Handling runoff from solid agricultural source material storages and outside livestock areas

Learn how to manage manure runoff from outdoor confinement areas, livestock yards and manure storage facilities. This technical information is for Ontario livestock producers.

ISSN 1198-712X, Published June 2020

Introduction

Uncovered manure storage facilities, livestock yards and permanent outdoor confinement areas (OCAs) (Figure 1) are exposed to rainfall and snowfall. These liquids and others (for example, urine), that are not absorbed by the manure are called “runoff” when they leave the facilities.

This fact sheet discusses runoff components and provides options for Ontario farmers to manage runoff from OCAs, livestock yards and manure storage facilities in compliance with the Nutrient Management Regulation, O. Reg. 267/03 as amended (the Regulation). Many of the terms used in this fact sheet are defined in Section 1 of the Regulation.

Most people recognize runoff as a brown or black liquid. It can be described as liquid that:

- has come into contact with manure in a permanent nutrient storage facility, temporary field nutrient storage site, OCA or livestock yard lined with concrete or other paving material of equal or lesser permeability

- may contain components of manure or other agricultural materials in solution or suspension, and

- is no longer contained in the permanent nutrient storage facility, temporary field nutrient storage site, OCA or livestock yard

Runoff from these facilities must be managed to prevent any flow over the ground and contaminating surface water as defined in Section 2 of the Regulation or leaching to groundwater where it may degrade water quality. Contamination caused by runoff can be chemical: nitrates and phosphates and/or biological: bacteria, viruses and parasites.

Farmers who are subject to the Regulation are required to manage their runoff so it does not harm surface water or groundwater. Farmers not subject to the Regulation may also wish to follow these runoff management requirements for due diligence. Water quality is also protected under the Ontario Water Resources Act, 1990, and the Environmental Protection Act, 1990.

Operations required to have a nutrient management strategy must have a runoff management system capable of handing all runoff generated by any of the following types of facilities (S.81):

- a permanent solid nutrient storage facility

- a livestock yard where farm animals are kept, and it is lined with a concrete floor (or other equivalent paving material)

- a permanent OCA

Runoff quality

Runoff has solid and liquid components. The main liquid component is from rainfall or snow melt. Other liquid components are urine and washwater, while the solid portion can consist of manure, bedding, feed and soil.

The constituent (contents) in runoff can be broken down into three categories: nutrients, microorganisms and compounds. Many of the same constituent that are found in runoff may also be found in liquid manure.

Nutrients

- nitrates: people who drink a lot of water containing nitrates above the Ontario Drinking Water Standard can develop a serious condition called methemoglobinemia, which limits the ability of blood to carry oxygen. Infants, children and pregnant women are particularly susceptible to this potentially life-threatening condition.

- phosphorus: phosphorus increases algae growth in surface water. When the algae dies and decays in surface water, it uses up oxygen, resulting in potential fish kills.

- potassium

Microorganisms

- bacteria: pathogenic bacteria such as various strains of coli can cause disease in humans and livestock when it gets into drinking water supplies.

- parasites

- viruses

Compounds

- organic

- inorganic

Table 1 provides a comparison between constituent levels for runoff and liquid dairy manure. The values show that runoff is a very dilute and lower-risk material as compared to liquid dairy manure.

| Constituents | Runoff | Liquid dairy manure |

|---|---|---|

| Nitrogen | 0.05% | 0.39% |

| Ammonium nitrogen | 0.03% | 0.16% |

| Phosphorus | 0.02% | 0.09% |

| Potassium | 0.18% | 0.25% |

| Dry matter | 1.5% | 8.6% |

| Biological oxygen demand | 1,400 mg/L | 15,000–30,000 mg/L* |

* A recognized value in Ontario for liquid dairy manure.

Runoff volume

The Regulation and Nutrient Management protocol explains how runoff volumes are calculated for each of the type generation sources.

