Colorado potato beetle dip test

Learn how to use the Colorado potato dip test to help manage insecticide resistance and to know the effectiveness of the product being applied to a potato field before the field is sprayed.

The choice of an insecticide to control the Colorado Potato Beetle (CPB) is difficult because of the high levels of resistance now being found in beetle populations. Resistance levels in Ontario may vary depending on the location; an insecticide may provide good control in one location but only moderate or poor control in another. In many instances, resistance varies between fields of the same farm depending on the spray record of each field.

An important factor in managing insecticide resistance is to know the effectiveness of the product that is going to be applied before the field is sprayed. This can be accomplished by using dip tests, a simple technique in which adults or larvae are immersed for a few seconds in insecticide solutions. The mortality rate determined for each insecticide indicates the products that are likely to be most effective under field conditions.

Continued dip testing of CPB of a given field will probably show that the activity of an insecticide will decrease if it is applied more than once during the growing season.

Dip tests before field spraying help to reduce costs by avoiding ineffective sprays.

Dip Test Items

Although dip test equipment is easy to obtain, it should be assembled well in advance of testing time. For this test you will need the following items:

- A minimum of 30 CPB (adults or larvae) per insecticide. In addition, you will need 30 or more CPB for the control (water test), regardless of the number of insecticides that you are going to test.

- Commercial formulation of insecticides to be tested.

- Rubber gloves to keep any chemical from getting on your hands.

- Plastic containers (lL or 35 oz each) with screw on tops to make up the insecticide solutions.

- Two plastic syringes, 5 ml and l0 ml each, to measure the volume of insecticide that is going to be mixed with water. Syringes are available in the pharmacy section of most drug stores.

- Plastic containers approximately 250 ml (8 oz) each, to pour dip solutions in.

- A 7.5 cm (3 inch) tea strainer to hold the beetles or larvae as they are being dipped.

- Styrofoam cups with perforated lids to keep the beetles in after the dip test is completed.

- Absorbent paper towels.

- A permanent type marking pen.

- Record sheet.

Collection of Beetles

Collect beetles or larvae from several places in the field, especially from problem areas. Usually, the life stage selected for dip testing is the one that is causing the greatest defoliation. Place the beetles or larvae in a plastic container with a perforated lid to allow air movement. Keep the container out of direct sunlight. If possible, collect the insects the same day that the dip test will be done. However, if the dip test is going to be conducted 24 hours after the beetles or larvae were gathered, place them in the refrigerator.

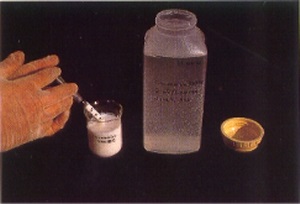

Figure 1. Measuring the volume of insecticide required for a stock solution.

Making up the Insecticide Solutions

All the chemical insecticides, either dilute or full strength, can be toxic if spilled on your hands. Wear rubber gloves throughout the test.

Choose insecticides you expect you might spray on your potato crop. To make up insecticide solutions, refer to Table 1 which shows the amount of insecticide that you have to mix with 1L (35 oz) of water. Check the formulation and rate per hectare of the insecticide that you are going to test, match this information with that given in Table 1. Select the volume per acre that you are going to apply to determine the amount of insecticide per 1L water. Table 1 shows only 3 possible spray volumes. The concentration of the dipping solution must be the same as that of the spray that will be applied in the field.

To avoid contradictory results, make sure that the plastic syringes that you use to make up the stock solutions are flushed with clean water several times before measuring the required volume of insecticide.

After testing is completed, the used dip test solutions can be poured in the sprayer tank to be diluted and spread over the field when you spray the crop.

Stability of insecticide solutions: Most insecticide solutions are more stable at a pH range of 5 to 7. At pH higher than 7, the solutions breakdown faster. This is an important factor that should be taken into consideration when spraying a field. If you suspect that water pH is a problem, consult your local OMAFRA extension personnel.

The most unstable insecticide recommended for CPB control is the organophosphate naled, which breaks down in 48 hours after being mixed with water.

| Insecticide | Formulation | Maximum Rate Ha | Maximum Rate Acre | 20 Gallons/Acre Amt./L. Water | 25 Gallons/Acre Amt./L. Water | 30 Gallons/Acre Amt./L. Water |

|---|---|---|---|---|---|---|

| methidathion | 240 E.C. | 1.20 L | .48 L | 5.2 ml | 4.2 ml | 3.5 ml |

| methamidophos | 480 E.C. | 2.25 L | .90 L | 9.9 ml | 7.9 ml | 6.5 ml |

| chlorpyrifos | 4 E | 1.00 L | .40 L | 4.4 ml | 3.5 ml | 3.0 ml |

| azinphos-methyl | 240 S.C. | 1.50 L | .60 L | 6.6 ml | 5.3 ml | 4.4 ml |

| phosmet | 50% W.P. | 2.25 kg | .90 kg | 9.9 g | 7.9 g | 6.5 g |

| naled | 8E | 1.l0 L | .44 L | 4.8 m1 | 3.9 m1 | 3.2 m1 |

| Insecticide | Formulation | Maximum Rate Ha | Maximum Rate Acre | 20 Gallons/Acre Amt./L. Water | 25 Gallons/Acre Amt./L. Water | 30 Gallons/Acre Amt./L. Water |

