Guide to Requesting a Site-specific Standard

A guide for facilities preparing to submit a request for an alternative air standard under section 32 of Ontario Regulation 419: Air Pollution – Local Air Quality (hereafter referred to as O. Reg. 419 or the regulation).

February 2017

Under Ontario Regulation 419/05: Air Pollution – Local Air Quality

made under the Environmental Protection Act

Version 2.0

PIBS # 6322e02

Contents of this document are subject to change without notice.

Foreword

This document, the “Guide to Requesting a Site-Specific Standard”, is intended for facilities preparing to submit a request for a site-specific air standard under section 32 of Ontario Regulation 419/05: Air Pollution – Local Air Quality (O. Reg. 419/05 or the Regulation). In 2005, the Ministry of the Environment and Climate Change (the ministry) introduced a regulatory process for site-specific air standards to deal with implementation issues such as time, technical and/or economic factors. The Regulation works within the province’s air management framework by regulating air contaminants released into communities by various sources, including local industrial and commercial facilities. The Regulation includes three compliance approaches for industry to demonstrate environmental performance, and make improvements when required. Industry can meet an air standard, request and meet a site-specific standard or register and meet the requirements under a technical standard (if available). All three approaches are allowable under the Regulation.

Under the Regulation, new, updated or more stringent air standards typically have a phase-in period. The purpose of the phase-in period is to allow facilities time to assess and if necessary take action to come into compliance with the Regulation. A facility should proceed to implement any necessary changes during the phase-in period, subject to the necessary Environmental Compliance Approval (ECA) requirements. A facility that is not able to meet an air standard within the phase-in period may be eligible to request a site-specific air standard under section 32 of O. Reg. 419/05. A site-specific standard is a standard for a contaminant established for an individual facility that is challenged in meeting a provincial air standard due to technical or economic issues. This compliance approach focuses on actions to reduce emissions to air as much as possible considering the technology that is available and best operational practices. The process for determining a site-specific air standard is set out in the Regulation and the “Guideline for the Implementation of Air Standards in Ontario”. Additional information is provided in this Guide. An approval for a site-specific air standard is not the same as an Environmental Compliance Approval (under section 20.3 of Part II.1 of the Environmental Protection Act). For information on the ECA process, please refer to the “Guide to Applying for an Environmental Compliance Approval” which is also available on the ministry’s website.

A site-specific air standard for a particular contaminant is facility-specific and becomes the standard for that facility for the purposes of compliance assessments and the ECA process. The Regulation provides that a site-specific air standard may be approved for a period of 5 years or up to 10 years. In addition, the Regulation provides that a facility may also make a subsequent request for a site-specific standard. The goal of the site-specific standard regime set out in sections 32 to 37.1 of O. Reg. 419/05 is continuous improvement of emissions that will occur as new technologies become available or economic circumstances change.

This “Guide to Requesting a Site-Specific Standard” is not meant to be a stand-alone document. Other related documents that facilities requesting a site-specific air standard should refer to are available on the ministry’s Rules on Air Quality and Pollution website. This guide will set out minimum expected requirements that the Director may apply when exercising his or her discretion while considering applications on a case-by-case basis. To the extent that this document sets out that something is “required” or “shall” be done or sets out a “requirement” or “limit”, it does so only to identify minimum expected requirements, the application of which remain subject to the discretion of the Director.

The Regulation will take precedence where a conflict or ambiguity exists between this Guide to Requesting a Site-Specific Standard and the requirements of O. Reg. 419/05. All web site addresses referred to in this document were current at the time of release. For any addenda or revisions to this Guide to Requesting a Site-Specific Standard please visit the ministry website or contact:

Ministry of the Environment and Climate Change Standards Development Branch

40 St. Clair Avenue West, 7th Floor

Toronto, Ontario M4V 1M2

While every effort has been made to ensure the accuracy of the information contained within this Guide to Requesting a Site-Specific Standard, it should not be construed as legal advice.

Note: For those interested in information on the technical standards compliance approach, please refer to the ministry document: Guide to Applying for Registration to the Technical Standards Registry – Air Pollution (dated September 2010) (as amended) available on the ministry’s Rules on Air Quality and Pollution website .

1.0 Introduction

1.1 Purpose

The Ministry of the Environment and Climate Change (the ministry), Standards Development Branch (SDB) is responsible for administering requests for site-specific air standards made under Ontario Regulation 419/05: Air Pollution – Local Air Quality (O. Reg. 419/05 or the Regulation) under the Ontario Environmental Protection Act, R.S.O. 1990 (the Act). Section 35 of O. Reg. 419/05 sets out the criteria that must be met for the Director to approve a site-specific air standard. General information on O. Reg. 419/05 is also available on the ministry’s Rules on Air Quality and Pollution website.

The purpose of this document, the “Guide to Requesting a Site-Specific Standard” (GRSSS) (hereafter referred to as GRSSS or the Guide), is to highlight the information required to be submitted to the ministry to support a request under section 32 of O. Reg. 419/05. While section 32 requests apply only to O. Reg. 419/05 standards, elements described in this Guide could be requested by the ministry in abatement situations related to standards, guidelines or other contaminants. The Guide is not intended to be a stand-alone document and must be read in conjunction with O. Reg. 419/05 and other related documents (as amended) which include:

- Guideline for the Implementation of Air Standards in Ontario (GIASO);

- Procedure for Preparing an Emission Summary and Dispersion Modelling Report (ESDM Procedure Document); and

- Air Dispersion Modelling Guideline for Ontario (ADMGO).

This Guide provides specific details on when, what and to whom to submit information. O. Reg. 419/05 will always take precedence where there is a conflict or ambiguity with any other ministry document.

The GIASO document is the primary ministry guideline that describes the framework for managing risk which includes setting a site-specific air standard. A site-specific air standard approval is a legal instrument that is different than an ECA (approved under s.20.3 of Part II.1 of the Environmental Protection Act). A site-specific air standard for a particular contaminant is a site-specific standard that would replace the standard for that contaminant in the schedules of the Regulation for that facility. The site-specific air standard would be used in order to assess compliance for a facility and in the ECA process or any other Emission Summary and Dispersion Modelling (ESDM) report. However, if an approval of a site-specific air standard is granted, there will also likely be a requirement to obtain an ECA to implement the preferred technically feasible pollution control combination for the facility. For more information on ECA applications and amendments, please refer to the “Guide to Applying for an Environmental Compliance Approval” which is also available on the ministry website. O. Reg. 419/05 provides that an application for an ECA may be made in conjunction with a request under section 32 of O. Reg. 419/05. It may also be made subsequent to an approval granted under section 35.

1.2 Where to send Requests

Standards Development Branch (SDB) is the lead branch for processing section 32 requests for site-specific air standards. The original copy of the submission is to be sent to SDB. A copy of the request must also be sent to the Environmental Approvals Branch (EAB) for logging and tracking purposes. A copy of all material pertaining to a request for a site-specific air standard must also be sent to the local ministry district office for their files. Ministry office locations and addresses can be found on the ministry website.

Standards Development Branch

Ministry of the Environment and Climate Change

Attention: Director, Site-specific Air Standards

Local Air Quality Section

40 St. Clair Avenue West, Floor 7th

Toronto, Ontario

M4V 1P5

Tel: 416-327-5519 Fax: 416-327-2936

(original copy, electronic files and public version)

Environmental Approvals Branch

Ministry of the Environment and Climate Change

135 St. Clair Avenue West, 1st Floor

Toronto, Ontario

M4V 1P5

Tel: 416-314-8001 Toll-free: 1-800-440-6389 Fax: 416-314-8452

(one copy of request)

The Regulation requires that copies of all reports, as well as the input and output dispersion modelling files must be submitted electronically with the request. The Regulation also requires a facility to have a copy of the request available for review by the public. Any facility who is concerned about proprietary information should also submit a version of the request that can be shared with the public. The ministry expects that public versions will include all information with the exception of personal information and trade business secrets. For facilities with questions regarding the confidentiality of the submission, please see GIASO Chapter 2.10.1 Submission of Confidential Information for more information. Public versions of the request will be made available at SDB, the local ministry office as well as at the office of the facility making the request subject to the obligations under the Freedom of Information and Personal Privacy Act.

