The effect of production practices on the quality of ginseng roots

Learn research results from trials on the impact of ginseng production practices related to root size and shape, plant stand, harvest date, drying temperature, and root conditioning.

Introduction

American ginseng, Panax quinquefolius, is a high value medicinal herb native to northeastern North America (Figure 1 and Figure 2).It is distinguished from its close relative, Asiatic ginseng (Panax ginseng), by both physical and chemical characteristics. Most commercial production in Ontario is under artificial shade. This Factsheet presents results from research trials conducted at the Agriculture and Agri-Food Canada, Southern Crop Protection and Food Research Centre, Delhi Farm, on the effects of commercial production practices on ginseng’s chemical and physical quality.

Two important measures of ginseng root quality are ginsenoside and polysaccharide content. Ginsenosides are a complex mixture of compounds called triterpene saponins and polysaccharides are a mixture of complex sugars. These chemical compounds are affected in both quality and quantity by the production practices employed by growers.

A number of distinguishing ginsenosides have been identified in American ginseng (Panax quinquefolius) through a chemical analysis procedure called High Performance Liquid Chromatography (HPLC). Ginsenosides have been identified in the roots, stem, leaves and flower heads of ginseng species but only the roots are used commercially. The total amount of ginsenoside concentration varies with species grown and environment.

The ginsenosides consistently associated with American ginseng are: Rb1, Rb2, Rc, Rd, Re, Rg1, Ro; the malonyl-ginsenosides: mRb1, mRb2, mRc, mRd, and gypenoside XVII. One of the distinguishing features of North American ginseng is the absence of ginsenoside Rf which is present in Asian ginseng.

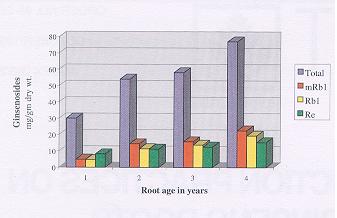

Root age

In the commercial production of ginseng, the total ginsenoside concentration in roots increases with plant age over the four years during which the ginseng is in the ground. (Figure 3). The most pronounced increase (about two thirds) occurs with the ginsenosides Rb1, mRb1, and Re. Total ginsenoside content increases from about 3% in year 1 to about 8% in year 4.

Root age has little effect on the sugar and starch levels of ginseng. Sugar increases in concentration over four years from 3% in the first year to 6% in year four. During this time, starch concentration shows a corresponding slight decrease from about 55% in the first year to about 49% in the fourth year.

Fresh root moisture content in the garden does not change appreciably with age.

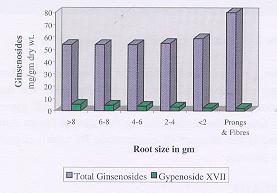

Root size and shape

No difference in the total ginsenoside content of roots between 2 and 8 grams dry weight was observed in research trials (Figure 4). Roots smaller than 2 grams contain slightly more total ginsenosides than larger roots. Prongs and fibres contain the highest concentrations.

Root shape (pencil or bullet) was not found to affect either the individual or total ginsenoside concentration.

Plant stand

Ginseng seed varies in both size and moisture content. One kilogram of seed can contain anywhere from 11,000 and 19,000 seeds (one pound = 5,000 to 8,336 seeds).

Studies have shown that ginseng self-thins over three years to between 80 and 100 plants per square metre (about 10 plants per sq. ft.) and over four years to between 35 and 70 plants per square metre (about 5 plants per sq. ft.) regardless of the initial plant stand in year one.

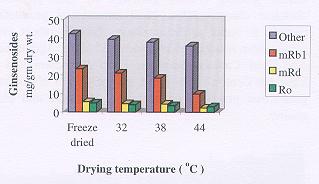

Drying temperature

Optimum drying temperatures for ginsenoside recovery appear to be 32°C to 38°C (Figure 5). The concentration of malonyl ginsenosides decrease if drying temperatures are increased from 38°C to 44°C. Total ginsenoside concentration can be reduced by 26% at a drying temperature of 44°C and by 17% at a drying temperature of 38°C compared to freeze-dried root. Only gypenoside XVII increases at the higher temperature.

