Artificial rearing of lambs

Learn about strategies for artificial rearing and cautions to ensure the health of lambs. This technical information is for Ontario sheep producers.

ISSN 1198-712X, published August 2021

Introduction

In sheep flocks with orphaned lambs or lambs whose birth mothers have too many lambs to feed, the most natural and economical route is to foster these lambs. Artificial rearing using a commercial substitute for ewe’s milk can be considered when fostering would be difficult or unlikely to be successful. The greatest benefit is the production of additional market lambs that would have been mortalities. Having a system in place to feed and raise these animals efficiently may increase profits and reduce welfare concerns. Additionally, in sheep milking operations, artificial rearing is the primary option, to reduce the lambs’ consumption of marketable milk.

This fact sheet discusses strategies for artificial rearing and cautions to ensure the health of lambs. The key to success is the development of a detailed system that ensures lamb health and uses farm resources efficiently.

Designing an artificial rearing system

Selecting lambs for artificial rearing

When a ewe is identified as not having enough milk for her lamb(s), the lamb(s) should be given supplemental milk or removed from the dam entirely. The preference is to foster, but this may be impossible. Typically, a system must be developed to determine which lamb(s) to remove. The best rule of thumb is to remove the most different one, with size and gender (in order) being the determining factors. For example:

- in a set of female triplets, if two are small, and one is big: remove the largest one

- in a set of quadruplets, two are male and two are female, and one male is tiny: remove him. If the ewe is only capable of raising two: remove both males

Individuals interested in generating replacement ewes should avoid removing the ewe lambs, as comparisons must then be made within the flock on lambs that have had unequal growth opportunities. By the same reasoning, a potential ram should also not be artificially reared.

Colostrum

The single most important aspect of any artificial rearing system is the proper administration of colostrum. Colostrum administration or feeding at birth is the single most critical feeding and management point in the lamb’s entire life. The longer the delay, the poorer the lamb’s ability to utilize the colostrum. Additionally, the ewe’s colostrum quality rapidly drops towards normal milk production within hours of lambing. The immunity passed from mother to offspring is also an opportunity to pass on antibodies from the vaccinations the ewe has received. Proper nutrition of the ewe during gestation will ensure adequate colostrum quality and increase the likelihood of adequate quantities.

Ideally a lamb should receive 50 mL/kg (1 oz./lb) of bodyweight of its own mother’s colostrum, within one hour of birth. Additionally, 150 mL/kg (3 oz./lb) spread over three more feedings within the first 24 hours of life should be provided. This is to promote passive protection of the lamb until its own immune system is functioning. If the ewe has too little colostrum, other options, in order of preference, are:

- pooled ewe colostrum from same flock

- pooled ewe colostrum from another flock (same disease status)

- pooled cow colostrum (use 30% more; feed every five hours to attain one additional feeding in the first 24-hour period)

- artificial colostrum

- any combination of the above

Feeding systems for artificially reared lambs

Various techniques are available for feeding orphan lambs, ranging from a nipple on a bottle to commercially available feeders. Commercial feeders measure and mix the milk replacer on a regular basis. The choice of system will depend on the number of lambs to be reared, individual circumstances and preferences. Regardless of which system is chosen, sanitation is critical.

Limit feeding

For small numbers of lambs, the most practical option is feeding a set amount of milk two or three times per day. Although labour intensive, this approach allows for reduced cost of the milk feeding period and a rapid transition to solid feed and easy early weaning. Either bottles fitted with nipples or nipple pails can be used. What is important is that there is one nipple for each lamb, so that all have an equal opportunity to consume their allotted amount of milk.

Free choice feeding

Most systems designed to handle large numbers of lambs allow lambs to have access to milk at all times. Animals do not require individual attention, which minimizes labour. Various systems from nipple pails to teat bars to commercial units are available. Regardless of the system used for free choice feeding, each nipple can accommodate four to five lambs. The price of various systems is addressed in Table 1.

| Feeder type | Advantages | Disadvantages | Cost |

|---|---|---|---|

| Bottle and nipple |

|

| $2.00–$2.50 |

| Nipple pail |

|

| $30–$70 |

| Teat bar |

|

| $75–$150 |

| Automatic feeding unit |

|

| $2,000–$7,000 |

Nipple pails offer a low-cost, easy-to-clean system. These can be purchased commercially or assembled by fitting the nipple-and-valve assemblies to the outer bottom portion of a bucket. The milk can easily be kept cold by floating a plastic bottle filled with ice in the milk replacer. The main disadvantage is the difficulty in protecting nipples from being chewed by the lambs. Damage to a nipple can result in the loss of all the milk replacer in the container.

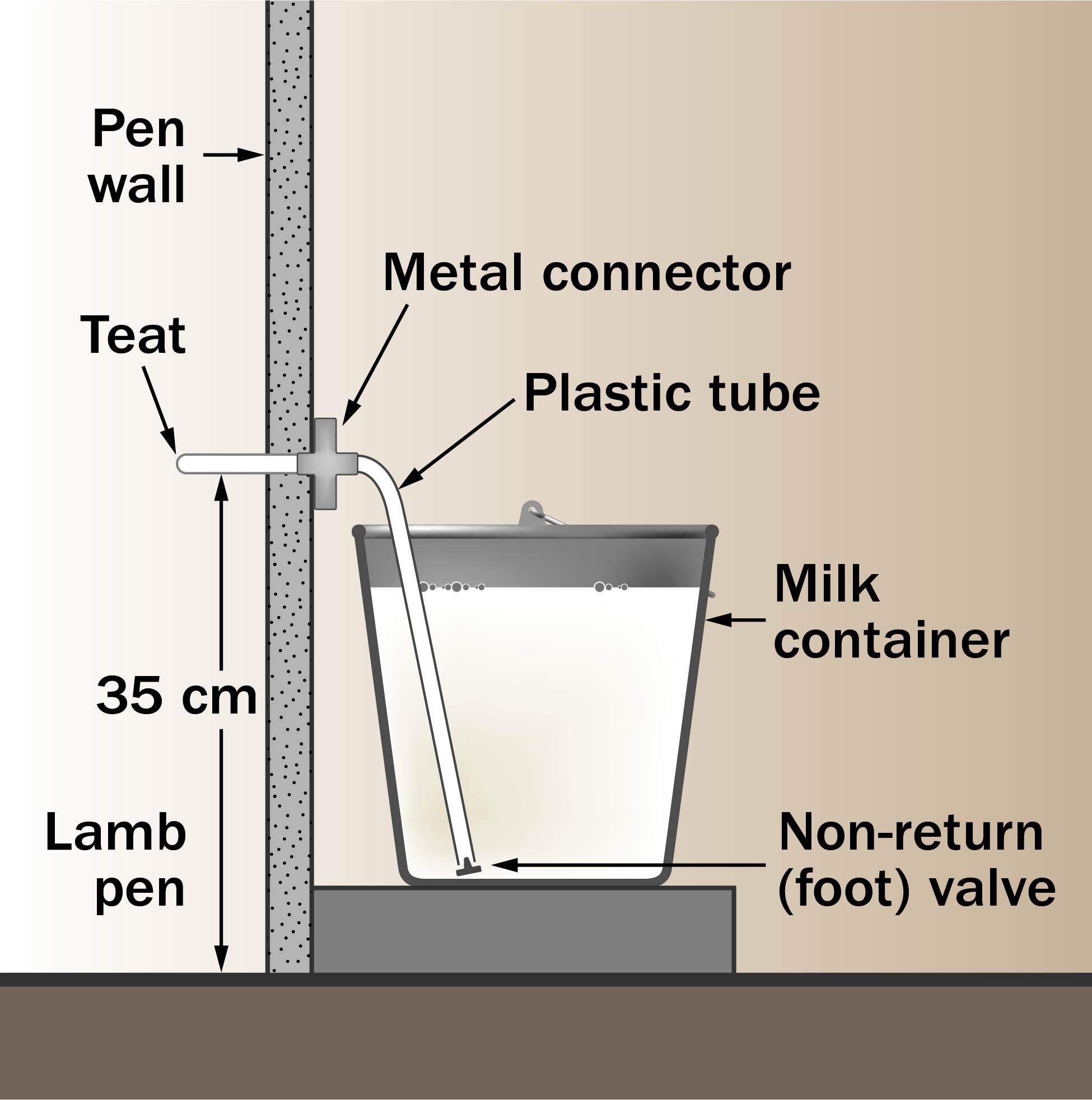

One variation of the nipple pail is to have nipples attached to the pail by a length of hose, as in Figure 1. The nipples are accessible by the lambs inside the pen, while the container holding the milk is outside the pen. This allows the container to be kept below the level of the nipples, so if nipples are chewed, no milk is lost. To ensure all lambs drink from this system, it is important to have the hoses running from the pail to the nipple equipped with a simple non-return (or foot) valve. These types of valve units are available through automotive supply stores (for windshield washers).

Teat bars can be relatively easy and inexpensive to build, as they can be assembled from readily available plastic plumbing supplies. They consist of nipples attached to pipes or tubing through which milk replacer flows by gravity or is circulated by pump from a bulk supply. The milk replacer can be refrigerated or left at room temperature. Nipples should be placed at least 20 cm apart to prevent crowding and a 65° angle will approximate the angle of the ewe’s udder and teats. Having at least six nipples per teat bar will prevent leakage from unused nipples, and nipples must be designed or modified so they do not leak when filled with liquid.

Automatic feeding units that measure and mix the milk powder with water and deliver the milk to the lamb pens are available commercially. They are an option when large numbers of lambs are being raised artificially, such as with dairy sheep operations or very prolific breeds on accelerated systems. These units should be sanitized daily.

Rearing healthy artificially fed lambs

Proper management practices will help avoid abomasal bloat and clostridial infections in artificially reared lambs.

Abomasal bloat

The milk replacer manufacturer’s instructions specify a temperature for mixing to ensure the even distribution of fats in the reconstituted milk. Quite often, once the milk has cooled to about body temperature, it is fed to the lamb or kid. In many cases there will be no problem, but an increasing incidence of abomasal bloat has been reported associated with this practice. In some operations there have been quite significant death losses from abomasal bloat associated with artificial rearing.

The usual history of lamb killed by bloat is that the lamb was fed milk replacer two or three times a day and a considerable volume of body temperature milk was given at each feeding. Within 30 minutes, the abdomen was bloated. Examination suggests that the ballooning is due to excessive gas in the stomach and kills the lamb within a few minutes. At postmortem, the abomasum is grossly distended with reddish areas in the wall and may have ruptured. Small packets of cocci bacteria of the Sarcinia species can be identified under the microscope, which is a common finding in cases of abomasal bloat but virtually never seen otherwise.

The mechanism of this bloat is not fully understood. Sarcinia species bacteria are known to be fermenters and can multiply across a wide range of acidity in the abomasum. A large quantity of warm milk arriving in the abomasum provides an excellent medium for the rapid multiplication of these bacteria. As they multiply, sugars in the milk are fermented with excess gas production. At the same time, the stomach contents become more acidic to the detriment of other bacteria. As the gas cannot escape, it bloats the abomasum, which presses on the other internal organs, notably the heart and lungs. Death is from heart failure as a result of this pressure.

Once the bloat is visible, there are virtually no successful treatments, so prevention is preferred. Occasionally, a lamb has been saved by relieving the bloat with a needle inserted into the abomasum to vent the gas. As the condition is associated with bacterial populations, feeding and storing the liquid below 4°C and ensuring thorough sanitation of milking equipment, will usually stop any further cases. The milk replacer powder still has to be mixed with water at the manufacturer’s recommended temperature, then cooled as quickly as possible in a refrigerator. To the producer, this means preparing the milk one feeding in advance of need (for example prepared in the morning for the evening feeding). Some reports suggest that adding 1.0 mL of a formalin solution (37% formaldehyde) per litre of milk replacer is a preventative.

Clostridial infections

Another problem for the artificially reared lamb is sudden death from enterotoxaemia. Often it is the best growing lamb that is found dead with no previous symptoms. At postmortem, the only lesions to be seen grossly are reddish areas in the wall of the small intestine. There are microscopic changes to be seen in other organs, and tests can confirm the presence of toxins. The causal organism is a bacteria, Clostridia perfringens type D. These bacteria can be present in small numbers in the intestine, but, with the normal speed of movement of the ingesta through the intestine, there are insufficient organisms to cause disease.

In artificially reared lambs, there are three factors that may allow sufficient multiplication of this bacteria to cause death:

- insufficient intake of colostrum; the lamb may not have received adequate antibody for protection.

- ewes not fully vaccinated before lambing; the level of protective antibody in the colostrum was too low.

- lack of movement in the gut; increased numbers of the bacteria were allowed to remain in the small intestine, releasing epsilon toxin.

Increased permeability of the intestine wall to this toxin allows it to spread rapidly through the lamb, to the nervous system and brain. Death can occur in two hours or less, and rarely more than 12 hours after infection.

Where artificial rearing is practised, a vaccination program against this group of bacteria is essential. All ewes should receive the initial primary course of vaccination before they lamb for the first time; two doses, 6 weeks apart, with the last injection at least two weeks before lambing. Ewes should receive a booster vaccination 2–4 weeks before they are due to start each lambing. If the ewe is fully vaccinated against the clostridial group of disease before lambing, antibodies should protect the lamb for 10–12 weeks. As antibody levels can be affected by stress, it is essential that the environment, flock management and nutrition be maintained at the optimum for the pre-lambing ewe and the lambs. Artificially reared lambs can be vaccinated at 4–6 weeks of age and receive a booster vaccination at 10–12 weeks of age.

Feeding guidelines for artificially rearing lambs

Feeding milk replacer to lambs

Milk replacer is a complete and convenient way of delivering nutrients to the lamb. The instructions associated with the product have been developed to ensure animal health and growth. Each detail is the result of observations in the field and research. Follow the manufacturer’s instructions precisely with respect to mixing (temperature and procedure), feeding rates and sanitation.

Mixing: Ensure proper mixing, perhaps by using an electric appliance such as a hand blender. Lumps will contribute to abomasal bloat problems.

Feeding rates: Employ the feeding rates with respect to amount of powder per animal per feeding per day and powder to water ratios. Diluted replacer may contribute to gorging (especially in free choice situations), as the animals are trying to compensate for lack of nutrients. The more frequently small meals are fed, the better.

Sanitation: Ensure feeding and mixing equipment is washed with sanitizing agents (for example dilute chlorine: water, 1:50), to prevent the proliferation of bloat and scour causing organisms.

Chilled milk: Any milk fed free choice should be chilled. Ice packs in the reservoir or keeping milk in a refrigerator may be solutions. Bottle-fed lambs should be fed warm milk, as per instructions with product.

Formalin: Formalin may be added to free choice milk (at 0.1% or 1.0 mL/1 L of mixed milk replacer) to prevent microbe growth, and to help restrict gorging (unpleasant flavour), especially if the milk is not chilled. Some lambs may reject the milk because of the formalin taste.

Automatic feeding units: The design of some units makes following milk replacer guidelines impossible. The mixing may be incomplete, sanitation poor or free-choice milk provided at warm temperatures. This will contribute to abomasal bloat when milk replacer is used. If these units are used, ensure the sanitation, mixing and feeding cycles do not conflict with the product used.

Waste milk feeding rates

Cow or goat milk may be used in the feeding of lambs, when available. One source might be from treated dairy animals whose milk can’t enter the supply chain. One caution is that cow’s and goat’s milk are both lower in fat (energy). This may be compensated for by fortifying the milk with fats or oils and can be accomplished by adding 25–50 mL of corn, canola or coconut oil per litre of cow’s or goat’s milk (1–2 oz./qt). Beef tallow, lard, shortening or butter could also be used, but may cause practical difficulties on account of their high melting point. Ensure that withdrawal times are adhered to for lambs fed milk that has been produced by treated animals. The total daily feeding rate should be no more than 10% of a lamb’s own body weight, and in as many as four feedings per day. Appropriate feeding frequencies at a given age are listed in Table 2. In instances where a range is given, more frequent feedings may give a better result but are not necessary.

