This page is no longer current and is provided for archival and research purposes.

Ontario Toxics Reduction Program - Reference Tool for Assessing Safer Chemical Alternatives

This document is intended to increase awareness of green chemistry and assist industries and businesses in evaluating which chemicals are safer alternatives.

This document has been prepared from a review and analysis performed in 2011 for the Ministry of the Environment by Senes Consultants.

Important Notices

There may be websites linked to and from this document that are operated or created for organizations outside of the Government of Ontario. Those organizations are solely responsible for the operation and information (including the right to display such information) found on their respective websites. These linked websites may or may not be available in French. The linking to or from this document does not imply on the part of the Government of Ontario any endorsement or guarantee of any of the organizations or information (including the right to display such information) found on their respective websites.

No Liability

The Ontario Ministry of the Environment assumes no responsibility for errors or omissions in any of the information contained on any of the websites. Ministry of the Environment (MOE) makes no representation or warranty of any kind whatsoever with respect to the web sites. More specifically disclaims any express or implied warranties related to the use of the websites and all contents including without limitation warranties of non-infringement or fitness for any particular purpose.

In no event shall the Ministry of the Environment, the Province of Ontario and their respective officers, employees, servants or agents be liable for any failure to keep the contents of the websites up to date, for errors or omissions contained on the website, or for any damages (including without limitation, damages for loss of profits, business interruption, loss of information, or direct, indirect, incidental, special, consequential or punitive damages) arising out of or related to the use or inability to use this document (including all contents), whether under contract, in tort or under any other basis of liability.

Preamble

This document was developed under the Ontario Toxics Reduction Program and is intended to increase awareness of green chemistry and to assist industries and businesses in evaluating chemicals as safer alternatives. The scope of the document is intentionally broad to assist a range of industries and sectors in understanding green chemistry principles and considerations for the assessment of safer alternatives. This document is not intended to be prescriptive, and is not meant to reflect endorsement, guidance or mandatory action in the Province on Ontario. Instead, it serves as a starting point for those enterprises/individuals looking to consider conducting an alternatives assessment and provides references and a general approach to help move towards safer chemical alternatives.

The framework outlined in this reference tool for the assessment of safer chemical alternatives is based on a thorough review of safer chemical assessment programs and approaches, assessment tools and frameworks, and is also a matter of professional judgement. The background information on alternatives assessment provided in this tool is meant to help companies and also facilitate conversations with contractors, who may be enlisted to complete an alternatives assessment on their behalf. It should be noted that an alternatives assessment should have the involvement of professionals with a scientific background with an understanding of the toxicity of chemicals as an alternatives assessment is not a simple task.

The MOE recognizes that there are challenges that may be encountered in the course of assessing and implementing safer chemical alternatives that may include restrictions due to global formulations, data gaps, interpretation of data (especially environmental and human toxicity), capital investments required, customer approval and satisfaction, evaluation costs, supply assessments, research and development, and facility down-time due to a change in chemical. Furthermore, the MOE recognizes that alternatives assessment is not an absolute process as the end result will not be a chemical or process that is ‘greener’ or ‘safer’ in its entirety; rather, alternatives assessment is a comparative methodology with the end result being a greener/safer chemical or process.

For additional information and any addenda or revisions to this guide, please visit the MOE website.

Public Information Centre (PIC)

Ontario Ministry of the Environment

135 St. Clair Avenue West

Toronto, Ontario

M4V 1M2

Tel: 416-325-4000 Toll-free: 1-800-565-4923 Toll-free TTY: 1-800-515-2759 Fax: 416-325-3195

Cette publication hautement spécialisée n’est disponible qu’en anglais en vertu du reglement 441/97, qui en exempte I’application de la Loi sur les services en français. Pour obtenir de I’aide en français, veuillez communiquer avec Ie ministere de I’Environnement au 416 314-7938 (Fax: 416 314-7949)

Acronyms

- AA

- Alternatives Assessment

- ACGIH

- American Conference of Governmental Industrial Hygienists

- ACS

- American Chemical Society

- AIM

- Analog Identification Methodology

- ASTM

- American Society for Testing and Materials

- ATSDR

- Agency for Toxic Substances and Disease Registry

- BAF

- Bioaccumulation Factor

- BCF

- Bioconcentration Factor

- Cal/EPA

- California Environmental Protection Agency

- CARB

- California Air Resources Board

- CARS

- Chemical Assessment and Ranking System

- CAS® RN

- Chemical Abstracts Service Registry Number

- CCOHS

- Canadian Centre for Occupational Health and Safety

- CDD

- Chlorinated Dibenzo-p-dioxin

- CDF

- Chlorinated Dibenzofuran

- CEPA

- Canadian Environmental Protection Act

- C

- Ceiling Limit

- CGCEN

- Canadian Green Chemistry and Engineering Network

- CMP

- Chemicals Management Plan

- CPA

- Clean Production Action

- CTSA

- Cleaner Technologies Substitutes Assessment

- DEHP

- Di(2-ethylhexyl) phthalate

- DfE

- Design for the Environment

- DSL

- Domestic Substances List

- EC/Dx

- Effect/Dose Concentration (that affects x per cent or organisms)

- ECICS

- European Customs Inventory of Chemical Substances

- Eco-SSLs

- Ecological Soil Screening Levels

- ECOSAR

- Ecological Structure Activity Relationships

- ECOTOX

- Ecotoxicology Database

- EFDB

- Environmental Fate Database

- EPCRA

- Emergency Planning & Community Right-to-Know Act

- EPI

- Estimation Programs Interface

- GATT

- General Agreement on Tariffs and Trade

- GCC

- GreenCentre Canada

- GCES

- Green Chemistry Expert System

- GCI

- Green Chemistry Institute (of the ACS)

- GCN

- Green Chemistry Network

- GHS

- Globally Harmonized System

- GLGCN

- Great Lakes Green Chemistry Network

- GWP

- Global Warming Potential

- HMIS

- Hazardous Materials Identification System

- HSDB

- Hazardous Substance Data Bank

- IARC

- International Agency for Research on Cancer

- IC/Dx

- Inhibitory Concentration/Dose (that affects x per cent of organisms)

- IDLH

- Immediately Dangerous to Life or Health

- IRIS

- Integrated Risk Information System

- IRR

- Internal Rate of Return

- ISO

- International Organization for Standardization

- LCA

- Life Cycle Analysis

- LC/Dx

- Lethal Concentration/Dose (that kills x per cent of organisms)

- LCI

- Life Cycle Inventory

- LCIA

- Life Cycle Impact Assessment

- LO(A)EL/C

- Lowest Observed (Adverse) Effect Level/Concentration

- LSS

- Lab Safety Supply

- Koc

- Organic carbon-normalized sorption coefficients

- Kow

- Octanol-Water Partition Coefficient

- MATC

- Maximum Acceptable Toxicant Concentration

- MBDC

- McDonough Braungart Design Chemistry

- mg/kg

- Milligrams per kilogram

- mg/kg-d

- Milligrams per kilogram per day

- mg/L

- Milligrams per litre

- mg/m3

- Milligrams per cubic metre

- MIR

- Maximum Incremental Reactivity

- MMC

- McMaster-Carr

- MOE

- Ontario Ministry of the Environment

- MSDS

- Material Safety Data Sheets

- NAFTA

- North American Free Trade Agreement

- NATO/CCMS

- North Atlantic Treaty Organization/Committee on the Challenges of Modern Society

- NDSL

- Non-Domestic Substances List

- NESHAP

- National Emissions Standard for Hazardous Air Pollutants

- NFPA

- National Fire Protection Association

- NIOSH

- National Institute for Occupational Safety and Health

- NJDEP

- New Jersey Department of Environmental Protection

- NO(A)EC/L

- No Observed (Adverse) Effect Concentration/Level

- NOHSC

- National Occupational Health & Safety Commission

- NOx

- Nitrogen Oxides

- NPCA

- National Paint & Coating Association

- NPRI

- National Pollutant Release Inventory

- NPV

- Net Present Value

- NTP

- National Toxicology Program

- O3

- Ozone

- OCETA

- Ontario Centre for Environmental Technological Advancement

- ODP

- Ozone Depleting Potential

- OECD

- Organisation for Economic Cooperation and Development

- OELs

- Occupational Exposure Limits

- OPPT

- Office of Pollution Prevention and Toxics

- OSHA

- Occupational Safety and Health Administration

- P2OASys

- Pollution Prevention Options Analysis System

- PAH

- Polycyclic Aromatic Hydrocarbon

- PBT

- Persistent, Bioaccumulative and Toxic

- PCB

- Polychlorinated Biphenyl

- PCE

- Perchloroethylene (Tetrachloroethylene)

