Composting of cattle on-farm

Learn about the requirements for on-farm composting of cattle according to the Nutrient Management Act, 2002. This is technical information for Ontario cattle farmers.

ISSN 1198-712X, Published November 2023

Introduction

This factsheet describes some of the requirements for on-farm composting of cattle as described in O. Reg. 106/09 under the Nutrient Management Act, 2002 (NMA). The fact sheet does not cover all composting requirements contained in the regulation or deadstock composting under emergency situations such as after a fire or other catastrophe. For this information, refer to the regulation.

What is composting

Composting is the natural breakdown of organic matter. The decomposition is carried out by micro-organisms, mostly bacteria, but also yeasts and fungi. When temperatures are low, a number of macro-organisms, such as springtails, ants, nematodes, isopods and red wigglers also contribute to the process, as well as soldier fly, fruit flies and fungus gnats. There is a wide range of organisms in the decomposer community.

When composting deadstock, the goal is to destroy the pathogens in the material by composting at high temperatures (55°C and higher). To obtain this temperature, the mixture must contain the right ingredients in the correct balance.

The key ingredients for proper composting are:

- a carbon (C) source

- a nitrogen (N) source

- moisture

- air or oxygen

The quantities and mixing of these components are critical to the success and speed at which the materials will compost or breakdown. Ideal conditions for composting have a C:N ratio of 30:1, 65% moisture and have air mixed throughout the pile. Composting will occur in non-ideal conditions, but the process takes longer, sometimes producing strong odours and causing liquid to leach from the pile.

Composting works best by providing the right growing conditions for aerobic (oxygen-using) bacteria to break down the organic material. If oxygen is not present, composting happens anaerobically — the temperature of the material remains low; the material eventually breaks down over a longer time and produces strong odours.

Composting facilities do not have to be expensive structures. Common methods to contain the compost pile are shown in Figures 1, 2 and 3.

The practice of disposing of animals in the manure storage is not considered composting, however, animals will decompose eventually if disposed of in this manner. With a few alterations to this practice, composting will occur, and the NMA regulations can be met.

Advantages of composting deadstock

Composting is an effective and viable option, as it is:

- uncomplicated, requiring little training

- simple, made with readily available equipment

- relatively inexpensive

- suitable to many locations

- biosecure, since deadstock remain on the farm

The composting process

The animal, when it dies, is usually intact (covered in hide, which retains the liquid and flesh). The animal at this time has an approximate moisture content of 80% and C:N ratio of approximately 6:1. Oxygen is not available except on the external surfaces of the body. Whereas, for composting, the moisture content should be 65%, the C:N ratio should be 30:1 and oxygen should be present. A carcass is not well set up for composting.

To reduce the moisture of the animal, it would have to be dried, which is just not practical. A simple solution is to add dry material and combine the two materials to obtain the proper moisture. This concept is similar to adding straw or shavings to manure to reduce the moisture content.

The next challenge is to increase the amount of carbon in the mixture. This is accomplished by the addition of a material with a high C:N ratio that will allow for an increase in the overall ratio (Table 1).

| Material | % C | % N | C:N ratio | Moisture content | Density |

|---|---|---|---|---|---|

| Sawdust | 56.2 | 0.1 | 511:1 | 39% | 417 kg/m3 (26 lb/ft3) |

| Straw | 56 | 0.7 | 80:1 | 18% | 80 kg/m3 (5 lb/ft3) |

| Corn silage | 43.8 | 1.0 | 44:1 | 65% | 688 kg/m3 (43 lb/ft3) |

| Hay | 42 | 2.1 | 20:1 | 15% | 80 kg/m3 (5 lb/ft3) |

| Wood shavings | 64 | 0.1 | 641:1 | 15% | 80 kg/m3 (5 lb/ft3) |

| Manure (well bedded) | 45.6 | 2.4 | 19:1 | 75% | 800 kg/m3 (50 lb/ft3) |

The ideal method

The moisture and the C:N ratio can be adjusted by the addition of a dry material with a high C:N ratio and mixed together with the animal. However, the animal doesn’t mix well when fully intact. The ideal method is to grind the animal and blend the materials together (Figure 4). Blending increases the efficiency of the composting process but it is not really necessary. The cost of the equipment needed to grind a cow makes a low-cost solution suddenly very expensive.

