10 ways to reduce the risk of barn fire

Learn about practical best management practices to reduce the risk of barn fires. This technical information is for Ontario producers.

ISSN 1198-712X, Published May 2024

Introduction

This fact sheet contains practical best management practices (BMPs) to assist Ontario farmers in reducing the risk of barn fires.

Barn fires are devastating events for Ontario’s farming families to deal with, and the financial and emotional impacts are felt for many years. Using BMPs in the farm’s daily operations will reduce the risk of such a catastrophic event occurring.

The content for this factsheet was developed by a committee comprised of representatives from multiple sectors, including fire protection and response, insurance, university, farm and/or commodity organizations and the Ministry of Agriculture, Food and Rural Affairs (OMAFRA).

The top 10 list is intended to focus on BMPs that can be implemented by a farmer without having to make major changes to building structures or equipment. More detailed information is found in OMAFRA Publication 837: Reducing the Risk of Fire on Your Farm.

1. Focus on housekeeping

Maintaining a clean and organized barn is a simple and cost-effective way to reduce the likelihood of barn fires. Practical actions like removing clutter and properly storing combustible materials can also limit the spread of a fire (Figure 1).

To reduce the risk:

- keep clutter, bedding, hay and other combustibles at least 1 m (3 ft) away from electrical systems

- remove highly combustible materials such as cobwebs and dust from building surfaces and equipment

- regularly sweep up hay, straw and other loose combustibles

- routinely clean fans, grain augers and other motors with compressed air to remove dust and debris

- ensure the barn is a smoke-free workplace and provide an outdoor location as a designated smoking area

- remove debris and clutter from fire exits and outside the building

- remove grass and weeds from outside the barn

- maintain accessible driveways around buildings during all seasons, including in winter

Source: Heartland Farm Mutual, Ontario.

2. Limit the use of temporary electrical equipment

Equipment that is not hard-wired into the electrical system is considered temporary equipment. This equipment may be plugged directly into an outlet using an extension cord (Figure 2), or it could be powered from an external fuel source such as a standby generator. Extended use of temporary equipment can increase the chance of a fire occurring through degraded outlets and extension cords, which can be a source of ignition.

To reduce the risk:

- Use temporary equipment only in an emergency. Monitor temporary equipment regularly during its use

- Do not use extension cords that are damaged or frayed

- Store extension cords out of livestock housing areas to reduce corrosion on the components

- Consider hard-wiring equipment such as fans or heaters

- Keep a 10-lb ABC fire extinguisher within reach when using temporary equipment

Note: An ABC fire extinguisher refers to the class of fire they are designed to extinguish:

- Class A for trash, wood and paper

- Class B for liquids and gases

- Class C for energized electrical sources

Source: Heartland Farm Mutual, Ontario.

