Permanent liquid nutrient storage covers

Learn about different systems that can be used to cover a permanent liquid manure storage. This technical information is for Ontario producers.

ISSN 1198-712X, Published August 2020

Introduction

All livestock farms must manage, handle and store livestock manure. Manure is either managed as a liquid or solid or both. Liquid manure is defined as any manure that is less than or equal to 18% dry matter (O. Reg. 267/03 as amended). Any manure greater than 18% dry matter is defined as solid manure.

Liquid manure is stored in concrete or steel tanks or in an earthen manure structure. Concrete tanks can be located under a barn, above ground or partially in ground and will vary in size and depth. Most exterior storage tanks are open top with the surface exposed to the air. Exposing the manure surface to the air allows odours and greenhouse gases to be released into the atmosphere. These gases include hydrogen sulfide (H2S), ammonia (NH3), volatile organic compounds (VOC), methane (CH4), carbon dioxide (CO2) and nitrous oxide (N2O).

This fact sheet introduces different systems that can be used to cover a permanent liquid manure storage. Using covers on liquid manure storages will:

- reduce manure storage odours

- reduce construction setback distances under the minimum distance separation (MDS) calculations

- increase nutrient contents in the stored manure

Some of the storage covers will:

- decrease manure storage volumes by reducing precipitation (snow/rain) infiltration

- decrease required storage capacity, which can reduce annual field application costs

Cover a manure storage

Covering open-top manure storages will reduce odours significantly and decrease the release of gases from the surface of the manure. Depending on the type of cover used, odours released from the manure storage can be reduced by 40%–95%. A covered manure storage can retain significantly more nitrogen, which in turn increases the nutrient value of the manure.

Types of manure storage covers

There are two types of covers: impermeable and permeable.

Impermeable storage covers seal the top of the manure tank or earthen manure storage structure, keeping out precipitation (for example, snow melt, rainwater). An impermeable cover is constructed from a variety of synthetic materials and products. These materials either float on the surface of the manure or are placed over the manure tank by supportive cables, air pressure, a frame structure or as a solid roof on top of the tank (Figures 1 and 2).