Table 5.2 of the Nutrient Management Protocol outlines the accepted values for rainfall effects when estimating the amount of runoff generated by a livestock yard, OCA or solid storage (Table 2). Current versions of OMAFRA’s NMAN software also use these values to estimate the volume of runoff generated by these facilities. NMAN software is part of the AgriSuite software package that is available from OMAFRA. This volume is dependent on the factors outlined in Table 2.

OMAFRA’s NMAN software is used to develop a farm’s nutrient management strategy (NMS) and nutrient management plan (NMP). The NMS also calculates the required manure storage sizing from both liquid and solid manure as well as the total volume of potential runoff from farm permanent OCAs, animal yards and permanent solid manure storages.

| Design factor | Explanation |

|---|---|

| Precipitation (rainfall and snow) | The Nutrient Management Protocol provides a provincial standard of 0.56 m/year as an estimate of the amount of runoff generated per square metre of facility. |

| Surface area of pens or manure storage | A smaller surface area reduces the runoff volume, which reduces the size of the runoff treatment or storage system. |

| Dry matter content of solid manure | Depends on the type of livestock, amount of bedding or water added. |

In general, runoff volumes from permanent OCAs, permanent solid nutrient storage facilities and paved livestock yards are much higher than anticipated by the farmer. For example, a permanent OCA can produce up to 36.6 cm (1.2 ft) of depth of runoff per square metre of the OCA over a 240-day period. This runoff amount depends on the dry matter content of the manure and manure quantity in the confinement area during this period. A significant percentage of the liquid that falls on a permanent OCA, a permanent solid nutrient storage facility or paved livestock yard can be absorbed by solid manure. This absorptive factor has been accounted for in the 0.56 m/year referred to in Table 2. However, when there is a small amount of solid manure in the confinement area, more runoff will result.

Reducing possible runoff

Before constructing a runoff management system, the amount of possible runoff can be minimized by directing all clean water away from the permanent OCA, a permanent solid nutrient storage facility or a paved livestock yard before it comes into contact with the manure. Directing clean water away from the facility will reduce the volume of contaminated runoff to be managed and keep the facility drier and safer for both the farmer and the livestock. A drier environment can help livestock stay healthier.