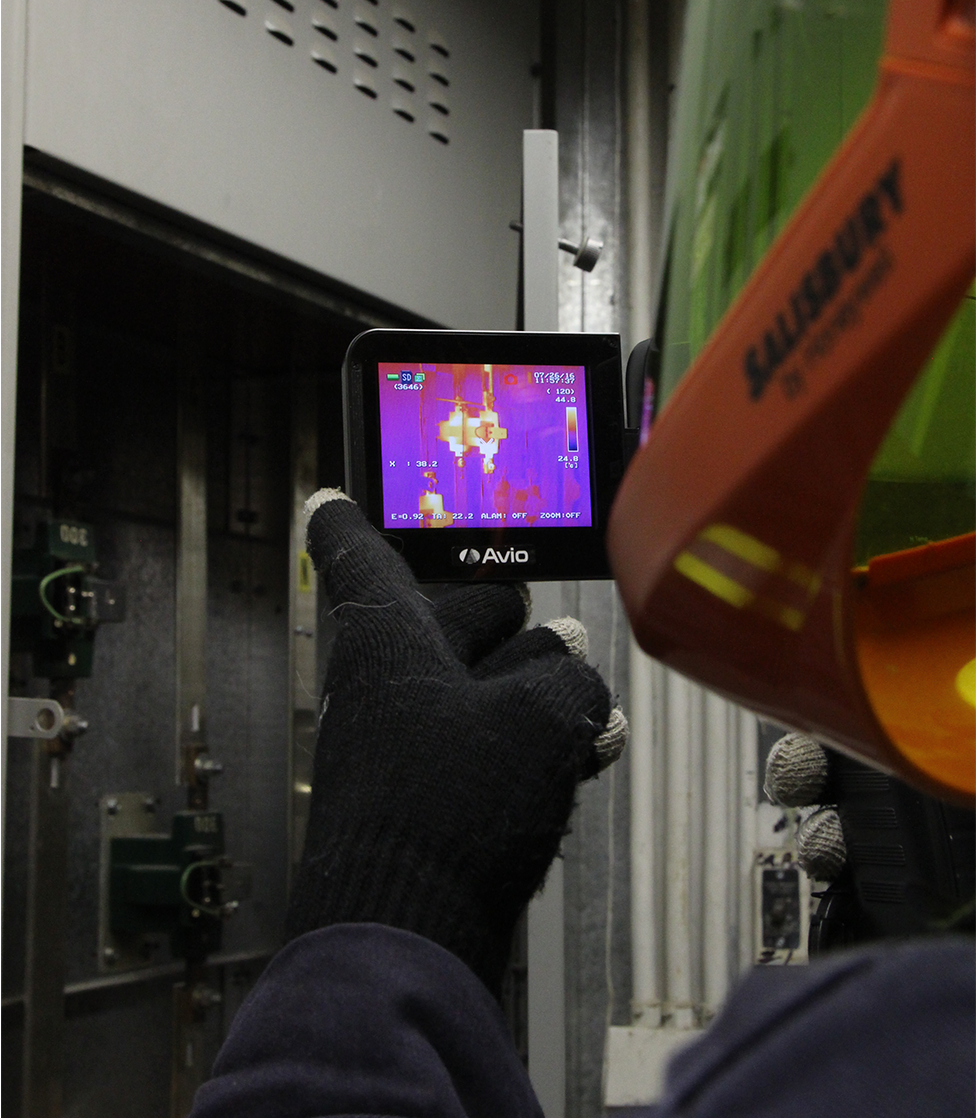

3. Regularly inspect and maintain permanent electrical systems

The permanent electrical system is one of the most vulnerable areas within a livestock barn. The humidity and corrosive gases generated by livestock and the storage of manure degrade the electrical system. The Electrical Safety Code has specific requirements for the installation of electrical equipment within livestock housing areas due to the humid and corrosive environment.

For more information, refer to Section 22-204 and Bulletin 22-3-7 in the Ontario Electrical Safety Code and the OMAFRA fact sheet, Electrical systems in barns.

To reduce the risk:

- ensure electrical equipment in concealed areas (such as within a wall or in an attic) is placed in conduit and junction boxes to prevent damage by rodents

- regularly inspect electrical equipment with a thermal camera to identify equipment that is overheating and needs to be serviced or replaced (Figure 3)

- use equipment that is designed for the humid and corrosive environment of a livestock barn (NEMA 4X). Only replace existing equipment with the correct components for the environment

- consider using arc fault–protected electrical equipment

- maintain permanent equipment such as fans, feed augers or generators according to manufacturer guidelines

- keep combustibles away from electrical equipment

- ventilate livestock buildings at all times, including when no livestock are present, to avoid humid, corrosive or explosive environments

Source: Heartland Farm Mutual, Ontario.

4. Perform hot works safely

Hot works such as arc welding, cutting with torches or grinding (Figure 4) are a common cause of fires, particularly inside farm buildings where combustible materials or manure gases are present.

Sparks falling into under-barn manure storages have caused explosions and fires in Ontario livestock barns. Heating sources such as torches used to thaw out water lines have also been connected to barn fires.

To reduce the risk:

- relocate hot work projects to well-ventilated areas outside buildings, with no combustibles nearby

- have a minimum 10-lb ABC fire extinguisher readily accessible to the hot works location

If relocation is not possible:

- consider replacing the object

- ensure the area is well ventilated to avoid a build-up of combustible gases. Turn on all fans and open all curtains. Consider using a portable exhaust system to provide ventilation to the area.

