.

- Install drainage culverts as part of the earth grading operation.

- Excavate cuts uphill to improve drainage and make material more workable. Complete ditches as cuts are being excavated.

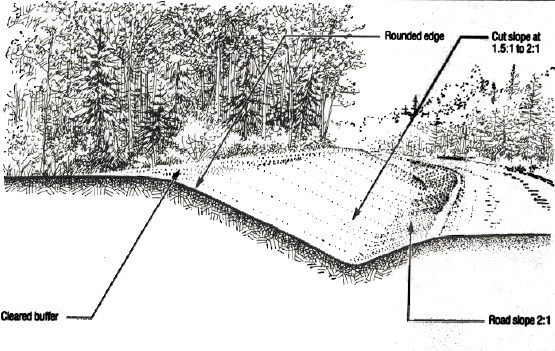

- Keep earth fills and earth cuts as shallow as possible, consistent with the geometric standard being constructed. A road surface about one metre (three feet) above the original ground should be satisfactory for most roads, if the terrain is favourable.

- Grade and crown the earth grade as it is being constructed, to shed water and minimize ponding in ruts.

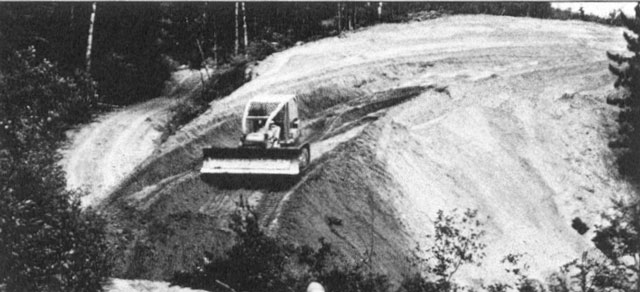

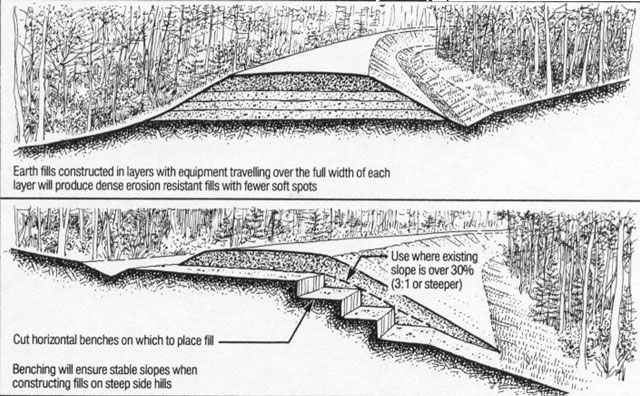

- Fills should be constructed in shallow, full width layers with stable side slopes (1-5 to 2.0:1). Equipment should be made to travel the full width of each layer to compact it and make the fill more dense. This will minimize slope erosion and soft shoulders.

- When building fills on side slopes, benching into the original ground will prevent slippage along the interface.

- When borrow from outside the right-of-way must be trucked in, try to obtain granular material. It makes a strong roadbed, drains well, is easy to compact, and is erosion-resistant.

- Limit the number of pits to minimize the area of disturbance.

- When obtaining material by excavation within or adjacent to the right-of-way, try to drain low pockets. This may not be necessary when standing water does not create any problems, e.g., in deep fill areas.

- Maintain adequate control over grading operations to ensure the road is not over-built or under-built. This usually requires some survey layout, staking limits of cuts and fills, and supervision by a grading foreman.

- When working with wet, fine-grained soils (clays, silts), it may be necessary to push the material up and leave it to dry for some time. When dry, such otherwise unsuitable materials can make an acceptable roadbed. Use of the backhoe for this operation may speed the drying time and reduce damage to the original ground.

5.6 Rock grading

Rock grading is the removal and movement of solid rock or large boulders to the desired gradeline. The operation involves stripping the overburden, drilling, blasting, excavating, transporting and placing of the material into rock fills.

As with earth grading, the desired road profile determines cut and fill requirements. For economic reasons, rock cut areas are avoided if at all possible during location of the road. In the construction of access roads, it is accepted practice to make a road more winding, or to steepen road grades to avoid rock excavation.

Rock grading equipment normally includes compressors, air track rock drills, backhoes, front-end loaders, bulldozers with ripper attachments, rock trucks and dump trucks.

Good practices - rock grading:

- Plan rock fracture to produce usable size particles for rip rap and other needs on the construction project.

- Plan drilling patterns and limit explosive loadings to an appropriate level that will shatter the rock and heap it up vertically, but will not throw the material into the bush. This will limit damage outside the right-of-way and make the material available for fill or other uses.

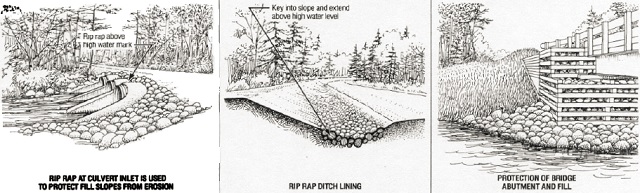

- Where ditches leading downhill from rock cuts pass over earth material, rip rap should be provided to protect the earth/rock interface from erosion.

- Where bedrock projects into the ditch line of a roadside ditch, construct an off take ditch into the bush, install a cross culvert, or excavate through the rock knob.

5.7 Drainage ditches and culverts

Drainage consists of the excavation of roadside ditches, the installation of cross culverts and the provision of off-take ditches. It is important to differentiate between drainage culverts and water crossings. The drainage culverts discussed in this section are those required to pass local surface flows channelized by the road construction. There is no defined channel prior to construction and there are no fish in these channels. Water crossings occur where the road crosses a natural water course that has a defined channel, they are dealt with in Section 6. All culverts should be installed in a manner which minimizes sedimentation as the downstream receiving water will eventually be fish bearing.

With proper drainage and protection from standing water, most soil types can be used to make economical access roads. A well-drained roadbed can support heavier loads, and will be usable for more of the year, than an improperly drained road. Furthermore, it can usually be constructed with less material than would be needed if good drainage was not provided. Proper roadside drainage reduces erosion and damage to inundated trees and vegetation.

The usual equipment for this operation includes bulldozers, backhoes, front-end loaders, graders and dump trucks.