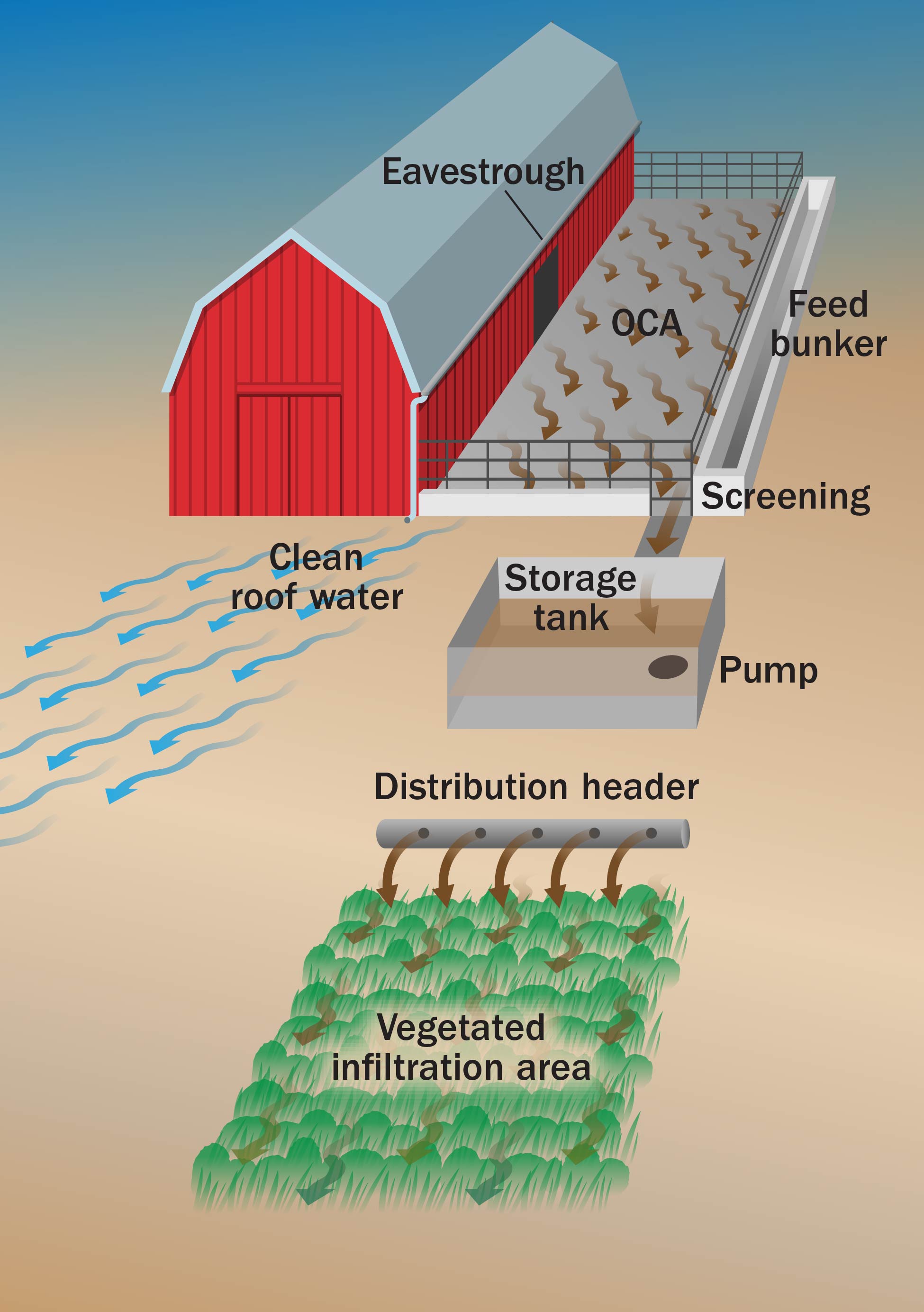

To reduce the runoff volume, surface water movement over the ground from higher elevations may be diverted by installing berms, ditches or other features. Eavestroughs on buildings can direct roof water away from these areas (Figure 2).

Runoff management systems

Consider how runoff is to be managed at the initial design stage of the manure storage facility, livestock yard or OCA. If the facility or area is not covered, provide a small slope (1%–2%) on the floor to one corner to allow the runoff to be collected and managed at one location. The installation of a system that can screen, such as a picket fence, and/or a small settling area at this low point will screen the solids and allow them to settle out before the runoff liquids will drain to the runoff management system.

The Regulation allows for five runoff management systems to be used on farms:

- roofed storage or roofed outside yard

- collection and storage system

- vegetated filter strip system

- another treatment system regulated under either Part 8 of the Building Code or under Section 53 of the Ontario Water Resources Act, 1990

- permanently vegetated area

The first four runoff management systems can be used for all OCAs, permanent solid nutrient storages and animal yards. The permanently vegetated area can only be used under very specific conditions set out in the Regulations.

Roofed storage, roofed outside yard or roof outdoor confinement area

Construction of a roof over a permanent solid nutrient storage facility, permanent OCA or paved livestock yard will prevent rain and snow from entering the facility (Figure 3). As long as up-slope water has been diverted, a roofed system reduces runoff volume, since rain and snowmelt do not need to be stored or treated. If precipitation enters the nutrient storage facility, the additional water may also change the dry matter content of the manure, which may change the type of storage system used.

Collection and storage system

Runoff may be collected and stored in a permanent liquid nutrient facility to be spread on cropland as a nutrient source. The storage facility may be constructed of concrete, steel or earth. See Sections 64 to 67 and 71 of the Regulation for the requirement regarding the need to employ a professional engineer or professional geoscientist for siting, design and construction of the storage facility. The initial construction or expansion of a permanent liquid nutrient storage facility must comply with the Regulation. Runoff may be collected and stored in a new or existing manure storage if the storage volume calculation includes the estimated runoff volume.