- remove all combustible materials from the hot works area and place non-combustible pads under the work area (sheet steel or welding mats) to catch any sparks/debris

5. Participate in a risk reduction assessment with insurance or fire departments

Many insurance companies and fire departments offer on-site reviews or risk reduction assessments for farms. These visits help the operator identify potential risks and provide recommendations to address the concerns. The person conducting the risk reduction assessment will often follow a checklist of common fire-related concerns, including storage of combustibles, electrical systems (Figure 5) and sources of heat or sparks.

How to get the most out of a risk reduction assessment:

- Contact the insurance company or local fire department to see if they provide risk reduction assessments.

- Prepare for the assessment by collecting information related to fire protection, risk assessment forms developed by commodity groups (for example, Ontario Pork), ESA inspections and worker training records.

- Review the assessment with the inspector to ensure the results are understood and discuss options for addressing identified risks.

- Develop a plan to respond to the recommendations.

Source: Heartland Farm Mutual, Ontario.

6. Prepare and implement a fire safety plan

A fire safety plan (Figure 6) summarizes how an operation will prevent a fire and the response in case a fire does occur. This type of plan ensures the operation is regularly maintaining safety equipment, avoiding or reducing high risk activities and is prepared to respond to a fire.

Information to include in a fire safety plan:

- identify existing fire prevention equipment and ensure it is regularly inspected and maintained:

- inspect fire extinguishers regularly and replace based on manufacturer recommendations

- regularly operate fire doors to prevent them from seizing or rusting

- test fire alarms twice a year

- inspect fire exit signs and other emergency signage monthly to ensure they are functional and visible at all times

- identify risky activities and how the operation intends to reduce the risk, such as:

- hot works (such as arc welding, cutting or grinding) will be performed in a designated safe area away from combustibles

- combustibles (such as straw or hay) will be stored long term in a separate building away from livestock

- perform regular housekeeping activities in and around buildings

- restrict smoking to designated areas outside buildings

- perform regular inspections and maintenance of wiring and electrical components

- develop a list of contacts to notify in case of a fire:

- police and fire services

- owners of animals housed at the farm

- commodity group (such as Ontario Pork, Dairy Farmers of Ontario)

- local heavy equipment contractors (for example, excavator)

- Spills Action Centre (

1-800-268-6060 ) — notify if substantial animal loss - list of licensed deadstock operators in Ontario

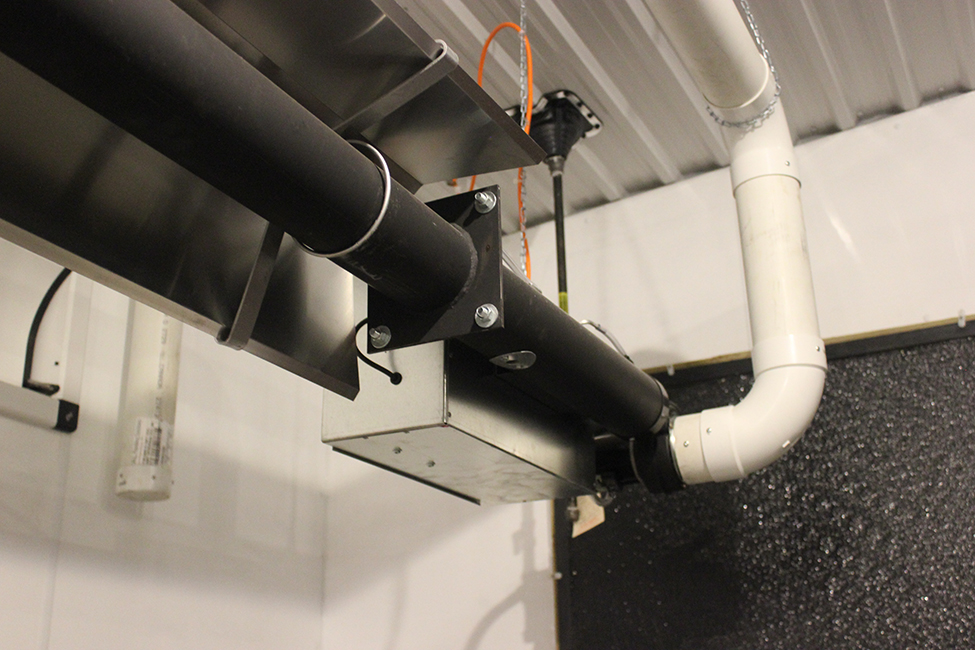

7. Regularly inspect and maintain fire walls, fire separations and attic fire stops

Fire walls, fire separations (Figure 7) and attic fire stops slow down the progression of a fire within a building and increase the time for people within the building to escape. Too often these structural components are compromised, such as by adding openings, which reduce or eliminate their effectiveness.

To reduce the risk:

- determine where fire walls, fire separations or attic fire stops are located in buildings

- if wiring, plumbing or duct work penetrate any fire separation, fire wall or firestop, ensure the space between the material and the object is sealed and caulked with fire-rated materials

- regularly inspect the fire walls, fire separations or attic fire stops for damage by rodents or the humid barn environment

- keep fire doors closed

- operate fusible link doors regularly to prevent them from seizing or rusting

Source: R. Drysdale, Farm Mutual Reinsurance Plan.

8. Regularly maintain heaters

Improperly installed or maintained heaters are a common cause of barn fires. The presence of combustible materials such as bedding and dust in the barn is a contributing factor to fires. Heaters can also be damaged if livestock have access to them.

To reduce the risk:

- consider another heating source that eliminates open flames and other ignition sources

- ensure all natural gas or propane-fired heating appliances (Figure 8) are installed as per manufacturer specifications and appropriate codes (the Natural Gas and Propane Installation Code)

- regularly inspect heat shields to ensure they have not been displaced or damaged

- keep heaters suspended well above combustibles (bedding) or where they can be chewed or damaged by livestock

- suspend electric heaters (heat lamps) using non-combustible materials such as chains

- if necessary, only use temporary heaters designed for agricultural purposes (such as Stelpro GFUHX Agricultural unit heater)

- do not operate heaters in barns with under-barn manure storage unless adequate ventilation is provided to prevent the accumulation of manure gases (for example, to keep methane well below the Lower Explosive Limit (LEL))

Note: The LEL refers to the lowest concentration (percentage) of a gas or vapour in the air capable of producing a flash of fire in the presence of an ignition source (arc, flame, heat). Concentrations lower than LEL are considered too lean to burn.

9. Store and maintain motorized equipment away from livestock

Motorized equipment, such as tractors, produce significant amounts of heat, even after being turned off and stored. This heat can dry debris caught in the equipment and cause the material to ignite. In addition, motorized equipment can develop electrical/mechanical failures that provide additional sources of ignition.

To reduce the risk:

- park equipment in a separate building from livestock housing (Figure 9)

- complete maintenance work, including repairs and oil changes, in a designated building, separate from livestock housing

- regularly clean and inspect engine and exhaust components

- ventilate the equipment storage building to avoid accumulation of fumes

- consider using spark arrestors on equipment exhaust

10. Store combustibles in a designated location away from livestock

Combustibles such as straw or oil provide the fuel to feed a fire. Isolating these materials in a separate area reduces the risk of a fire spreading throughout the barn.

To reduce the risk:

- store liquid fuels (such as jerry cans) in a separate building away from livestock

- protect fuel stored outside with bollards to prevent vehicle impact

- designate a building separate from livestock for long-term storage (more than 1 week) of bedding and feed (Figure 10)

- store oily rags in a fire-proof container

Summary

It is possible to reduce the risk of fire on a farm by implementing these best management practices as part of the routine operating procedures. Simple actions like keeping a clean and tidy environment, properly installing and maintaining equipment, conducting a fire assessment and creating a plan are fire safety best practices.

With attention to detail, fire safety risks to farm workers, emergency responders and livestock can be reduced and the trend of increasing financial losses reversed.

For more information on how to reduce the risk of barn fires, visit Barn fires in Ontario or contact the Agricultural Information Contact Centre at

Author credits

This fact sheet was written by Steve Beadle, P. Eng. livestock structure and equipment - swine and sheep, OMAFRA, Vicki Hilborn, P. Eng., program coordinator, OMAFRA, Dan Ward, P. Eng., poultry and other livestock housing and equipment, OMAFRA, Jason Benn, North Perth Fire Department, Susan Raymond and Gayle Ecker, Equine Guelph, Brent Royce, Farm and Food Care, Jim Zyta, Heartland Farm Mutual and Sam Bradshaw, Ontario Pork.