1.3 Background

Under the Regulation, newer requirements such as more advanced air dispersion models or any new, updated or more stringent air standard(s) are generally phased-in. The purpose of the phase-in period is to allow facilities time to assess and, if necessary, take action to select the most appropriate compliance approach. The Regulation includes three compliance approaches for industry to demonstrate environmental performance, and make improvements when required. Industry can meet the air standard, request and meet a site-specific standard or register under a technical standard (if available for the sector). All three approaches are allowable under the Regulation.

Ontario’s Local Air Quality Regulation recognizes that sometimes significant investments may be needed to keep pace with new or updated requirements. The site-specific standard compliance approach allows a facility the time needed to assess and implement where possible technical or operational adjustments to improve their environmental performance over time. A facility that meets a site-specific standard is in compliance with the Regulation.

It is expected that most facilities will be able to achieve compliance with the standards during the phase-in period. Subject to the necessary ECA requirements, a facility should proceed to implement the necessary changes to achieve compliance before the end of the phase-in period. A facility that is not able to meet the provincial standards within the phase-in period may be eligible to request a site-specific air standard under section 32 of O. Reg. 419/05 or to register for a Technical Standard (if available).

A site-specific standard is a standard for a contaminant established for an individual facility that is challenged in meeting a provincial air standard due to technical or economic reasons. This compliance approach focuses on actions to reduce emissions to air as much as possible considering the technology that is available and best operational practices. Information that is required to be submitted and considered by the Director before a decision can be made is set out in sections 33 to 34.1 of O. Reg. 419/05. This Guide is intended to assist facilities with the requirements of section 32 to 34.1.

An approval for a site-specific air standard under section 35 of O. Reg. 419/05 is a legal instrument that may be issued to a facility. There may be conditions of approval associated with a site-specific air standard that must be complied with, or the approval ceases to exist and the facility will be required to meet the applicable Schedule 3 standard for that contaminant. In some cases, the ministry may consider issuing an order under subsection 35 (14) of O. Reg. 419/05 to bridge to the requirements of a site-specific standard. In other cases, site-specific standards may change as action items are implemented and progress is made.

O. Reg. 419/05 provides that a site-specific air standard can be approved for a period of 5 years and up to 10 years. A facility can also make a request to renew a site-specific standard. Facilities that have already received an approval for a site-specific standard and are making a subsequent request may not be required to host a public meeting if there are no significant changes to the original request. However, public notification and comments will still be required through the Environmental Registry posting. The ministry will consider, on a case-by-case basis, whether to host or require the company to host a public meeting. GIASO provides more information on the overall framework for managing risks.

Facilities eligible to request a site-specific standard are summarized in Part 2 Regulatory Framework of this Guide, see Table 2-2 Eligibility to Make a Request for a Site-Specific Air Standard. The Director responsible for issuing an approval for a site-specific air standard, under section 35 of O. Reg. 419/05, must consider site-specific factors related to the facility and its surrounding environment. Site-specific factors may include a number of items such as site geometry, nearby receptors, location, terrain, and frequency of exceedences.

Section 37 of O. Reg. 419/05 provides the Director the authority to revoke the site-specific air standard approval under certain conditions. Subsection 35 (7) O. Reg. 419/05 states that if conditions are imposed in a section 35 approval, the approval applies only if the conditions are complied with.

The granting of a section 32 request, however, is not a guarantee that the equipment or facility will operate in compliance with the Act or other applicable ministry legislation, regulations or guidelines. If, at any time, air emissions from a facility contravene any part of the Act, O. Reg. 419/05, or any conditions included in any authorizing document or other legal instrument, then such contravention may become the subject of abatement or enforcement in accordance with section 186 of the Act.

1.4 How to Use this Guide

This Guide lists the minimum information that a facility requesting a site-specific air standard must include in their submission. The Guide, however, is not intended to provide a detailed explanation of all of the information that is required to be submitted. The ministry guidelines listed in Part 1.1 Purpose of this Guide provide further details and instructions on the technical and other information that must support the request for a site-specific air standard. This Guide summarizes the key pieces of information that need to be provided as well as whom the information should be submitted to in the ministry for approval. The final decision on a request for a site-specific standard will be made by a signing director appointed under section 5 of the EPA for the purposes of section 35 of the Regulation. This currently includes the Environmental Sciences and Standards Division (ESSD) which includes SDB.

A glossary of terms is included at the end of Appendix A. When a term is used in the Guide, which is in the glossary, it shall appear in italics to alert the reader to definition used for the purposes of this Guide only.

For reference purposes Table 1-1 Outline of Guide outlines the information contained in the various parts of this Guide.

| Part | Contents |

|---|---|

| 1. Introduction | An introductory section to provide background and context to the Guide. |

| 2. Regulatory Framework | Provides an overview of the requirements that are considered by the Director under sections 32-34.1, O. Reg. 419/05 prior to assessing a request for a site-specific air standard. It also describes who is eligible to make a request for a site-specific air standard. |

| 3. Information Required For Site-Specific Air Standard Requests | Provides an overview of the technical supporting information and other information to be submitted as part of the request. |

| 4. Processing Site-Specific Air Standard Requests | Outlines the information that must be included in the request in order to be considered complete. |

| Appendix A: Technical Guidance for Preparing a Technology Benchmarking Report that is submitted as part of a request for a site-specific air standard | Provides supplemental information to ensure transparent decisions are made when choosing technically feasible control strategies and combinations for the contaminant that is the subject of the section 32 request for a site-specific air standard. |

| Appendix B: Consequence Category Assignments | This Resource Table is provided to assist in applying the scoring methodology which may be considered in the ranking of economically feasible pollution control options. |

2.0 Regulatory Framework

Facilities that submit a request under section 32 of O. Reg. 419/05 must have technical reasons to support the selection of this compliance approach. Economic factors may also be considered. This part of the Guide describes who is eligible to make a request under section 32 and what information must be submitted, to whom and when. It also provides highlights of the Regulation to provide some context as to when a facility may be eligible to submit a request for a site-specific air standard.

2.1 Highlights of the Regulation

In 2005, Regulation 346 was revoked and replaced with O. Reg. 419/05. The Regulation came into effect on November 30, 2005. The Regulation works within the province’s air management framework by regulating air contaminants released into communities by various sources, including local industrial and commercial facilities. The ministry regulates contaminants in air because we want to be protective of communities who live close these sources. It aims to limit substances released into air that can affect human health and the environment and requires industry to operate responsibly under a set of rules that are publicly transparent.

The Regulation includes three compliance approaches for industry to demonstrate environmental performance, and make improvements when required. Industry can meet an air standard, request and meet a site-specific standard or register and meet the requirements under a technical standard (if available). All three approaches are allowable under the Regulation.

This Guide focuses on the site-specific standard compliance approach (formerly referred to as alternative, altered, or alteration of standards process). It includes guidance on development of technology benchmarking reports. A technology benchmarking report is required for a site-specific standard request and can also be used to support the development of sector-based technical standards or required as part of a notice issued under section 27.1 of the Regulation.

In broad terms, O. Reg. 419/05 includes:

- Air standards for a number of contaminants contained in Schedules 2 and 3. New or updated air standards that have been introduced into O. Reg. 419/05 are listed in Schedule 7. Phase-in dates for new or more stringent standards are as specified in the Regulation.