Good engineering practice is usually good environmental practice. Soft roadbeds, washouts and sedimentation are generally the consequences of improper culvert installations or lack of ditching.

Good practices - culverts:

- Use permanent materials on permanent roads (e.g., csp culvert). If the road is temporary, culverts and fill deposited in the floodplain should be removed when no longer required.

- Installation should be done in driest possible time of the year.

- Installation should be carried out ahead of fill construction or as part of it.

- Culverts should be placed so that 10% of their diameter is below the original ground elevation. A high culvert will cause ponding upstream and outlet erosion downstream. Too low a culvert will fill with sediment and may freeze over in the winter. A single larger pipe may be preferable to several smaller ones, because it should be less susceptible to blockage or icing.

- In swamps, culverts should be placed where the organic depth is least to minimize settlement.

- Where cross-culverts are used on down grades to divert flow and minimize ditch erosion, they should be angled across the road so water will flow easily.

- When foundation conditions are such that a sagging of the central portion of the culvert is anticipated, the central portion should be installed with an upward camber. Anticipated sag will then tend to restore the culvert to a constant gradient.

- Culvert length should be selected to ensure ends will not be blocked by fill slopes.

- The minimum culvert size used on roads needed for more than ten years should be 500 millimetres (18 inches) in diameter.

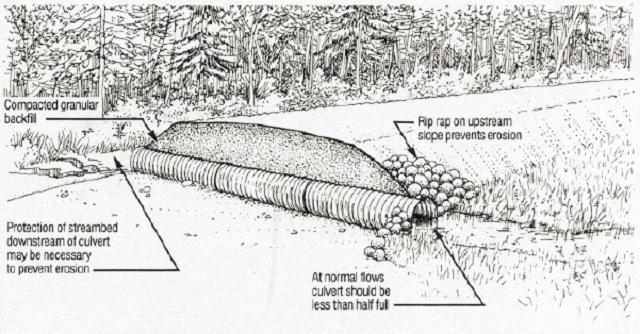

- Rip rap should be placed on the upstream fill slope around the culvert inlet, to the top of the pipe, to prevent fill washout during high flow periods.

- If scour of the streambed downstream of the culvert is expected due to the high flow velocities, an erosion resistant apron or energy dissipater should be provided.

Good practices - ditches:

- Ditching should be carried out as part of earth grading, to encourage good drainage early and to minimize soil disturbance.

- Ditches should be constructed uphill, to avoid trapping rainwater.

- All roadside ditches should flow to an outlet downstream of the road right-of-way.

- Ditches should be sized to handle the expected runoff from the area draining onto them. Large drainage areas may require deeper or wider ditches than are normally provided.

- On all-weather roads, ditches should ensure that the water level is maintained at least one metre (three feet) below the road surface.

- Cross culverts and off take ditches are required to ensure adequate road-side drainage. The recommended spacing of these depends on ground slope and soil type, as indicated in Table 1.

| Ground Slope | Erodible Silt-Clay | Normal Soils, Loams | Rock Soil, Sand & Gravel |

|---|---|---|---|

| Gentle (Under 5%) | 300 m (1000 ft) | 600 m (2000 ft) | No Limit |

| Moderate (5 - 10%) | 150 m (500 ft) | 300 m (1000 ft) | 600 m (2000 ft) |

| Steep (Over 10%) | 100 m (350 ft) | 150 m (500 ft) | 300 m (1000 ft) |

Distance shown is from height of land to outlet or on a long continuous slope, the distance between outlets.

If erosion protection or check dams are provided in the ditches, these distances may be increased.

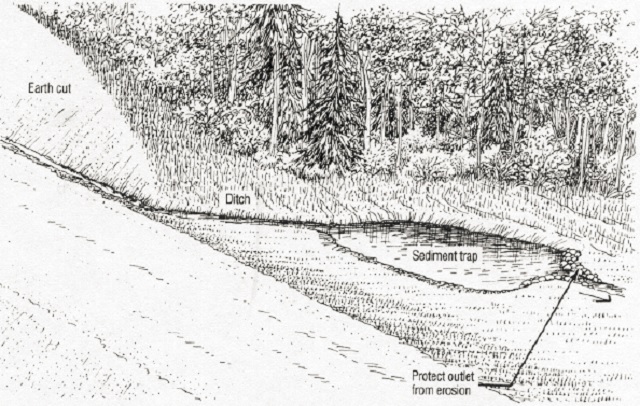

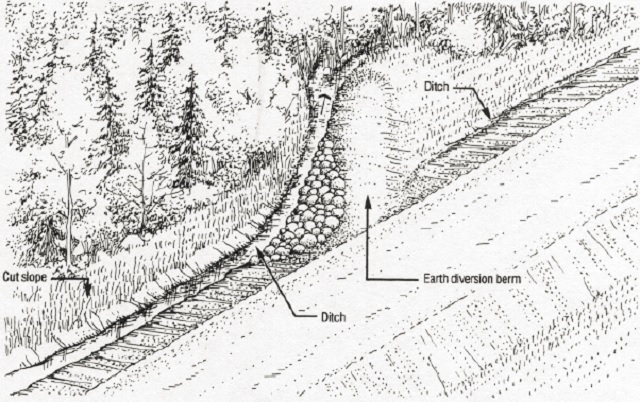

- Roadside ditches should not discharge directly into waterways; rather, off take ditches should divert flow into the bush so the water filters through natural vegetation before entering the waterway. Construction of diversion berms in the ditch-line may form part of the off take ditch scheme; refer to the appropriate guidelines in Section 7.

- Interceptor ditches may be necessary to divert water away from steep cut or fill slopes.

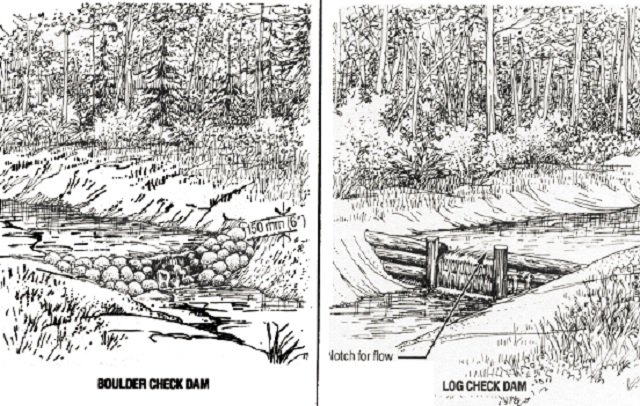

- Long roadside ditches on slopes over 3% may require check dams, intermediate cross culverts or offtake ditches, to reduce flow velocity and water quantity if erosion is a problem.