The practical method

The dead, intact animal goes through various stages of decomposition. An intact animal begins to break down or decompose anaerobically (without oxygen). The process produces odours and gases. There may be foul-smelling liquids draining away from the body as it breaks down. To prevent the escape of these odours, gases and liquids, a cover of organic matter is used as a bio-filter. This bio-filter is the same material used to adjust the moisture and the C:N ratio. Once the initial decomposition of the carcass is completed — a period that can take 1–2 months — mixing the carcass and the substrate is much easier. The initial mixing releases strong odours.

Mixing the pile should break up the carcass and also add the required air to get the composting process really going. A thorough mixing ensures an increased rate of decomposition. Moisture now becomes critical. If the pile is too wet, the material will pack together and not allow enough air in the pile. If it is too dry, the bacteria do not have enough moisture to thrive. High moisture conditions require frequent mixing to keep the pile aerated. Adding water will correct low moisture conditions.

Mix the compost occasionally to allow air to penetrate the pile and keep the process active. Mixing at 2-week intervals in the next month is usually sufficient.

The composting process should continue until the soft material from the carcass has fully broken down and is not visible when mixing. Large bones take longer to decompose. Some operators separate the bones from the finished pile and add them to an active compost pile for further decomposition. This is not necessary if there is no hurry to dispose of the compost pile; this material will eventually break down.