- A phase-out (between 2010 and 2020) of the models in the Appendix to Regulation 346, according to a schedule that varies by industrial sector (using the North American Industry Classification System (NAICS) code).

- A set of defined dispersion models referred to in O. Reg. 419/05 as “approved dispersion models” that are required to be used when assessing compliance with the standards in Schedules 2 and 3. O. Reg. 419/05 also stipulates how the models must be used with the various inputs (as applicable), including:

- operating conditions (section 10);

- source of contaminant emission rates (section 11);

- meteorological data (section 13);

- area of modeling coverage (section 14); and

- terrain data (section 16).

- O. Reg. 419/05 specifies the content of an Emission Summary and Dispersion Modelling (ESDM) Report (section 26). These reports are required to be submitted for ECA applications. There is also a phased introduction of a requirement for sectors listed in Schedules 4 and 5 to update an ESDM report annually; keep the report on-site; and make it available to the ministry upon request.

- O. Reg. 419/05 allows requests for site-specific air standards. Requests for site-specific air standards submissions include, among other things, the requirement to host a public meeting; a comparison of technology requirements and methods that are available for use; and economic feasibility (optional). For more information on site-specific air standards, see GIASO.

The US EPA air dispersion models and air standards will eventually affect all industries in Ontario. A phase-in period for new or updated standards and the US EPA air dispersion models has been established to allow facilities time to address potential implementation issues before the new requirements (new or updated standards or newer US EPA models) in the Regulation begin to apply to them. New or more stringent standards will apply to all emitters of those contaminants by the phase-in period specified in the O. Reg. 419/05. The new model requirements will be phased-in by sector: Schedule 4 sectors by February 1, 2010, Schedule 5 by February 1, 2013 and all others by February 1, 2020. A list of sectors in Schedules 4 and 5 is provided in Table 2-1 Schedule 4 and 5 Sectors below. For more information on phase-in dates, please see the O. Reg. 419/05 and the ministry website.

| NAICS Code | North American Industry Classification System Description |

|---|---|

| 2122 | Metal Ore Mining |

| 221112 | Fossil-Fuel Electric Power Generation |

| 324110 | Petroleum Refineries |

| 3251 | Basic Chemical Manufacturing |

| 3252 | Resin, Synthetic Rubber, Artificial and Synthetic Fibres and Filaments Mfg |

| 3311 | Iron and Steel Mills and Ferro-Alloy Manufacturing |

| 331410 | Non-Ferrous Metal (except Aluminum) Smelting and Refining |

| NAICS Code | North American Industry Classification System Description |

|---|---|

| 3221 | Pulp, Paper and Paperboard Mills |

| 324190 | Other Petroleum and Coal Products Manufacturing |

| 325 | Chemical Manufacturing |

| 326150 | Urethane and Other Foam Product (except Polystyrene) Manufacturing |

| 3279 | Other Non-Metallic Mineral Product Manufacturing |

| 331 | Primary Metal Manufacturing |

| 332810 | Coating, Engraving, Heat Treating and Allied Activities |

| 332999 | All Other Miscellaneous Fabricated Metal Product Manufacturing |

| 336 | Transportation Equipment Manufacturing |

| 5622 | Waste Treatment and Disposal |

2.2 Who is Eligible to Make a Request?

A facility is eligible to request a site-specific standard if it is affected by a new or updated air standard, the requirement to use a more advanced air dispersion model or if it is issued an order or a Notice as summarized in Table 2-2 Eligibility to Make a Request for a Site-Specific Air Standard. A phase-in period for new or updated standards and the a more advanced air dispersion models has been established to allow facilities time to address potential compliance issues before Schedule 2 standards (sections 19) or Schedule 3 standards (standards with variable averaging periods are assessed using a more advanced model) (section 20) of the O. Reg. 419/05 begins to apply to them. Those facilities that cannot achieve the air standard within the phase-in period may consider a request for a site-specific air standard if they are eligible.

Section 32 of O. Reg. 419/05 specifies which facilities are eligible to make a request for a site-specific air standard and the specific timeframes within which the request must be made. Table 2-2 Eligibility to Make a Request for a Site-Specific Air Standard shows the eligibility of facilities to make a request for a site-specific air standard. The window of opportunity to make a request (shown in the right hand column) varies depending on the request scenario (shown in the left hand column).

| Request Scenario | Opportunity to Make a Submission for a Request for a Site-Specific Air Standard | |

|---|---|---|

| 1 | An existing facility† within a sector identified in Schedule 4 is affected by a newer model listed in s. 6. [s.32(1)1 - revoked]* | February 1, 2007 – October 31, 2008 [s.32(5) revoked]* |

| 2 | An existing facility† within a sector identified in Schedule 5 is affected by a newer model listed in s. 6. [s. 32(1)2]* | February 1, 2010 – October 31, 2011 [s.32 (6)]* |

| 3 | A facility† that is not in Schedule 4 or 5 is affected by a requirement to use a newer model (i.e. section 20 applies). [s.32(1)3] | February 1, 2013 – October 31, 2017 [s.32(7)] |

| 4 | A new facility† that is affected by a standard for a contaminant listed in Schedule 7. [s. 32(1)4] | Concurrent with initial ECA application or, if the standard has not yet come into force, 15 months before the new standard comes into effect or 12 months after the new standard is introduced, whichever is later. [s.32 (8) and (9)] |

| 5 | An existing facility† that is affected by a standard for a contaminant listed in Schedule 7. [s. 32(1)5] | 15 months before the new standard comes into effect or 12 months after the new standard is introduced, whichever is later. [s.32(9)] Note: For example, a request with respect to a standard that takes effect July 1, 2016 must be have been made by April 1, 2015. |

| 6 | A facility† is given a notice under s.7 by the Director before February 1, 2020 specifying that there is only one model that is able to be used. [s.32(1)6] | Within 3 years of the Director giving the notice [s.32(10)] |

| 7 | A facility† is given a notice under s.7 by the Director on or after February 1, 2020 specifying that there is only one model that is able to be used and the model is not listed in s.6. [s.32(1)7] | Within 3 years of the Director giving the notice [s.32(10)] |

| 8 | A facility† is given a notice under s. 20(4) or an order under s.20 (5) by the Director for the early application (“speeding up” before February 1, 2020) of the Schedule 3 standards and the newer models listed in s. 6. [s.32(1)8] | Within 3 years of the Director giving the notice or making the order [s.32(11)] |

| 9 | A person making a subsequent request (i.e. requesting a renewal of) with respect to a site-specific standard. [s.32(1)8.1] | The subsequent request be made at least 15 months before the expiry date of the site-specific standard approval. [s.32(12)] |

| 10 | A facility is required to make a request under this subsection as part of a plan developed or amended pursuant to an order under section 7 or 17 of the Act or paragraph 7 or 8 of subsection 18 (1) of the Act. | As specified in the order. |

* Dates for these items have passed but remain in the table for reference since some decisions are still current.

† Although the Regulation does not define the term ‘new facilities’, it does refer to facilities where construction of the facility began after November 30, 2005 and no application for an ECA (air) was made on or before that date.

Section 35 of O. Reg. 419/05 provides authority for the Director to grant an approval for a site-specific air standard for a contaminant that is different than the Schedule 3 standard in O. Reg. 419/05 provided certain criteria are met. A facility governed by section 19 of O. Reg. 419/05 (i.e. that must meet Schedule 2 standards) is also eligible to request a site-specific air standard if it cannot meet a Schedule 2 air standard

These windows of opportunity are very important. The standards are phased in so that industry has time to react to a change in a standard and/or a newer model. It is the responsibility of the industry to determine if a request for a site-specific air standard is required and submit all of the required information within the applicable window of opportunity available. The ministry will use its time to adequately review the requests and to seek input from external expertise, as necessary. If a facility misses a window they may lose their opportunity to make a request for a site-specific air standard.