Permanent nutrient storage facilities and livestock housing facilities must be sited to meet municipal bylaw requirements. In most cases, the siting will be calculated based on the Minimum Distance Separation II (MDS II) formula. Contact the municipality about siting prior to applying for a building permit.

Section 63 of the Regulation stipulates the siting requirements for runoff containment facilities:

- Facilities must be 15 m (50 ft) from a well drilled 15 m (50 ft) or deeper, with watertight casing to a depth of at least 6 m (20 ft) below ground level.

- Facilities must be 100 m (328 ft) from a municipal well.

- Facilities must be 30 m (98 ft) from any other well.

- Facilities must be 15 m (50 ft) from field drainage tiles or piped municipal drains.

- Drainage tiles within a 15 m (50 ft) zone around the storage system must be removed, and a field drainage system or piped municipal drains must be redirected away from the facility.

- Drainage systems constructed within the 15 m (50 ft) zone of the facility must use non‑perforated pipe with all subsurface joints sealed, unless the collected water discharges to a treatment system or to foundation drains of the storage facility equipped with an observation and shut-off station.

- There must be a flow path at least 50 m (164 ft) long from the storage to the nearest top of bank of surface water or tile inlet.

- No construction is allowed in 1-in-100-year flood lines unless a permit is issued under Section 28 of the Conservation Authorities Act, 1990.

Vegetated filter strip system

A vegetated filter strip system (VFSS) is an engineered designed runoff treatment system. This system or infiltration area is a densely vegetated strip of land, engineered and constructed to accept and manage agricultural runoff and washwater by settling, filtration, dilution and absorption of pollutants and infiltration into the soil. The Regulation provides design, construction, operation and maintenance criteria for this type of runoff treatment system. If these standards are not met, a Certificate of Approval for a sewage works under the Ontario Water Resources Act, 1990, must be obtained.

Runoff is collected and stored in a settling basin, which could be:

- a curbed area on the paved livestock yard or OCA

- a curbed pad adjacent to the permanent solid nutrient storage facility, or

- a separate external basin

From the settling basin, the runoff either flows by gravity or is pumped to the vegetated filter strip. A perforated distribution pipe is located across the top end of the filter strip to distribute the runoff along the width of the strip (Figures 4 and 5). Treatment occurs as runoff moves down the strip.

Another treatment system

Other types of treatment systems may be appropriate for farm operations in certain circumstances. The regulation allows for the use of treatment systems other than a VFSS, but these systems must be approved under either Section 53 of the Ontario Water Resources Act, 1990, or Part 8 of the Building Code. Examples of these other treatment systems could include a septic tank and weeping bed system or a constructed wetland.

Permanently vegetated area

Under the NMA, a permanently vegetated flowpath is allowed to be used to contain and treat any minimal runoff that might result from animal yards, solid manure storages that are not larger than 300 m2 or OCAs that are no larger than 2,000 m2. A permanently vegetated area can be a permanent pasture, permanent hayfield or forested area that the runoff flows over. The permanently vegetated area cannot be tiled and must meet all the following criteria:

- have 0.5 m (1.6 ft) minimum soil depth

- be at least 3 m (10 ft) from field tile drains

- be at least 100 m (328 ft) from municipal wells

- be at least 15 m (50 ft) from drilled well

- be at least 30 m (100 ft) from any other well

A permanently vegetated area can only be used as the runoff management system in certain lower-risk situations. To use this runoff management option, the manure in the storage facility or paved livestock yard must be at least 30% dry matter.

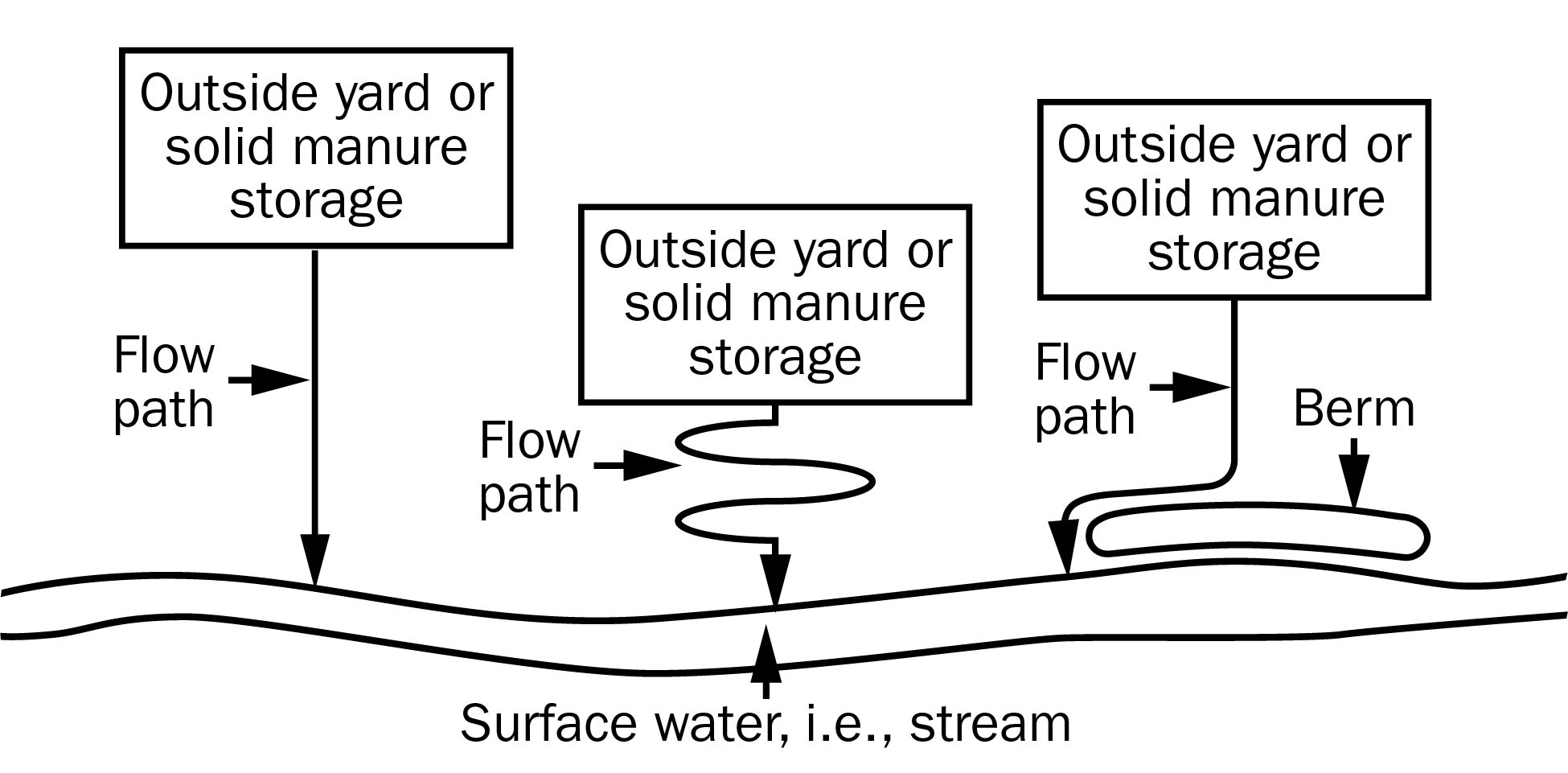

The area where the runoff flows over the permanently vegetated area is referred to as a flow path. The flow path runs through the permanently vegetated area and can be a surface channel or depression that conducts the runoff away from the facility. Treatment occurs as the runoff moves along the length of the flow path.

The flow path from the facility to surface water must be a minimum length. The flow path may go directly from the facility to surface water, meander back and forth or be located parallel to a berm along surface water to achieve the minimum length required (Figure 6).