Starch hydrolysis (the conversion of starch to sugar) occurs at all of these temperatures during forced air drying of ginseng. More starch is converted to the sugar sucrose when ginseng is dried at 32°C or 38°C than at 44°C. Sucrose is the main sugar found in American ginseng.

Internal root colour darkened as the drying temperature increased from 32°C to 44°C. At 44°C the colour of ground root was darkened to the point of significant reduction in value.

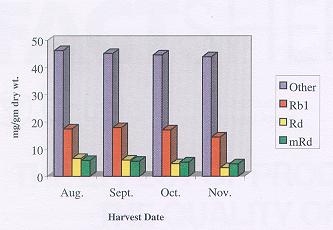

Harvest date

Harvest date does not affect the dry matter content of ginseng roots. Root moisture and dry matter levels did not change between August and November in research trials (Figure 6).

Starch concentration decreases as harvest date is delayed. The formation of sucrose accounts for about 80% of the starch loss. The other 20% results in the formation of other forms of carbohydrates, possibly polysaccharides. This characteristic increase in sugar concentration has been observed in potato and parsnip and serves to protect the root from freezing.

Root colour was slightly darker in root harvested between mid-August and mid-September.

Total ginsenoside levels decline after mid-September and by November may decrease by about 14%. The individual ginsenosides Rb1, Rb2, Rc, Rd, mRd and gypenoside XVII decreased as harvest date was delayed from mid-August until mid-November.

Root conditioning

The greatest impact of post harvest low temperature conditioning prior to kiln drying appears to be moisture loss resulting in surface wrinkling as well as darkening of the surface colour (Figure 7). Roots with this shriveled and darkened exterior appearance have been preferred in the past. After 40 days of low temperature storage at 85% to 90% relative humidity, roots can lose 27% of their original weight (25.5% moisture and 1.5% dry matter). Significant wrinkling does not occur until 20% moisture has been lost.

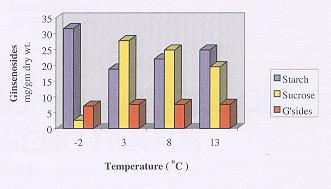

Optimum temperature for post-harvest conditioning appears to be between 3°C and 8°C. At these temperatures there is a small dry matter loss due to respiration of about 1.5% during the first 14–21 days of root conditioning. The dry matter content of fresh root is about 30% but it varies with age. One year old roots have a dry matter content of about 24.9% while four year old roots have a dry matter content of about 30.9%.

The greatest conversion of starch into sucrose occurs between 3°C and 8°C. Extreme conditioning temperatures of -2°C and +13°C decreased the conversion of starch into sucrose. Roots remain alive during the conditioning process (this is why they respire). Past research has shown that roots held at a constant temperature can remain alive at -5°C while temperature fluctuations between -3°C and 20°C caused roots to die. This emphasizes the importance of reliable temperature control.

Total ginsenoside content is reduced by about 7% when root is conditioned at -2°C. Conditioning temperatures between 3°C and 13°C do not affect the ginsenoside content.

Root colour is darkened significantly by exposure to -2°C. Slight darkening occurs at +13°C.

During post-harvest conditioning at 3°C–8°C, roots harvested in August, September and October show a decrease in starch concentration and an increase in sugar concentration during the first 30 days of conditioning. There is no further change in starch or sugar concentrations after 30 days. For roots harvested in November, most of the hydrolysis of starch into sugars has already occurred in the field and additional low temperature conditioning does not result in any further hydrolysis of starch.

The length of post harvest conditioning affects sugar concentration in roots harvested in August, September and October but not in roots harvested in November. Maximum sugar concentration is reached after 30 days of conditioning (except for roots harvested in November). Minimal differences in colour and a slight increase in ginsenoside level (of about 0.6%) occurred within 30 days.