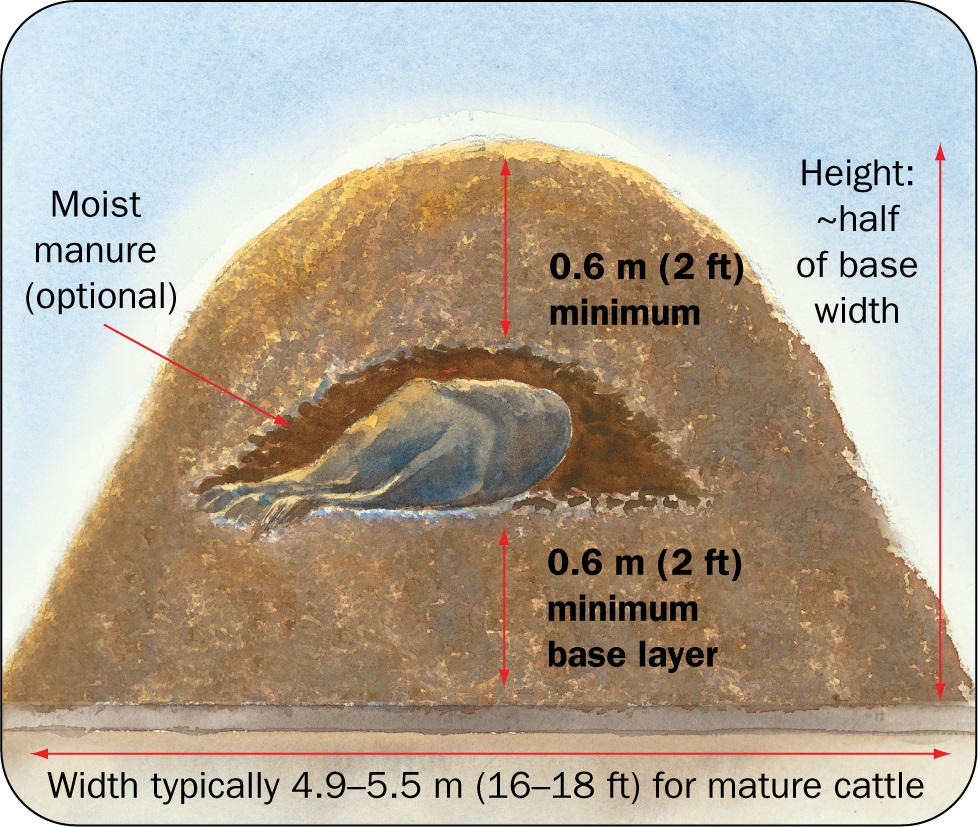

How to build a compost pile

To build a compost pile, first lay down a base layer (straw, sawdust, shavings). It should be at least 4.9 m × 4.9 m (16 ft × 16 ft) for a full-sized animal and have a depth of approximately 0.6 m (2 ft). This material initially absorbs the seepage from the carcass and eliminates moisture escaping from the pile (Figure 5).

Place the animal on top of this base. Using the bucket or spear of the loader when transferring the animal to the pile, cut the hide of the carcass and puncture the intestines to allow easier access for bacteria to begin the composting process. Add material with a higher moisture content around the animal (such as well-bedded manure), then cover the entire pile with the type of material that was used for the base (such as straw, sawdust, shavings). Covering the pile addresses the odour problem and reduces the chance of scavengers finding the carcass.

The choice of material used as the substrate for building the compost pile is usually based on cost. The materials in Table 1 all work well if handled correctly and mixed in the proper proportions. The volume required to cover a cow in a separate pile is approximately 12.74 m3 (450 ft3).

Note that sawdust may pack too tightly and not allow enough air to penetrate the pile. This is corrected by mixing it with hay or straw. Well-bedded manure can also pack tightly and not allow air into the pile. The addition of a dry material such as shavings, hay or straw can reduce the moisture content to the 60–65% range and allow for good aeration.

Recipes for composting

The composting process will progress rapidly if the animals and the selected substrate are mixed thoroughly at the start, which is a difficult and expensive process with large animals. However, composting will take place even if the pile is not mixed thoroughly.

The following recipes give the ratio of ingredients required to build the thick base and cover needed for the initial pile.

Recipe 1

Mixtures of corn silage (may be spoiled) and preferably poor quality hay in a ratio of 3 parts silage to 1 part hay (by volume) make a good substrate for composting. If the hay is chopped and mixed well with the silage, the compost pile will begin heating when built and increase the speed of the composting process.

Recipe 2

A mixture of straw and bedded cow manure with 3 parts straw and 1 part manure also provides a substrate that will compost readily. Again, chopped straw mixed with the manure ensures a speedier composting process.

Recipe 3

For farms using shavings as a bedding material, a mixture of 2½ parts shavings to 1 part manure makes a good base.

Recipe 1 can be used with corn silage and hay as the substrate. Build a cone-shaped pile approximately 4.5 m × 4.5 m (15 ft × 15 ft) at the base and 1.8 m (6 ft) in height. Add the material using a loader in quantities of 3 buckets of silage to 1 bucket of hay until the pile reaches the required dimensions. Mix the resulting pile thoroughly, open up the pile and deposit the animal. Close the pile, making sure the carcass is fully covered with at least 0.6 m (2 ft) of substrate.

Regulated setbacks and separation distances for on-farm composting

In Ontario, all on-farm compost must stay on the farm where it originates because federal regulations prohibit the sale or removal of on-farm composted material containing specified risk material (SRM) from the farm of origin. Wide distribution or sale of on-farm compost is also contrary to the Disposal of Dead Farm Animals Regulation under the NMA.

The Canadian Food Inspection Agency's (CFIA) position, based on a Bovine spongiform encephalopathy (BSE) Risk Assessment completed in 2006, is that SRM compost applied to land constitutes a very low-to-negligible risk with respect to BSE when carried out in accordance with NMA regulations.

The CFIA does not regulate land application of compost generated and remaining on the farm, but recommends that compost produced from SRM not be spread on pasture land or on land directly used to graze domestic ruminants. If SRM has been spread on pasture or grazing land, do not allow ruminants (cattle) access to this land for at least 5 years.