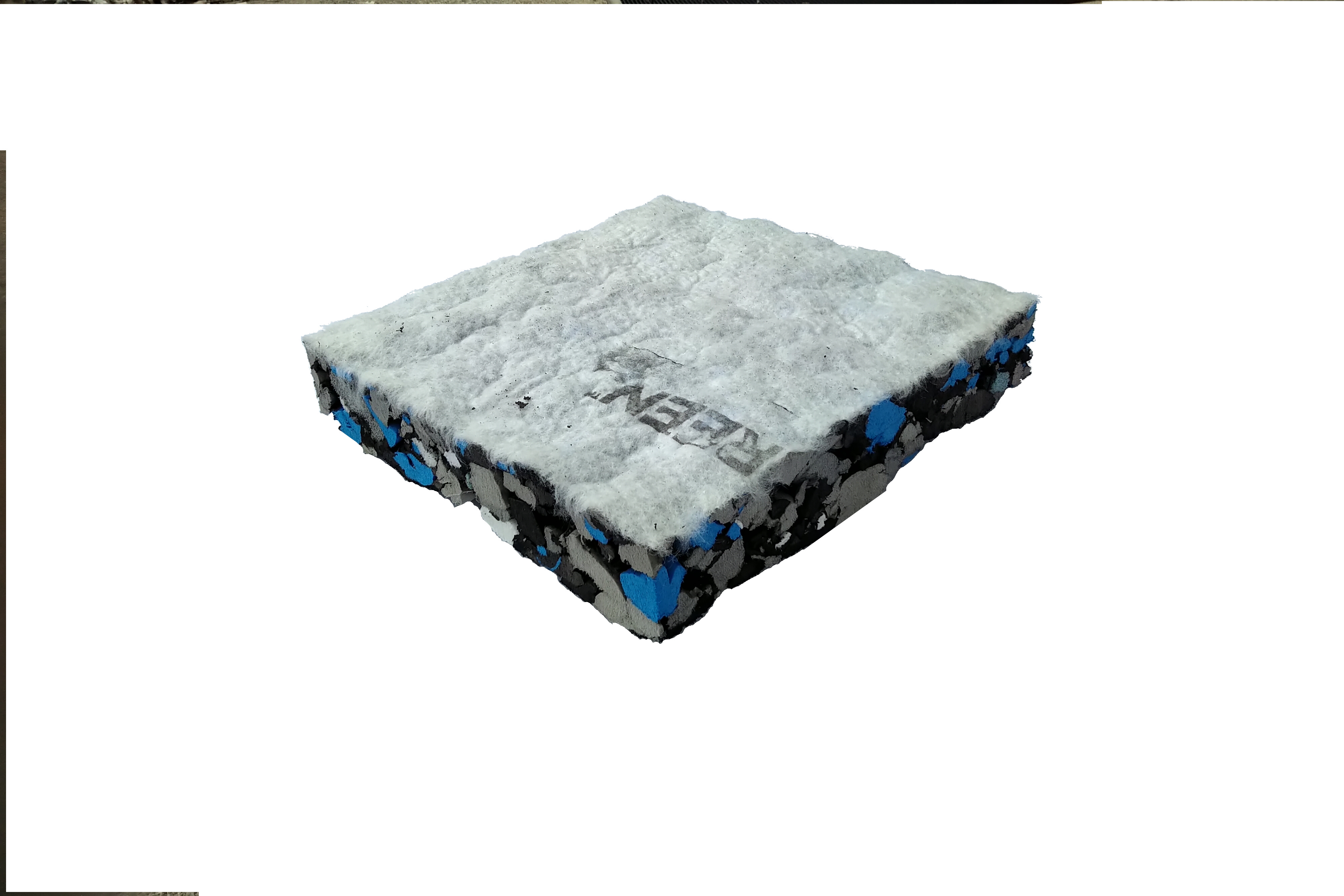

Permeable storage covers do not seal the surface, and precipitation is collected in the storage facility. The covers are either placed on the surface of the manure or above the manure. They are made from different types of straw, synthetic materials or a combination of both (Figure 3).

Impermeable manure storage covers

Impermeable covers consist of two types: rigid and flexible.

Impermeable rigid covers

Impermeable rigid covers include concrete, wood/metal roofed structures and plastic-coated fabrics stretched over framing. Rigid covers are used on concrete manure storages (Figure 4) but are not recommended over lined earthen storages. The cover materials, structural members and fasteners must be able to withstand exposure to moisture, corrosive gases and manure. Impermeable covers must also withstand wind damage, ultraviolet radiation and other environmental effects such as rainfall, hail and wildlife. Since these rigid covers seal the manure storage tanks, they require a ventilation system to vent off small amounts of manure gas and maintain constant air pressure under the cover.

Impermeable flexible covers

Impermeable flexible covers are made from plastic, normally either high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC) or a similar material. There are three methods used with plastic covers to hold them over the manure storage:

- negative air pressure system

- positive air pressure system

- floating cover system

Impermeable negative air pressure system

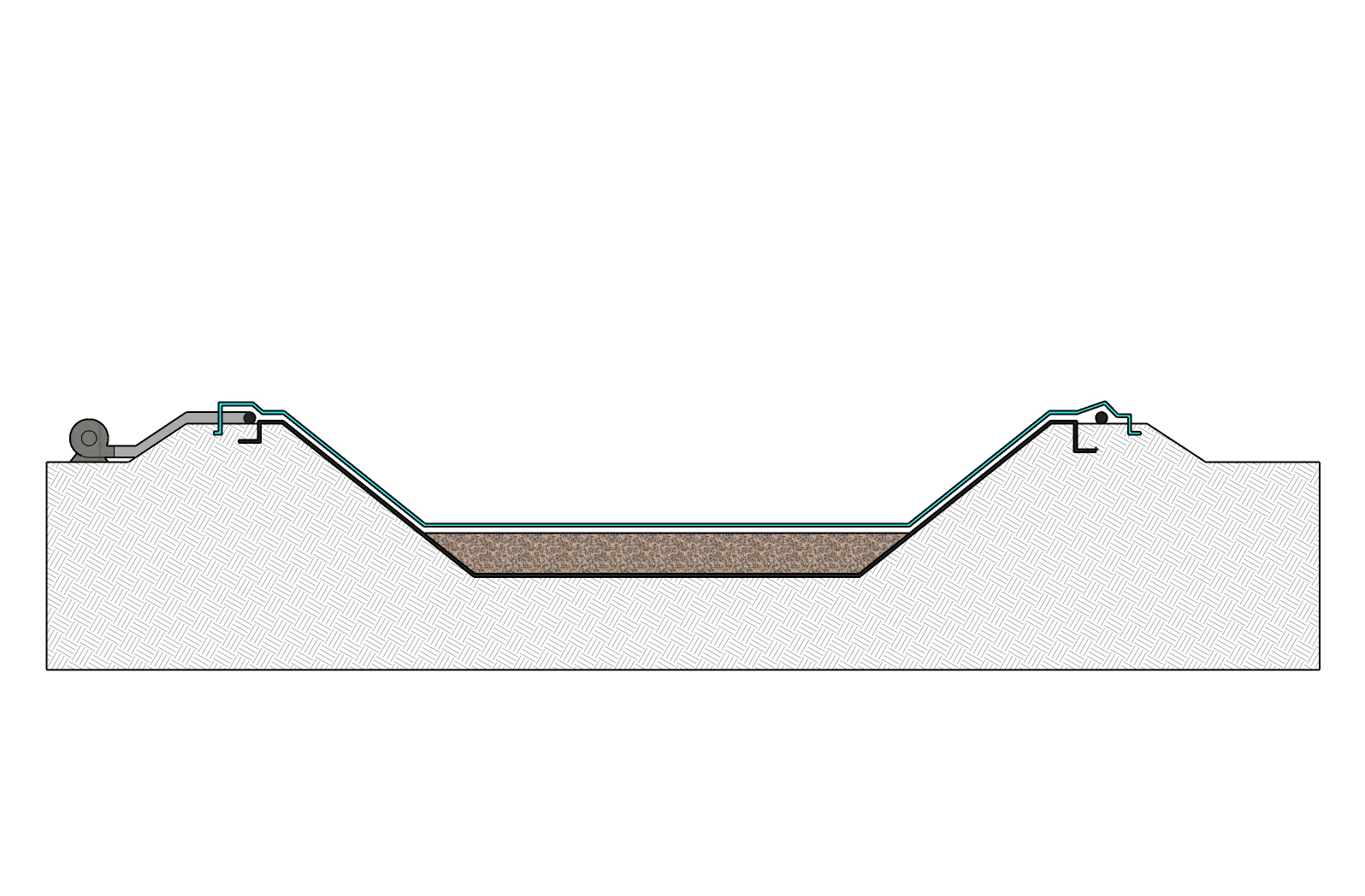

An impermeable negative air pressure system consists of a flexible cover placed over the manure storage that is pulled down against the surface of the manure using a fan that operates constantly, drawing air out from under the cover. The constant operation of the fan prevents the cover from being blown off in windy conditions. This system is mostly used on large earthen manure storage structures (Figure 5). The cover is keyed into the top of the manure storage bank, a perforated pipe is placed around the top under the cover and connected to a squirrel fan that constantly draws air out from under the cover as illustrated in Figures 6 and 7. Precipitation that accumulates on the storage cover is collected and pumped out.

There are two methods to remove the manure from the covered storage:

- Remove the cover, agitate and remove the manure.

- Use an under-cover system, which allows the manure to be agitated and pumped out without removal of the cover.