- To ensure that drainage ditches are not blocked, side roads should be located on high ground, or entrance culverts should be installed.

- Side slopes of the fill and cut back-slopes should be flat enough to be stable in the long term, so that slumping and filling of the ditch does not occur.

5.8 Swamp treatments

Swamps are a common terrain feature in Ontario. In constructing roads over swamp areas, there are two main considerations:

- Do not exceed the load-carrying capacity of the soft material; and

- Provide adequate cross drainage.

Loading the swamp too much could lead to excessive settlements or rotational failure. In either case, it can prove to be very difficult and costly to correct. Cross culverts should be placed in swamp areas in order to equalize the water levels on both sides, and thus minimize any change in the water table.

The equipment normally used includes bulldozers, perhaps with special-sized tracks, wood-moving equipment such as skidders and loaders with grapples, and graveling equipment.

Good practices - swamp treatments:

- Deep swamps should be avoided if at all possible, due to the risk of failure and the potential cost of repair.

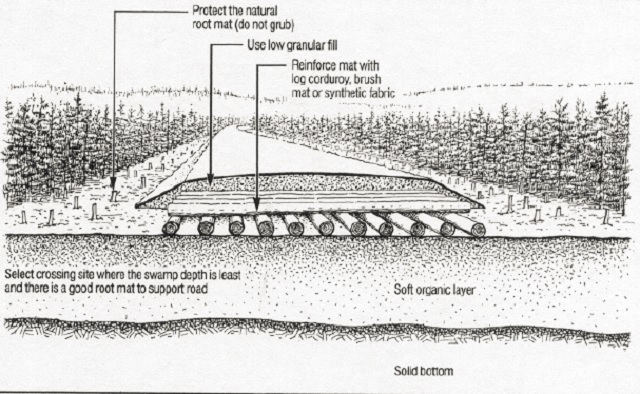

- Select a crossing location where there is a well-developed root mat supporting tree growth.

- Construction of swamp treatments in the winter has several advantages: it permits shear balding of stumps; heavier construction equipment can cross without getting bogged down or disturbing the root mat; and, construction can also proceed beyond the swamp without having to wait for the treatment to be completed.

- The most common swamp treatment method on access roads is to float the road fill on the natural root mat and minimize disturbance of the organic deposit. This is economical and, of the methods available, causes the least disturbance to the natural environment.

- If possible, limit fill depths over the swamp to 1.3 metres (four feet) or less.

- When fill heights (swamp loadings) cannot be limited to shallow depths, the swamp should be sounded with a steel rod to a solid bottom, so that future performance can be predicted.

- The root rant under the roadway should be protected from equipment damage. This can be done by: diverting through traffic to the edge of the right-of-way; close cutting or shear blading stumps instead of grubbing; and, using special wide-pad equipment.

- Avoid ditching in deep swamps unless absolutely necessary (say over one metre thick (three feet)).

- If the consequences of the natural mat failing are serious, use reinforcement materials such as geotextile fabric, geo-grid mats, brush mats or log corduroy.

- Fill used on swamp crossings, where the road is floated on the natural mat, should be free from large boulders or rocks that can puncture the mat.

- Provide frequent cross culverts, approximately every 300 metres (1000 feet), to ensure that surface water is equalized on both sides of the road. The culverts should be located where organic deposit thickness is least (thus less settlement). If culverts must be placed on top of deep organic material, it is best to leave their installation until late in the road construction, after some settlement has already occurred.

5.9 Graveling

This operation refers to the placing of sand and gravel materials to form the structural road sub-base and surface that supports the wheel loads.

A sand cushion may be used as a sub-base under the gravel surface if the underlying earth cut or fill materials are poor and of low strength.

The operation generally involves importing select material from a gravel pit nearby.

The equipment normally used includes front-end loaders, dump trucks, bulldozers, graders and back-hoes. Occasionally, crushing units, compaction equipment and water trucks are also used.

Good practices - graveling

- For the top 150 millimetres (six inches), a well-graded gravel with particle sizes evenly distributed between clay size and 25 millimetre (one inch) stones is preferred. It can be easily placed and compacted to the desired shape and will be more stable under load than a poorer quality material. Well-graded gravel tends to be erosion resistant, and its use will reduce the amount of road maintenance required.

- Shape, compact and crown the earth grade before placement of the gravel layer. This will minimize the amount of gravel needed and it will shed water seeping through porous gravel during wet periods.

- Avoid rutting by providing an adequate depth of gravel so the road will be able to carry the types of vehicles expected to be travelling over it during the times it will be needed.

5.10 Road maintenance

Access roads are maintained during the period of time they are required. The level of maintenance on an access road varies depending on its use at any given time. For example, during wood extraction operations, when numerous heavily loaded trucks are using a road, it is maintained to keep the riding surface very smooth. Later, if the road is no longer used for timber management, the road use may change. It can either be maintained at minimal levels for light recreational and other traffic uses or abandoned in an environmentally sound manner as described in Section 5.11.

The operations carried out for road maintenance can be broken into two main groups: routine and non-routine.

Routine operations include those day-to-day activities necessary to maintain the road for the traffic using it. These may include grading, snow plowing, and the maintenance of drainage by cleaning out blocked ditches and culverts.

Non-routine maintenance includes major repairs and restoration. Since roads gradually deteriorate with time, there is a periodic need to restore the condition of roads serving a long-term need. These roads may require major maintenance or re-construction to restore their original condition every ten to twenty years. Example operations falling into this category include: brush control with mechanical and chemical methods; replacement of gravel surfacing material; repair of major flood damage, and, replacement of sub-standard bridges.

If a road is not maintained, it should be abandoned in accordance with the use-management strategy for the road.

Good practices - maintenance:

- The usefulness and permanence of an access road depends on a good drainage system. Maintenance of drainage includes: regular inspection, clean-out of blocked ditches and culverts, grading to remove ruts and crowning of the road to shed water.

- During grading operations, loose materials should be brought back towards the center of the roadway to prevent the creation of berms that could channelize run-off down the road and erode the fill slopes.

- Nuisance beaver activity around culverts should be dealt with (refer to mitigation techniques in Section 7).

- Heavy equipment should not be used on roads during spring breakup, as this will lead to rutting, gravel contamination and possible erosion. The spring breakup usually corresponds with the period of half-load restrictions on secondary highways.

- In winter, sand is preferred over chemical de-icing salts. Where used, alts should be applied sparingly.

- Salt should be stored in dry sheds, to prevent infiltration into the water table.

- During snow clearing operations, snow banks should be winged back. This will decrease the time to melt the snow, and minimize spring saturation and erosion of the roadbed. It will also avoid creating an obstruction to wildlife movements.

- Remove roadside vegetation that shades the road, for safety (visibility) and for drying of the road. In erodible soils, do not expose the mineral soil during the brushing operation.

- Special mitigative techniques such as sediment traps and check dams should receive regular maintenance as long as they are needed.

- Calcium chloride may be used to stabilize the road surface and control dust problems. It should always be applied in accordance with the manufacturer’s recommendations.

- If herbicides are used for vegetation control, the person applying the herbicide should be licensed and a 10 metre buffer zone must be maintained adjacent to all water bodies. Mechanical means of vegetation control are usually preferable environmentally and are often economically competitive.

- Following timber management operations along the roadside, the roadway cross section should be restored by repairing damaged slopes, culverts and ditches.

5.11 Road abandonment

A Use Management Strategy is developed for primary and secondary roads as part of the Timber Management Plan or other planning process. The Use Management Strategy addresses the duration of use for the road and what actions are proposed when that use ends. The strategy may call for abandonment of the road when its original purpose ends. There are two forms of abandonment:

Physical Abandonment occurs when there is a deliberate act to render a road unusable by vehicular traffic. Physical abandonment could include taking steps which will minimize the environmental impacts of non-maintenance.

Natural Abandonment occurs when road maintenance has ceased, yet steps are not taken to prevent the use of the road by vehicles. With natural abandonment, no physical changes are made to the road.

In either case, abandonment should be carried out in an environmentally sound manner. Erosion and decay processes can lead to sediment problems in the area of water crossings.

Consideration should be given to regeneration of the road right-of-way to make the area productive for growing trees and to prevent erosion. This will lead to a more rapid re-establishment of natural conditions.

Erosion Control

Preventative measures can be taken to minimize erosion of the road fill and subsequent sedimentation in the watercourse. When a road is not maintained, frost and runoff will lead to loosening and erosion of fill and road surfaces. In the area of water crossings, the roadway slopes downhill, towards the stream. Water flowing down the road can erode the gravel surface and underlying fill. Preventative measures can be taken to minimize erosion of the road fill and subsequent sedimentation in the watercourse.

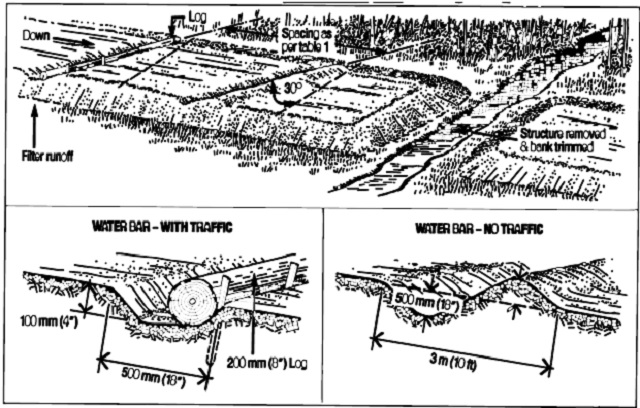

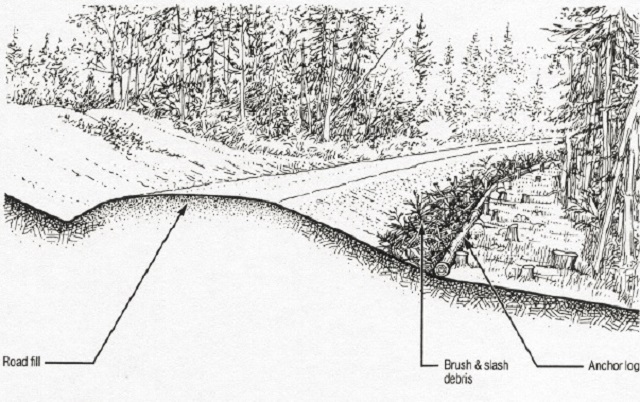

Water bars can be used to control surface water runoff and minimize erosion of the road surface and fill. Water bars are transverse ditches excavated across the road surface to intercept runoff and deflect it towards the ditches instead of flowing down the road surface. The outlet of a water bar should be extended into an area that is erosion resistant and that will filter out sediment. This control of runoff will prevent surface erosion and lead to quicker re-establishment of vegetation on the road.

- Remove roadside vegetation that shades the road, for safety (visibility) and for drying of the road. In erodible soils, do not expose the mineral soil during the brushing operation.

- Special mitigative techniques such as sediment traps and check dams should receive regular maintenance as long as they are needed.

- Calcium chloride may be used to stabilize the road surface and control dust problems. It should always be applied in accordance with the manufacturer’s recommendations.

- If herbicides are used for vegetation control, the person applying the herbicide should be licensed and a 10 metre buffer zone must be maintained adjacent to all water bodies. Mechanical means of vegetation control are usually preferable environmentally and are often economically competitive.

- Following timber management operations along the roadside, the roadway cross section should be restored by repairing damaged slopes, culverts and ditches.

There are two types of water bars, as shown on the sketch. One uses a log to divert water while still permitting passage by vehicles over it, the other would be used where there is no traffic on the road. Water bars should be spaced closer together in steeply sloping terrain. Spacing similar to that shown in Table 1 in Section 5.7 would be appropriate.

Removal of Structures

Water crossing structures that have required on-going maintenance to keep functioning, or which have deteriorate with time and may collapse into a waterway (for example untreated log bridges) should be removed when the road is abandoned. Structures built of permanent materials, such as steel or treated timber, that have been maintenance free, may be left in place.

Removal of structures will involve excavation of all materials below the high water mark. This may include bridge piers, stringers, decking, culverts and roadway fill. It is not necessary to excavate stable bridge abutments and erosion protection works. Often removal of piling from the river bed is not possible. Excavated material should be trucked away to a suitable disposal site at least 100 metres (350 feet) away from the water course. The banks and approach fills should be graded and trimmed to a stable angle similar to the adjacent natural river banks. The banks should then be provided with erosion control treatment if necessary to prevent erosion. Exposed soil on the river banks should have seed and fertilizer applied to speed re-vegetation.

6.0 Water crossings - good practices

6.l Introduction

Water crossings are locations where an access road crosses a natural water course having a defined channel. Any water crossing has the potential for significant detrimental impacts on water quality. Through good design, adherence to good construction practices and use of special mitigation techniques where required, disturbances during construction can be minimized and the site can be stabilized to prevent long term changes.

Water crossings have several characteristics in common:

- Selection of the water crossing location has a significant effect on the type of structure required and its cost.

- They require a properly engineered structure to safely carry the load.

- They usually involve water diversion and de-watering to allow construction in a dry condition, with foundations extending below the creek bottom.

- They are usually quite expensive.

- They can have a significant impact on fish habitat (e.g., spawning areas), water quality (e.g., turbidity) and fish migration.

- Protection and maintenance of aesthetics, fisheries habitat and wildlife habitat values are usually important considerations.

- Failure of water crossing structures can have serious consequences in terms of public safety, property damage, damage to the natural environment and inconvenience to road users.

This section is divided into the following four components:

- site selection and design

- fords and temporary bridges

- construction

- site clean-up

6.2 Site selection and design

A preferred site for construction is in a rapids section of a stream or river. These areas are often of high value for fisheries as spawning areas; as well, rapids are important for recreation. The area adjacent to a rapids may contain historical or archaeological material. Although these other values must be considered and protected, from an engineering viewpoint a rapids site offers the following advantages:

- Soils are usually resistant to erosion at high flow velocity.

- Foundation conditions are usually good, requiring less river bottom disturbance.

- The effects of upstream backwater, due to the constriction created by the crossing, will be limited to a short length of river.

- Water depths are usually shallow, and the encroachment for cofferdams to construct abutments or piers will be minimal.

Good practices - site selection and design

- Avoid poor crossing sites if at all possible. A poor site would be one where:

- Water depths at abutments and piers are great, i.e., over two metres (six feet).

- Soils are erodible and/or require expensive foundations to distribute the load, i.e., clay, silt or fine sand.

- Water surface widths are quite wide and flow velocities are low.

- Steep high banks or hilly approaches could make satisfactory road construction to the water crossing very costly.

- There are areas of bank instability, erosion or bends in rivers.

- Occasionally, islands can be used in a rapids or at waterfalls, to break a long span into two or more shorter spans. This also makes de-watering much simpler, since one channel can be completely closed at a time.

- If recreation or fisheries values are high in the area, the crossing location may have to be adjusted to a site that minimizes the impact on these values. For this reason, alternatives to the preferred site should be considered.

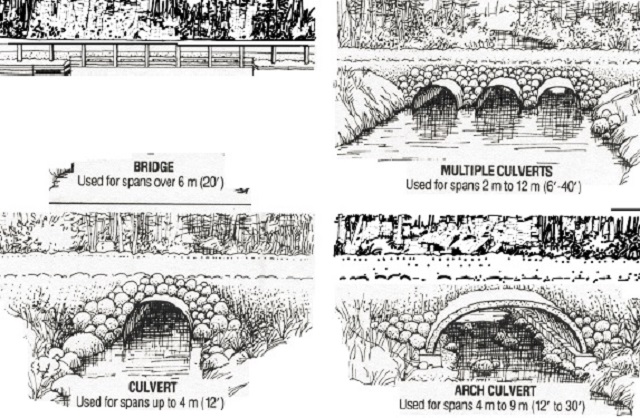

- Select a structure appropriate to the site. Commonly used alternatives are:

- Bridges with crib abutments, single span or multiple spans corporating piers in the river.

- Bridges with pile-supported abutments of single span or multiple spans.

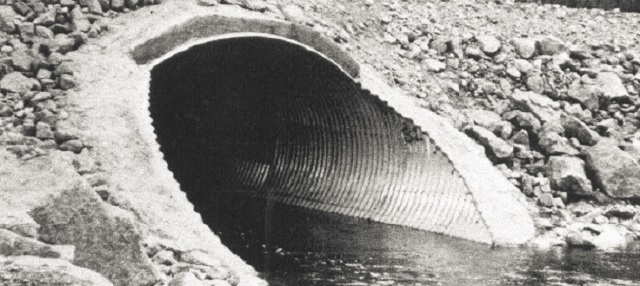

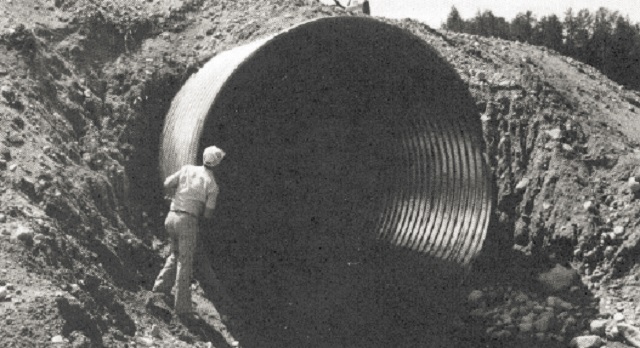

- Single corrugated steel pipe culvert or multiple csp culverts; these could be either circular pipe with couplers or field-assembled structural plate.

- Arch-type culverts incorporating two side footings and a corrugated steel arch to support the fill. This type of culvert leaves the natural streambed between the footings on either side.

- Box culverts with closed or open bottoms.

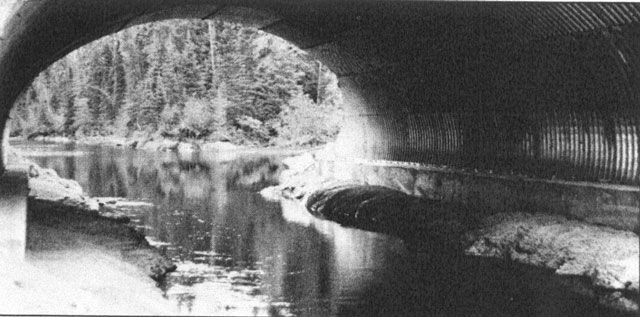

- For streams which are used for fish migrating or spawning areas, bridges or arch culverts, which retain the natural stream bottom and slope, are preferred over pipe culverts.

- The crossing should have structural capacity to carry the vehicle loads expected to cross it.

- The waterway opening size should be selected to minimize the risk of washout during the expected life of the structure.

- Hydrologic and hydraulic analyses should be in accordance with design procedures developed for Ontario use; refer to the Ministry of Transportation Drainage Manual. This conforms with review criteria under the Lakes and Rivers Improvement Act.

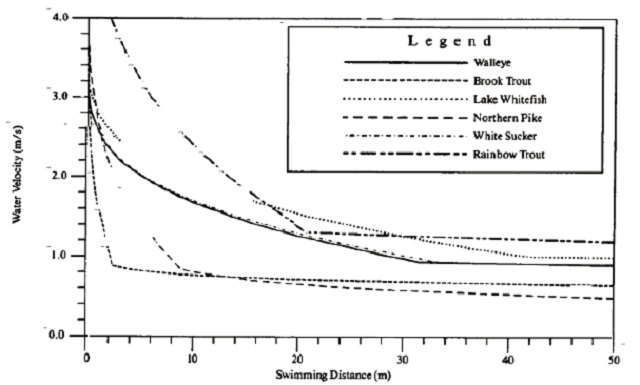

- The waterway opening size should be selected to ensure that upstream water levels will be acceptable, and that flow velocities will not be too high to prevent fish migration. Multiple smaller pipes will have lower flow velocity and may be preferred for fish migration purposes but may be more susceptible to blockage by ice or debris. The maximum number of culverts at a water crossing should be no more than three.

- Design mitigative techniques to accommodate any special requirements identified through the planning phase, or by Ministry staff during their review of the proposed construction.

- Culvert size should be selected so normal water levels rise no higher than half the diameter of the pipe.

- If possible, align the road so it crosses the waterway at right angles. Bridge abutments and piers should be aligned parallel to the direction of flow.

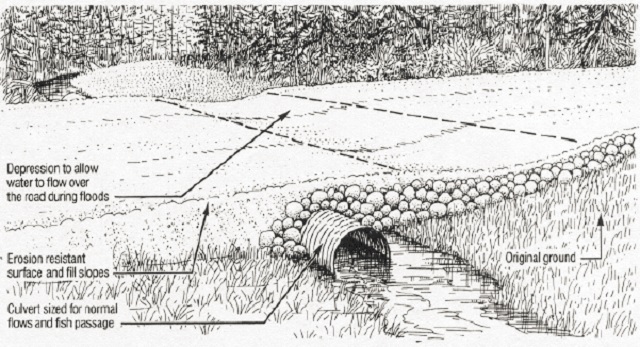

- It may be appropriate to place a dip in the approach grade to allow water spillage over the road if the pipe capacity is exceeded. This would also lower repair costs if a washout occurred.

- Select adequate lengths of culverts and use wing walls on bridges, to keep fill from spilling into flowing water, and to reduce maintenance costs.

6.3 Fords and temporary bridges

(a) Fords

Fording, or driving through a water course, may be an alternative used for access in limited specific circumstances. Sites favourable for use as a ford are those where:

- The streambed has a firm rock or coarse gravel bottom and where the approaches are both low and stable enough to support traffic.

- Use of the ford will be temporary and limited to low volumes of light vehicles such as initial access during clearing operations, or for mining exploration equipment.

The water depth should be less than one metre (three feet).

The natural carrying capacity of a stream bottom can be improved by constructing an underwater roadbed using log corduroy, coarse gravel, rock fill or gabions. If used, these materials should be set into the bottom so the driving surface will be flush with the stream bed to minimize erosion and to allow fish passage.

Good practices - fords

- Crossings should be at right angles to the stream.

- The road width should be not more than 10 metres (32 feet) wide and it should be well marked to be visible to drivers.

- If necessary, stabilize the approaches by using non-erodible material to 15 metres (50 feet) up the bank on both sides of the ford.

- Fords should be constructed and used during the driest times of the year.

- Minimize the amount of vegetation removed adjacent to the water crossing.

- Fish passage should be accommodated by maintaining a water depth of at least 200 millimeters (eight inches) or the natural stream depth at the location.

- Any material used within the stream to improve the crossing should be clean, non-erodible and non-toxic to aquatic life.

- Do not use the ford during fish spawning, incubation or migration periods.

- Equipment crossing the ford should be mechanically sound with no oil or gas leaks.

- When the ford is no longer required, restore the stream channel and banks to their original contours by removing material placed to construct the ford.

(b) Temporary bridges

Temporary bridges are constructed across waterways to serve a short-term purpose. Typical examples include access for bridge construction, and access for several months of timber harvest and extraction.

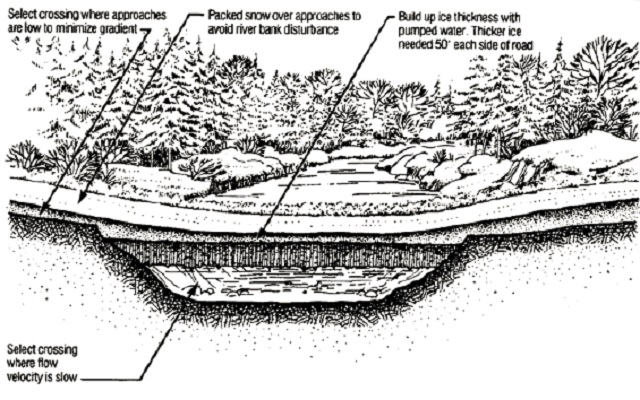

The crossings would not normally be designed to pass extreme flood events; they are usually intended to be in place for only a short period of time and then to be removed. They should have an adequate opening for expected flows during the time they will be in place without unduly backing up water. Ice bridges are constructed in the winter to take advantage of frost and ice in the waterways, to reach areas which may be otherwise inaccessible.

Bridges serving a short-term need may be constructed economically, using untreated log poles, however their strength diminishes with time as bacterial decay destroys the wood fibre. Untreated wood should not be used for bridges required for more than ten years of service. Temporary bridges usually span the water surface width, just above normal water level. Piers may be placed on the river bottom to break a wide river into short spans that log poles can bridge.

It is important that temporary bridges be removed when their use is finished. This is necessary since the waterway opening and the materials used for construction may be unsuitable for a permanent crossing.

6.4 Construction

in the dryis a key to proper installation.

Considering the effort that is normally invested in site selection and design prior to construction of a major water crossing, those responsible for on-site work should be aware of potential environmental impacts, and should take appropriate precautions to ensure those impacts under their control are kept to a minimum. Normally, this precaution adds little or no additional cost to the project.

In most cases, the satisfactory construction of a water crossing requires that flowing water be diverted away from work areas so that the structure can be constructed under dry conditions. Excavation for a bridge in the river bed, or placement of a large culvert, should not be done in flowing water. Rather, the work area should be isolated with a cofferdam or stream diversion.

Often there may be access to only one side of a water crossing, and it will be necessary to construct a means of temporary access to facilitate construction.

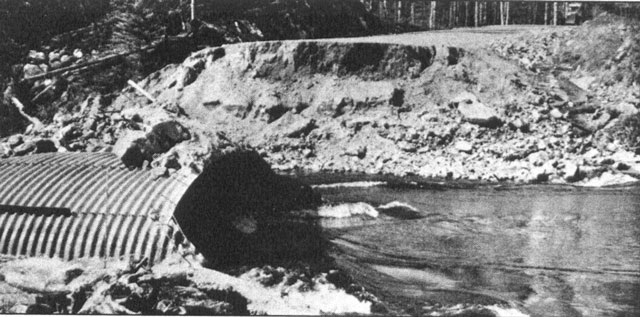

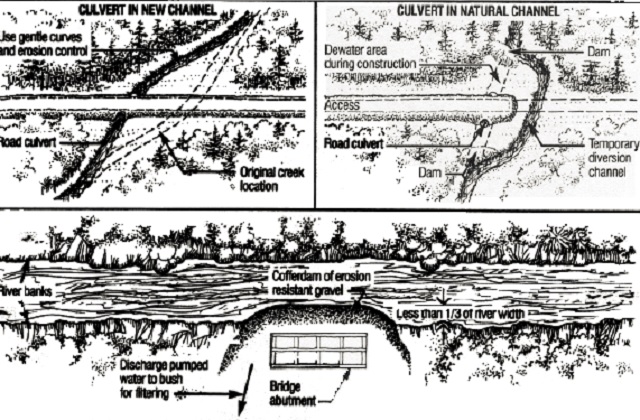

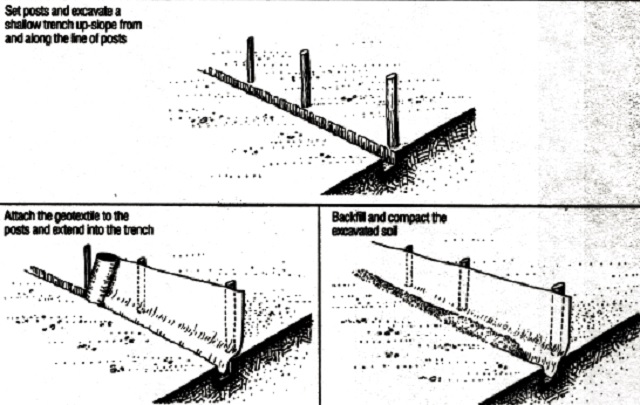

If a culvert is to be installed in a flowing stream channel, the water should be diverted around the work site during construction. Isolating the work site from the flow of water is necessary to minimize the release of soil into the water course and to ensure a satisfactory installation in a dry environment. Two methods of water diversion are commonly used for culvert installations: construction in the stream bed, or construction in a new channel, these are detailed in the sketch.

If a bridge is to be installed it is usually not possible to divert all of the flowing water, so partial diversions are constructed using cofferdams around the work areas.

Good practices - water crossing construction

- Cofferdams for bridge construction should not block more than one third of the waterway at a time.

- Provide sufficient waterway size for a diversion channel and temporary openings. Use erosion-resistant material, i.e., gravel fill with rip rap or geotextile lining.

- Restrict clearing width, and do not grub the right-of-way between the road and bush line within 100 metres (350 feet) of the waterway. Preserve vegetative cover as long as possible.

- Work in the river should be scheduled for the driest time of the year, usually July and August, unless this would create noise or visual impact problems for users of the waterway.

- Borrow material should not be excavated from the watercourse, except as part of a designed channel improvement.

- Equipment and materials should be stored well back from the water’s edge.

- Pump water should outlet into vegetative areas for filtering during de-watering operations.

- The number of equipment crossings in the river should be minimized by constructing a temporary bridge.

- Waste debris from grubbing should be hauled back and disposed of more than 100 metres (350 feet) from the waterway.

- Every effort should be made to complete water crossing construction as quickly as possible once the work begins. Limit the duration to minimize environmental impacts.

- Construction of water crossings must not take place during spawning/ incubation periods or major fish migration periods, as determined by the Ministry.

- Culverts should be installed in accordance with manuals available from the pipe manufacturers. To ensure satisfactory performance, particular attention should be paid to bedding, invert elevation, backfill material quality, placement of backfill in even shallow lifts on each side, backfill compaction and erosion protection.

- Culverts should be installed so the pipe has at least 10% of its diameter below the streambed. This will encourage formation of a shallow sediment layer in the pipe, and should ensure enough flow depth for fishmigration. During flood periods, the sediment will quickly erode. This practice will also minimize the chance of undercutting at inlet or outlet.

- Control materials on the job so that loose boards, nails and other debris will not enter the waterway and flow downstream. A log boom should be used downstream of the bridge site if there is a chance that debris (lumber) could fall into the water and be carried downstream.

- Do not clean concrete buckets, wheelbarrows, shovels in water bodies. Instead, wash them with hoses so that run-off is filtered through vegetation. Prevent the entry of lime, cement or fresh concrete into waterways.

- Oil-based treated timber (pentach-lorophenol, creosote) used below or near water level should be reasonably dry, without excessive surface oils. Timbers with oil base preservative treatments should be ordered early to allow air drying before use. Those with abundant surface oils should be used at the back of the cribs, against the approach fill.

- Field cuts and drill holes should be painted liberally with preservative to prevent decay; care should be taken to avoid contamination of the water by field-applied preservatives.

- If the project is a bridge replacement, remove the old stringers and decking. If reasonably possible, also remove foundation piers and abutments unless these may be useful to break up ice or protect against erosion.

- If culverts are founded on soft material, a granular bedding shaped with a camber should be provided, so that when settlement occurs, the pipe will function.

- For pier construction in open water, in which there are erodible river bottom sediments and where water quality must be protected, silt barrier curtains floating on the surface and anchored to the bottom should be installed around the work area.

6.5 Site clean-up

The final stage of construction is clean-up of the site. An extra effort on the part of construction staff can assist in the restoration of stable ground contours and protective vegetative cover, to prevent erosion and make the crossing more attractive in appearance to those who view it from the road or the water.

Considering the time and money spent on the physical structure to carry traffic over the waterway, a few days of effort on site restoration, while the resources are available, is a good investment for mitigating the long term environmental impacts of a water crossing.

Good practices - site clean-up

- Heavy rock rip rap material should be placed around abutment faces exposed to flowing water. This will minimize the possibility of undercutting and will help provide stability to the abutment.

- Rip rap should be placed on fill areas exposed to flowing water below the expected high water level. This includes areas around the inlet end of culverts.

- Place an erosion-resistant rip rap apron in the river bed downstream of the pipe, where increased flow velocities could cause serious scour. The apron should extend six culvert diameters beyond the end of the pipe and it should be sloped toward the centre of the channel to allow fish migration at low water flows.

- Restore or enhance fish habitat (spawning beds or aids to migration) if required by the Ministry; suggested methods are described in Section 7.

- All temporary imported material on the site should be removed, including any debris which has floated downstream of the crossing.

- Disturbed areas within 100 metres (350 feet) of a water body should be stabilized and re-vegetated to prevent erosion and to intercept sediment.

- River banks and fill slopes should be trimmed to a relatively flat angle that will be stable, i.e., 2:1 or flatter.

7.0 Mitigation techniques

7.1 Introduction

The environmental guidelines presented in the previous sections are recommended practice for all access road construction. In addition, there will be occasions when special mitigation techniques are needed to deal with a potentially serious problem, or to protect specific values that have been identified as needing protection from the impacts of construction.

This section is intended as a source of information for those involved in road construction who require technical detail concerning such mitigation techniques. The need to implement a special technique in order to prevent serious problems from developing could arise in situations such as the following:

- water crossings where there are important fish habitat, such as spawning beds, that could be destroyed if sediment levels are high.

- areas of concern identified during the planing phase.

- special values identified in advance that are to be protected from potential negative impacts (e.g. tourism).

- unexpected conditions identified during construction that require treatment or protection (e.g. erosion, archaeological material).

The subject is not treated here in an exhaustive manner; rather, commonly occurring treatments are described, and references are provided for those who require more information.

The techniques described are currently used in Ontario on access roads and, if properly implemented, can mitigate the specific impact of roadconstruction being addressed. The material covered in this section includes:

Even though special methods and measures exist for mitigating the impact of road construction, they may not be applied unless a need for them is apparent and a rational decision is made requiring their use.

Considerations for assessing the degree and extent of mitigation techniques required should include the following:

- compliance with standards and applicable legislation

- the value of the tangible and intangible resources to be protected

- the cost of supplying the protection

- the pre-construction conditions in the environment, i.e., natural water turbidity, natural erosion.

This document does not presume to determine when, where and at whose cost, mitigation techniques should be used; these are the perogative of those involved in the decision-making process preceding approval of road construction on Crown land. Whenever such choices must be made by those directly and indirectly involved in a project, their value systems, preferences, traditions and customs all have an effect on the ultimate decisions. Thus, one group might go to great lengths to protect and preserve a resource that would get little attention in another area. The considerations and criteria for special mitigation techniques should therefore be viewed by those making the decisions in light of their own perceptions of what is valuable, what is right and what is acceptable in the public interest.

Through the use of written description, illustrative sketches and photography, the objective here is to provide sufficient generic design information on the recommended techniques so as to minimize the need for further reference to other documents.

- erosion and sediment control

- control of beaver problems

- fish habitat protection

- aesthetic considerations

7.2 Erosion and sediment control

Erosion is the natural process of wearing away of the land surface by water, wind, ice and gravity. The construction of access roads exposes the mineral soil to the action of these forces, particularly erosion by water. Erosion rates from construction sites are much higher than the average rates in undisturbed areas. On a well-constructed access road, with appropriate use of mitigation techniques when and where required, restoration of stable erosion resistant conditions is possible within a few years.

7.2.1 Erosion and sediment control - causes of erosion

Erosion is essentially a two-part process. One part is the loosening of soil particles caused largely by raindrop impact. The other part is the transportation of soil particles, largely in flowing water. The principal factors influencing the existence or extent of soil erosion are precipitation (duration and force of loosening agent), soil characteristics (susceptibility to erosion), topography (duration and force of transporting agent), and ground cover (protection). Any erosion control treatment must address at least one of these factors to be effective. A brief explanation of each factor will aid in understanding the mitigation techniques suggested.

Precipitationis the driving force behind erosion. Raindrops falling on exposed soil dislodge individual particles. The duration, intensity and raindrop size all influence the erosive force exerted by rainfall on the soil.

Soil characteristicsthat affect erosion include permeability and stability. Soil porosity affects the infiltration of rainwater into the soil and its capacity to store water before overland flow begins. Soils exposed to compaction by equipment and vehicles driving over them will have less porosity than undisturbed soils. Soil stability is the resistance of the individual particles to displacement and transport under the action of rainfall and flowing water. Generally coarse soil particles, soils with a well-graded mixture of particle sizes and cohesive clay soils are more stable than fine single-particle sized soils.

The volume of water flowing over a soil and its velocity are determined by the topographyof the area. Important variables are the upstream drainage area and the slope of the ground at the particular point. Roadside ditches on long steep slopes are especially vulnerable to erosion because the drainage area can be large, and flow velocities can be quite high as the runoff builds up momentum.

Vegetationis one of nature’s methods of erosion control. Ground cover protects the mineral soil from the erosive action of falling raindrops and flowing water. It also slows the velocity of runoff, it holds soil particles in place and it maintains the soil’s capacity to absorb water.

7.2.2 Erosion and sediment control - design principles