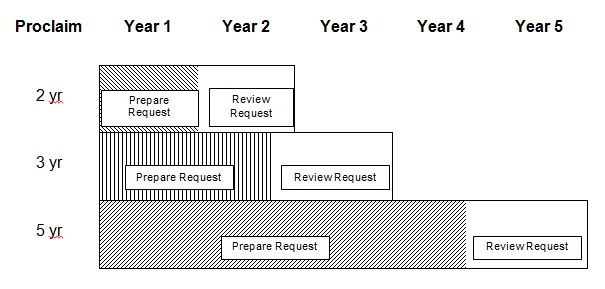

As more standards are added to the O. Reg. 419/05, the window to request a site-specific standard will shift for those contaminants. Figure 2-1 Windows of Opportunity as New Standard Added to Schedule 7 graphically illustrates how the windows of opportunity to request a site-specific standard open when a new standard is added to Schedule 7. The first line shows that for a new contaminant listed in Schedule 7 with a 2 year phase-in period, eligible facilities will have 12 months to prepare and submit a request under section 32 (and the standards would not take effect until 12 months later). The second line shows that for a new contaminant listed in Schedule 7 with a 3 year phase-in period, eligible facilities will have 21 months to prepare and submit a request (and the standards would not take effect until 15 months later). The final example in the figure is for a 5+ year phase-in period in which eligible facilities will have 3 years and 9 months years to prepare and submit a request (and the standards would not take effect until 15 months later) [see subsection 32 (9) of the Regulation.]

Figure 2-1 : Windows of Opportunity as New Standard Added to Schedule 7

3.0 Information Required for a Request for a Site-Specific Air Standard

This part of the Guide summarizes section 33 of the Regulation which set out the information that is required to be submitted to support a request for a site-specific air standard. The ministry guidelines GIASO, ADMGO and the ESDM Procedure Document provide more detail on the contents of the reports as well as other regulatory requirements and as such must also be consulted when preparing a request for a site-specific standard. Facilities with questions regarding the legal issues associated with a request for a site-specific air standard, or the technical aspects of completing an assessment of the emissions and point of impingement (POI) concentrations from a facility, should seek the services of qualified professionals.

For facilities with questions regarding the confidentiality of the submission, please see GIASO Chapter 2.10.1 Submission of Confidential Information for more information.

3.1 Summary of Requirements

This part of the Guide outlines in more detail the information requirements for the reports that must be submitted to support a request for a site-specific air standard.

Requests for a site-specific air standard, under section 32 of O. Reg. 419/05 must include the information set out in sections 33,34 and 34.1 (note that information on economics set out in subsection 33 (4) is optional).

The following is a summary of the information that is required to be submitted as part of a request for a site-specific air standard:

- an application form (which summarizes legal information including name and location of applicant, contaminant name, etc.);

- an Emission Summary and Dispersion Modelling (ESDM) Report (which must include the results from a modelling/monitoring study, and an assessment of the magnitude and frequency of exceedence of the standard(s), etc.);

- a Technology Benchmarking Report (which must assess and rank technical methods for reductions in contaminant concentrations and provide an assessment of feasible technologies);

- an Economic Feasibility Analysis (Optional);

- a Public Consultation Report that summarizes the results of the mandatory public meeting with the local community; and

- an Action Plan with schedule of dates/timelines.

Table 3-1 Items to be submitted with Request below provides a summary of the information required in each of these with a reference to the specific sections of the O. Reg. 419/05. For a full description of the contents of these reports and the material that is to be submitted with the request, as well as other requirements, please see GIASO, ADMGO and the ESDM Procedure Document. Appendix A of this Guide also provides guidance on the development of the Technology Benchmarking Report.

The information summarized in Table 3-1 Items to be submitted with Request must be included in the request in order for the request to be considered complete.

| Information to be Submitted | O. Reg. 419 | Ministry Contacts† | Forms/Reference Documents | Timing and Other Factors |

|---|---|---|---|---|

| Application Form | - | SDB | Application for Approval of a Site-Specific Air Standard | Form to be submitted with the section 32 request for a site-specific air standard. |

| Emission Summary and Dispersion Modelling (ESDM) Report |

s. 33(1) paras 0.1, 1 and 2 prepared in accordance with s. 26. s. 10, 11, and 12 (refinement, higher data quality). s. 33 (3), (6), (7), (8), (9) and (10), (use more advanced US EPA models for contaminant that is the subject of the section 32 request for a site-specific air standard). s. 20 for contaminant that is the subject of the request. |

SDB |

ESDM Procedure Document ADMGO GIASO, chapter 2.2.2 CAMMs Pre-submission requirements as per of Table 3-2 Pre-submission Requirements this Guide |

ESDM report to be submitted with the section 32 request for a site-specific air standard. Executive Summary of ESDM report must be made available to the public at the public meeting. [clause 34(3)(a)]. Must offer to provide a complete copy of the request. [clause 34(3)(b)]. ESDM report shall be prepared using both operating scenarios in s. 10(1). See subsections 33 (6), (7), (8) and (9). |

| Technology Benchmarking Report | s. 33 (1) paragraphs 3, 4, 5 and 6 | SDB |

GIASO, chapter 2.4 Technology Benchmarking Appendix A to this Guide |

Technology Benchmarking Report must be submitted with submission of request. Must be made available to the public upon request. clause 34(3)(b). |

| Economic Feasibility Analysis (Optional) | s. 33(4) | SDB |

GIASO, chapter 2.5 Economic Considerations Guideline F-14: Economic Analyses of Control Documents on Private Sector and Municipal Projects (PIBS# 1517) |

Optional with submission of request. Must be made available to the public upon request. clause 34 (3)(b). |

| Public Consultation Report: A summary of the pre-submission consultation meeting with local stakeholders |

s. 33(1) paragraph 8 s.34 s. 34.1 |

Notification of SDB and local ministry district. | GIASO, Chapter 2.6 Stakeholder Involvement | Meeting to be held prior to submission of request. Notification of the meeting must occur at least 15 days prior to meeting and in accordance with the requirements of O. Reg. 419/05. Submission includes a summary of comments made and responses provided. A person making a request under section 32 may make the request without holding a public meeting if the Director has ever set a site-specific standard under section 35 for the same contaminant in respect of the same facility. |

| Action Plan | s. 33(1) paragraph 7 or s. 33(4), paragraph 4 s. 35(9) and 35(10). |

SDB with input from local ministry District office | GIASO, Chapter 2.7 The Action Plan and 2.8 Continuous Improvement | With submission of request. Must be made available to the public upon request. s. 34(4) and s. 34.1(6) |

| Scoring Method (Optional) | The method is optional and is not referenced in O. Reg. 419. | SDB | Appendix B of this Guide describes the optional Scoring Method. This method is also part of the costing assessment. | With submission of request. May be included in Cost-Effectiveness report or Technology Benchmarking Report with supporting documentation in ESDM report. |

† SDB is the main contact for requests for site-specific air standards and all original copies should be sent there. One copy must also be submitted to EAB, and one copy to the local District Office (see Part 1.2 Where to send Requests). An electronic copy of the ESDM and Technology Benchmarking reports and the input and output dispersion modelling files must also be provided. If a facility is concerned about proprietary information, then a public version of the documents for viewing should also be provided to SDB and the local district office. The ministry expects that public versions will include all information with the exception of personal information and trade business secrets.