Drier manure has less potential for runoff, therefore a shorter length of flow path to surface water is permitted. For larger facilities, multiple flow paths may be required.

Further details regarding permanently vegetated areas may be found in Section 81 of Ontario Regulation 267/03, as amended.

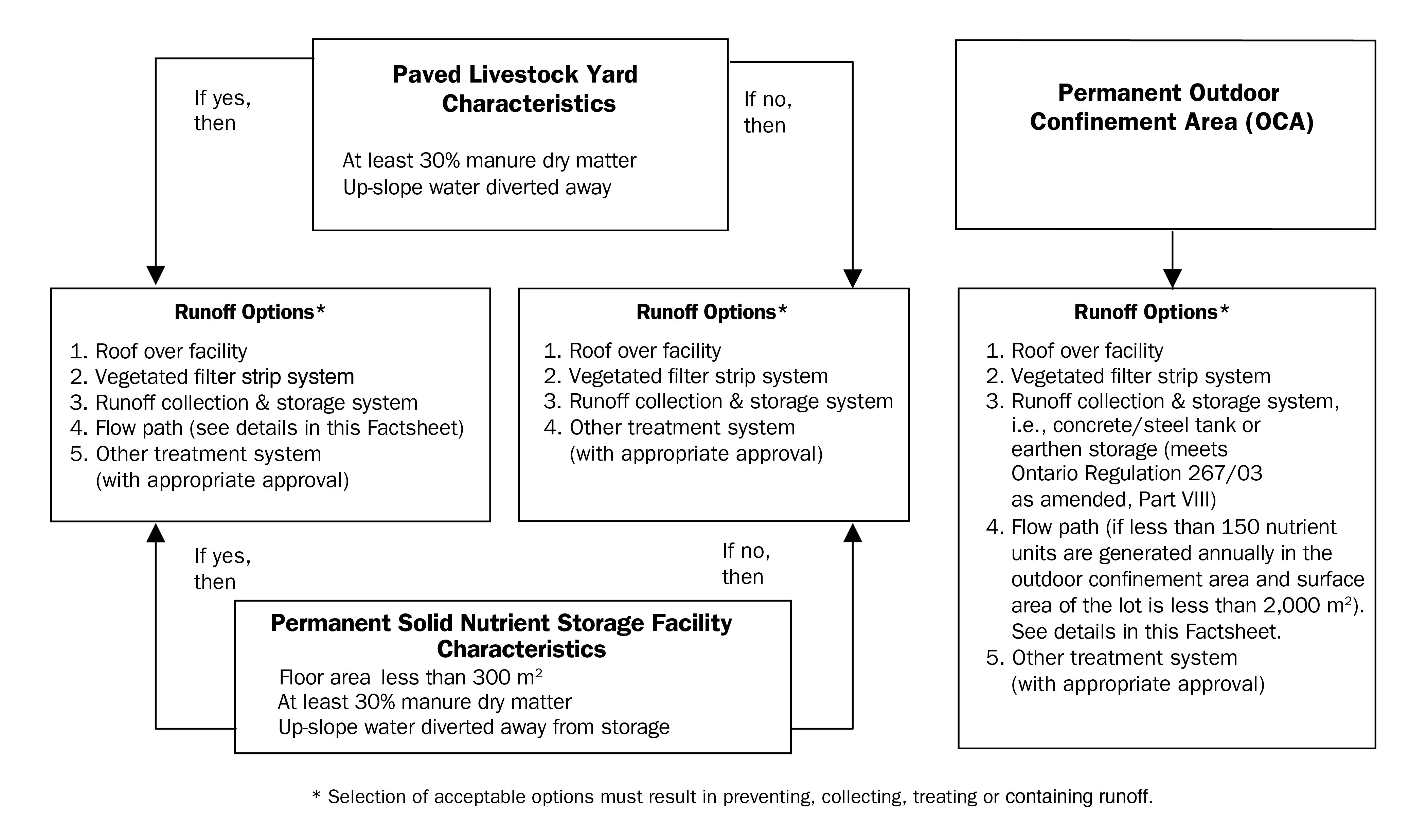

Facilities requiring runoff management

Under Section 81 of the Regulation, permanent outdoor livestock confinement areas, permanent solid nutrient storage facilities and livestock yards paved with concrete or other suitable material require a runoff management system that will handle all the runoff generated by the facility.

Table 3 shows a comparison of the three options. All options include a requirement of diverting up‑slope water away from the facility.

| Permanent solid nutrient storage facilities* | Manure dry matter (greater than or equal to) |

|---|---|

| Roofed storage (no runoff) | 18% |

| Runoff collection and storage (concrete, steel tank or earthen storage) | 18% |

| Vegetated filter strip system (professional design) | 18% |

| Other treatment system (with appropriate approval) | 18% |

| Permanently vegetated area flow path, minimum length of 150 m (492 ft)** | 30% |

| Permanently vegetated area flow path, minimum length of 50 m (164 ft)** | 50% |

| Paved livestock yard | Manure dry matter (greater than or equal to) |

|---|---|

| Roof over paved yard (no runoff) | 18% |

| Runoff collection and storage (concrete, steel tank or earthen storage) | 18% |

| Vegetated filter strip system (professional design) | 18% |

| Other treatment system (with appropriate approval) | 18% |

| Permanently vegetated area flow path, minimum length of 150 m (492 ft)** | 30% |

| Permanently vegetated area flow path, minimum length of 50 m (164 ft)** | 50% |

Permanent outdoor confinement areas

- Roof over confinement area (no runoff)

- Runoff collection and storage (concrete, steel tank or earthen storage)

- Vegetated filter strip system (professional design)

- Other treatment system (with appropriate approval)

-

Permanently vegetated area flow path can be used if the facility:

- generates less than 150 NU annually in the area

- has a maximum outdoor confinement area of less than 2,000 m2 per flow path

-

Flow path length requirement:

- If outdoor confinement area is under 500 m2, then minimum flow path length of 100 m (328 ft) is required from surface water or tile inlets.

- If outdoor confinement areas is between 500 m2 and <2,000 m2, then minimum flow path length of 150 m (492 ft) is required from surface water or tile inlets

* All options include a requirement to divert up-slope water away from the facility.

** Where solid manure storage floor area is less than 300 m2.

Permanent solid nutrient storage facilities

Section 81(1) of the Regulation requires that a permanent solid nutrient storage facility be equipped with a runoff management system capable of handling all the liquid generated by the facility. The type of runoff management system that can be used depends on the storage area and dry matter of the manure being stored.

Paved livestock yards

Paved livestock yards typically are “exercise” yards where no feeding or watering occurs or where the animals are present for less than 200 days per year.

Section 81(2) of the Regulation requires that a livestock yard paved with concrete or other acceptable material, other than a permanent OCA, be equipped with a runoff management system capable of handling all the liquid generated by the facility.

Permanent outdoor confinement areas

Section 81(3) of the Regulation requires that a runoff management system be provided for all permanent OCAs (Figure 7). The runoff management system must be composed of natural or manufactured runoff collection, treatment and/or containment devices that can prevent, collect, treat or contain runoff. All clean water must be diverted away from the OCA. Select from the runoff management systems options presented in Table 3.

Summary

The following flow chart (Figure 8) shows an overview of the runoff management systems that can be used for permanent OCAs, permanent solid nutrient storage facilities and paved livestock yards.

Nutrient Management Disclaimer 2018

The information in this fact sheet is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was revised by Richard Brunke, P.Eng., Nutrient Management, OMAFRA, London and reviewed by Jake DeBruyn, P.Eng., New Technology Integration, OMAFRA, Guelph, Peter Doris, Nutrient Management Specialist, OMAFRA, Brighton and Dale McComb, Environmental Specialist, OMAFRA, Guelph.