Liquid nutrient storages

Learn about storage design and transfer systems for liquid manure and other agricultural source materials. This technical information is for Ontario livestock producers.

Overview

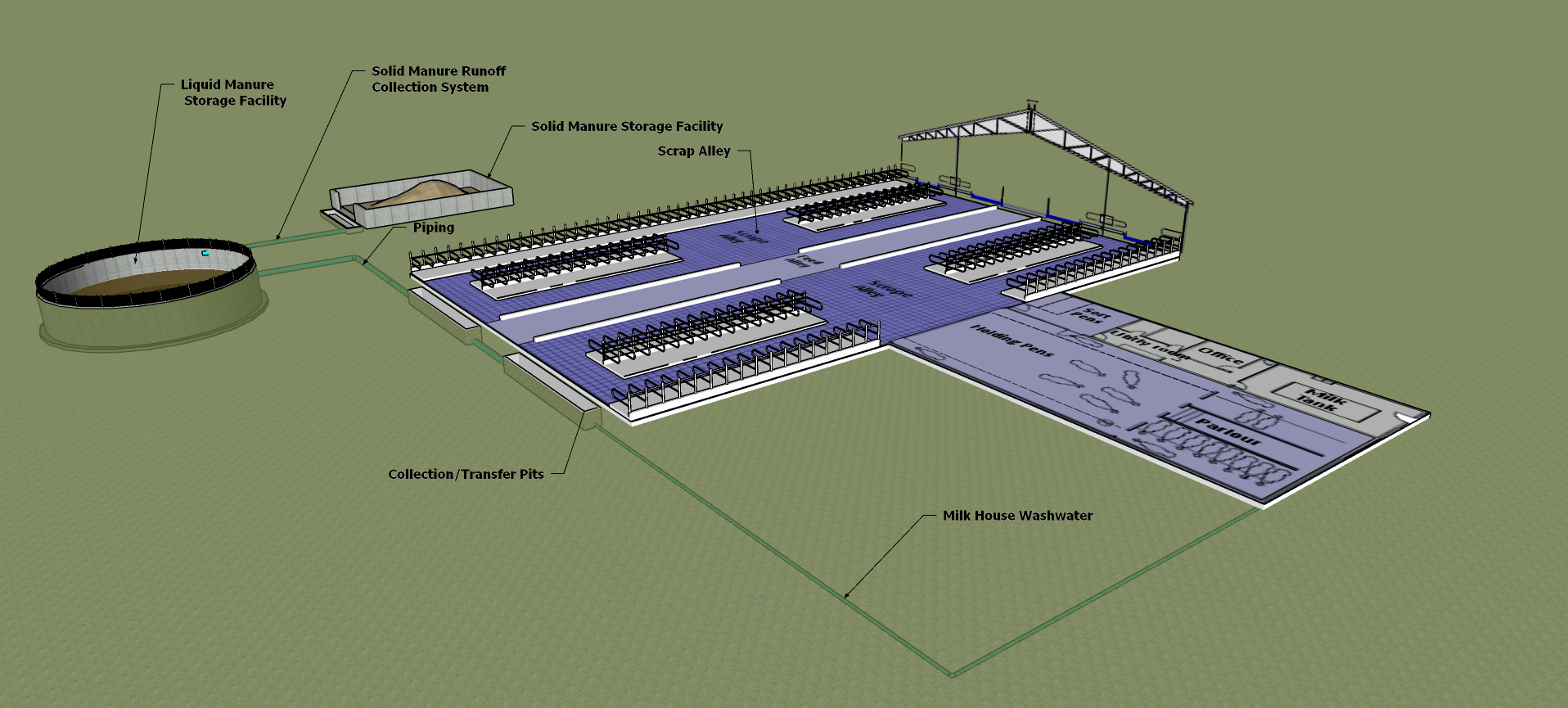

Under the Nutrient Management Act, 2002 (NMA), agricultural source materials are defined to include manure (liquid and solid), milk house washwater, animal yard runoff and solid manure runoff. These materials must be stored within or under a barn or transferred to an external storage facility.

Storage design

A professional engineering service is required for the design and general review of construction for all liquid nutrient storages. The design includes stamped drawings and specifications for the liquid nutrient storage construction. These drawings must include details for wall openings where transfer piping penetrates a storage, sump or holding pit that includes the provision for flexible watertight gasket or membrane to prevent leakage. All the drawings and design details must be retained on site and with the local building authority.

The system used to transfer liquids to a nutrient storage is defined in the NMA regulations as a liquid transfer system.

Liquid transfer system design

The liquid transfer system is an important part of the farm operation. It is built to transfer manure to a permanent storage facility easily and efficiently. The NMA regulations require all transfer systems be designed and inspected by a professional engineer.

The liquid transfer system includes components that come into contact with agricultural source materials such as pumps (hydraulic/mechanical/air), cross augers, pump-out chambers, mechanical scrapers, collections pits and all associated pipes (Figure 1). It does not include the floors of the permanent storage facilities.

The engineer-designed transfer system must include all the designed gasketed fittings for the pipes and connections at walls. This may include tees, end caps, and elbows that are compatible with the pipe material. All pipes that enter through the floor or wall of a storage tank (pump-out chamber or transfer/collection pit) must have a flexible watertight gasket or membrane to serve as an anti-seepage collar.

Installing liquid transfer systems

Contractors who install liquid transfer systems must be aware of the requirements of the NMA regulations. Before installing the transfer system, the contractor should contact:

- the barn design engineer to understand how the transfer system will be connected to the barn and/or transfer pits

- the transfer design engineer to ensure you understand construction requirements of the transfer system

- the storage tank design engineer to ensure the tank is sized and placed correctly and to know how the engineer will seal the pipe that will penetrate the tank wall

Adhering to engineering design requirements for liquid nutrient transfer systems is vital to prevent leakage at pipe joints, connections and penetrations through storage tank walls or floors. It is also important that the contractor notify the engineer to review installation before the transfer system piping is covered. Otherwise, excavation of the system may be required to inspect the joints for presence of flexible watertight gaskets or membranes.

Resources

See the Ontario Ministry of Agriculture, Food and Rural Affairs fact sheet for more detailed information about on-farm liquid nutrient transfer systems.