3.2 Pre-submission Requirements

Some requirements to support a request under section 32 require pre-approval or notification in advance of the submission of a formal request. These items are listed in Table 3-2 Pre-submission Requirements and include:

- Approval of Site-specific Meteorological Data;

- A Plan for Combined Assessment of Modelled and Monitored Results as an emission rate refinement tool (see Technical Bulletin – Combined Assessment Of Modelled and Monitored Results (CAMM) as an Emission Rate Refinement Tool (as amended))

- Source Testing Pre-Test Plan (if required or desired) [Note: source testing across a range of operating conditions can be submitted in lieu of a CAMM. See s. 12(1.1) of the Regulation];

- Proposal for Negligible Sources (under Chapter 7.3 General Guidance to Identifying Insignificant or Significant Sources and Contaminants of ESDM Procedure Document);

- Notification for pre-submission consultation meeting with local stakeholders.

Table 3-2 Pre-submission Requirements sets out when such pre-approval or notification must be completed and indicates which branch of the ministry should be contacted for each item. If there are any questions regarding these items, pre-submission consultation with the ministry is possible and may be advisable. This is strongly encouraged. Please contact the appropriate ministry office listed in Table 3 2. Please note that use of the term Director does not mean the director of a ministry branch. It is the position identified and appointed under s. 5 of the Environmental Protection Act designated in the ministry as a Director for the purposes of O. Reg. 419/05.

It should be noted that it takes time and effort both on behalf of the proponent to prepare the necessary documents for pre-approval or notification and on behalf of the ministry to review these submissions. It is important to use the phase-in period efficiently and allow enough time for the pre-submission requirements.

| Information to be Submitted | When | O. Reg. 419/05 | Ministry Contacts | Forms/Reference Documents |

|---|---|---|---|---|

| Site-specific Meteorological Data | Site-specific meteorological data must be approved prior to completing the ESDM report to support the section 32 request for a site-specific air standard. | s. 33(10) and s. 13(2) |

Environmental Monitoring and Reporting Branch (EMRB) | ADMGO – Form† for "Request for Approval under s.13(1) of Regulation 419/05 for use of Site Specific Meteorological Data" PIBS # 5350e: |

| A Plan for Combined Assessment of Modelled and Monitored Results (CAMM) |

A combined assessment of modelled and monitored results is typically done for sources of fugitive air emissions (see Technical Bulletin available on the ministry website - “Combined Assessment of Modelled and Monitored Results (CAMM) as an Emission Rate Refinement Tool”). Assessment of emissions in accordance with an approved plan under section 11(1) paragraphs 2 or 3 must have been done prior to completing the ESDM report to support the section 32 request for a site-specific air standard. ESDM reports submitted for a section 32 request must have highest data quality as per s.12. Note: see GIASO for reference to new facilities |

s. 33(8) Will require a plan to be approved under s. 11(1) paragraph 3 s. 12 s. 33(9) |

Submit proposed modelling/monitoring plan to SDB with a copy to local ministry district office. SDB will coordinate comments from the ministry’s Regional Technical Support Section and EMRB. Note: It is recommended that the draft report be submitted to the ministry for comment. Site-specific meteorological data must also be included in a combined modelling/monitoring assessment. |

The Technical Bulleting “Combined Assessment of Modelled and Monitored Results (CAMM) as an Emission Rate Refinement Tool “is available from the ministry web-site. Form† "Request for Approval of a Plan for Combined Analysis of Modelled and Monitoring Results" PIBS # 6323e |

| Negligible Sources | If additional negligible sources are identified beyond current ministry guidelines, agreement must be achieved prior to completing the ESDM report to support the section 32 request for a site-specific air standard. |

s. 33(1) paragraph 1 s. 26(1) subparagraph 3.iii. |

SDB | The development of specific criteria for assessment of negligible source under Chapter 7.3 General Guidance to Identifying Insignificant or Significant Sources and Contaminants of ESDM Procedure Document. The use of accepted methods such as those in Chapters 7.1 Screening-Out Contaminants that are Emitted in Negligible Amounts and 7.2 Screening-Out Sources that Emit Contaminants in Negligible Amounts do not require pre-approval. |

| Source Testing Pre-Test Plan (if applicable) |

Source testing must have been done prior to submission of the ESDM report to support a section 32 request. The ministry must also be given 15 days notice prior to source testing to allow the opportunity to witness the test. |

s. 33(9) s. 12(1.1) s. 11(1) paragraph 2 |

SDB; approving Director for s. 11(1) paragraph 2 SDB Manager of Technology Standards Section. Submission should be identified as being in support of a request for a site-specific air standard. |

Ontario Source Testing Code Note: source testing may not be necessary if an approved modelling/monitoring plan has been conducted. |

| Organize Pre-submission consultation meeting with local stakeholders | Prior to submission of request. Provide notification to local stakeholders, local ministry district office and SDB 15 days prior to meeting. |

s. 33(1) paragraph 8 s. 34 s. 34.1 |

Provide copy of the Notice for the meeting to local ministry district office and SDB. | GIASO, chapter 2.6 Stakeholder Involvement Note: All the material listed in Table 3-1 Items to be submitted with Request must be summarized and made available to the public upon request. |

† For more information on forms, please go to the ministry’s Rules on air quality and pollution website.

The following is a discussion of each item in Table 3-2 Pre-submission Requirements.

3.2.1 Site-specific Meteorological Data

Meteorological data used in modelling must represent facility site conditions as accurately as possible. Site-specific data may include the most appropriate available ministry data set, data from an on-site meteorological station or data derived from computational methods. Subsection 33 (10) of O. Reg. 419/05 requires that the most site-specific meteorological data be used, as approved by the Director, to support a request for a site-specific air standard. This means meteorological data referenced in subsection 13 (1), paragraphs 3 or 4 of O. Reg. 419/05 must be used and approved by the Director. Where regional meteorological data is deemed to be the best data available, this will be considered but is subject to pre-approval. Site-specific meteorological data is important because a request for a site-specific air standard must consider the frequency of exceedence of the standard at specified locations (subsection 35 (2) and 35 (12) paragraph 2). Site-specific meteorological data is also mportant in assessing the pattern and geographic extent of exceedences. For more information on frequency, see Chapters 2.3.1 Identification of Receptors and 4 Factors to Consider When There Are Exceedences of GIASO.

It should be noted that Director approved meteorological data is also required for the days where monitored results are available for the combined modelling/monitoring assessment. This specific meteorological data would only be considered as part of that approval for a combined modelling/monitoring plan under subsection 11 (1), paragraph 3 of O. Reg. 419/05 (see Part 3.2.2 Combined Modelling/Monitoring Assessment of this Guide).

A form to Request the use of Site Specific Meteorological Data can be obtained from the ministry website. When this form is being submitted to support a section 32 ESDM report, copies are to be provided to the following ministry Branches: EMRB, SDB, EAAB and the local ministry district office.

3.2.2 Combined Modelling/Monitoring Assessment

The decision to grant a request for a site-specific air standard under section 32 will be based in part on the POI concentration (µg/m3) that results from a “refined” ESDM report that has considered all technically feasible pollution control combinations to reduce the concentration of the contaminant that is the subject of the request as much as possible for every non-negligible source of that contaminant. Sections 10, 11 and 12 of O. Reg. 419/05 govern the concept of “refinement” of emission inputs to the model (see also subsection 33 (9)). The ESDM report must include an “as accurate as possible” assessment of existing emissions/concentrations for the contaminant that is the subject of the request. The emission rate used must be based on a director approved plan under subsection 11 (1) paragraphs 2 or 3. This section focuses on paragraph 3 of subsection 11 (1). Emission rates that rely on paragraph 2 of subsection 11 (1) is further discussed in Chapter 3.2.3 Source Testing Plan.

The modelling/monitoring assessment allows for the confirmation and refinement of emission rates. The general approach involves the use of iterative modelling to adjust the emission rate of each source being refined so that the model results best match the monitored data at all of the monitors for that day. For more information, please see the Technical Bulletin – Combined Assessment of Modelled and Monitored Results (CAMM) as an Emission Rate Refinement Tool (as amended). For additional information on monitoring, including proper siting considerations, please refer the Operations Manual for Source Emissions Monitoring document (latest version).