- PEL

- Permissible Exposure Limit

- PentaBDE

- Pentabromodiphenyl Ether

- PHYSPROP

- Physical Properties Database

- pKa

- Acid-base dissociation constant

- PPE

- Personal Protective Equipment

- PSL

- Priority Substances List

- QSAR

- Quantitative Structure Activity Relationship

- REACH

- Registration, Evaluation, Authorization and Restriction of Chemical Substances

- REL

- Recommended Exposure Limit

- RfD

- Reference Dose

- RfC

- Reference Concentration

- RoC

- Report on Carcinogens

- RSEI

- Risk-Screening Environmental Indicators

- SCRAM

- Scoring and Ranking Assessment Model

- SETAC

- Society of Environmental Toxicology and Chemistry

- SF

- Sustainable Futures Initiative

- SIN

- Substitute It Now

- SMART

- Synthetic Methodology Assessment for Reduction Techniques

- SNAc

- Significant New Activity (requirements)

- SRC

- Syracuse Research Corporation

- STEL

- Short-term Exposure Limit

- T1/2

- Half-life

- TEF

- Toxicity Equivalency Factor

- TEQ

- Toxic Equivalent

- TLV

- Threshold Limit Value

- TRA

- Toxics Reduction Act

- TRI

- Toxics Release Inventory

- TRV

- Toxicological Reference Value

- TSCA

- Toxic Substances Control Act

- TURI

- Toxics Use Reduction Institute

- TWA

- Time-Weighted Average

- U.S. EPA

- United States Environmental Protection Agency

- VE

- Virtual Elimination

- VOC

- Volatile Organic Compound

- WHO

- World Health Organization

- WSIB

- Workplace Safety and Insurance Board

- ZWA

- Zero Waste Alliance

1.0 Introduction

1.1 Project Background

The Ontario Ministry of the Environment (MOE) has introduced the Toxics Reduction Program with the purpose of preventing pollution and protecting human health and the environment through the reduction in the use and creation of substances which may pose a threat to human health and the environment, and informing Ontarians about these substances. The Toxics Reduction Program includes promotion of green chemistry and engineering, and support to industry and other stakeholders. Towards this end, the MOE has completed a review of programs and approaches for assessing safer chemical alternatives, and has developed this reference tool to provide support and guidance for stakeholders to identify and consider safer chemical alternatives.

The MOE conducted a jurisdictional review of safer alternative practices (Jurisdictional Review of Safer Chemical Alternatives) and, based on this review, developed a reference tool for chemical substitution. This tool is intended to provide information and increase awareness of green chemistry and assessment of safer chemical alternatives, and to inform individuals who are in decision-making roles or negotiating positions with their suppliers.

This report is the second part of the safer chemical alternatives initiative and provides references and guidance to assist the Ontario government, industry and other stakeholders in assessing chemicals that may be used as safer alternatives. The information contained herein was obtained from a review of existing programs, networks, and assessment tools (programs) related to the promotion, evaluation and implementation of green chemistry and safer chemical alternatives. The complete review of these programs is provided in the 2012 document entitled Jurisdictional Review of Safer Chemical Alternatives.

This document is not intended as a prescriptive tool, and is purposely as general as possible so that it may be applied broadly across multiple industries and sectors. It is aimed at drop-in chemical substitution, although other aspects of safer alternatives and green chemistry in general can encompass production processes, materials, products, economic systems and functions, as well as product redesign to eliminate the need for a current activity or function of a chemical substance. In addition, it should be noted that an evaluation of safer chemical alternatives may not find a better alternative at present but that does not preclude an examination of a safer alternative using the guidance provided in this tool.

The framework outlined in this reference tool for the assessment of safer chemical alternatives is based on a thorough review of other assessment tools, frameworks and programs, and is also a matter of professional judgement. It is recognized that each industry and manufacturer may have to adapt the tool to their specific needs and, as such, is intended to provide a general approach that can be followed to help industry move towards a greener economy.

As a small or medium size company, possibly with limited resources to devote to an alternatives assessment, this reference tool is provided as an educational overview for the procedure and considerations for completing an alternatives assessment. Some components discussed in this document may be outside the scope and resources available to small or medium-sized companies. However, a broad understanding of alternatives assessment will enhance discussions with, for example, chemical suppliers and possibly create opportunities for improvements within the guiding principles of green chemistry. Additionally, an awareness of the green chemistry principles and considerations for safer alternatives might lead to other process or formulation improvements.

As a large company, some components of alternative assessment may already exist within the organization. This reference tool is not intended to override existing functions or procedures; however, it may provide guidance for the enhancement of existing procedures or help with the expansion of green chemistry programs within the organization.

As a facility that is subject to the Toxics Reduction Act, 2009 (TRA), the facility is required to develop a plan to reduce their use and creation of a prescribed toxic substance. As part of this, the facility must identify and assess at least one option from each of the seven categories listed in Ontario Regulation 455/09, or explain why an option could not be identified for any set category. One of those seven categories is materials or feedstock substitution (i.e., a safer chemical alternative). An identified option cannot contravene another law nor have a greater net negative impact on human health and the environment. The TRA and Regulation provide a facility with the flexibility to determine an appropriate approach for undertaking the identification and analysis of options.

As part of the assessment of the option, technical feasibility and economic feasibility must be considered. A useful starting point for a facility may be to identify the specific technical and economic factors that should be considered as part of this. And while there are a number of factors that can be considered by a facility, it must include the anticipated savings for each option, if any, and the anticipated payback period as part of the analysis of economic feasibility. For more information, please refer to the MOE website for additional information or guidance.

If you are a company that receives parts and materials from other suppliers, you may not have the control to modify the parts and materials; however, discussions with suppliers could be initiated to encourage the supplier to implement improvements. This reference tool is also not necessarily relevant for a company or facility that does not produce chemicals; again, discussions could be initiated with suppliers to encourage the implementation of improvements. In addition, the selection of an alternative chemical may be done through a sector based approach so that all members can benefit from the change in a common chemical.

1.2 Green Chemistry & Safer Chemical Alternatives

Traditionally, environmental protection has focused on controlling risk by controlling or reducing exposure. Green chemistry, on the other hand, looks to reduce risks at their source by stimulating innovation in safer and cleaner forms of production, products and activities. In other words, green chemistry looks at developing manufacturing processes that do not use or lead to the generation of harmful substances, rather than finding end-of-pipe solutions to dispose of toxics and reduce emissions (GLGCN 2010, Rossi et al. 2006).

Green chemistry is the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances (U.S. EPA 2010a). This is usually accomplished through the reduction of waste, use of non-toxic components, and improvement in process efficiency. Green chemistry typically encompasses the life cycle of a product, including by-products of the manufacturing process and use. The 12 principles of green chemistry developed by Anastas and Warner (1998) are as follows:

- It is better to prevent waste than to treat or clean up waste after it is formed.

- Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product.

- Wherever practicable, synthetic methodologies should be designed to use and generate substances that possess little or no toxicity to human health and the environment.

- Chemical products should be designed to preserve efficacy of function while reducing toxicity.

- The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and, innocuous when used.

- Energy requirements should be recognized for their environmental and economic impacts and should be minimized. Synthetic methods should be conducted at ambient temperature and pressure.

- A raw material or feedstock should be renewable rather than depleting wherever technically and economically practicable.

- Unnecessary derivization (block group, protection/deprotection, temporary modification of physical/chemical processes) should be avoided whenever possible.

- Catalytic reagents (as selective as possible) are superior to stoichiometric reagents.

- Chemical products should be designed so that at the end of their function they do not persist in the environment and break down into innocuous degradation products.

- Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances.

- Substances and the form of a substance used in a chemical process should be chosen so as to minimize the potential for chemical accidents, including releases, explosions, and fires.

It should be noted that these 12 principles are not to be used as assessment tools, and merely serve to provide suggestions of how the concepts of green chemistry may be implemented into an alternatives assessment process. Therefore, following any one principle does not necessarily imply that a chemical or process is ‘green’ but would serve to move towards a ‘greener’ process or ‘safer’ chemical.

There are many benefits to the use of green chemistry outside of the direct benefits of reducing the use and creation of toxic chemicals. Green chemistry can reduce costs through a reduction in capital investment, insurance costs, required inputs, energy, disposal and treatment of hazardous waste, and improved process efficiency. Many countries have approval processes that favour green chemicals through reduced permitting time (e.g., the U.S. EPA Sustainable Futures Initiative [SF]) and special labelling programs (e.g., the U.S. EPA Design for the Environment [DfE]). The manufacture and use of green chemicals minimizes the potential for future liabilities, either through waste management, chemical accidents, or workplace exposures. Green chemistry can also present business opportunities for suppliers and manufacturers and marketing advantages for products and companies. Additionally, investors are becoming increasingly wary of toxic risks, not just as health risks but also as a business risk.

The selection of safer chemical alternatives is an important but complex component of green chemistry. Substituting with alternatives can be more efficient at reducing multiple risks in the long term, as alternative assessment examines a broader range of factors and options than traditional problem-based approaches. Alternatives can encompass production processes, chemicals, materials, products, economic systems and functions, as well as product redesign to eliminate the need for a current activity or function of a product (Rossi et al. 2006). This reference tool, however, is limited to the assessment of chemicals that may be used as drop-in safer chemical alternatives.

The selection of a safer chemical alternative includes consideration of possible chemical substitutes and an assessment of a full range of criteria, such as persistence, toxicity, degradation, cost, performance, etc. It should be noted that alternatives assessment is not an absolute process as the end result will not be a chemical or process that is ‘green’ in its entirety; rather, alternatives assessment is a comparative methodology with the end result being a greener chemical or process. For example, an alternative chemical may be safer (i.e., less persistent or toxic) in one aspect, but it may introduce other hazards that the original chemical did not present. The information gathered for the assessment is geared towards promoting informed decisions, minimizing the potential for unintended consequences such as switching to a poorly understood and potentially more hazardous alternative (Lavoie et al. 2010). As such, the selection of an alternative is not a black and white decision and requires prioritization of criteria.

Currently, Canada has very few regulations and programs geared towards large-scale adoption of green chemistry and the evaluation of safer chemical alternatives, with the exception of the International Organization for Standardization (ISO) 14040 standards. Instead, technologies to control emissions are often used in an effort to manage hazards and risks. There is therefore a need to provide industry with guidance and tools on how to voluntarily implement the principles of green chemistry and the potential selection of safer chemical alternatives (Thorpe 2005). Alternatives assessment is a process that has been implemented by a number of organizations, and various regulations, frameworks assessment tools and manuals have been developed around this subject internationally; however, a standard method for alternatives assessment has not been established to date.

1.3 Existing Programs

The MOE conducted a review of existing programs, networks and assessment tools for the evaluation of safer chemical alternatives (Jurisdictional Review of Safer Chemical Alternatives). From this review, several key conclusions were drawn with respect to what features are necessary in the development and implementation of a reference tool aimed at promoting green chemistry. The most challenging aspect of a green chemistry initiative is the establishment of a defined metric system for the assessment of chemicals and processes so that a preferred alternative can be selected. The criteria that form the basis of this metric system must be specific to industry use, but should also have some consistency between multiple industries.

Many of the programs that were reviewed focused on the assessment of safer alternatives based on human and environmental health. For example, the comparison of chemicals based on some definition of persistence, bioaccumulative potential and toxicity was common to almost every program reviewed. While most of the programs neglected to evaluate other crucial aspects such as economic and technical feasibility and social impacts, there were some assessment tools and frameworks that did recognize the importance of economics and technical requirements. For example, the Lowell Center for Sustainable Production has published an Alternative Assessment Framework (Rossi et al. 2006) that comparatively assesses chemicals, materials or products based on their human health and environmental effects, social justice, economic feasibility and technical performance. Although the U.S. EPA DfE Safer Product Labeling Program only considers the hazards of a product, the DfE has also developed the Cleaner Technologies Substitutes Assessment (CTSA) Methodology which evaluates the comparative human health and environmental risks, competitiveness (e.g., performance, cost) and resource conservation of traditional and alternative chemicals, manufacturing methods and technologies (DfE 1996). This methodology has been updated recently and renamed to the Alternatives Assessment (AA) Methodology (Lavoie et al. 2010). McDonough Braungart Design Chemistry (MBDC) has created their own Cradle to Cradle® Certification program which recognizes companies that choose chemicals, materials or processes for health and perpetual recyclability and social responsibility (MBDC 2010).

All of the programs reviewed in detail in the Jurisdictional Review of Safer Chemical Alternatives have aspects that are relevant to green chemistry and safer alternatives; however, the Lowell Center Alternatives Assessment Framework (Rossi et al. 2006) seems to be one of the most comprehensive, and therefore serves as the basis for this reference tool. Information and concepts from other programs, such as the U.S. EPA DfE CTSA Methodology (DfE 1996) and AA Methodology (Lavoie et al. 2010), the Alternatives Assessment Process Guidance provided by the Toxics Use Reduction Institute (TURI 2006a) and MBDC’s Cradle to Cradle® program (MBDC 2010) have also been incorporated into the development of this reference tool.

2.0 Evaluating Safer Chemical Alternatives

Purpose: This section provides an overview of the evaluation of safer chemical alternatives.

If you are a small/medium company… It is important to be aware of all components of the evaluation, although not all components may be relevant to your company.

If you are a large company… This framework provides the major components of an evaluation of safer chemical alternatives.

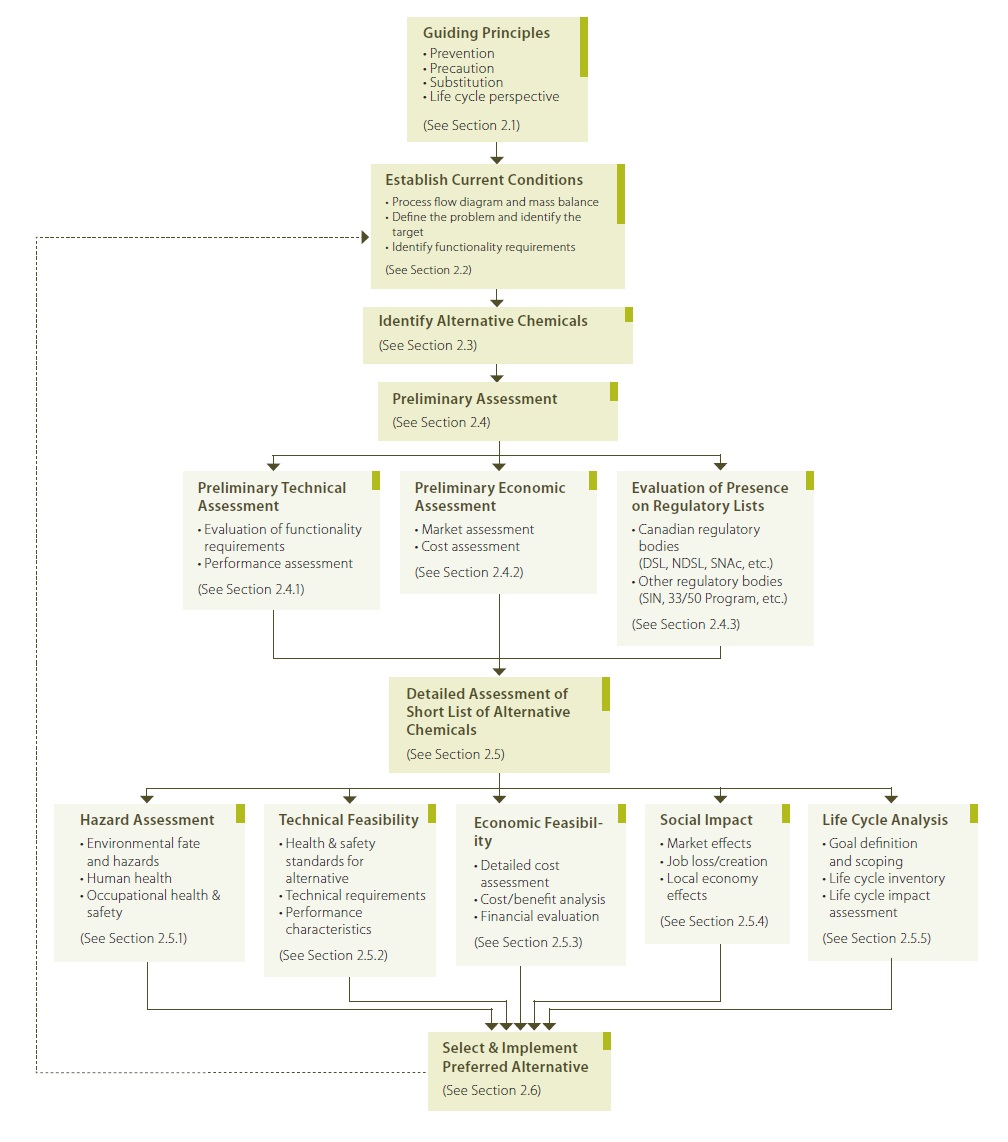

Chemicals, materials and products are terms which cannot be entirely separated from one another. In industry, chemicals (raw materials, by products, end-products) can be sold directly as products, but they can also be used to make materials, which can in turn be sold as is or used in the fabrication of other products which are then sold to consumers. All of these terms play a role in green chemistry, and safer chemical alternatives can be implemented at multiple stages in the production process. The framework presented herein pertains only to the evaluation of safer chemical alternatives; however, a similar framework can also be applied to the evaluation of materials and products. The framework is outlined in Figure 2.1, and the components are discussed in the following sections. It should be noted that the framework provided in this tool is intended to be as general as possible and not be prescriptive so that it can be applied by companies and industries of varying sizes. As seen from the framework (Figure 2.1), there are several stages to the evaluation of a chemical alternative and it is not expected that every aspect of the assessment framework will necessarily be applicable to all manufacturers and companies. For example, some small companies may only be able to accomplish the first part of the assessment (the preliminary assessment) whereas large industries may be able to carry out a complete detailed assessment including a life cycle analysis. The information provided in this reference tool may be explicit in some instances; however, in many cases, the information that is presented serves only to provide suggestions for factors to consider in the assessment. Examples have been provided whenever possible.

Additionally, the guidance provided in this reference tool is intended to be applicable to all industries in Ontario, and not just for those industries subject to reporting under the Toxics Reduction Act, 2009 (TRA, Ontario Regulation 455/09). Evaluation steps within this reference tool that overlap with TRA reporting requirements are highlighted as appropriate. Reporting requirements under the TRA can be found on the Service Ontario e-laws home page.

Figure 2.1 Framework for Assessing Safer Chemical Alternatives

Note: Adapted from Rossi et al. (2006)

2.1 Guiding Principles

It is recognized that there are no regulations in Ontario related to alternatives assessment; thus, any alternatives assessment in Ontario will be voluntary. This reference tool has been developed with this in mind and is based on a set of guiding principles to help direct the decision-making process. Although implementation of safer chemicals is voluntary in Ontario, it should be highlighted that there is a worldwide movement in this direction and therefore companies and industries in Ontario that consider alternatives assessments would be better placed to implement programs related to green chemistry and alternatives assessment in the future.

In developing this reference tool, a number of guiding principles were considered including prevention, precaution, substitution and life cycle perspective. In addition, an alternatives assessment can be complex and resource intensive, especially when a large number of alternative chemicals are available. As such, preliminary technical and economic analyses should be conducted in an effort to pare down a potentially long list of alternative chemicals by removing those that may, for example, be prohibitively expensive or which may not offer the required functionality. This step may be the only step completed by smaller companies with limited resources. Those alternative chemicals which appear feasible would then be carried forward to a more detailed assessment. A major part of the detailed assessment examines the potential hazards of the alternative chemicals (Section 2.5.1) since an alternative should be selected to reduce, avoid or eliminate the use of hazardous chemicals in order to result in a reduction of risk to the health of workers, the general public and the environment. In addition, an alternative chemical must undergo detailed technical and economic feasibility analyses (Sections 2.5.2 and 2.5.3), a social impact analysis (Section 2.5.4), and show that overall it is an improvement over the current chemical over the entire life cycle (Section 2.5.5). A qualitative or quantitative life cycle analysis can provide a broad consideration of the environmental, economic and social aspects across the life cycle of the product.

2.2 Establish Current Conditions

Purpose: This section provides information onestablishing current use and function conditions for the alternatives assessment.

If you are a small/medium company… This may be the only component of your evaluation.

If you are a large company… This is an important component of your evaluation.

Before an alternatives assessment can be conducted, the process should be examined to identify whether a safer chemical alternative may be required or beneficial. Therefore, a good starting point is the development of a process flow diagram and mass balance, which can help to identify the problem and target chemical, as well as any functionality requirements of that chemical.

2.2.1 Process Flow Diagram

A process flow diagram is useful in identifying the target chemical for the alternatives assessment, and also provides information for the other steps in the assessment such as the economic feasibility analysis (Section 2.5.3).

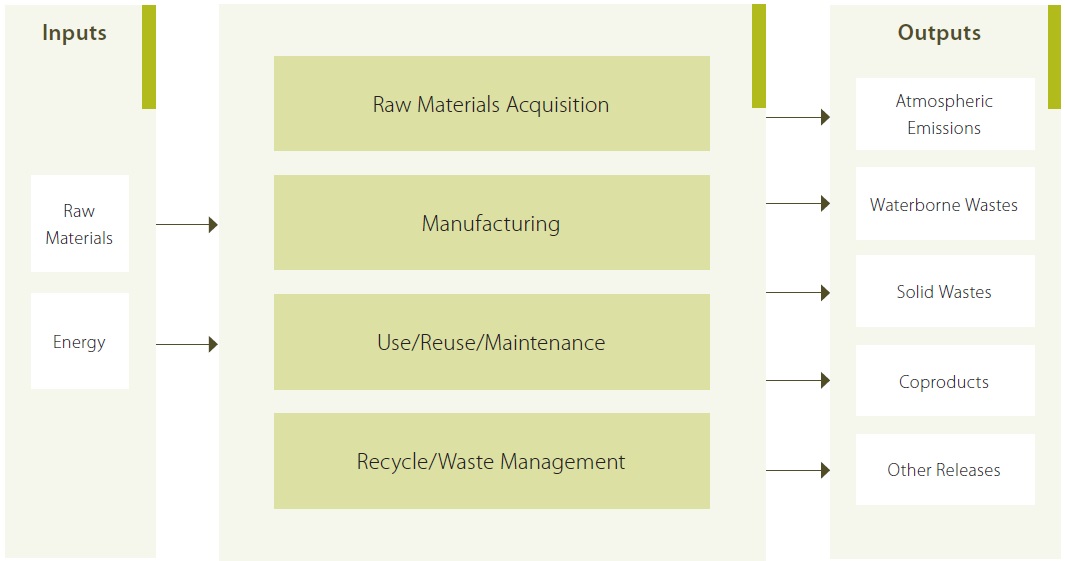

A process flow diagram can have varying levels of detail. In its simplest form, it can show the flows into and out of a production process (i.e., raw material inputs, products, and non-product output streams), while more detailed diagrams may include piping information, operating conditions, etc. It may be useful1 to prepare a more detailed flow diagram by including a mass balance (i.e., labelling all process streams with flow rates of all chemicals) (NJDEP 2002). At the simplest level the assessor can determine the total periodic (e.g., annual) mass or volume inputs and outputs of a chemical (i.e., as a raw material, and as waste) at the facility.

Process flow diagrams should be prepared for every process in each stage of the manufacturing cycle2. This helps to ensure that the assessor fully understands the process(es), and serves to highlight processes or process streams which are problematic and which may benefit from an alternative assessment (NJDEP 2002). Even if a problematic process or process stream has already been identified, the process flow diagram still represents a useful tool in the assessment. By fully understanding the process and identifying all operating conditions and chemicals used, opportunities for improvement will be easier to recognize.

Although process flow diagrams can add value to the assessment, and the more detail the better, it is recognized that a detailed flow diagram of every production process may not be feasible for all companies due to resource constraints3. In this case, the process flow diagram can focus on the production process of interest, showing only the flows into and out of that process.

If desired, emissions can be estimated at a higher level of detail. Under the National Pollutant Release Inventory (NPRI) reporting, facilities are required to estimate releases, disposals and transfers of NPRI substances. If the current chemical is an NPRI substance, then the emitted mass of the current chemical should be easy to determine from NPRI reporting. The same methodology can be applied on a more simplistic level to the alternatives or current chemicals which are not NPRI substances. Environment Canada has an online resource for General NPRI Tools, including equations and conversion factors, example calculations and a listing of software which may be useful when estimating releases.

More information on the basic concepts of process flow diagrams can be found in many engineering textbooks (e.g., Himmelblau 1990, Luyben and Wenzel 1988). The Synthetic Methodology Assessment for Reduction Techniques (SMART) module of the U.S. EPA’s Green Chemistry Expert System (GCES) may be of use when developing the mass balance. Information on the batches per year, reaction yield, reagents and products is entered into the module and the module calculates the amounts of wastes generated. It also categorizes the wastes according to EPA’s level of concern. The results are summarized in a report which outlines the overall level of concern for the process, identifies the waste sources of most concern, and also suggests other modules within the GCES which may help in identifying possible alternatives. The GCES is available for free via download from the U.S. EPA.

More information on chemical manufacturing process and product formulation can be found in the Hazardous Substance Data Bank (HSDB), the Kirk-Othmer Encyclopedia of Chemical Technology, or Ullmann’s Encyclopedia of Industrial Chemistry (information obtained from DfE 1996).

2.2.2 Define the Problem and Identify the Target

From the process flow diagram that was developed in the previous step, the potential benefits of conducting an alternatives assessment should become clear. An assessment may be advantageous if any of the following apply:

- A chemical in one or more processes is going to be subject to new or stricter regulations;

- A chemical in one or more processes requires separate, costly disposal options (e.g., hazardous waste);

- There is high potential for environmental or human exposure to a hazardous chemical used or produced in the process;

- A chemical in one or more processes is on an existing list of chemicals of concern (e.g., priority list, see Section 2.4.3);

- A particular process requires a hazardous substance for cleaning; or

- A chemical in one or more processes is a non-renewable feedstock.

This list is by no means exhaustive. There may be any number of other reasons to conduct an alternatives assessment, and this list is intended merely to serve as a starting point to help assessors determine chemicals in their processes for which an alternatives assessment may be warranted. An alternatives assessment may also be warranted if concerns have been initiated by industry or consumer requests and by policy or regulatory drivers (Lavoie et al. 2010).

Once the chemical to be evaluated is identified, the key issue(s) with this chemical needs to be defined. For example, is it being evaluated because it is persistent or bioaccumulative? Are purchasing and/or disposal costs significantly higher for this chemical than other chemicals in the process? This information will help in the evaluation of the alternative(s) since the selection of a preferred alternative will address the identified issue(s).

2.2.3 Identify Functionality Requirements

The assessor may also need to determine whether there are any functionality requirements that the chemical, and hence any alternative, must fulfill. This is generally determined by the function and use of the chemical. A good starting point for identifying functionality requirements is to describe the role of the chemical in the process and define all operating conditions (e.g., temperature, pressure, etc.). Are there ignition sources directly near the process area so that highly volatile chemicals must be avoided? Does the end product require that all raw materials be water soluble? Some examples of chemical properties that may influence the functionality of a chemical include:

- Ability to withstand extreme reaction conditions — is the process temperature- or pressure-sensitive? For example, polymerization reactions generally occur at temperatures of approximately 50°C to 60°C and atmospheric pressure to prevent evaporation of organic solvents, while ammonia synthesis occurs at a higher temperature of between 300°C and 550°C at a pressure of approximately 150 to 250 atmospheres.

- Low volatility — does the process require the raw materials to be non-volatile at the reaction temperature? A higher vapour pressure of a liquid at a given temperature signifies a higher volatility, meaning that the liquid will readily evaporate. For example, the vapour pressures of propane and water at 20°C are 16,500 mm Hg and 17.5 mm Hg, respectively, indicating that propane is more volatile and will therefore evaporate at a lower temperature than water.

- Physical state — does the process require any or all of the raw materials to be in solid, liquid or gaseous form?

- Viscosity — does the process require the raw materials to be of low viscosity (‘thickness’)? For example, castor oil is a thicker fluid with a viscosity of approximately 0.985 Pa·s (Pascal second) at 25°C, while water is a thinner fluid with a viscosity of approximately 0.0009 Pa·s at the same temperature.

Once the functionality requirements are identified, the physical and chemical properties that an alternative must possess should become clear. This information will then be used for both the preliminary (Section 2.4.1) and the detailed (Section 2.5.2) technical evaluations of the identified alternative(s).

2.3 Identify Alternatives

Purpose: This section provides information on identifying possible chemical alternatives for the alternatives assessment.

If you are a small/medium company… This is a key component of your evaluation.

If you are a large company… This is a key component of your evaluation.

Once the chemical and its associated process are identified and described, the next step in the assessment is the identification of any alternatives that exist for the chemical, paying particular attention to those that are designed for that particular use.

The framework presented in this reference tool focuses on the replacement of a chemical with a safer alternative (i.e., a drop-in replacement); however, it should be noted that the term ‘alternative’ does not only refer to a drop-in replacement, but it may also refer to a process or product change that would eliminate the function or need for the chemical in the first place as per Principle 5 of the 12 Principles of Green Chemistry (Section 1.2). For example, TURI conducted an alternatives assessment study of five chemicals in which it identified UV sterilization as a safer process alternative to the use of para-formaldehyde as a dry sterilant (TURI 2006b).

Alternatives can be identified from other sources, or from brainstorming based on a detailed understanding of the function of the chemical that has been developed from the previous steps. Alternatives can include those that are already available, as well as those that may be on the horizon. It is highly recommended that if a chemical or process is common across an industry sector, that the individual industries in the sector may combine their resources in the identification and assessment of safer alternative chemicals.

Sources that may have a list of possible alternatives include the following:

- U.S. EPA Green Chemical Expert System (GCES) — available for free download.

- Green Synthetic Reactions Module — a searchable database that provides details on alternative techniques that have been used successfully to design green reactions.

- Designing Safer Chemicals Module — through examples or through information based on chemical class (e.g., polyesters), chemical characteristics (e.g., persistence) or chemical use (e.g., surfactants), this module provides guidance on how safer chemical substances can be designed. It should be noted that not all of the features were fully operational at the time this tool was prepared.

- Green Solvents/Reactions Conditions — provides information on greener solvent systems and is also a searchable database that can provide suggestions for replacement solvents based on physiochemical properties.

- U.S. EPA Sustainable Futures Initiative (SF) — Analog Identification Methodology (AIM).

- Although the intended purpose of AIM is to estimate potential hazards (toxicity) of chemicals that have not yet been experimentally tested, it can also be used to identify chemical analogs (chemicals of similar structure) which may behave similarly but with different hazardous properties.

- Green Chemical Alternatives Purchasing Wizard

- A publicly available tool aimed at reducing hazardous waste by replacing hazardous chemicals with greener substitutes. Greener chemicals can be identified by searching by the chemical or process that needs replacing or by known alternative chemicals or processes.

- CleanGredients® — accessible through subscription

- An online database aimed at promoting the flow of information between chemical suppliers and chemical product formulators, by providing technical information on the chemicals used in various cleaning products to enable identification of chemicals with potential environmental and human health benefits.

- Toxics Use Reduction Institute (TURI) — Five Chemicals Alternatives Assessment Study (TURI 2006b)

- A thorough assessment of possible alternatives for five chemicals (lead, formaldehyde, perchloroethylene (PCE), hexavalent chromium, di(2-ethylhexyl) phthalate (DEHP)) for a total of 16 different use categories including manufacturing, consumer products, and other applications.

This list is not exhaustive and serves only as a starting point for a thorough search for alternative chemicals. Identified alternatives are carried forward in the next steps of the evaluation.

2.4 Preliminary Assessment

Purpose: This section provides information on a preliminary assessment for the alternatives assessment by identifying any alternative chemicals that may be a potential concern and therefore, not ideal as a safer chemical alternative.

If you are a small/medium company… This may be the final step; however, further analysis is recommended if possible in your assessment.

If you are a large company… This step has the potential to remove unfavourable alternatives from your evaluation and reduce the scope of your evaluation.

As discussed previously, alternatives assessment can be a time and labour intensive exercise. While a larger industry may have the resources to do a full assessment of all alternatives, it is recognized that smaller companies may not. As such, this preliminary assessment can serve to conserve resources by paring down the list of alternative chemicals identified in Section 2.3, eliminating chemicals that are not economically or technically feasible or that may be of potential concern based on their presence on one or more priority lists. This may also be the final step of an assessment for a smaller company without the resources to complete a full assessment.

2.4.1 Preliminary Technical Assessment

As discussed in Section 2.2.3, there may be several functionality requirements that an alternative chemical must meet in order to be a suitable replacement for the current chemical. The preliminary technical assessment evaluates the alternative chemicals on the basis of their fulfillment of these requirements. Functionality requirements for alternative chemicals may include properties such as density, water solubility, colour, boiling point/melting point, odour, and vapour pressure. Information on these properties can generally be found on a chemical’s Material Safety Data Sheet (MSDS). As an example, if an end product requires that the raw materials are water soluble and an alternative chemical is not water soluble, then the chemical is not technically feasible for that end product and therefore it would not be logical to carry this alternative chemical through the detailed assessment.

Other considerations can include performance characteristics such as durability or longevity of the end product, maintenance requirements, energy consumption, etc. Table 2.1 provides an example of some physical properties that may be important in the technical assessment of alternatives to the use of pentabromodiphenyl ether (PentaBDE) as a flame retardant. Physical properties for both the current chemical (PentaBDE) as well as three identified alternative chemicals are provided in the table (based on information obtained from the U.S. EPA (2005)). As seen from this table, data can be found for some of the physical properties from literature sources; however, some data are not available and can be estimated from structural relationships as described in this reference tool (Section 2.5.1). This example also demonstrates how an alternatives assessment can benefit from consulting scientific experts.

Of note, facilities subject to the Toxics Reduction Act, 2009 (TRA) are required to consider technical feasibility to reduce their use and creation of prescribed toxic substances.4

2.4.2 Preliminary Economic Assessment

Many factors must be considered in an alternative assessment; however, one of the most important factors to consider is that the alternative should yield a profitable end product. As will be discussed in Section 2.5.3, there are many components to an economic analysis including a detailed cost assessment, cost/benefit analysis and financial evaluation.

A market assessment can be considered as part of this preliminary economic assessment and compiles price information for chemicals for use in the cost assessment and identifies trends in the manufacturing and use of the chemicals for consideration in the future supply and demand of the chemicals (DfE 1996). Availability of the alternative chemical should also be considered. Will it be relatively easy to obtain the alternative chemical, and is it available locally or only from suppliers that are great distances away? Are there multiple suppliers so that if one supplier shuts down there are other options for obtaining the chemical?

Some consideration of the international market is also important, such as taxes or tariffs on chemicals imported from foreign suppliers and any international trade regulations or agreements (e.g., General Agreement on Tariffs and Trade [GATT] and the North American Free Trade Agreement [NAFTA]). Additionally, it should be determined if any of the alternatives fall under a chemical or category that might affect the ability of an industry to market the product (either positively or negatively). For example, one of the alternative chemicals may be a restricted substance under a jurisdiction, thereby precluding its sale in that jurisdiction.

In terms of the preliminary cost assessment, at the most basic level, this can compare the direct and indirect costs of the current chemical and its alternatives. In general, the raw material costs play a large role in determining the profitability of the product. If no major process change is expected as a result of implementation of an alternative chemical, then to be profitable, the raw material cost for the alternative chemical should be similar to that for the current chemical. Therefore, in the preliminary assessment, a search can be conducted of various chemical suppliers to determine approximate raw material costs for the alternative chemicals. Of note, facilities subject to the Toxics Reduction Act, 2009 (TRA) are required to consider economic feasibility to reduce their use and creation of a prescribed toxic substance.5

As an example, in the TURI Five Chemicals Alternative Assessment Study (TURI 2006b) one of the main considerations for the alternative selection for DEHP in resilient floor covering was plasticizer cost. The flooring market is so competitive that even a small change in product cost could make the product unattractive to customers. Therefore, for the DEHP alternatives in resilient floor covering it was concluded that the plasticizer cost must not be more than 10 per cent greater than DEHP on a processed per pound basis. From Table 2.2, it can be seen that only two of the six alternative chemicals meet the 10 per cent cost requirement and therefore the other four alternative chemicals would be dropped from a more detailed assessment.

| Factor | Current: PentaBDE | Alternative Chemicals: Triphenyl Phosphate | Alternative Chemicals: Tribromopentyl Alcohol | Alternative Chemicals: Tris(1,3-dichloro-2-propyl) Phosphate |

|---|---|---|---|---|

| Physical Form | Solid | Solid | Solid | Liquid |

| Melting Point (°C) | -5 (E) | 50.5 | 62-67 | -58 |

| Boiling Point (°C) | 436 (E) | 389 (E) | 760 (E) | > 200 |

| Vapour Pressure (mm Hg) | 3.1 x 10-8 (E) | 6.3 x 10-6 | 6.2 x 10-5 (E) | < 10-6 (E) |

| Water Solubility (g/L) | 9.0 x 10-4 (E) | 1.9 x 10-3 | 2 | 0.042 |

| Log Kow | 6.84 (E) | 4.59 | 2.6 | 2.4 |

Note: Data for alternative chemicals as cited in U.S. EPA (2005); data for PentaBDE estimated using U.S. EPA PBT Profiler (2006a); E indicates data are estimated.

| Plasticizer | Raw Material ($/lb) | Adjustment Factor | Adjusted Cost (Processed $/lb) | Less than 10 per cent higher than DEHP? |

|---|---|---|---|---|

| DEHP (current) | 0.70 | 1 | 0.70 | - |

| Di(2-ethylhexyl) adipate | 0.74 | 0.94 | 0.70 | Yes |

| Di(2-ethylhexyl) phosphate | 2-3 | 1 | 2-3 | No |

| Di(isononyl) phthalate | 0.73 | 1.06 | 0.77 | Yes |

| Di(isononyl) phthalate | 0.77 | 1.1 | 0.85 | No |

| Trioctyl trimellitate | 0.95 | 1.17 | 1.11 | No |

| Trioctyl trimellitate | 2.10 | 1 | 2.10 | No |

Note: Data obtained from TURI (2006b).

2.4.3 Evaluation of Presence on Regulatory Lists

There are a number of chemicals that are present on one or more regulatory lists as a result of high use, production rates, emissions rates, etc. within the jurisdiction which publishes the list, or as a result of hazardous properties or high potential for exposure. The chemicals that have been identified by the organizations and programs discussed below may be considered among the more hazardous and/or high use/release substances and may currently be subject to some legislative control, or may be subject to it in the future.

If an alternative chemical is on one or more of these lists it does not mean that it necessarily should be dropped from further assessment since it may, for example, still be less toxic than the current chemical used in the process. Furthermore, the alternative chemical may be used in smaller quantities such that the exposure is lower (see Section 2.5.5.3) and thus may be considered as an alternative.

The following paragraphs discuss some of the regulatory lists that should be consulted.

Part 5 of the Canadian Environmental Protection Act, 1999 (CEPA 1999) focuses on understanding and reducing the risks posed by new and existing substances. As part of the Act, various substance inventories and lists have been established, including the following:

- Domestic Substances List (DSL) — The DSL is an inventory of approximately 23,000substances that, between January 1, 1984 and December 31, 1986, were manufactured in, imported into or used in Canada on a commercial scale (in a quantity of or exceeding 100 kg per calendar year). All substances not on this list, with a few exceptions, are considered to be ‘new’ and are subject to notification which includes an assessment of toxicity. The list is amended regularly to include additional substances that have been deemed eligible following their assessment under the new substances notification and assessment regime. A searchable database is available online.

- Non-Domestic Substances List (NDSL) — The NDSL is an inventory of more than 58,000 substances based on the U.S. EPA’s Toxic Substances Control Act (TSCA) Chemical Substances Inventory for 1985. The list is updated annually to add or delete substances incorporated into, or removed from, the TSCA inventory. Substances not on the DSL but listed on the NDSL are subject to lesser information requirements. A searchable database is available online.

- Priority Substances List (PSL) — This is a list of substances that need to be assessed on a priority basis to determine whether they are ‘toxic’ (as defined under Section 64 of CEPA 1999) and pose a risk to the health of Canadians or to the environment. A total of 44 substances are included in the first list (PSL1), while 25 substances are included in the second list (PSL2). A substance must be assessed within five years of addition to the list. The PSL substances are listed at the PSL website.

- Toxic Substances List (Schedule 1 of CEPA 1999) — Substances are recommended for addition to this list if they are found to be ‘toxic’ or capable of becoming ‘toxic’ (as defined under Section 64 of CEPA 1999) after having undergone a PSL assessment, a screening assessment, or the review of a decision by another jurisdiction. This list is available online at the Toxic Substances List webpage.

- Virtual Elimination (VE) List — This is a newer list developed as part of the Government of Canada’s Chemical Management Plan (CMP) and includes substances that are designated for virtual elimination. The compilation of this list is mandated under Section 65 of CEPA 1999. The level of quantification is set for each substance on this list and the quantity or concentration of the substance that may be released into the environment either alone or in combination with any other substances from any source or type of source is prescribed. Hexachlorobutadiene and perfluoroctane sulfonate (and its salts) are the only substances currently on this list.

- Non-Statutory List — This is a list of substances that have been found to meet at least one of the criteria for ‘toxic’ as set out in Section 64 of CEPA 1999 but that have not been added to Schedule 1 of the Act (i.e., the Toxic Substances List). These substances have effective risk management measures in place under other provincial and territorial programs or federal acts; however, these substances may be upgraded to Schedule 1 if the Government of Canada finds that those existing preventive and/or control actions are not effective. This list is available online at the Non-Statutory List webpage.

Any chemical on these lists can be determined by using the Search Engine for Chemicals and Polymers.

As mentioned above, the Government of Canada has recently introduced the Chemical Management Plan (CMP), which includes a number of new, proactive measures to make sure that chemical substances are managed properly in an effort to improve the degree of protection against hazardous chemicals. As part of the plan, the Government of Canada has begun issuing Significant New Activity (SNAc) requirements under subsection 81(3) of CEPA 1999 for approximately 300 highly hazardous substances that have been or currently are used in Canada (i.e., are on the DSL). Data must be submitted to Environment Canada and Health Canada for review before re-introduction or increased use of these substances in quantities of greater than 100 kg per year. Substances on the DSL that are subject to SNAc requirements can be determined with the Search Engine for Chemicals and Polymers. Alternatively, a listing of the 145 substances that are currently on the SNAc list can be found online.

As part of the MOE’s Toxics Reduction Act, 2009 (TRA) and the Toxics Reduction Program to reduce the use and creation of toxic substances, a total of approximately 350 substances on NPRI and acetone (Ontario Regulation 127/01) are prescribed. From this list, various review processes have resulted in the prioritization of 47 substances and substance groups (Phase 1) while the remainder form part of Phase 2 implementation. A complete listing of Toxic Substances and Substances of Concern is available electronically.

In other jurisdictions, chemicals on regulatory lists have generally been identified as chemicals that are persistent, bioaccumulative or toxic (i.e., PBTs). For example, the Substitute It Now! (SIN) list is a listing of 356 chemicals that have been identified as substances of very high concern based on criteria established by the European Union REACH program (Registration, Evaluation, Authorization and Restriction of Chemical Substances). The SIN list can be accessed from the website of the International Chemical Secretariat. The Norwegian Pollution Control Authority has also developed criteria for health and environmental hazards and, based on these criteria, have produced three lists: (1) the List of Dangerous Substances; (2) the Priority List; and (3) the Observation List (online listing available). TURI (2006b) has completed a detailed alternatives assessment study on five chemicals that have been identified as hazardous or toxic. These include lead, formaldehyde, perchloroethylene (tertrachloroethylene [PCE]), hexavalent chromium, and di(2-ethylhexyl)phthalate (DEHP). In 1988, the U.S. EPA organized a voluntary pollution prevention program, the 33/50 program, which targeted 17 chemicals for which a 33 per cent reduction in releases and transfers of these chemicals to the environment should be achieved by 1992, and 50 per cent by 1995, measured against a 1988 baseline. These chemicals included (U.S. EPA 1999):

- benzene

- carbon tetrachloride

- chloroform

- dichloromethane

- methyl ethyl ketone

- methyl isobutyl ketone

- tetrachloroethylene

- toluene

- 1,1,1-trichloroethane

- trichloroethylene

- xylenes

- cadmium and cadmium compounds

- chromium and chromium compounds

- cyanide compounds

- lead and lead compounds

- mercury and mercury compounds

- nickel and nickel compounds

In summary, the selection of an alternative chemical from one of these lists serves only to caution the assessor that there may be issues or implications associated with the use of the substance such as stricter or more cumbersome reporting requirements. For example, if an alternative chemical is identified that is not on the DSL, then the alternative chemical would be considered ‘new’ to Canada and would be subject to the New Substances Notification Regulations (NSNR), more information available online.

Alternatively, if an alternative chemical is on the DSL, the assessor should check to see if the alternative is considered ‘toxic’ or is capable of becoming ‘toxic’ (i.e., is listed on Schedule 1 under CEPA 1999 [List of Toxic Substances]. It should be noted that the lists presented here are not exhaustive and high priority substances may also be identified elsewhere.

2.5 Detailed Assessment of Short List of Alternative Chemicals

Purpose: This section provides information on a detailed assessment for alternative chemicals.

If you are a small/medium company… This may be outside the scope of your assessment; an awareness of the detailed assessment would be useful for future chemical considerations, purchasing or for discussions with chemical suppliers, for example.

If you are a large company… This is the main component of your evaluation; all aspects should be considered, although the depth and level of detail will depend on your individual requirements and resources.

As discussed in the previous section, only those alternative chemicals that are determined to be economically and technically feasible based on preliminary analyses are carried forward into this more detailed assessment. As indicated previously, some small and medium size enterprises may not be able to progress to this step of the alternatives process and may instead end the assessment after the preliminary assessment (Section 2.4). In addition, the preliminary assessment may not identify any viable or reasonable chemical alternatives that are currently available. In such a case, steps could be taken with chemical suppliers or formulators to develop alternatives for the future or process changes could also be considered. Process changes are not discussed in this reference tool. The alternatives assessment is a continuous process and industries should always be examining their chemicals and processes.

The following sections outline the information that is useful for comparing the current chemical to potential alternative chemicals on the basis of their environmental fate and hazards, technical feasibility, economic feasibility, social impacts and life cycle analysis to aid in the selection of a preferred safer chemical alternative in Section 2.6. The information provided in the following sections allows for a broad evaluation of the alternative chemicals, providing a company or institution with the ability to select an alternative that is consistent with their environmental, technical economic and social priorities. It should be noted that the evaluation of environmental fate and hazards (including toxicity) forms part of a chemical risk assessment process that could potentially be used in an alternatives assessment. Caution needs to be applied when considering a risk assessment process for the evaluation of chemical alternatives as it is a highly technical process and involves implicit judgement of what is a ‘safe’ level of risk. The scoring matrices provided in this tool are a simpler way of evaluating some of the fundamental steps in a risk assessment process.

2.5.1 Hazard Assessment

Purpose: This section provides information on particular components of a hazard assessment.

If you are a small/medium company… Information provided on a hazard assessment can be used for discussions with chemical suppliers to encourage the development of chemicals/products with less hazardous properties or ingredients.

If you are a large company… The evaluation of chemical hazards outlined in the hazard assessment should be completed by or include input from a scientist or others trained in the evaluation of chemical hazards and toxicity.

The hazard assessment involves the collection of data on environmental fate and hazards, human health hazards, and occupational health and safety for the current chemical used in the process and all identified alternative chemicals.

As per the 12 Principles of Green Chemistry (Section 1.2), a safer chemical alternative should possess little to no toxicity to human health and the environment, and should break down into innocuous degradation products. As mentioned previously, priority lists are often developed based on the persistence, bioaccumulative potential and toxicity of chemicals (PBTs); as such, these attributes are part of the Hazard Assessment. The criteria for PBTs adopted by the various jurisdictions and programs that were evaluated in the Jurisdictional Review of Safer Chemical Alternatives are summarized in Appendix A.

These criteria for PBTs have been examined and values that are considered to be best suited for application in the Ontario context have been selected for the evaluation of PBT in this reference tool. The selection is based on a review of all values, professional judgement and in keeping with current regulations and guidelines for Canada and Ontario. For example, the DSL provides ‘cut-off’ values for persistence (i.e., half life) and bioaccumulation (i.e., bioconcentration factor (BCF), bioaccumulation factor (BAF), log octanol-water partition coefficient (log Kow). If these values are exceeded then that substance is classified as persistent and/or bioaccumulative. It should be noted, however, that other jurisdictions and programs such as the DfE’s Safer Products Labeling Program have set more stringent cut-off values. For example, the cut-off value for the half-life of a chemical in water is six months for the DSL but only 60 days for other jurisdictions; as such, values from other jurisdictions have also been provided as reference in order to assess a potential chemical alternative.

Well-defined metrics need to be developed in order to aid in the evaluation and interpretation of the hazards of a chemical. Various ranking methodologies have been developed by the programs that were reviewed in the Jurisdictional Review of Safer Chemical Alternatives. Examples include, but are not limited to, the following:

- Clean Production Action Green Screen for Safer Chemicals (Rossi and Heine 2007)

- In the Green Screen, a chemical is evaluated by comparison to a series of four benchmarks, with each benchmark defining a progressively safer chemical. Similar to other programs, the criteria used in this program are persistence, bioaccumulation and toxicity. The levels of concern are defined by threshold values that are quantitative, qualitative, or based on expert references and aim to harmonize existing hazard classification and labelling systems.

- TURI Five Chemicals Alternative Assessment Study (TURI 2006b)

- Alternatives that passed screening based on health and environmental effects and PBT were prioritized for further study by assessment of chemical- and application-specific criteria in the categories of technical performance, health and environmental effects, economic considerations, and importance to stakeholders. Each alternative was evaluated against the reference (current) chemical by assigning a ‘+’, ‘−’ or ‘=’ to each criterion (better than, worse than or equal to the reference). No conclusions were drawn as to which alternative was preferred.

- TURI Alternatives Assessment Process Guidance (TURI 2006a)

- This document defines a consistent process for setting priorities for study and evaluating the alternatives for the five chemicals evaluated by TURI (2006b). Metrics are provided to evaluate the feasibility of each alternative based on technical, financial, environmental hazards and human health and safety criteria. This document also includes suggestions for specific types of resources for certain phases of the study.

- The Scoring and Ranking Assessment Model (SCRAM) (Snyder et al. 2000a, b, c and d)

- SCRAM was developed as a risk-based screening tool to provide relative rankings of 140 chemicals based on persistence, bioaccumulation and toxicity. Additionally, the model provides a score based on the uncertainty of the information available for each of these categories.

- The MOE categorization procedure of Phase I and Phase II substances (MOE 2009a)

- This document provides a ranking procedure for identifying toxic substances and substances of concern. Hazard scoring information was obtained from RSEI (Risk-Screening Environmental Indicators) and SCRAM (the Scoring and Ranking Assessment Model). Scores from RSEI and SCRAM were converted to rankings. The relevance of the chemical to MOE program areas, and also other programs and agencies, was a consideration.

- The U.S. EPA Design for the Environment (DfE) Cleaner Technologies Substitutes Assessment (CTSA) Methodology (DfE 1996)

- The CTSA methodology provides a way of evaluating the comparative human health and environmental risks, competitiveness (e.g., performance, cost) and resource conservation of traditional and alternative chemicals manufacturing methods and technologies using a systematic methodology. Considerations in the methodology include: environmental fate, human health, environmental hazards, exposure assessment and workplace risk, performance assessment, and energy impacts, among other things.

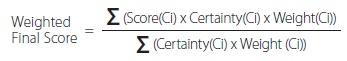

- TURI Pollution Prevention Options Analysis System (P2OASys) (TURI, unknown year)

- The P2OASys scores alternative chemicals according to an established metric system. Users also input a score for the certainty of the data to reflect the confidence in the value, which is then accounted for in the final scoring. The score for each criterion is computed and a final score for a chemical or process is calculated to incorporate the certainty of the data. Considerations include: human effects, hazards (physical, aquatic, atmospheric, disposal, chemical, product), persistence and bioaccumulation, exposure potential, and energy and resource use.

- MBDC Cradle to Cradle® design framework (MBDC 2010)

- The materials and manufacturing practices of a product are assessed in five categories: Material Health, Material Reutilization, Renewable Energy Use, Water Stewardship, and Social Responsibility. Material health includes the evaluation of every chemical or material for its health and safety for humans and the environment against 19 criteria. Criteria include carcinogenicity, toxicity, persistence and bioaccumulation, among other things. A Material Reutilization Score is calculated for a material based on the recyclable, reusable, and compostable content. Energy use and water use are also considered, along with labour practices.

- The Australian Government Criteria for Classifying Hazardous Substances (NOHSC 2004)

- This document provides guidance on the classification of carcinogenicity, mutagenicity and reproductive toxicology. Criteria are also provided for health effects and determining whether a substance is hazardous based on its ecotoxicological and physicochemical properties.

Based on a review of the above-mentioned metrics, a ranking system has been developed for the hazard assessment in this reference tool and is provided in Table 2.3 through to Table 2.7. The outcome of this step is a matrix of shaded cells (i.e., high (dark green), moderate (medium green) or low (light green) concern)) for both the current chemical and the various alternative chemicals. In most cases, the comparison is relative to set criteria that have been determined to be appropriate for the given categories; however, for a few of the categories in the occupational exposure evaluation, the comparison is relative to the current chemical used in the process. In general, if no value for a parameter is available in the literature or it cannot be estimated based on empirical or other relationships, then the chemical should receive a moderate risk score for that parameter (i.e., medium green). If a range of values are reported, then the value used in the matrix should be the most conservative of the individual values. The factors to consider in this part of the assessment are discussed below. It must be noted that ‘low concern’ (i.e., light green) does not imply that the chemical is ‘safe’.

Interpretation of the matrix is a complex step when determining whether a chemical is a reasonable alternative since a number of the factors are inter-related and often data may not be available for multiple categories. It may at first seem logical to drop a chemical from further assessment based solely on the fact that there are numerous dark green cells in the matrix; however, this is not appropriate. For example, a chemical may have a BCF of greater than 1,000 (i.e., a dark green score (high concern)), but a half life (T1/2) in water of only two days (i.e., a light green score (low concern)) and therefore would not be as much of a concern as the shaded matrix would lead one to believe. Adding complication to interpretation is the fact that there is often a lack of toxicological information available. Although estimation tools and analogs can sometimes be used, caution must be used in applying these techniques and may require the input of a scientist with a background in toxicology. Interpretation of the hazards for selecting a preferred alternative may require the use of ranking and weighting factors such as those developed for the TURI P2OASys tool. This is discussed further in Section 2.6.

2.5.1.1 Environmental Fate and Hazards

As discussed above, persistence, bioaccumulation and toxicity are the major factors to be considered in the assessment of environmental fate and hazards. Additionally, there should also be some consideration of the toxicity of the degradation products. Although it is difficult to provide well-defined metrics for degradation products, the general hazards of any potential degradation products can be evaluated from a search of peer-reviewed literature. If there are documented degradation products which are of concern, then the chemical should be scored as being of high concern (i.e., dark green). The factors and criteria that are deemed appropriate for the Ontario context are presented in Table 2.3.

This step in the Hazard Assessment is a data intensive step. Material Safety Data Sheets (MSDS’s) will have some of the information that is pertinent to this screening step but there are also other sources of data. For example, Chapter 5 of the CTSA Methodology developed by the DfE (1996) provides an exhaustive listing of potential sources of environmental fate and toxicity data, and references for estimating environmental fate parameters. Some of the most comprehensive sources for these data include, but are not limited to, the following:

- Hazardous Systems Data Bank (HSDB)

- Provides information on chemical manufacturing processes and product formulations.

- Syracuse Research Board Environmental Fate Data Base (EFDB) (SRC 1994, as cited in DfE 1996)

- Provides information on environmental fate data, microbial toxicity and biodegradation, and physical/chemical properties.

- The U.S. EPA ECOTOXicology Database (ECOTOX) (U.S. EPA 2000)

- Provides toxicity data for ecological species.

- Ecological Soil Screening Levels (Eco-SSLs) documents (U.S. EPA various years)

- Provides soil screening levels for terrestrial plants and animals.

- Handbook of Environmental Degradation Rates (Howard et al. 1991, as cited in DfE 1996) (not available online)

- Provides environmental degradation rates for select chemicals.

If data on environmental fate and/or toxicity are not available for the chemical or identified alternatives, values can often be estimated using various analytical models and quantitative structure-activity relationship (QSAR) models. There are several sources which provide guidance on estimating values for these parameters. Again, the CTSA Methodology (DfE 1996) provides an extensive list or sources, including the following:

- BioByte Inc. Bio-Loom program

- Provides log octanol-water partition coefficient (log Kow) and acid-base dissociation constant (pKa) values, as well as hydrophobic and molecular refractivity parameters.

- Handbook of Chemical Property Estimation Methods (Lyman et al. 1990)

- Provides methods for estimating chemical properties such as density, vapour pressure, solubility, etc.

- U.S. EPA PBT Profiler (U.S. EPA 2006a)