|---|---|---|---|---|---|---|

| deltamethrin | 2.5 E.C. | 300 m1 | 120 m1 | l.3 m1 | l.0 ml | 0.9 m1 |

| fenvalerate | 300 E.C. | 150 ml | 60 ml | 0.7 ml | 0.5 ml | 0.4 ml |

| permethrin | 500 E.C. | 200 ml | 80 ml | 0.9 ml | 0.7 ml | 0.6 ml |

| permethrin | 384 E.C. | 250m1 | l00 ml | l0 ml | 0.9m1 | 0.7m1 |

| cypermethrin | 400 E.C. | 90 ml | 36 ml | 0.4 ml | 0.3 ml | 0.2 ml |

| cypermethrin | 250 E.C. | 140 ml | 56 ml | 0.6 ml | 0.5 ml | 0.4 ml |

| Insecticide | Formulation | Maximum Rate Ha | Maximum Rate Acre | 20 Gallons/Acre Amt./L. Water | 25 Gallons/Acre Amt./L. Water | 30 Gallons/Acre Amt./L. Water |

|---|---|---|---|---|---|---|

| oxamyl | 240 L | 3L | 1.2L | 13 m1 | l0.5 ml | 8.8 m1 |

| Insecticide | Formulation | Maximum Rate Ha | Maximum Rate Acre | 20 Gallons/Acre Amt./L. Water | 25 Gallons/Acre Amt./L. Water | 30 Gallons/Acre Amt./L. Water |

|---|---|---|---|---|---|---|

| endosulfan | 50% W.P. | 1.1 kg | 0.44 kg | 4.8 g | 3.9 g | 3.2 g |

| endosulfan | 400 E.C. | 1.4L | 0.56 L | 6.0 ml | 4.9m1 | 4.0 ml |

| endosulfan | 4 E.C. | 1.5 L | 0.60 L | 6.6 ml | 5.3 ml | 4.4 ml |

*The lower the volume per acre, the higher the concentration of the dip test and spray solution

The trade name formulation, chemical family and rate/hectare of the above insecticides for CPB control are listed in OMAFRA Publication 363, Vegetable Production Recommendations, under "Potato".

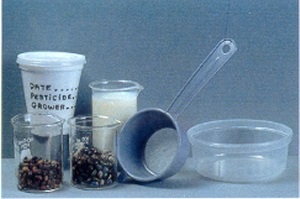

Figure 2. Equipment for dipping CPB.

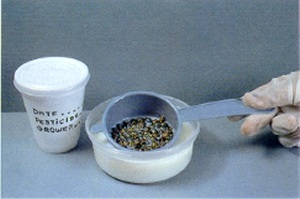

Figure 3. Dipping beetles.

Labelling the Containers

The containers where the insecticide solutions (stock solutions) are made up should be labelled as follows:

- Insecticide trade name and formulation (e.g. Colorkill 400EC)

- Concentration of dipping solution (e.g. 5 ml/L)

- Date of preparation

The styrofoam cups where the beetles are placed after the test should indicate:

- Insecticide trade name (e.g. Colorkill)

- Location (field where the beetles came from)

- Date of the test

Dipping the Beetles

Pour the insecticide solution into the 8 oz plastic container being used for dipping. Place either 30 beetles or larvae in the tea strainer. Place the tea strainer in the insecticide solution and swish the CPB around for approximately 8 to 10 seconds to make sure all beetles or larvae are covered with the solution. At the end of the 8 to 10 seconds, lift the strainer, let it drain for a moment and place it on absorbent paper towels for about 1 minute to take up any free solution. Dump the treated beetles into a labelled styrofoam cup. Put the perforated lid on. It is recommended to do the control test (dipping CPB in water) first, and also to wash the tea strainer thoroughly between dip tests of different insecticides.

Immediately after you have finished with the dip test, place the cups in an area that is between 20° - 220C (69° - 740F) and out of direct sunlight.

Determination of Mortality

Check the beetles after 12-24 hours. Remove them from the cup and place them on a piece of paper to determine mortality. The beetles sometimes play dead. If the legs are held tightly to the body, the beetle is probably not dead. If the area is warm or directly illuminated with a light bulb, the beetles or larvae that survived the test start to move and walk.

Beetles that are lying on their backs and have extended legs, sunken abdomens and cannot walk without falling over should be considered dead.

What the Results Mean

Control: The water treatment or control indicates the accuracy of the dip test. If more than 10% (3 out of 30 beetles or larvae) in the control test are dead, you should repeat the test with healthier CPB. (One of the reasons for mortality in the control test could be keeping the CPB at high temperatures in a closed container after gathering them in the field.)

Insecticide treatments: If between 85% to 100% (25 or more out of 30) CPB are dead in an insecticide test, that insecticide will give good control in the field if spray coverage is good. If between 75% to 84% (22 to 24 out of 30) CPB are dead, the majority of the population is still susceptible, but resistance should develop quickly if that insecticide is applied more than once during the season. If 50% or less (15 or less out of 30) CPB are dead and you spray that insecticide in the field, it may kill only some CPB or it may be completely ineffective.

Keeping Records

Dip test records can be kept on a record sheet which should include the following information:

- Date

- Field

- Insecticide

- Concentration of stock solution (e.g. 3 mL in 1L water)

- Number of CPB tested

- Dead % Mortality

- Adults

- Large larvae

- Small larvae

For further information, contact your local Ontario Ministry of Agriculture and Food extension personnel.