All requests for a site-specific standard must include the submission of a plan as per s.11(1) paragraph 3 which must be pre-approved by SDB. A form to Request for Approval of a Plan for Combined Analysis of Modelled and Monitoring Results can be obtained from the ministry’s Rules on air quality and pollution website. When this form is being submitted to support a section 32 ESDM report, copies are to be provided to the following ministry Branches: EAAB, EMRB, SDB and the local ministry district office.

In general, these plans will include details on a modelling/monitoring approach. The plan typically includes the rationale for the placement of the monitors, the sampling frequency and the sampling methodology and analysis. It is very important to allow sufficient time for the ministry to review the plan. If there are neighbouring facilities that also emit the same contaminant, care will need to be taken to determine the contribution from the facility requesting the site-specific air standard.

See subsections 33 (6 thru 10) of the Regulation for more information on refining an ESDM report submitted under section 32.

3.2.3 Source Testing Plan

An ESDM report submitted in support of a request for a site-specific air standard must include refined emission rates for the contaminant that is the subject of the request (and others as necessary). Source testing that is conducted in accordance with ministry requirements may be one method to refine emissions rates if the Director is of the opinion that it will accurately determine emissions of that contaminant. Generally, source testing is used for point sources and modelling/monitoring is used for fugitive sources. Please see subsections 33 (7), 33 (8) and 33 (9) of O. Reg. 419/05 for more information on refining modelling in an ESDM report submitted in respect of a request made under section 32.

Any source testing that is to be used in support of a request for a site-specific air standard must be must be conducted according to a plan approved by the Director as likely to provide an accurate reflection of emissions. The plan should indicate that this data is intended to be used in a section 32 request. In addition, under subsection 11 (1) paragraph 2, the proponent is required to test using a range of operating conditions. The proponent must also provide the ministry 15 days’ notice of the date of the source testing to allow the ministry the option to witness the test. The final report must also be submitted and approved by ministry staff.

Note: When estimating emission rates according to paragraph 2 of subsection 11(1) of the Regulation, source testing is required to be conducted comprehensively across a full range of operating conditions. The range of operating conditions must be approved by the ministry (SDB – Local Air Quality Section) before source testing is conducted. This plan is not the same as a pre-test plan for source testing. For more information, please contact SDB, Local Air Quality Section.

3.2.4 Pre-submission Consultation with Local Stakeholders

O. Reg. 419/05 requires the facility to hold a public meeting prior to submitting a proposed request for Director’s approval of a site-specific air standard. Paragraph 8 of subsection 33 (1) of the Regulation requires that information pertaining to a public meeting be submitted with the request made under section 32. Details of the requirements for the public meeting and stakeholder notification are set out in section 34 and, if a meeting is required by the Director, section 34.1. The local community must be given an opportunity to be made aware of the nature of the request and to be provided with a full understanding of the options that are being considered including the technical challenges that a facility faces. Economic issues may also form part of the basis of the request for a site-specific air standard. It is recommended that stakeholder identification begin as soon as possible in the process and that risk communication focus on the key stakeholder(s) – the local community. For more information on public meetings and risk communication, please refer to Chapter 2.6 Stakeholder Involvement of GIASO. The ministry has also developed public fact sheets for use with public engagement activities.

The facility making the request for a site-specific air standard shall, at least 15 days before the public meeting, publish a notice in a newspaper having general circulation in the area where the source of contaminant is located, setting out the name, address and telephone number of the facility making the request and informing the public of the facility’s intention to make the proposed request, the purpose of the request and the date, time and place of the meeting. The company is responsible for organizing the meeting and ensuring that appropriate local stakeholder groups have been notified at least 15 days prior to the meeting. Clause 34(4)(b) provides a list of the stakeholders that are required to be notified of the meeting. Notification to the ministry shall be both to the local ministry district office as well as to the Director of Standards Development Branch.

The notices for the public meeting must be in language that can be understood by persons without specialized scientific training. The format, style, title or content of the notice may vary from facility to facility to suit specific circumstances and local requirements. The following is recommended:

- name and address of the facility making a request for a site-specific air standard;

- a brief description of the basis of the request and the reasons why the site-specific air standard is needed;

- an indication that the facility is following a process required by O. Reg. 419/05;

- details of when and where the public meeting will take place and where further information can be obtained if a member of the public is unable to attend the meeting;

- name or title of a company contact person to whom comments or requests for information should be directed; and

- the final date for submission of stakeholder comments to the proponent.

3.3 The Emission Summary and Dispersion Modelling Report

The ESDM report submitted under section 33 of O. Reg. 419/05 must include all contaminants emitted from the facility not just the contaminant that is the subject of the request for a site-specific air standard. Subsections 33(6) and 33(10) of O. Reg. 419/05 require that the contaminant(s) that is the subject of the request for a site-specific air standard be assessed using an approved dispersion model that uses the most representative hourly meteorology data (e.g. AERMOD) as if section 20 of O. Reg. 419/05 applied. The approved dispersion model will be used to assess compliance against the standards in Schedule 3 of O. Reg. 419/05. For all of the other contaminants, the facility may choose to use any one of the approved dispersion models. If the facility is not yet required to use the US EPA air dispersion models to assess all contaminants from their facility, then the Appendix to Regulation 346 can be used (only if applicable) to assess contaminants that are not the subject of the request.

For presentation purposes, it may be easier to separate the information on the non-section 32 contaminants from the section 32 contaminant(s). A separate source summary table for the section 32 contaminant(s) is necessary to assist in the review of the sources that are significant to the request being made. A table summarizing the POI contributions from each source must also be included in the ESDM report submitted under section 32. The ESDM report must contain the following information (in addition to all of the other required information) for the contaminant that is the subject of the request:

- An assessment of the POI concentrations at both of the operating conditions described in subsection 10 (1) of O. Reg. 419/05 paragraphs 1 and 2.

- An assessment of the POI concentrations at the currently approved operating condition if this is different than the above.

- The modelling runs to support the assessment of the POI concentrations that would result if the various technically feasible pollution control strategies identified as part of the Technology Benchmarking Report (see Appendix A of this Guide) were in place. It would be helpful to clearly identify each modelling run as linked to the various combinations detailed in the Technology Benchmarking Report.

- An assessment of the POI concentrations at both of the operating conditions described in subsection 10 (1) of O. Reg. 419/05 paragraphs 1 and 2 that would now include implementation of the preferred technically feasible pollution control strategy that was recommended in the Technology Benchmarking Report. This POI concentration will form the basis of the site-specific air standard.

For more information on ESDM reports, including requirements to assess the frequency of exceedences at specific points, please refer to the ESDM Procedure Document, ADMGO and GIASO.

Electronic Modelling Files

All of the necessary electronic modelling files to support a section 32 ESDM report must be included on a data disk. Examples of the types of files that must be supplied (assuming use of AERMOD model) include:

- meteorological-related files;

- unprocessed and fully processed model ready meteorological files for modelling/monitoring comparisons;

- the ministry approved 5 year meteorological set;

- AERMET stage 1, 2 and 3 input files (.in1, .in2, .in3);

- BPIP input, output and summary files;

- terrain-related files;

- DEM files used;

- AERMAP input file;

- AERMAP output files (.rou and .sou);

- AERMOD-related files; and

- electronic base map;

- input and output files for every model run;

- plot files of concentrations and exceedences;

- spreadsheets, database files;

- emission input files;

- model output manipulation (post-processing) files.

All of the above files should be organised into well labelled folders and/or may be archived using zip or another common compression file format.

