Control air emissions from large wood-fired combustors

Learn about controlling air emissions from large wood-fired combustors with a maximum heat input capacity of three megawatts or more.

Purpose and introduction

The purpose of Guideline A-13: Guideline for Control of Air Emissions from Large Wood-Fired Combustors

(≥ 3 MW) is to provide guidance to applicants applying for Environmental Compliance Approvals (ECAs) under section 20.3 of the Environmental Protection Act (EPA) for large wood-fired combustors with a heat input capacity of 3 megawatts or greater.

This guideline will set out minimum expected requirements that the Director may apply when exercising his or her discretion while considering applications on a case-by-case basis. To the extent that this document sets out that something is “required” or “shall” be done or sets out a “requirement” or “limit”, it does so only to identify minimum expected requirements, the application of which remain subject to the discretion of the Director.

During the review of an application for an ECA, the Director under s.20.3 of the EPA considers the requirements set out in relevant regulations as well as all applicable Ontario Ministry of the Environment (ministry) guidelines and policies. With this in mind, applicants for ECAs for large wood-fired combustors should review this guideline with care while preparing their applications and supporting information for consideration by the Director.

In addition, this guideline may provide guidance to persons operating large wood-fired combustors in Ontario, as the requirements is this document may be incorporated into abatement or enforcement tools, where appropriate.

The requirements of this guideline are compulsory to the extent that they are contained in conditions of an Environmental Compliance Approval issued under s.20.3 of Part II.1 of the Environmental Protection Act or other legally binding instrument.

Finally, while every effort has been made to ensure the accuracy of the information contained in this guideline, it should not be construed as legal advice. In the event of a conflict with requirements identified in the Environmental Protection Act or O. Reg. 419/05, the legislative requirements shall determine the appropriate approach.

Definitions and abbreviations

The following definitions apply for the purposes of this guideline,

- air pollution control equipment

- means equipment that is designed to decrease emissions to the atmosphere of one or more contaminants that are present in the flue gas stream.

- Act

- means the Environmental Protection Act, RSO 1990, c E.19;

- combustion air

- means air that is conveyed into the combustor to provide oxygen for the combustion process;

- combustor

- means a device in which combustible material is oxidized resulting in release of heat and products of combustion and includes a furnace section and a heat exchanger section downstream of the furnace;

- commissioning period

- means the 90-day period following the first start-up of a new or significantly modified large wood-fired combustor;

- dioxins, furans and dioxin-like PCBs

- has the same meaning as in subsection 1(1) of O. Reg 419/05 and is calculated in accordance with subsection 1(2.02) of O. Reg. 419/05, as amended;

- district manager

- means, in respect to the facility, the district manager of the local ministry office located closest to the facility;

- ECA

- means environmental compliance approval, as defined in subsection 1(1) of the Ontario Environmental Protection Act R.S.O. 1990, as amended;

- electrostatic precipitator

- means a device which removes dust or other finely divided particles from a gas by charging the particles inductively with an electric field then attracting them to highly charged collector plates;

- existing large wood-fired combustor

- means a large wood-fired combustor that has not undergone a significant modification and,

- construction of the large wood-fired combustor was completed or began on or before January 1, 2015, or

- an application was made on or before January 1, 2015 for an environmental compliance approval in respect of the large wood-fired combustor;

- fabric filter

- means a device that uses fabric bags or cartridge filters to remove particulate from a gaseous stream prior to its discharge of the gaseous stream into the air;

- flue gas

- means a gas that is generated by a combustion process;

- furnace

- means part of a combustor where combustion takes place;

- furnace volume

- means the volume is calculated from the top of the wood pile or the top operating burner level to the furnace exit.

- guideline

- means Guideline A-13: Guideline for Control of Air Emissions from Large Wood-Fired Combustors (≥ 3 MW) published by the Ministry in January 2015;

- heat input capacity

- means the ability of a large wood-fired combustor to combust a maximum amount of fuel based on the physical design of the large wood-fired combustor and is calculated by multiplying the flow rate of the fuel by the higher heating value of the fuel;

- higher heating value

- means the amount of heat released during the complete combustion of a unit quantity of fuel. In contrast, the net or lower heating value is obtained by subtracting the latent heat of vapourization of the water vapour formed by the combustion;

- hogged wood fuel

- means an unprocessed mix of coarse chips of bark and wood fibre generated by grinding or chipping action;

- large wood-fired combustor

- means a combustor that has a heat input capacity of at least three megawatts and that is designed to burn wood fuel. See Chapter 3.0 for information on the applicability of this guideline to large wood-fired combustors that may burn municipal waste;

- mg/Rm3

- means milligrams per reference cubic metre at reference conditions;

- Ministry

- means the Ministry of the government of Ontario responsible for the Act and its regulations and includes all officials, employees or other persons acting on its behalf;

- municipal waste

- has the same meaning as in Ontario Regulation 347 R.R.O. 1990, as amended;

- MW

- means megawatt and is equal to 3600 megaJoules per hour;

- new large wood-fired combustor

- means a wood-fired combustor, the construction of which began after January 1, 2015 and no application was made on or before that date for an environmental compliance approval in respect of the large wood-fired combustor;

- record

- includes a written procedure, a measurement result, a written notification, a table, a report, a document, a written practice, and an update to any of the preceding;

- reference conditions

- mean conditions at which the temperature is 25 degrees Celsius and the pressure is 101.3 kiloPascals;

- residence time

- means the average amount of time that a gas spends in a furnace and is calculated by dividing the furnace volume by the volumetric flow rate of the gas going through the furnace;

- shut-down

- means an operating condition during which the operation of a source of contaminant is decreased from normal operating conditions to an inoperative state;

- significant modification

- means a modification that,

- increased the intensity (i.e., increased the mass of emissions per unit heat input capacity) of emissions of suspended particulate matter or benzo[a]pyrene,

- increased the heat input capacity of the large wood-fired combustor,

- resulted in the large wood-fired combustor having a heat input capacity of greater than 20 MW, and

- began after July 1, 2016 and no application was made on or before that date with respect to the modification;

- significantly modified large wood-fired combustor

- means a large wood-fired combustor that has undergone a significant modification;

- start-up

- means an operating condition during which the operation of a source of contaminant is increased from an inoperative state to normal operating conditions;

- suspended particulate matter

- means particulate matter that has an aerodynamic diameter of less than 44 microns;

- suspension firing

- means a process that combusts small fuel particles (e.g., less than 4mm in size) in which the fuel and supporting air is introduced into the furnace via dedicated burners mounted on the furnace walls or corners.

- wet scrubber

- means a device that is used to separate and collect gaseous, liquid and particulate pollutants from a gas stream into a water-based solution;

- woodchip

- means a piece of wood of a defined size, cut or chipped from a larger piece of wood;

- wood fuel

- means fuel comprised of one or more of the following materials: hogged wood fuel, wood chips, wood pellets, bark, sawdust, woodwaste, cellulosic plant material, paper and paper sludge;

- wood pellet

- means a pellet made from wood fuel or woodwaste; and

- woodwaste

- has the same meaning as in Ontario Regulation 347 R.R.O. 1990, as amended.

In this guideline, a reference to:

- the Director means the Director appointed under section 20.3 of the Environmental Protection Act or other director that issues a legally binding instrument;

- a percentage by weight, as fired, is a reference to a percentage that is calculated based on the weight of the fuel as it is introduced to a large wood-fired combustor;

- a concentration is a reference to a concentration by volume, on a dry basis, corrected to 11% oxygen-dry in the flue gas; and

- a percentage of oxygen is a reference to percentage oxygen by volume on a dry basis.

Applicability

The purpose of this guideline is to promote the minimization of air pollution from large wood-fired combustors as defined in this guideline. This guideline will set out requirements that may be considered as conditions in an ECA or as part of other legally binding instruments such as orders.

Recall that, by definition, a large wood-fired combustor must be designed to burn wood fuel. Combustors that burn fuel other than wood fuel are governed by rules other than this guideline. In particular, it should be noted that a large wood-fired combustor that burns waste that is predominantly wood but that does not meet the definition of woodwaste is expected to be controlled, designed and operated in accordance with Guideline A-7: Air Pollution Control, Design and Operation Guidelines for Municipal Waste Thermal Treatment Facilities, October 2010 as may be amended from time to time.

The recommendations in this guideline vary according to three types of large wood-fired combustors:

- existing large wood-fired combustors;

- significantly modified large wood-fired combustors and

- new large wood-fired combustors. It is recommended that this guideline be used to assess applications for ECAs for large wood-fired combustors that are received after October 1, 2014.

It should be noted that several of the suggested requirements phase in over time for existing and significantly modified large wood-fired combustors. The timing for such requirements will be set out in the relevant chapters and is summarized in the Table in Appendix A. Proponents of ECA applications may also request that the phased-in requirements become applicable earlier than the dates outlined in this guideline.

Where this guideline indicates that a requirement has phased in and may be considered in reviewing an ECA application for a particular type of large wood-fired combustor, the requirement may also be considered as a condition in another legal instrument (e.g. an order)

Design and operating requirements for large wood-fired combustors

This chapter includes minimum design and operating requirements that will be considered when reviewing an ECA applications for new, significantly modified, and existing large wood-fired combustors. Having regard to these considerations while reviewing an ECA application for a large wood-fired combustor will help ensure effective/complete combustion of the wood fuel (e.g., minimize excessive concentrations/variation in carbon monoxide (CO) levels) and minimize the emission of unburned hydrocarbons including polyaromatic hydrocarbons such as benzo[a]pyrene.

Applicability of Chapter 4:

- Chapter 4.1 Design and Expected Performance Information: It is expected that this information will be submitted in ECA applications for new and significantly modified large wood-fired combustors.

- Chapter 4.2.1 Furnace Residence Time and Furnace Exit Flue Gas Temperature for New Large Wood-Fired Combustors: These requirements will be considered in reviewing ECA applications for new large wood-fired combustors.

Chapter 4.2.2 Combustion Air Requirements, Chapter 4.2.3 Requirements for Fuel Management and Chapter 4.2.4 Exemptions during Start-up and Shut-down: The requirements set out in these chapters will be considered when reviewing ECA applications for all types of large wood-fired combustors (existing, significantly modified and new).

4.1 Design and expected performance information

This chapter recommends that information on the design and expected performance of a large wood-fired combustor be submitted as part of an ECA application. The submission of this information will assist the Director in assessing whether the large wood-fired combustor is capable of meeting the guideline requirements.

The following information should be submitted in an ECA application made in respect of a new or significantly modified large wood-fired combustor:

- a tabulated summary of the design and expected performance of the large wood-fired combustor;

- a side-sectional schematic of the combustor including an illustration of the method of introduction of wood fuel to the furnace (e.g., fluidized bed, travelling grate; burner; etc.); identification of points of introduction of combustion air; and furnace dimensions used to estimate furnace volume;

- a tabulated summary of the characteristics of the wood fuel (including wood fuel sizing, moisture content and any relevant information on mixed fuel usage); and

- a tabulated summary of the design and expected performance of the air pollution control equipment associated with the large wood-fired combustor.

It is recommended that ECAs for new or significantly modified large wood-fired combustor contain a condition requiring that operating data

- Flue gas temperature leaving the combustor (i.e., downstream of the heat exchanger or where measured);

- Percent by volume (dry) excess oxygen in the flue gas.

- Percent by volume (dry) carbon monoxide in the flue gas.

be made available, upon request by the district manager, to the ministry. The operating data can be compared with the original design information and will assist in ensuring that the large wood-fired combustor is operating as intended.

For more detail with respect to the above-noted submission requirements, see Tables B-1, B-2, B-3 and B-4 in Appendix B of this guideline.

4.2 General design and operating parameters

4.2.1 Furnace residence time and furnace exit flue gas temperature for new large wood-fired combusters

Minimum design and operating parameters for residence time, combustion temperature and combustion air distribution are recommended to provide guidance to proponents designing large wood-fired combustors to ensure that the design will achieve high combustion efficiencies

It is expected that detailed engineering drawings, specifications and calculations be submitted to the ministry in support of ECA applications for new large wood-fired combustors. The submission is not expected to include final “construction” drawings but it should include details necessary to:

- verify residence time estimates;

- identify points where combustion air is introduced; and

- indicate monitoring locations for key parameters including, temperature, oxygen, carbon monoxide and opacity (as required).

To promote good combustion, it is recommended that a new large wood-fired combustor be designed to operate in a manner that ensures the flue gas in the furnace (as measured at the furnace exit) attains a temperature of at least 1000 degrees Celsius for a residence time of at least 1 second. The origin of this time-temperature window shall be taken as the lowest point of fuel delivery into the furnace.

Operating at lower furnace exit flue gas temperature may also be acceptable as long as:

- the unit is designed to achieve a minimum combustion temperature of 1000 degrees Celsius for a residence time of at least 1 second;

- the CO and O2 requirements (see Chapter 8.3) are maintained; and

- the temperature measurements (see Chapter 8.3) provide evidence that intended operating temperatures within the furnace are being maintained.

Other combinations of these design criteria (e.g., lower design temperature but longer residence time) may also be considered as long as all other conditions of the guideline are met. Proposals for technologies that deviate from the recommended combustor residence time or furnace exit temperature are expected to include detailed justification for any alternative designs. Additional testing and long-term monitoring may be required to verify the performance of the alternative designs. Table 4-1, below, provides a matrix combination of alternate minimum design combustion temperatures and residence times that would likely be found acceptable by the ministry.

| Minimum Design Residence Time | 1 second | 1.5 seconds | 2 seconds |

|---|---|---|---|

| Minimum Design Combustion Temperature (°C) | 1000°C | 900°C | 850°C |

Special Case – Fluidized Bed Designs: In fluidized/bubbling/circulating bed technology the wood fuel is introduced into a medium, such as sand, that can improve combustion dynamics (e.g., improved temperature homogeneity and mixing of the fuel with combustion air). This technology generally operates at lower design combustion temperatures as a means to preserve system components and in recognition of the improved combustion dynamics. It is recommended that new large wood-fired combustors, that employ a fluidized bed technology, be designed to achieve a minimum combustion temperature of 800 degrees Celsius for a minimum residence time of 1 second.

4.2.2 Combustion air requirements

It is recommended that combustion air systems for all large wood-fired combustors be designed and operated to achieve the following:

- A large wood-fired combustor should be designed to ensure that the air distribution within the large wood-fired combustor can be controlled. Ideally, control systems shall have the capability of adjusting the distribution of combustion air in order to provide adequate mixing of the gases and the desired level of residual oxygen in the exhaust gases under all load conditions.

- A large wood-fired combustor should be designed such that the amount of combustion air entering the combustor can be controlled to ensure that an oxygen level in the flue gas is not less than 4 percent by volume on a dry basis on a 3-hour rolling average basis.

Special Case – Suspension Burners: In the case of large wood-fired combustors employing suspension burners for sawdust or similar wood fuel comprised of small particles, the design and operating levels of combustion air should be maintained such that the percent oxygen in the flue gas is not less than 1.5 percent by volume on a dry basis on a rolling 3-hour average basis.

4.2.3 Requirements for fuel management footnote 3

Fuel quality is a critical component for ensuring efficient combustion. In order to ensure that fuels being supplied to the large wood-fired combustor are appropriate and are managed in a manner that maintains the quality and characteristics of the fuel, facilities would be expected to prepare, implement and maintain a formal Fuel Management Plan.

The Director may consider imposing a condition in an ECA related to a large wood-fired combustor that would require the following information to be included in a wood fuel management plan:

- A list of the types of wood fuel that may be stored at the facility.

- For each type of wood fuel listed in item 1, an identification of parameters that will demonstrate the storage quality of the wood fuel, including size and moisture content.

- For each parameter identified under item 2, a determination of a range of values within which the wood fuel will be considered of acceptable quality for storage at the facility.

- A procedure to ensure that the wood fuel is tested to ensure that the value for each parameter identified under item 2 is within the range determined under item 3 for the parameter.

- A procedure to ensure the wood fuel is inspected on a regular basis and that the inspection includes an inspection of the pile and of the feed system.

- A procedure to ensure that wood fuel not considered acceptable for storage at the facility is rejected and not stored at the facility.

- An indication of the maximum time that a wood fuel may be stored at the facility.

- A pile turn-over procedure to ensure that wood fuel that has been at the facility longest is used first.

- A procedure to ensure that records are prepared and retained at the facility that set out,

- the quantity of wood fuel purchased by the facility and the source from which it was purchased,

- the quantity of wood fuel generated at the facility, and

- the quantity of wood fuel rejected for storage at the facility, in accordance with paragraph 6, and the reasons for the rejection.

4.2.4 Exemptions during start-ups and shut-downs

The Director may consider clarifying in an ECA related to a large wood-fired combustor that certain requirements (e.g., the requirements in Chapters 5 thru 7, inclusive) of this guideline do not apply during the following periods:

- The commissioning period of the large wood-fired combustor.

- The period during which the large wood-fired combustor is starting up or shutting down if,

- the shut-down does not last for more than 6 hours,

- the start-up does not last for more than 24 hours,

- the start-up or shut-down is conducted according to a written plan that minimizes discharges into the air during the period of start-up or shut-down,

However, all measurements required by Chapters 8.2 and 8.3 are expected to be recorded during the start-up and shut-down period.

Flue gas concentration requirements

This chapter of the guideline sets out limits that are intended to ensure good combustion conditions.

Applicability of Chapter 5:

Chapter 5 is applicable to large wood-fired combustors in accordance with the schedule identified in Table 5-1, below.

5.1 Carbon monoxide, flue gas limit

Table 5-1 sets out limits for the concentration of carbon monoxide at the exit of a large wood-fired combustor (or at a location approved by the Director). If an ECA application related to an existing large wood-fired combustor is submitted in the one-year period preceding the dates in Column 1 (e.g. 2015 or 2020), it is expected that such an application will demonstrate compliance with the corresponding carbon monoxide limits that will apply the following year.

| Existing Large Wood-Fired Combustors | Existing Large Wood-Fired Combustors | New Large Wood-Fired Combustors | Significantly Modified Large Wood-Fired Combustors |

|---|---|---|---|

| Starting July 1, 2016 | Starting July 1, 2021 | Starting the date of this Guideline | Starting July 1, 2016 |

| ≤ 800 ppmv-dry (at 11% oxygen-dry) 10-day rolling averaging | ≤ 500 ppmv-dry (at 11% oxygen-dry) 10-day rolling averaging | ≤ 400 ppmv-dry (at 11% oxygen-dry) 24-hour rolling average | ≤ 400 ppmv-dry (at 11% oxygen-dry) 24-hour rolling average |

5.2 Notification of exceedences and record keeping

It is recommended that the Director consider imposing the following requirements in conditions of an ECA related to a large wood-fired combustor:

- Notification of Exceedences: conditions that require the owner and operator of a large wood-fired combustor to ensure that the local District Manager is notified, no later than five days in writing (via email or letter) of any exceedence of the carbon monoxide limits outlined in Table 5-1. If notification is required to be given, it is recommended that a condition of the ECA require that following information, as it relates to the period of exceedence, be recorded:

-

- the type of wood being processed;

- the moisture content of the material;

- continuous emission monitor data; and

- a description of actions taken to mitigate and reduce the carbon monoxide emissions.

This section is not applicable if a facility is operating under a Written Abatement Plan for Carbon Monoxide per Chapter 5.3 of this guideline.

- Record Keeping: conditions that require the owner and operator of a large wood-fired combustor to maintain records that contain the above-noted information for any exceedence of the carbon monoxide limits outlined in Table 5-1. The records should be in electronic format and retained for a period of not less than three years. See Chapter 9 for additional record-keeping requirements related to combustor performance.

The Director may consider allowing, at the discretion of a Ministry District Manager, to use a general plan of notification from the facility to address multiple exceedences of the applicable limit for carbon monoxide in the flue gas.

5.3 Written abatement plan for carbon monoxide

It is recommended that the Director consider imposing the following requirements in conditions of an ECA related to a large wood-fired combustor:

- Abatement plan development and implementation: If there is information that indicates that the carbon monoxide in the flue gas of a large wood-fired combustor is exceeding the applicable limit set out in Table 5-1 of this guideline, the owner and operator shall ensure that a written abatement plan that includes steps to be taken in order to prevent discharges of carbon monoxide from exceeding the concentration limit set out in Chapter 5.1 of this guideline is developed and implemented.

- The Director may consider allowing, at the discretion of a Ministry District Manager, to use a common written abatement plan to address multiple exceedences of the applicable limit for carbon monoxide in the flue gas.

Tune-ups of the wood-fired combuster every 2 years

It is recommended that the Director consider imposing an ECA condition to require a tune-up of a large wood-fired combustor once in every two-year period. The purpose of a combustor tune-up is to assist in achieving effective combustion. A tune-up includes an assessment of combustor operation, such as the relationship between continuous measurements of carbon monoxide and controlling the amount of combustion air introduced to the combustor, and may result in adjustment of key operating set-points (e.g., oxygen in the flue gas).

It is recommended that the Director consider imposing, in conditions of an ECA related to a large wood-fired combustor, that a report of each bi-annual tune-up be retained for a minimum of five years and be made available for review by ministry staff upon request.

Applicability of Chapter 6:

- The recommendations set out in Chapter 6 are to be considered when reviewing ECA application made in respect of any large wood-fired combustor (existing, significantly modified or new).

For more detail with respect to suggested combustor tune-up requirements see Table B-4 in Appendix B of this document.

In-stack Concentration Limits

| New Large Wood-Fired Combustor With Heat Input Capacity > 20MW | Significantly Modified Large Wood-Fired Combustor With Heat Input Capacity > 20MW | New Large Wood-Fired Combustor with Heat Input Capacity of ≤20 MW | Existing Large Wood-Fired Combustors |

|---|---|---|---|

| ≤ 25 mg/Rm3 at 11 % oxygen-dry | ≤ 25 mg/Rm3 at 11 % oxygen-dry | ≤ 50 mg/Rm3 at 11 % oxygen-dry | ≤ 120 mg/Rm3 at 11 % oxygen-dry |

Special Case – Direct Contact Wood-Fired Dryers: The above-noted suspended particulate matter emission limits are not applicable for ECA applications that include direct contact wood-fired dryers: for these units, only the suspended particulate matter point of impingement standard in Ontario Regulation 419/05 applies.

7.2 Nitrogen Oxides (NOx)

When reviewing an ECA application with respect to a new large wood-fired combustor that has a heat input capacity of at least 100 MW, it is recommended that the Director consider imposing an in-stack limit to ensure that the concentration of nitrogen oxide does not exceed 198 mg/Rm3 corrected to 11% oxygen - dry on a 24-hour rolling average basis.

7.3 Total dioxins, Furans and Dioxin-like PCBs (toxic equivalency)

Recall that, in general, this guideline only applies to large wood-fired combustor that burn wood fuel. For details see Chapter 3.0. Despite this general premise, a Director may wish to rely on elements of this guideline when reviewing an ECA application that relates to a large wood-fired combustor that may burn municipal waste that is predominantly wood (but does not meet the definition of woodwaste) in combination with wood fuel. It is recommended that this guideline only apply to situations where such waste comprises no more than 7.5% by weight, as fired, of the total fuel burned.

If the Director decides to rely on elements of this guideline when reviewing an ECA application with respect to a large wood-fired combustor that meets the description above, it is recommended that the Director consider imposing an in-stack limit to ensure that the concentration of total dioxins, furans and dioxin-like PCBs (toxic equivalency) do not exceed 80 picograms per reference cubic metre (80 pg/Rm3), corrected to 11% oxygen - dry content. It is recommended that compliance with this limit be determined through ministry validated stack testing. The toxic equivalent concentration shall be determined based upon the International Toxic Equivalency (I-TEQ) factors presented in Appendix D.

Monitoring requirements

Applicability of Chapter 8:

- On and after July 1, 2016 the monitoring requirements set out in Chapters 8.1 and 8.3 should be considered when reviewing ECA applications with respect to all large wood-fired combustors. Prior to July 1, 2016, the requirements should be considered when reviewing an ECA application with respect to a new large wood-fired combustor. In addition, prior to July 1, 2016, certain monitoring requirements (as described in this chapter) may be considered when reviewing an ECA application with respect to an existing large wood-fired combustor.

- The monitoring requirements set out in Chapter 8.2 should be considered when reviewing an ECA application for a sub-set (as described in this chapter) of new and significantly modified large wood-fired combustors.

8.1 Periodic in-stack concentration monitoring

On and after July 1, 2016, it is recommended that the Director consider imposing monitoring conditions in ECAs that relate to any large wood-fired combustor (existing, significantly modified or new) that burns only wood fuel. In particular, it is recommended that the conditions require the following parameters to be measured:

- SPM: Stack testing requirement, at an operating condition that will result in maximum emissions, for suspended particulate matter first within twelve months of commencement of operations and thereafter every four years.

- BaP: Stack testing for benzo[a]pyrene shall also be conducted first within twelve months of commencement of operation and thereafter every four years.

Prior to July 1, 2016, the above-mentioned conditions may be considered by the Director when reviewing an ECA application that pertains to a new large wood-fired combustor.

If the Director is reviewing an ECA application with respect to a large wood-fired combustor that may burn municipal waste that is predominantly wood, but does not meet the definition of woodwaste, in combination with wood fuel where such waste does not comprise more than 7.5% by weight, as fired, of the total fuel burned, it is recommended that the a condition to measure the following parameters be considered:

- A requirement to stack test, every year, for:

- Suspended particulate matter;

- Benzo[a]pyrene;

- Total dioxins, furans and dioxin-like PCBs (reported as toxic equivalency); and

- Any metals that may be present in the wood either due to treatment, intentional addition or as a result of contamination.

The Director may impose a condition in the ECA requiring that all stack tests be validated by the ministry and stack test reports be submitted to the ministry within four months of the completion of the stack test.

8.2 Continuous in-stack monitoring

The Director may consider imposing a condition in an ECA requiring that in-stack opacity be continuously monitored and recorded (where measurements are taken on a minute-by-minute), if the application for the ECA relates to a large wood-fired combustor that meets the following criteria:

- The large wood-fired combustor is a new or significantly modified large wood-fired combustor.

- The large wood-fired combustor has a heat input capacity of at least 50 MW.

- No wet scrubber is associated with the large wood-fired combustor.

- The large wood-fired combustor is not used as a direct contact dryer.

Particle counting devices, such as some bag leakage detection devices installed downstream of a fabric filter air pollution control device, can be proposed as an alternative to the above-suggested condition.

In addition, it is recommended that new large wood-fired having a heat input capacity of at least 100 MW, be equipped with devices to continuously monitor and record nitrogen oxides.

Reporting of opacity exceedences shall be in accordance with the requirements of Ontario Regulation 419/05: Air Pollution – Local Air Quality. For more information on opacity exceedences, please see the Opacity Technical Bulletin [PIBS ##].

All continuous emission monitoring devices and sampling locations must be approved by the ministry (e.g., during the ministry review of an application for an ECA approval). In summary, it is recommended that the Director impose conditions on ECAs which indicate that proponents submit (to the Manager of Technology Standards Section, Standards Development Branch) a plan for the approved installation, operation and maintenance of the above-noted continuous in-stack monitoring devices.

8.3 Continuous flue gas monitoring

On and after July 1, 2016, it is recommended that the Director consider imposing, in an ECA that relates to any large wood-fired combustor, a requirement to continuously monitor and record the following parameters:

- The undiluted percentage of oxygen by volume, on a dry basis, in the flue gas leaving the combustor (measured and recorded in dry flue gas; or in wet flue gas and converted and recorded on a dry basis).

- The undiluted concentration of carbon monoxide in the dry flue gas leaving the combustor (measured and recorded in dry flue gas; or in wet flue gas and converted and recorded on a dry basis). It is recommended that the measurements of oxygen and carbon monoxide are conducted at the same location.

- The temperature of the flue gas leaving the combustor (downstream of the heat exchanger or boiler-bank). This temperature measurement can then be compared to design and expected performance information, from the manufacturer, for heat exchanger exit temperature and furnace exit temperature.

Prior to July 1, 2016, the above-mentioned conditions may be considered by the Director when reviewing an ECA application that pertains to a new large wood-fired combustor. Also prior to July 1, 2016, the Director may also consider imposing the requirements set out in items 1 and 3 above, when reviewing an ECA application that pertains to an existing large wood-fired combustor.

All continuous emission monitoring devices and sampling locations must be approved by the ministry. In summary, it is recommended that the Director impose conditions on ECAs which indicate that proponents submit (to the Manager of Technology Standards Section, Standards Development Branch) a plan for the approved installation, operation and maintenance of the above-noted continuous in-stack monitoring devices.

Special Case – Direct Contact or Indirect Contact Wood-Fired Dryers: The Director may consider alternative approaches (e.g., periodic stack testing of carbon monoxide) for continuous measurement of oxygen and/or carbon monoxide and/or temperature in the flue gas where it can be demonstrated that the presence of excessive amounts of wood fibre in the flue gas of a Direct Contact or Indirect Contact Dryer may result in unreasonable challenges to the operation and maintenance of these continuous monitors.

Note: For clarity, the oxygen, carbon monoxide and temperature monitors may be installed either downstream of the furnace or downstream of the combustor’s main heat exchanger. The oxygen and carbon monoxide monitors may also be installed downstream of an economizer type heat exchanger (which is sometimes included downstream of the combustor’s main heat exchanger) but it is not recommended that the oxygen and carbon monoxide monitors be installed downstream of an air heater because ambient air in-leakage can occur through an air heater.

Summary reports on combustor performance, up-dated every 2 years

Applicability of Chapter 9:

- The recommendations in Chapter 9 should be considered with reviewing an ECA application that relates to any large wood-fired combustor.

- It is recommended that the Director require in a condition of an ECA that the owner and operator of a large wood-fired combustor ensure that records are prepared at least once in every two-year period. The records should summarize the relevant requirements imposed on the large wood-fired combustor and should include, as applicable, the following records:

- For each parameter where, in Chapter 8.0 of this guideline, testing or continuous monitoring is recommended, the following statistical information:

- the maximum measurement taken over the two-year period

- the minimum measurement taken over the two-year period

- the average measurement taken over the two-year period.

- A record of all notices required to be given under Chapter 5.2 of this guideline during the two-year period.

- The dates during the two-year period when start-up or shut-down of a large wood-fired combustor occurred

footnote 7 . - A record of approved fuel management procedures required by Chapter 4.2.3 of this guideline and details of instances where these were not followed.

- For each air pollution device associated with a large wood-fired combustor, the dates during the two-year period when the device did not operate.

- A record of the results from the bi-annual tune-up required under Chapter 6 of this guideline.

Appendix A

| Requirement | New LWC ≥ 100MW | New LWC 20-100MW | New LWC ≤ 20MW | Existing LWC | Significantly Modified LWCA |

|---|---|---|---|---|---|

| Minimum Residence Time and Combustion Temperature | Yes | Yes | Yes | No | No |

| Combustion Air | Yes | Yes | Yes | Yes | Yes |

| Fuel Management | Yes | Yes | Yes | Yes | Yes |

| CO Limit (Pre July 1, 2016) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | No | No |

| CO Limit (July 1, 2016 – June 30, 2021) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | ≤ 800B ppm (10-day avg) | ≤ 400 ppm (24-hr avg) |

| CO Limit (On and after July 1, 2021) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | ≤ 400 ppm (24-hr avg) | ≤ 500B ppm (10-day avg) | ≤ 400 ppm (24-hr avg) |

| Notification | Yes | Yes | Yes | Yes | Yes |

| CO Abatement Plan | Yes | Yes | Yes | Yes | Yes |

| Bi-Annual Tune-up | Yes | Yes | Yes | Yes | Yes |

| SPM Limit (Pre July 1, 2016) | ≤ 25 mg/Rm3 | ≤ 25 mg/Rm3 | ≤ 50 mg/Rm3 | No | No |

| SPM Limit (On and after July 1, 2016) | ≤ 25 mg/Rm3 | ≤ 25 mg/Rm3 | ≤ 50 mg/Rm3 | ≤ 120B mg/Rm3 | ≤ 25 mg/Rm3 |

| NOx Limits | ≤ 198 mg/Rm3 | No | No | No | No |

| Total Dioxins Furans and Dioxin-Like PCBs LimitC | 80 pg/Rm3 | 80 pg/Rm3 | 80 pg/Rm3 | 80 pg/Rm3 | 80 pg/Rm3 |

| Periodic In-Stack Monitoring (SPM, B[a]P)C Pre July 1, 2016 | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years | No | No |

| Periodic In-Stack Monitoring (SPM, B[a]P)C On and after July 1, 2016 | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years | Within 12 months of commissioning and every 4 years |

| Periodic In-Stack Monitoring (SPM, B[a]P, Total Dioxins Furans & Dioxin-Like PCBs)C | Every year (one-time only for dioxins and furans) | Every year (one-time only for dioxins and furans) | Every year (one-time only for dioxins and furans) | Every year (one-time only for dioxins and furans) | Every year (one-time only for dioxins and furans) |

| Continuous Monitoring – OpacityD | Yes | Yes | No | No | Yes |

| Continuous Monitoring – NOx | Yes | No | No | No | No |

| Continuous Monitoring - O2 and Temperature | Yes | Yes | Yes | Yes | Yes |

| Continuous Monitoring – CO (Pre July 1, 2016) | Yes | Yes | Yes | No | No |

| Continuous Monitoring – CO (On and after July 1, 2016) | Yes | Yes | Yes | Yes | Yes |

| Bi-Annual Summary Reports | Yes | Yes | Yes | Yes | Yes |

Table notes

ANote that no significantly modified large wood-fired combustors will exist prior to July 1, 2016.

BA person who applies for an ECA in the one-year period preceding the date the limit applies must show compliance with the limit.

COnly applicable to a large wood-fired combustor that may burn municipal waste (that is predominantly wood) together with wood fuel where such waste does not exceed 7.5% of total fuel burned.

DOnly applicable to a large wood-fired combustor ≥ 50MW that is not associated with a wet scrubber and this is not used as a direct contact dryer.

Appendix B

Table B-1: Combustor Design and Expected Performance

Table B-2: Description and Key Properties of the Wood Fuel

Table B-3: Air Pollution Control Equipment Design and Expected Performance

Appendix C

Emission conversions and calculations

| From | To | Multiply by |

|---|---|---|

| Btu | J | 1055.1 |

| Btu/hr | kJ/hr | 1.0551 |

| Btu/hr | W | 0.29307 |

| MM Btu/hr | MW | 0.29307 |

| Pounds-mass | Kilograms | 0.45359 |

References: Perry’s Chemical’s Engineer Handbook (50th Anniversary Edition, 1984)

Table 1-6, pages 1-15 to 1-17.

Notes:

- MM = 1 million in US customary units and Imperial British Units (e.g., 1 MM Btu = 1 million Btu).

- M = 1 million in metric units (e.g., 1 MW = 1 megawatt or 1 million watts).

- G = 1 billion in metric units (e.g., 1 GJ = 1 billion Joules).

Table C-2: Emission conversions

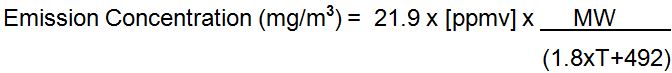

- Converting from parts per million by volume of a gaseous contaminant to milligrams per cubic metre at the same Conditions:

T is the temperature, in °C, of the flue gases that corresponds to the (ppmv) measurement

MW= Molecular weight of contaminant

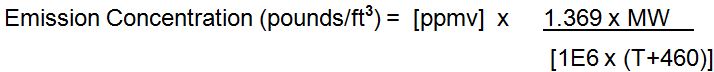

Note: In the above-noted formula, the converted emission concentration (mg/m3) is on the same dry or wet basis and at the same flue gas conditions (e.g., % oxygen and/or % carbon dioxide) as the measured concentration (ppmv). - Converting from parts per million by volume of a gaseous contaminant to pounds per cubic foot at the same Conditions:

T is the temperature, in °F, of the flue gases that corresponds to the (ppm-v) measurement

MW= Molecular weight of contaminan

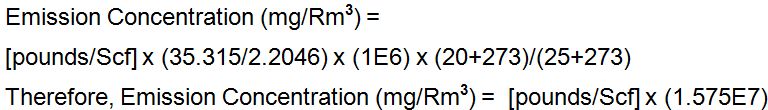

Note: In the above-noted formula, the converted emission concentration (pounds/ft3) is on the same dry or wet basis and at the same flue gas conditions (e.g., % oxygen and/or % carbon dioxide) as the measured concentration (ppmv). - Converting from pounds per standard cubic foot of a gaseous contaminant to milligrams per reference cubic metre at the same oxygen level and same wet/dry basis:

Notes:- Standard conditions (with respect to “standard ft3“ or Scf) are at 68 °F or 20 °C and reference conditions (with respect to Rm3) are at 25 °C.

- In the above-noted formula, the converted emission concentration (mg/Rm3) is on the same dry or wet basis and at the same flue gas conditions (e.g., % oxygen and/or % carbon dioxide) as the measured concentration (pounds/Scf).

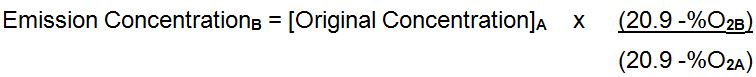

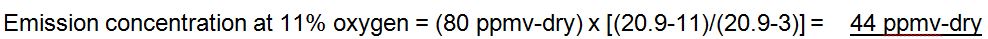

- Converting a measured concentration from one level of volumetric percentage of oxygen-dry in flue gas to a different volumetric percentage of oxygen in flue gas:

%O2B = percent, by volume-dry, oxygen at the new concentration

%O2A = percent, by volume-dry, oxygen at the original concentration

Example: converting 80 ppmv (dry) at 3% oxygen-dry to a concentration at 11% oxygen-dry:

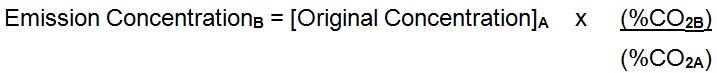

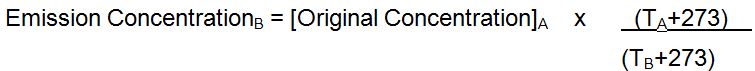

- Converting a measured concentration from one level of volumetric percentage of carbon dioxide-dry in flue gas to a different volumetric percentage of carbon dioxide in flue gas:

%CO2B = percent, by volume-dry, carbon dioxide at the new concentration

%O2A = percent, by volume-dry, carbon dioxide at the original concentration

Example: converting 100 ppmv-dry at 10% by volume-dry carbon dioxide to a concentration at 12% carbon dioxide:

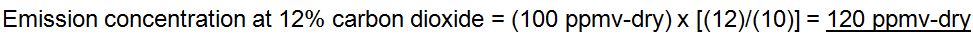

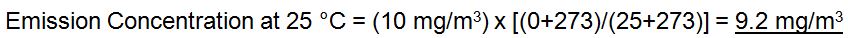

- Converting a measured concentration (in mg/m3) from one flue gas temperature to another:

TB = Temperature, in °C, at the new concentration

TA = Temperature, in °C, at the original concentration

Example: converting 10 mg/m3 at 0°C to a concentration at 25 °C

Note: There is no need for a temperature correction for a concentration

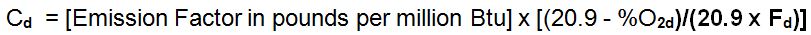

in ppmv because both the numerator and denominator are volume-based. - Converting from pounds per million Btu (a common emission factor metric used in the United States) to milligrams per reference cubic metre

When measurements of contaminant concentration (Fd) and oxygen (%O2d) are both on a dry basis, then the following conversion formula can be used:

Note: This involves the following two step conversion process:- First, converting from pounds per million Btu to pounds per standard cubic foot where standard conditions are defined as 68 °F (ie., 20 °C) and 760 mm Hg (ie., 101.3 kPa); and

- Second converting pounds per standard cubic foot to milligrams per Reference cubic metre where, for the purposes of this document, reference temperature and pressure are defined as 25 °C and 101.3 kPa.

- Cd: contaminant concentration, dry basis, pounds per standard cubic foot

- %O2d: percent by volume oxygen, dry basis, that corresponds to the contaminant concentration, Cd

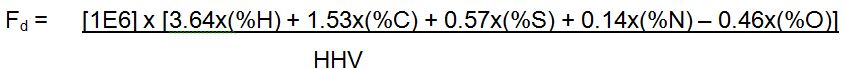

- Fd: Fuel factor (volumes of combustion components per unit heat content)

%H: percent by weight hydrogen (as-fired, from ultimate analysis of fuel)

%C: percent by weight carbon (as fired, from ultimate analysis of fuel)

%S: percent by weight sulphur (as fired, from ultimate analysis of fuel)

%N: percent by weight nitrogen (as fired, from ultimate analysis of fuel)

%O: percent by weight oxygen (as fired, from ultimate analysis of fuel)

HHV: Higher heating value of fuel, as fired, Btu/lb

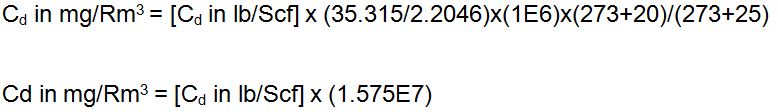

Step 2: Convert pounds per standard cubic foot to milligrams per reference cubic metre:

Where, standard conditions (with respect to Scf) are at 68 0F or 20 °C and reference conditions (with respect to Rm3) are at 25 °C.

| Fuel Type | Fd (dry standard cubic foot/million Btu heat input) |

|---|---|

| Coal (Anthracite): | 10,100 |

| Coal (Bituminous): | 9,780 |

| Coal (Lignite): | 9,860 |

| Oil: | 9,190 |

| Gas (natural gas, propane, butane): | 8,710 |

| Wood: | 9,240 |

| Wood Bark: | 9,600 |

| Municipal Solid Waste: | 9,570 |

Note: The above fuel factors (Fd) are determined at standard conditions:

20 °C (68 °F) and 101.3 kPa (760 mm Hg)

Reference for Fuel Factor Conversion Information and Typical Fuel Factors:

- US EPA, Method 19 – Determination of Sulphur Dioxide Removal Efficiency and Particulate Matter, Sulfur Dioxide and Nitrogen Oxide Emission Rates

- See EPA website

Appendix D

Application of the air standard for dioxins, furans, and dioxin-like PCBs requires the calculation of the total toxicity equivalent (TEQ) concentration contributed by all dioxin-like compounds in the mixture. This is a legal requirement set out in s.1 (2.0.2) and Schedule 8 of Ontario Regulation 419/05 and is similarly applicable to this guideline (when municipal waste is co-fired with wood).

Table D-1 below lists 29 specific dioxins, furans, and dioxin-like PCBs (along with the corresponding WHO2005 toxic equivalency factors (TEFs)) to which the new standards would apply. The following formula should be used in order to meet the requirement in the regulation of calculating the total concentration of dioxins, furans and dioxin-like PCBs:

- A = Σ(B × C), where,

- A = the amount (or concentration) of total dioxins, furans and dioxin-like PCBs in TEQ

- B = the amount (or concentration) of each dioxin-like compound listed in Table 2

- C = the corresponding TEF for each dioxin-like compound listed in Table 2

For the purpose of calculating the total TEQ concentration for a mixture of dioxin-like compounds, a value of half the minimum detection limit (MDL) should be substituted for concentrations less than the MDL.

| Number | Dioxins, Furans and Dioxin-Like PCBs | CASRN | WHO(2005) Toxic Equivalency Factors (TEFs) |

|---|---|---|---|

| 1 | 2,3,7,8-Tetrachlorodibenzo-p-dioxin (2,3,7,8-TCDD) | 1746-01-6 | 1 |

| 2 | 1,2,3,7,8-Pentachlorodibenzo-p-dioxin (1,2,3,7,8-PeCDD) | 40321-76-4 | 1 |

| 3 | 1,2,3,4,7,8-Hexachlorodibenzo-p-dioxin (1,2,3,4,7,8-HxCDD) | 39227-28-6 | 0.1 |

| 4 | 1,2,3,6,7,8-Hexachlorodibenzo-p-dioxin (1,2,3,6,7,8-HxCDD) | 57653-85-7 | 0.1 |

| 5 | 1,2,3,7,8,9-Hexachlorodibenzo-p-dioxin (1,2,3,7,8,9-HxCDD) | 19408-74-3 | 0.1 |

| 6 | 1,2,3,4,6,7,8-Heptachlorodibenzo-p-dioxin (1,2,3,4,6,7,8-HpCDD) | 35822-46-9 | 0.01 |

| 7 | 1,2,3,4,6,7,8,9-Octachlorodibenzo-p-dioxin (1,2,3,4,6,7,8,9-OCDD) | 3268-87-9 | 0.0003 |

| 8 | 2,3,7,8-Tetrachlorodibenzofuran (2,3,7,8-TCDF) | 51207-31-9 | 0.1 |

| 9 | 1,2,3,7,8-Pentachlorodibenzofuran (1,2,3,7,8-PeCDF) | 57117-41-6 | 0.03 |

| 10 | 2,3,4,7,8-Pentachlorodibenzofuran (2,3,4,7,8-PeCDF) | 57117-31-4 | 0.3 |

| 11 | 1,2,3,4,7,8-Hexachlorodibenzofuran (1,2,3,4,7,8-HxCDF) | 70648-26-9 | 0.1 |

| 12 | 1,2,3,6,7,8-Hexachlorodibenzofuran (1,2,3,6,7,8-HxCDF) | 57117-44-9 | 0.1 |

| 13 | 1,2,3,7,8,9-Hexachlorodibenzofuran (1,2,3,7,8,9-HxCDF) | 72918-21-9 | 0.1 |

| 14 | 2,3,4,6,7,8-Hexachlorodibenzofuran (2,3,4,6,7,8-HxCDF) | 60851-34-5 | 0.1 |

| 15 | 1,2,3,4,6,7,8-Heptachlorodibenzofuran (1,2,3,4,6,7,8-HpCDF) | 67562-39-4 | 0.01 |

| 16 | 1,2,3,4,7,8,9-Heptachlorodibenzofuran (1,2,3,4,7,8,9-HpCDF) | 55673-89-7 | 0.01 |

| 17 | 1,2,3,4,6,7,8,9-Octachlorodibenzofuran (1,2,3,4,6,7,8,9-OCDF) | 39001-02-0 | 0.0003 |

| 18 | 3,3’,4,4’-Tetrachlorobiphenyl (3,3’,4,4’-tetraCB (PCB 77)) | 32598-13-3 | 0.0001 |

| 19 | 3,4,4’,5-Tetrachlorobiphenyl (3,4,4’,5-tetraCB (PCB 81)) | 70362-50-4 | 0.0003 |

| 20 | 3,4,4’,5-Pentachlorobiphenyl (3,3’,4,4’,5-pentaCB (PCB126)) | 57465-28-8 | 0.1 |

| 21 | 3,3’,4,4’,5,5’-Hexachlorobiphenyl (3,3’,4,4’,5,5’-hexaCB (PCB 169)) | 32774-16-6 | 0.03 |

| 22 | 2,3,3’,4,4’-Pentachlorobiphenyl (2,3,3’,4,4’-pentaCB (PCB 105)) | 32598-14-4 | 0.00003 |

| 23 | 2,3,4,4’,5-Pentachlorobiphenyl (2,3,4,4’,5-pentaCB (PCB 114)) | 74472-37-0 | 0.00003 |

| 24 | 2,3’,4,4’,5-Pentachlorobiphenyl (2,3’,4,4’,5-pentaCB (PCB 118)) | 31508-00-6 | 0.00003 |

| 25 | 2’,3,4,4’,5-Pentachlorobiphenyl (2’,3,4,4’,5-pentaCB (PCB 123)) | 65510-44-3 | 0.00003 |

| 26 | 2,3,3’,4,4’,5-Hexachlorobiphenyl (2,3,3’,4,4’,5-hexaCB (PCB 156)) | 38380-08-4 | 0.00003 |

| 27 | 2,3,3’,4,4’,5’-Hexachlorobiphenyl (2,3,3’,4,4’,5’-hexaCB (PCB157)) | 69782-90-7 | 0.00003 |

| 28 | 2,3’,4,4’,55’-Heptachlorobiphenyl (2,3,3’,4,4’,5,5’-heptaCB (PCB 167)) | 52663-72-6 | 0.00003 |

| 29 | 2,3,3’,4,4’,5,5’-Heptachlorobiphenyl (2,3,3’,4,4’,5,5’-heptaCB( (PCB 189)) | 39635-31-9 | 0.00003 |

The above-noted table includes a list of specific types of dioxins, furans and dioxin-like polychlorinated biphenyl compounds and a factor, published by the World Health Organization (WHO) that identifies the relative toxicity of each chemical compound that is identified in the table.

Appendix E

Interpretative Examples for Identifying Significant Modifications

Definition of existing large wood-fired combustor: means a large wood-fired combustor that has not undergone a significant modification and,

- construction of the large wood-fired combustor was completed or began on or before January 1, 2015, or

- an application was made on or before January 1, 2015 for an environmental compliance approval in respect of the large wood-fired combustor;

Note: The requirements of this guideline will necessarily be triggered for new and significantly modified large wood-fired combustors because of the need for such combustors to obtain an ECA; however, to be clear, the requirements will not apply to an existing large wood-fired combustor unless such a combustor is the subject of an ECA application or other legal instrument (e.g. order).

Example 1 – Existing Large Wood-Fired Combustor:

A facility has been operating a wood-fired combustor with a heat input capacity of 150MW for many years prior to January 1, 2015.

The requirements of this guideline are NOT intended to be applicable to any wood-fired combustors having heat inputs less than 3 MW and only intended to be applicable to existing large wood-fired combustors (see above-noted definition for existing large wood-fired combustors), under one or more of the following circumstances:

- the existing large wood-fired combustor is under-going significant modifications (see definition for significantly modified large wood-fired combustor, below);

- the existing large wood-fired combustor is part of an application for ECA (e.g., as part of a request for a site-wide or comprehensive ECA); or

- in the event that the ministry has issued an order, that includes some or all of the requirements in this guideline, with respect to an existing large wood-fired combustor.

Definition of significantly modified large wood-fired combustor:

“significant modification” means a modification that,

increased the intensity (i.e., increased the mass of emissions per unit heat input capacity) of emissions of suspended particulate matter or benzo[a]pyrene,

- increased the heat input capacity of the large wood-fired combustor,

- resulted in the large wood-fired combustor having a heat input capacity of greater than 20 MW, and

- began after July 1, 2016 and no application was made on or before that date with respect to the modification;

“significantly modified large wood-fired combustor” means a large wood-fired combustor that has undergone a significant modification;

Example 2:

A wood-fired combustor with a heat input capacity of 50 MW is proposed to be modified to increase its capacity by 50% (ie., increase by 25 MW). It is also estimated that the mass emission rate (e.g., grams per second) of suspended particulate matter and/or benzo[a]pyrene will not increase, as a result of the proposed modifications, by more than 50%. The submission includes the following information to support the estimate that there will be no increase in the intensity of emissions of particulate nor benzo[a]pyrene:

- The modification proposal demonstrates that the current or modified particulate emission control equipment is capable of managing the increased inlet emissions of particulate such that any increase in outlet emissions is no greater than, proportionally, than the increase in heat input capacity for the modified combustor; and

- There are enhancements to the current combustion control system that are designed to limit the emission of carbon monoxide and polyaromatic hydrocarbons (such as benzo[a]pyrene).

The above described large wood-fired combustor may not be a “significantly modified large wood-fired combustor”; assuming that the supporting technical information is sufficient to support the contention of no increase in the intensity of neither suspended particulate matter nor benzo[a]pyrene.

Example 3:

A wood-fired combustor with a heat input capacity of 15 MW is proposed to be modified to increase its capacity by 200% (ie., increase by 30 MW to 45 MW). It is also estimated that the emissions of suspended particulate matter and/or benzo[a]pyrene will not increase, as a result of the proposed modifications, by more than 100%. The submission includes the following information to support the estimate that there will be no increase in the intensity of emissions of particulate nor benzo[a]pyrene:

- The modification proposal demonstrates that the current or modified particulate emission control equipment is capable of managing the increased inlet emissions of particulate such that any increase in outlet emissions is no greater than, proportionally, than the increase in heat input capacity for the modified combustor; and

- There are enhancements to the current combustion control system that are designed to limit the emission of carbon monoxide and polyaromatic hydrocarbons (such as benzo[a]pyrene).

Although the current combustor is less than 20 MW, the proposed modified unit is a large wood-fired combustor that has a heat input capacity of greater than 20 MW and it may be reasonable to assess against the definition for “significantly modified large wood-fired combustor”. However, the above described large wood-fired combustor may not be a “significantly modified large wood-fired combustor”; assuming that the supporting technical information is sufficient to support the contention of no increase in the intensity of either suspended particulate matter or benzo[a]pyrene.

Example 4:

A wood-fired combustor with a heat input capacity of 50 MW is proposed to be modified to increase its capacity by 50% (ie., increase of 25 MW). It is also estimated that the emissions of suspended particulate matter and/or benzo[a]pyrene will not increase, as a result of the proposed modifications, by more than 50%. The submission is deemed by the ministry technical reviewer to not include sufficient information to support the contention of no increase in the intensity of emissions.

The proponent will either have to provide sufficient information to support the contention of no increase in the intensity of emissions or the project may be assessed by the ministry reviewer as if the definition for significantly modified large wood-fired combustor is applicable.

Example 5:

The ministry has received a proposal, in 2025 for the capacity de-rating of a significantly modified wood-fired combustor (modified in, say, 2017) from 30 MW to 10 MW.

In this example, the general intent is that the guideline requirements that are applicable to significantly modified large wood-fired combustors would continue to apply, even after the capacity de-rating. The intent is that when an existing large wood-fired combustor undergoes a significant modification, it no longer meets the definition of an “existing large wood-fired combustor” and thus would continue to be treated as a significantly modified large wood-fired combustor. However, the Director may use discretion to consider whether or not to continue to apply the guideline requirements for a significantly modified large wood-fired combustor on a site-specific basis.

Example 6:

A new large wood-fired combustor has a heat input capacity of 10 MW and undergoes a modification in 2025 to be a 30 MW large wood-fired combustor and, in this example, there is an increase in the intensity of air emissions of suspended particulate matter as a result of the proposed modifications.

In this example the modification in 2025 is, by definition, a significant modification, according to the guideline definition of significant modifications, and the requirements in the guideline for significantly modified large wood-fired combustors become applicable after the 2025 modifications (e.g., the emissions limit for suspended particulate matter would be reduced from 50 to 25 mg/Rm3). As accordingly, it should be noted that it is possible for a new large wood-fired combustor to become a significantly modified large wood-fired combustor.

Footnotes

- footnote[1] Back to paragraph The requirements of this guideline will necessarily be triggered for new and significantly modified large wood-fired combustors because of the need for such combustors to obtain an ECA; however, to be clear, the requirements will not apply to an existing large wood-fired combustor unless such a combustor is the subject of an ECA application or other legal instrument (e.g. order)

- footnote[2] Back to paragraph For example, the range and average measurements, over the previous three month period, of the following parameters:

- footnote[3] Back to paragraph See Ontario Regulation 347 - General Waste Management (woodwaste combustor sites) for additional requirements for the management of woodwaste at combustor sites.

- footnote[4] Back to paragraph Note: For consistency of approach, the Director may use discretion in assigning emission limits for situations where there are multiple units of similar technology on a site or operated by the same owner.

- footnote[5] Back to paragraph Note that air standards in Ontario Regulation 419/05 are also applicable unless a facility is registered for contaminants listed in a technical standard that addresses emissions from wood-fired combustors.

- footnote[6] Back to paragraph The limit for existing large wood-fired combustors applies starting July 1, 2016. It is recommended that this limit be considered when reviewing an ECA application submitted after July 1, 2015.

- footnote[7] Back to paragraph Special case for direct and indirect contact wood-fired dryers: due to the nature of the potentially intermittent nature of the use of wood-fired dryers, it is recommended that these type of units are not required to include the dates when start-ups and shut-downs occurred.