| Age | Feed source | Frequency |

|---|---|---|

| 0–24 hr | colostrum | 4–5 times |

| 1–3 days | waste milk or replacer | 3–4 times daily |

| 4–7 days | waste milk or replacer + creep | 2–3 times daily |

| 8–21 days | waste milk or replacer + creep | two times daily |

| 21–35 days | waste milk or replacer + creep or solid feed | consider weaning |

Water

Fresh water provided in bowls will make the animals more likely to utilize feed from troughs and bowls. Clean, fresh water must always be available from one or two days of age onward. At first, this water will be more of a novelty to the animals than actually used but it will ingrain the behaviour of non-nipple feeding.

Solid feed — creep feeding

While lambs are being fed milk or milk replacer, it is imperative to begin providing solid feed. The more quickly lambs can adapt to eating grain or forage, the sooner milk products can be withdrawn successfully. The use of molasses to stimulate intake or older animals to demonstrate trough feeding (mimicking behaviour) are useful to stimulate hard feed intake. This creep feed should be similar to the weaning ration in composition and analysis, in that it must be made of high-quality ingredients, with 17%–20% crude protein. A coccidiostat may be included to control coccidial scours and improve vigour and performance. Commercial creep feed is available, but it may also be prepared on-farm with the aid of your nutritionist. A sample creep ration is given in Table 3.

| Ingredient | Percent of ration (as fed basis) | Ingredient processing | Ingredient attribute |

|---|---|---|---|

| Barley | 35 | rolling, grinding | energy |

| Oats | 35 | rolling, grinding | energy |

| Corn | 8 | rolling, grinding | energy |

| Fish meal | 5 | none | protein |

| Soybean meal | 11 | none | protein |

| Molasses | 6 | heating, mixing | palatability |

| Premix | see Note | none | vitamins, minerals |

| Additive | see Note | proper mixing | lamb health |

Note: Supplemental vitamins and minerals should be included in the ration. If using a premix, use a lamb or sheep mineral (as opposed to beef, dairy) to avoid mineral metabolism complications, such as copper toxicity. Alternatively, trace mineralized salt (“TM 10”) and Vitamin ADE mix (10,000 IU vitamin A activity-per-gram potency) may each be added at 50 g per 100 kg feed.

Note: Therapeutic medications may be given to the lamb through the feed, under a veterinarian’s guidance.

Conclusion

Attention to detail is important when rearing lambs artificially. Following the feeding guidelines, regular monitoring and ensuring lambs are adequately trained to nipple on your feeding system are important. In particular, adequate colostrum, sanitation and early access to creep feed are essential to having a successful system.

Additional reading

Additional information on artificial rearing of lambs can be found in these OMAFRA fact sheets:

- Care of the newborn lamb

- Early weaning of lambs

This fact sheet was originally written by Dr. S. John Martin, veterinary scientist, sheep, goat and swine, Anita O’Brien, sheep and goat specialist, and Christoph Wand, beef and sheep nutritionist, OMAFRA. It was updated by Erin Massender, small ruminant specialist, and Delma Kennedy, sheep specialist, OMAFRA.

Footnotes

- footnote[1] Back to paragraph Five feedings are required in the first 24 hours if cow colostrum is used, to accommodate the requirement of 30% more colostrum.

- footnote[2] Back to paragraph Percent of ration basis can be used to mix 100-lb or -kg batches (for example 35% barley = 35 kg in 100-kg batch). Although oats are recommended to be included, barley may be substituted one for one to replace oats without altering ration analysis. Oat inclusion in the diet should be reduced if any hay is provided, on account of the high fibre content of oats and the possibility to cause “hay bellies.” Corn may also be replaced by barley; this exchange will marginally increase CP levels, and marginally lower energy. Alternatively, corn may also be used in the place of part of the oats or barley in the ration; this will raise energy but lower CP levels of the diet.

- footnote[3] Back to paragraph Fish meal is an expensive protein, so is often not used. The high levels indicated are to help provide a high-quality protein to the lamb’s system, with ease of digestion. Molasses will help mask odour.