Complete documentation of the modelling files is necessary for the ministry review staff to follow what modelling was undertaken. Documentation must be supplied that clearly describes each of the supplied model runs including the name of files supplied, the emission scenario being modelled and the purpose of the run. If the modelled source names do not match exactly the source names listed in the ESDM report, a correlation table must be supplied. All source groups need to be documented including source group name of emission sources included in the group and the purpose of the source group. Any post-processing of the modelling output files using a database program such as Microsoft Access or a custom developed executable file or script needs to be well documented.

Overall sufficient documentation and electronic files must be supplied that will allow the reviewer to duplicate the results.

Most Refined ESDM Report

ESDM reports submitted under section 32 must be the most “refined” ESDM report possible for the contaminant that is the subject of the request for a site-specific air standard. The decision to grant a request for a site-specific air standard under section 32 will consider the POI concentration (µg/m3) that results from a “refined” ESDM report as well as the technically feasible pollution control strategies identified in the Technology Benchmarking Report (see Appendix A of this Guide).

The information referred to in Parts 3.2.1 Site-specific Meteorological Data and 3.2.2 Combined Modelling/Monitoring Assessment of this Guide is needed before a proponent can complete an ESDM report for the purposes of a request for a site-specific air standard. ESDM reports submitted under section 32 must include the following information for the contaminant that is the subject of the request:

- a plan submitted as per paragraph 3 of subsection 11 (1) of the Regulation which typically includes a combined modelling/monitoring assessment (see Technical Bulletin: Combined Assessment of Modelled and Monitored Results (CAMM) as an Emission Rate Refinement Tool (as amended);

- source testing information (if applicable);

- an assessment of the frequency and magnitude of exceedences for the contaminant that is the subject of the request (see Part 3.5 Assessing Concentrations and Frequency at Receptors of this Guide);

- site-specific meteorological data approved by the ministry (EMRB) prior to finalizing the ESDM report.

Examples of information contained in the ESDM report that can be “refined” include:

- emission inputs for air dispersion modelling, which can be refined to a higher data quality (sections 11 and 12 of O. Reg. 419/05);

- operating conditions of the facility (sections 10 and 12 of O. Reg. 419);

- selection of approved dispersion model can be refined to more accurately assess concentrations (sections 6 and 7 of O. Reg. 419/05); and

- meteorological data can be refined to be site-specific (section 13 of O. Reg. 419/05).

As previously discussed, the ESDM report submitted in support of a section 32 request must be refined in accordance with section12 of O. Reg. 419/05.

For the contaminant that is the subject of the request, the ESDM report must contain a review of the contribution and significance of various sources to total emissions and maximum POI concentrations (see also GIASO Chapter 2.4.3 Step 3: Technically Feasible Options are Ranked/Benchmarked). A table summarizing the POI contributions from each source should be included in the ESDM report.

The ESDM report must also contain modelling results that allows for the ranking of technically feasible pollution control options and strategies based on minimizing the maximum POI concentration on a source-by-source basis. An ESDM report submitted under section 32 of O. Reg. 419/05 must include a modelling assessment for all technically feasible pollution control strategies and combinations identified in the Technology Benchmarking Report (see Appendix A of this Guide). It is recommended that this information be submitted as a separate Appendix to the ESDM report. This information on POI concentrations in the ESDM Report can then be used in the Technology Benchmarking Report to rank the technically feasible pollution control strategies and overall pollution control combinations in terms of effectiveness at minimizing the maximum POI concentrations for this contaminant. A separate section or appendix must be included in the ESDM report for each modelling scenario that is required in the Technology Benchmarking Report for the contaminant that is the subject of the request. Information on the frequency of exceedences at both the maximum POI as well as POIs at specified receptors (see subsection 30 (8) of O. Reg. 419/05) must also be included for each technically feasible pollution control combination being considered in the report(s). The significant sources that contribute to the POI concentrations at these other receptors should also be identified. For more information regarding frequency and receptors, please see Part 3.5 Assessing Concentrations and Frequency at Receptors of this Guide and Chapter 4 Factors To Consider When There Are Exceedences of GIASO.

It should be noted that if a request is being made to consider economic feasibility, the ESDM report must include a comparison of the POI concentrations for the existing emission/operating conditions at the facility; the POI that would result from the installation of the best technically feasible pollution control combination identified in the Technology Benchmarking Report; and the POI that would result from the preferred technically feasible pollution control combination based on economic feasibility arguments that are supported by an Economic Feasibility Report (see GIASO, Chapter 2.5 Economic Considerations).

Continuing Requirement to Update ESDM Reports

The submission of the ESDM report to support a request for a site-specific air standard engages the requirement to update and maintain an ESDM report annually as per sections 25 and 27 of O. Reg. 419/05. For the contaminant for which a site-specific standard was approved under section 35, the ESDM report update must include both operating conditions set out in subsection 10 (1) (e.g. actual emissions in the previous year as well as the maximum operating scenario).

3.3.1 Negligible Sources

Chapter 7 Assessment Of The Significance Of Contaminants And Sources of the ESDM Procedure Document discusses sources that need not to be considered in the air dispersion modelling component of an ESDM report – known as negligible sources. Sources may be considered negligible if it discharges an amount of the contaminant that is negligible in comparison to the plant-wide rate of emission giving consideration to the nature of the contaminant. Table B-3A of the ESDM Procedure Document lists specific examples of sources that emit contaminants in negligible amounts (items in Table B3-B may also be considered no significant but require additional information to be provided). Contaminants may also be considered negligible if they are emitted in negligible amounts compared to their applicable ministry POI limits

It is important to note that the ESDM report must identify all sources that emit a contaminant that is the subject of the request whether or not they qualify as negligible sources. To streamline the process of assessing feasible technologies to reduce POI concentrations, negligible sources identified in the ESDM report may be eliminated from the technology benchmarking assessment. Guidance on negligible sources may be found in the ESDM Procedure Document, Chapter 7 Assessment Of The Significance Of Contaminants And Sources. It is also possible for facilities requesting a site-specific air standard to develop their own criteria for determining negligible sources under Chapter 7.3 General Guidance to Identifying Insignificant or Significant Sources and Contaminants of the ESDM Procedure Document. However, any approach that is different than those outlined in Chapters 7.1 Screening-Out Contaminants that are Emitted in Negligible Amounts and 7.2 Screening-Out Sources that Emit Contaminants in Negligible Amounts must be agreed to by the ministry (SDB) prior to finalizing the ESDM report that is to be submitted in support of a section 32 request.

3.4 Technology Benchmarking Reports

All submissions under section 32 of O. Reg. 419/05 must include a technology benchmarking assessment as set out in paragraphs 3 through 6 of subsection 33 (1). This “Technology Benchmarking Report” assesses the technical feasibility of implementing applicable pollution control strategies and pollution control combinations. For more information on the content of this report, please refer to Appendix A of this Guide.

Methods to reduce or control air emissions can vary for different sectors as well as for facilities within the same sector. One of the purposes of a Technology Benchmarking Report is to ensure that the action plan proposed by the proponent represents the best practices available in limiting off-site impacts of a contaminant(s). A Technology Benchmarking Report must demonstrate that all applicable pollution control options have been identified and considered in determining that a site-specific standard is necessary. Organizing information as described in the GIASO five step "top-down" process (see Chapter 2.4 Technology Benchmarking (Risk Control) of GIASO and Appendix A Technology Benchmarking Reports of this Guide) should facilitate the identification of technically feasible pollution control options and combinations and the ministry review process.

To expedite the ministry’s review, it is important to develop a Technology Benchmarking Report that transparently shows and comprehensively justifies the decisions made in recommending a technically feasible pollution control combination that minimizes the POI concentrations from all relevant sources of the contaminant that is the subject of the request. In order to achieve this goal, the following must be considered:

- Ensure that the selected list of technical methods to reduce POI concentrations and air emissions is comprehensive. This list of methods can generally be based upon a review of the technical literature listed in Part 2.3 Information Resources of Appendix A to this Guide as well as GIASO. The Technology Benchmarking Report must identify all technically feasible pollution control options for each non-negligible source. The pollution control options considered are to be categorized as either a material substitution; a process change, or an add-on control.