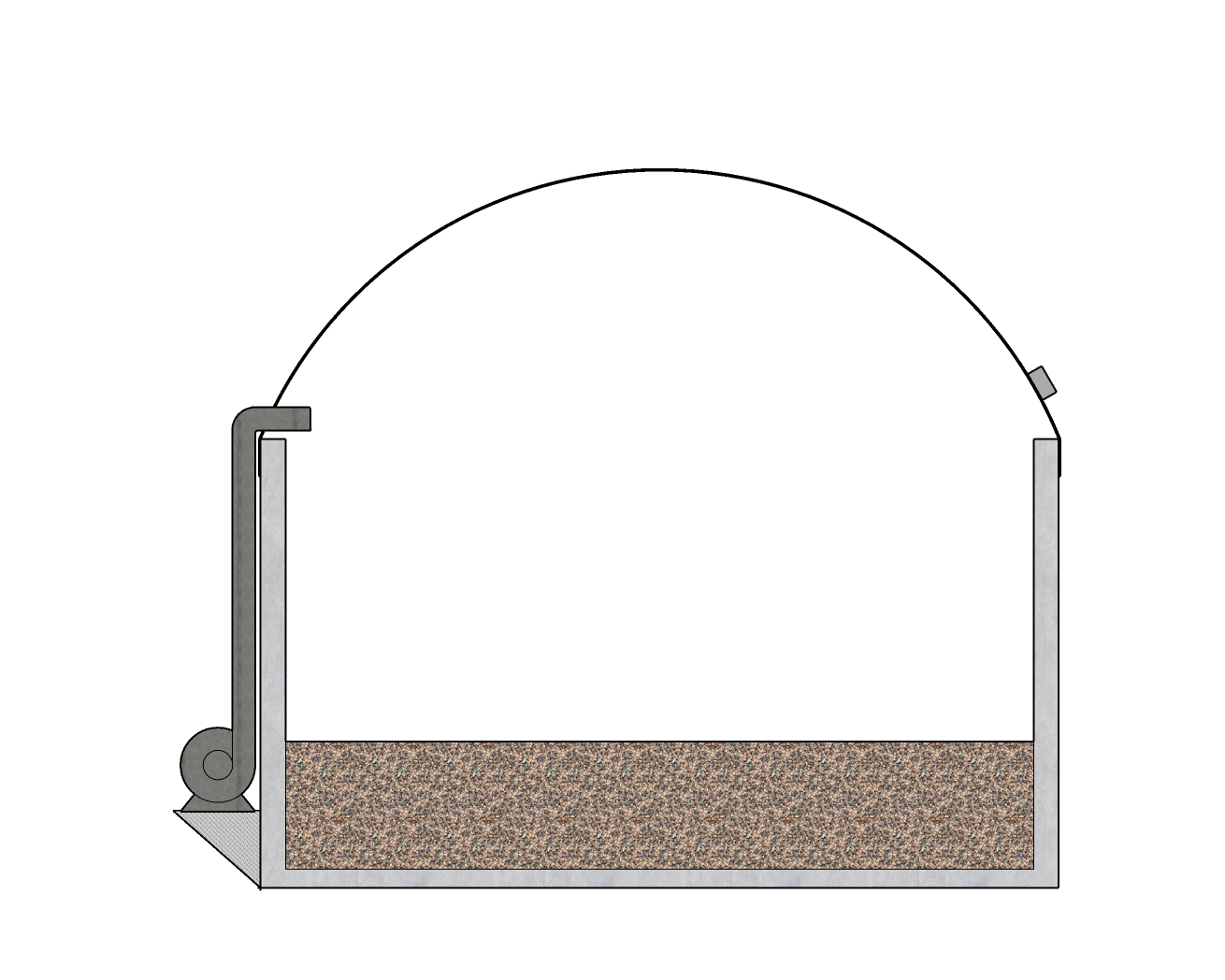

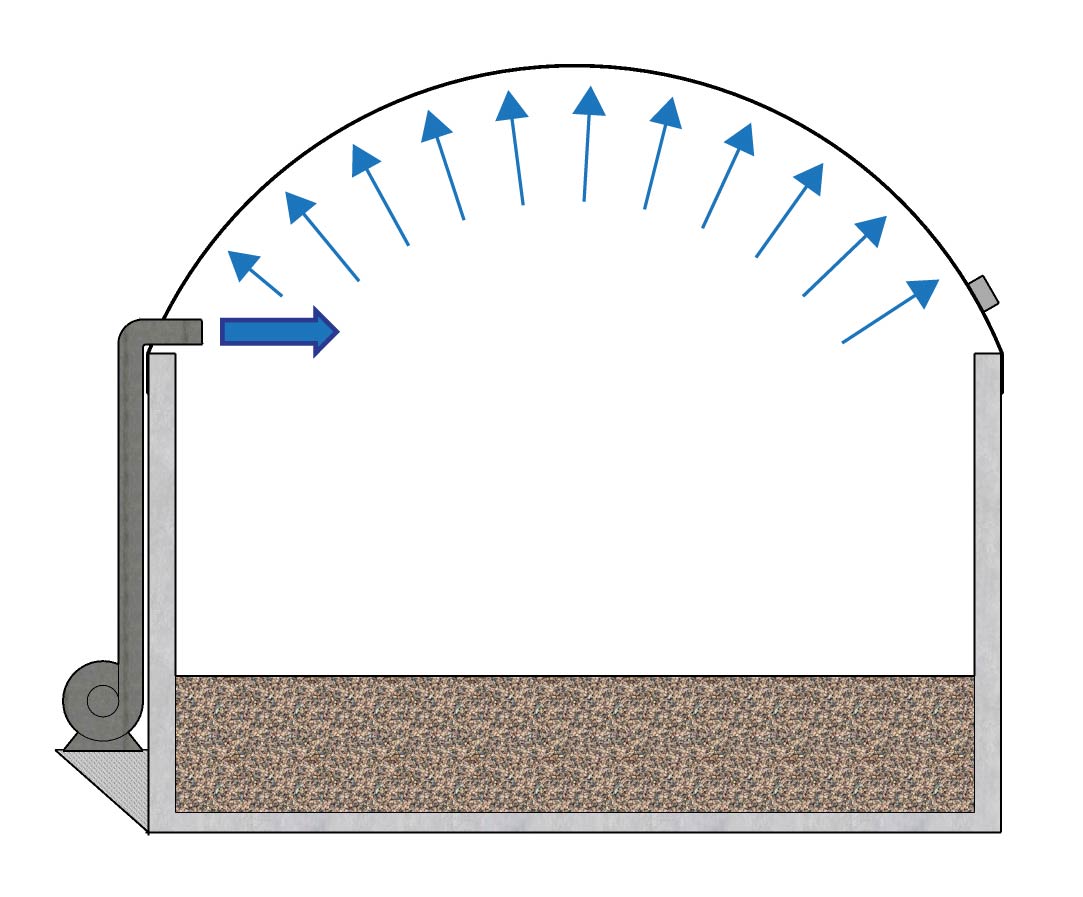

Impermeable positive pressure system

The impermeable positive pressure system consists of a flexible cover that is attached and sealed to the sides of the manure storage. A constant air pressure is maintained under the cover. This air pressure will cause the cover to dome over the manure storage. The dome will drain any precipitation off the tank. (Figure 8 and 2). Constant air pressure is normally kept at approximately 5 psi. The cover is designed with a type of built-in door that is opened to allow manure agitation and removal from the tank. Cables are placed across the top of the tank or a centre post is placed within the tank to hold the cover when the pressure is released to agitate and remove the manure from the tank. After the manure is removed, the air pressure is again increased under the cover to hold it in place. When using this type of cover, the farm should have a back-up generator connected to the air pressure pump to keep it operating during any power failure, otherwise the liner can be damaged if the cover deflates (for example, under windy conditions).

Impermeable floating cover system

The impermeable floating cover system keeps a cover floating on the surface of manure and is sealed around the edge of the storage. As with the negative pressure system, these systems must allow the collected precipitation to be pumped off the surface of the cover. These covers remove almost all the odour that is released from the manure storage.

Manure gases

Manure gases are trapped under all impermeable covers. These gases, mostly H2S, NH3, VOC, CH4, CO2 and N2O are produced from the breakdown of the liquid manure over time. As the gas concentration in the entrapped air space increases, the production of the gases by the manure storage decreases. Therefore, the NH3 stays in the manure.

Maintenance

Plastic cover maintenance includes repair of tears and punctures, and removal of debris that accumulates on the surface of the fabric. Additionally, maintenance will include removal and replacement of the cover for manure agitation and pumping, unless the cover has an access door for agitation of the manure.

Maintain the precipitation removal systems, including the pump, to ensure that the drainage system stays in place and operates correctly. Plastic and fabric covers are not usually designed to support animals or people walking on them. A fence around the storage structure is highly recommended to protect the safety of people and animals.

Permeable manure storage covers

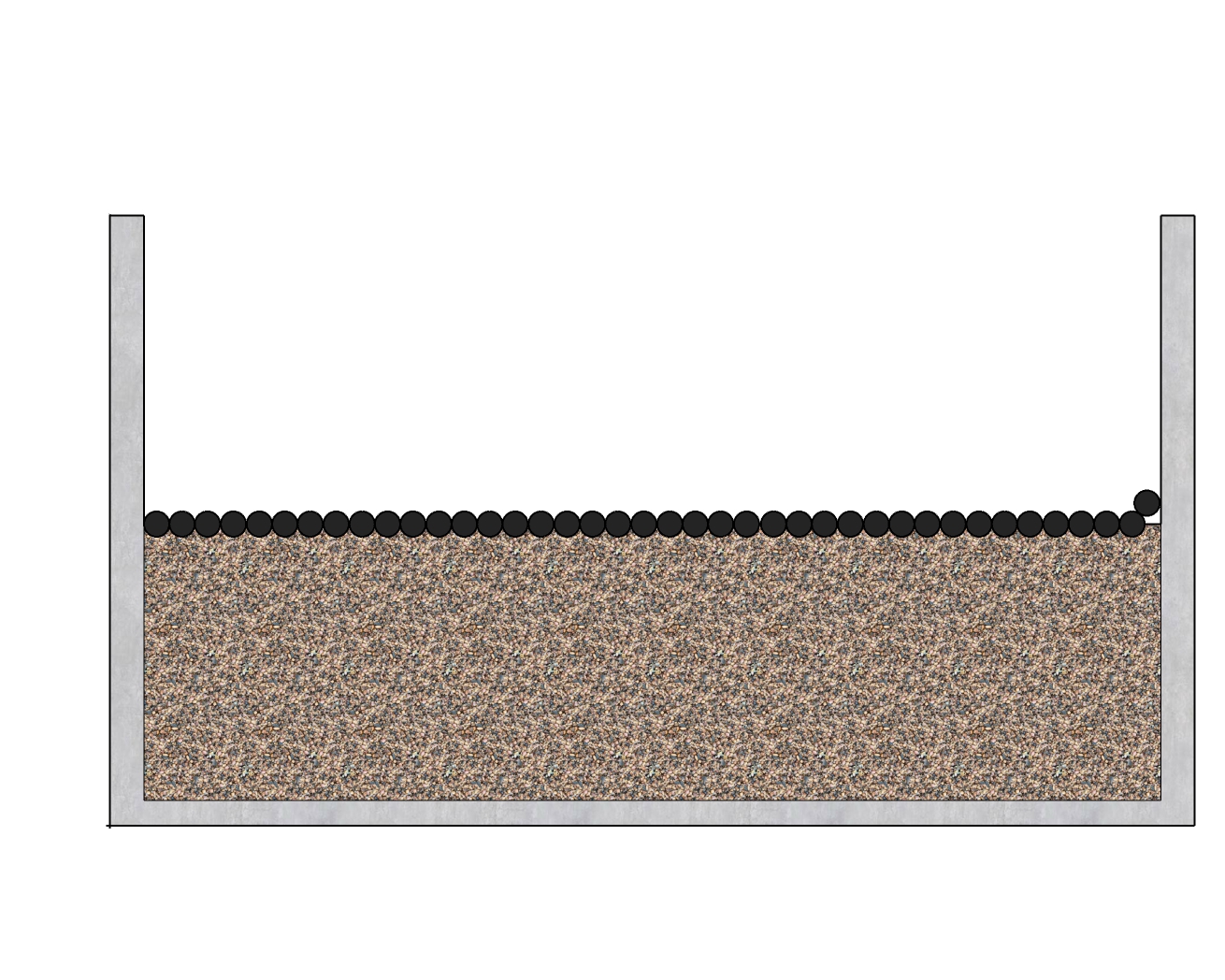

Permeable covers are constructed from different types of straw, synthetic materials or a combination of both. Floating clay balls, floating plastic balls or floating hexagon-shaped discs are used as permeable storage covers. All permeable covers reduce the exposed surface area of the manure storage, which reduces loss of the manure gases. Within these covers, an aerobic biofilm is formed. An aerobic biofilm is a thin layer of microorganisms (for example, bacteria) that form on the surface of the liner. These microorganisms absorb and aerobically break down the gases released from the manure storage, thereby reducing odours.

Straw manure storage covers consist of chopped wheat or barley straw that is blown over the surface of the manure or over a geotextile material floating on the manure surface (Figure 9). Chopped straw pieces approximately 10–30 cm (4–12 in.) long are placed on the manure surface and act like a biofilter that breaks down the manure gases that leave the storage. Research has shown that 10 cm (4 in.) of thick straw cover can reduce odours from the storage by approximately 60%. If the depth of straw is increased to 30 cm (12 in.), odours are reduced by 70%–90%. However, losses of nitrogen remain constant at approximately 60%. Over time, the effectiveness of a straw cover decreases as the straw slowly sinks and a touch-up application is required later in the season. The straw cover is chopped and blended with the manure during the agitation of the storage tank prior to field application.

Geotextile floating permeable covers are a non‑woven fabric composed of thermally bonded, continuous polypropylene filaments that float and provide a barrier between the manure surface and the air (Figures 10 and 11). This cover reduces the manure surface area exposed to the air and in turn reduces gas emissions from the manure surface. Over time, these floating permeable covers will develop a biofilm on the surface that will act like an aerobic layer.

Floating clay balls, floating plastic balls or hexagonal-shaped discs all act as a barrier between the manure surface and the air (Figure 12). This barrier reduces the exposed manure surface by approximately 95% and decreases the manure gases being released. Like geotextile covers, this type of cover can develop an aerobic biofilm that helps break down manure gases as they are released.

Cost considerations

Consider the following factors prior to purchasing a manure storage cover:

- type and size of storage facility to be covered

- method used to remove manure from storage

- purpose of the cover and effectiveness

- type of cover that will meet the purpose (impermeable or permeable)

- method used to collect and pump precipitation from surface of cover

- longevity of the cover material

- method of cover removal for repair

- plan and cost for final disposal of cover

Geosynthetic covers are expected to last 10–25 years with installation costs of approximately $2.50–$12.50 per m2 ($3–$15 per yd2) covered. The cost is dependent on the size of the storage, the level of sophistication required in the gas collection/vent system and the precipitation removal system.

Impermeable covers have an additional annual cost savings. Since precipitation is collected and removed from the surface of the liner, the volume of stored manure in the tank is reduced by approximately 60 cm (2 ft) of depth. As a result, the nutrient content of the stored manure is higher, and less manure has to be transported and applied to fields annually.

Conclusion

There are different types of manure storage covers, all of which will reduce manure odours. Reductions in manure gas losses of 40%–95% can be measured, depending on the type of cover installed. As a result of this reduction in gas loss, the nutrient content of the manure is increased. In Ontario, the required minimum distance separation (MDS) between the manure storage and neighbouring property is calculated based on size and type of livestock, type of storage and whether the storage is open or covered. Covering a manure storage will reduce the required minimum setback distance, which can be beneficial if the farm is on a small property.

This fact sheet was written by Richard Brunke, P. Eng., engineering specialist, nutrient management, OMAFRA, London, and reviewed by Benoit Lebeau, P. Eng., engineering specialist, non-agricultural source materials, OMAFRA, Kemptville, and Brian Dickson, P. Eng., engineer, by-products/manure, OMAFRA, Woodstock.