Composting sites may generate some liquid runoff, which presents a potential threat to surface and groundwater. To reduce the potential for nuisance complaints from neighbours and any potential threat to water quality, choose the proper setbacks when locating a compost pile. Table 2 shows the setbacks for composting sites required by the regulation.

| Sensitive area | Setback (m) |

|---|---|

| Highway | 30 |

| Lot line of land on which site is located | 15 |

| Flow path to the top of the bank of the nearest surface water or tile inlet | 50 |

| Field drainage tile | 6 |

| Lot line of land with an industrial or parkland use | 100 |

| Lot line of land in a residential area or from land with a commercial, community or institutional use | 200 |

| Municipal well | 100 |

| Drilled well with depth of at least 15 m and watertight casing to depth of at least 6 m | 15 |

| Any other well (such as a gas well) | 30 |

| Livestock housing facility, outdoor confinement area and residential structure (neighbour's house) located on land not part of the land on which the site is located | 100 |

| Another composting site on the same parcel of land | 100 |

| Areas subject to flooding every 100 years | Not allowed |

| Organic soil or hydrologic soil group AA | Not allowed unless placed on impervious pad |

Troubleshooting compost piles

The composting of whole cattle carcasses is not considered composting until the pile has been turned the first time, the carcass is broken up and the material is thoroughly mixed. The carcass is beginning to break down in the pile (before the first turning) but not under optimal conditions.

This process can produce unpleasant odours. The first time the pile is mixed or turned, the odours may be strong. The actual composting process begins from this stage on if properly managed. Once the pile generates heat, the odours will disappear. Table 3 contains some tips on the causes and solutions of some of the more common problems encountered when composting deadstock.

| Problem | Probable cause | Solution |

|---|---|---|

| Odour or smell is terrible | Material is packed too tightly, and oxygen is limited. | Mix and fluff up pile to allow more air to circulate. |

| Odour or smell is terrible | Composting process has failed to start. | Check ratio of materials. Ensure C:N ratio is correct and moisture is at the right level. |

| Pile fails to heat and maintain temperature | Moisture content is too high, causing packing of material and resulting in a lack of oxygen. | Mix and fluff up pile to allow more air to circulate. |

| Pile fails to heat and maintain temperature | Moisture content is too low for bacteria to flourish. | Add moisture to pile. |

| Pile fails to heat and maintain temperature | C:N ratio too high. Too much carbon and not enough nitrogen. | Add nitrogen in the form of a chemical fertilizer. |

| Material is not decomposing | Pile moisture content is not in the proper range. | Adjust as necessary. |

| Material is not decomposing | C:N ratio is not in the proper range. | Adjust as necessary. |

| Material is not decomposing | Carcass was frozen when put in pile. | Ensure carcass is thawed before putting in pile. |

Conclusion

Successful composting of cattle is possible by following a recipe like those found in this fact sheet. The C:N ratios and moisture contents of the substrate may vary from values given in Table 1, however, the ratios will be in the correct range.

Mixing or turning the pile supplies oxygen to the bacteria and ensures aerobic digestion of the organic material and thus higher temperatures and less odour.

The process requires time for the complete breakdown of the animal carcass. Foul odours may be present during the first turning of the pile but should not be objectionable during subsequent turnings.

The process should be complete after 4 months, with only the large bones still intact. The bones can be added to another composting process for further breakdown.

Learn more about the regulatory requirements for managing on-farm and off-farm deadstock.

Resources

Ministry of Agriculture, Food and Rural Affairs (OMAFRA) Best Management Practices Book, Deadstock Disposal, BMP22E

Disclaimer

The information in this document is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was updated by Dan Ward, P. Eng. poultry and other livestock housing and equipment engineer, OMAFRA. It was originally written by Ben Hawkins, P. Eng., BMP technical integration and transfer specialist, OMAFRA (retired) and reviewed by Bill Groot-Nibbelink, livestock regulatory affairs specialist, OMAFRA.