- The proponent must then identify the possibility of combining technically feasible pollution control options for each source to minimize POI concentrations or emissions from the facility. This combination of options for each source is referred to as a pollution control strategy for each source.

- The assessment of technical feasibility will eliminate approaches that are not feasible for the facility. There are at least two stages of assessing technical feasibility: 1) technical feasibility of available and applicable technologies; and 2) technical feasibility of the combination of pollution control options and strategies for individual as well as multiple sources. Factors that can be considered to assess feasibility can include: availability of technologies or methods; applicability for the facility; and other factors that consider site-specific issues such as: physical restrictions; resource availability; chemical restrictions; engineering principles; and/or significant safety concerns (that cannot be reasonably mitigated).

- The default technically feasible pollution control strategy for each source is a selection of the best material substitution pollution control option plus the best process modification pollution control option plus the best add-on pollution control option assessed for feasibility.

- The preferred technically feasible pollution control combination will assess the technical feasibility of combining the best of each individual technically feasible pollution control strategies to achieve the best technically feasible pollution control combination for the entire facility for all their sources. This final assessment of the feasibility to combine pollution control strategies for multiple source combinations will lead to a list of technically feasible pollution control combinations for the overall site.

- The final ranking of technically feasible pollution control combinations must be based upon minimizing POI concentrations from all sources of the contaminant. O. Reg. 419/05 requires the ranking to be based on modelled POI concentrations. However, if it can be demonstrated that dispersion factors would not vary with the technically feasible pollution control strategies being considered, then an initial ranking of the pollution control strategies for each source based upon emission reduction metrics such as mass of contaminant reduced per unit production or per material throughput may be appropriate

footnote 4 . For more information, please see Appendix A of this Guide, Part 4.1.1 Emission Metrics. - The final ranking of technically feasible pollution control combinations must be based upon the minimization of POI impingement concentrations for the site. If the request for a site-specific air standard does not include an (optional) economic feasibility report, then the best technically feasible pollution control combination is to be selected as the preferred approach: this would be referred to as the preferred technically feasible pollution control combination.

- However, in most cases, if two or more technically feasible pollution control combinations are within 15% of each other in terms of overall maximum POI concentrations, then the proponent may choose between the technically feasible pollution control combinations. For example, if there are two options with POI concentrations within 15% of each other, the proponent may choose the option with the lower cost. The proponent’s proposal must be well documented with a rationale and is subject to ministry discretion and approval. For more information, see also GIASO Chapter 2.4.3.1 Ranking Technically Feasible Options.

O. Reg. 419/05 allows the section 32 Director to approve a site-specific standard request if that a site-specific standard is as close to the standard in Schedule 3 as possible. Subclause 35(1)(b)(ii) of the Regulation refers to this as “the minimum difference necessary”. The Technology Benchmarking Report must be able to support this assessment. In addition, the assessment of the frequency of exceedences at various receptors must also be evaluated for the following options: the existing situation or status quo option; the best overall technically feasible pollution control combination (default option); and the preferred technically feasible pollution control combination (if it differs from the default option). For more information on frequencies, please see Part 3.5 Assessing Concentrations and Frequency at Receptors of this Guide.

The process that leads to the recommended course of action needs to be well documented in the various reports that are required to be submitted in support of a section 32 request for a site-specific air standard. As set out in subsection 34 (3), the proponent must make available to everyone in attendance at the pre-submission consultation meeting, a written copy of the executive summary of the request and an explanation written in language that is understandable to persons without specialized scientific training, of the materials that are to be submitted as part of the request. The proponent must offer to provide a complete written copy of the proposed submission to every person in attendance who asks for a copy (a request for a copy of the material may also be made within 30 days of the public meeting). If a facility is concerned about proprietary information, then, in addition to the original request, a public version of the document without confidential information may be provided to SDB and the local district office for public viewing. The reason that public consultation is required is to give the public an opportunity to review and comment on the request. As such it is of the utmost importance that the material provided to the public is easily understandable and complete in order to achieve the purpose of this portion of the Regulation. For more information on the content, please see GIASO, Chapter 2.6 Stakeholder Involvement.

Sector based approaches

Subsection 33 (1) of the Regulation sets out the requirement for assessing feasible technical solutions. An analysis of all available technically feasible alternatives must be submitted by a facility to support a request for a site-specific air standard. Technology Benchmarking Reports may be developed for a sector (or part of a sector) if the facilities in the sector share common technical challenges in reducing contaminant concentrations. Individual facilities in that sector may then use this Technology Benchmarking Report to support their own individual requests for a site-specific standard with appropriate site-specific modifications (please see GIASO). The report can be used to determine their preferred technically feasible pollution control combination at the site in question. Each facility would also still need to complete the other requirements of a request for a site-specific air standard including an ESDM report. Since each facility will have different dispersion characteristics due to differences in source locations and exhaust parameters, configuration of on-site buildings and property size it will be necessary to prepare an ESDM report for each facility to determine what site-specific air standard will apply to that specific facility.

Pre-submission consultation with the ministry is required for sector approaches. In some cases, a sector may also request a technical standard. For more information on technical standards, please refer to GIASO.

3.5 Assessing Concentrations and Frequency at Receptors

In making a decision regarding a site-specific air standard, the Director will consider receptors and the frequency of exceeding the standard as per subclause (35) (1) (b) (iv) as well as subsection 35 (2) and paragraph 2 of subsection 35 (12) of O. Reg. 419/05. As a minimum, frequency must be evaluated at the maximum POI concentration location as well as at the receptors listed in subsection 30 (8) of O. Reg. 419/05 which include:

- A health care facility.

- A senior citizens’ residence or long-term care facility.

- A child care facility.

- An educational facility.

- A dwelling.

- A place specified by the Director in a notice under subsection 30 (9) as a place where discharges of a contaminant may cause a risk to human health.

A facility requesting a site-specific air standard is required to identify potential receptors and determine the magnitude and the frequency of the exceedence of the standard (see Chapters 2.2.1 ESDM Reports to Support a Request for a Site-Specific Standard and 4 Factors To Consider When There Are Exceedences of GIASO). Only receptors within the modelling domain defined in section 14 of the O. Reg. 419/05 need to be considered.

Subsection 33 (1) paragraph 2 of O. Reg. 419/05 details the following requirements:

- a written statement or contour map that identifies the location and magnitude of the POI concentrations for the scenario that results in the maximum POI concentration for the contaminant(s) where compliance with the Schedule 3 standard cannot be achieved; and

- a written statement of the frequency of occurrence of the exceedences and the magnitude at all the locations set out in subsection 30 (8) of O. Reg. 419/05 as well as at the maximum POI concentration based upon the use of the most site-specific meteorological data in conjunction with an approved dispersion model (see ADMGO for more information on the appropriate use of an approved dispersion model).

For more information, please see subsections 33 (2) and 33 (3) of O. Reg. 419/05.

Generally, the ministry is interested in knowing the following:

- the frequency of exceedence at the maximum POI anywhere off property;

- the highest frequency of exceedence anywhere off property;

- the frequency of exceedence at the maximum POI on the site of a human receptor; and

- the highest frequency of exceedence on a site of a human receptor (or other identified receptor).

The assessment of magnitude and frequency shall be included for various ESDM report operational scenarios including: the existing base case; the default best technically feasible pollution control combination; and the preferred technically feasible pollution combination if it differs from the default option. The assessment of frequency of exceedence for these technically feasible pollution control combinations is important for several reasons including: