Farm layout for deer and elk

Learn about farm layout designs for raising deer and elk. This technical information is for commercial deer and elk producers in Ontario.

ISSN 1198-712X, Published February 2011

Introduction

The layout of a deer farm must:

- ensure the safety and well-being of the animals

- allow easy movement of the animals between paddocks and from paddocks into the handling facilities without injury or loss

- ensure the animals remain inside the perimeter fence

- be cost effective

- consider plans for future expansion.

First steps

The basic concept of all deer farming systems is similar. However differences arise due to the size and temperament of the various species of deer.

The first step is to identify the species of deer to be farmed and anticipate the future herd size. An efficient plan for the layout of the farm can then be developed. Items to consider include:

- quality and topography of the land

- shape, size and location of paddocks, including holding areas and winter yards

- number of paddocks and gates

- predator-proof fawning/calving paddocks

- raceway to allow movement of animals between paddocks and from paddocks to the handling facilities

- location and design of the handling facility and restraint systems

- water and electrical supply

- feeding and watering systems

- year-round access to storage areas and handling facilities by vehicles and machinery

- shelter

Good design for the handling areas is critical. With advance planning these areas will need minimal change over the years, possibly needing only minor additions for expansion.

With an effective layout, deer may be moved from one area of the farm to another and sorted with minimum stress and injury to either the animals or the handlers.

To prevent escapes, locate the handling facility and loading chute inside, but not abutting, the perimeter fence. A double-gate pass-through area at the main entry gate, which is off-limits to the deer, will also prevent escapes. This area should be a minimum length of 15 m (50 ft), with enough length for a tractor and wagon or truck to pass through and secure the first gate prior to opening the second gate.

With an effective layout, deer may be moved from one area of the farm to another and sorted with minimum stress and injury to either the stock or the handlers.

Land

In general, good productive land results in the lowest cost of production per head. With careful planning the most land possible will be enclosed with the least amount of fence. Do not fence:

- wetlands

- ponds

- streams

- flood plains

- ditches

- areas of heavy snow drifting

- very rocky or hilly land

- wooded areas

Floods and snowdrifts may destroy fences or allow deer to escape. Rocky, hilly and heavily wooded areas are more expensive to fence and generally provide less forage material. In addition, deer will eventually destroy trees that are not protected.

Environmentally friendly practices

- Maintain water quality and prevent erosion by fencing off ponds, rivers, streams and their banks.

- Keep livestock away from watercourses to minimize nutrient loading of the water and to reduce the transmission of parasites to and from wildlife.

- Fence off treed areas to protect and maintain the trees as wind shelters.

Species of deer

Design the layout of paddocks, raceways and sorting and handling yards to meet the specific needs of the deer being raised. For details about fencing see Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) factsheet 97-027, Fencing for deer and elk.

Variations include:

- height and mesh size of wire fences

- height and strength of gates and latches

- size and design of raceway and handling facility

- types of restraint devices to be incorporated in the handling facility

Preventing escapes

The main causes of escape of farmed deer are open gates and inadequate fencing.

Tips to prevent escapes

- Use recommended fencing only.

- Regularly inspect and maintain the fences.

- Lock all exterior gates and ensure all interior gates are secured.

- Build a pass-through with double gates at the main entry to allow easy, yet secure, access for trucks, tractors, etc. This area should be long enough to permit a tractor and wagon or truck to pass through and close and secure the first gate before opening the second gate, thus reducing the opportunity for escape.

- Place handling facilities within, but not abutting, the perimeter fence.

- Ensure the handling facilities' fences and walls are high enough to discourage jumping. Deer are most likely to attempt to jump fences leading up to or in the handling facility.

- Keep deer in central-interior paddocks during the winter, in the event of snow drifting along perimeter fences.

- Fence off ditches, creeks and rivers.

What to do if deer escape

- Ensure that the rest of the herd is safe and secure.

- Identify and resolve the cause of the escape.

- Entice the animals back calmly and quietly, using feed to attract them to an entrance into a paddock.

- Notify the Ministry of Natural Resources (MNR), Canadian Food Inspection Agency and surrounding landowners.

- See the Recovery protocol for escaped or released farmed deer and elk. This document outlines the required actions and reporting responsibilities and is available from MNR or OMAFRA.

- See OMAFRA Factsheet Best management practices: for recovering escaped or released farmed deer or elk.

- Obtain a tranquilizer gun and drugs from your veterinarian if necessary.

- Once the deer are back, isolate them for observation.

Paddocks

The number and size of paddocks should reflect the projected number of deer at full capacity. Plan an adequate number of paddocks to hold and sort the deer as required throughout the year. Consider the following:

- different ages and sexes have different nutritional needs

- males of breeding age will fight and damage fences if they are in adjacent paddocks during the rut (breeding season)

- building separate paddocks for:

- various breeding groups

- for non-breeding males

- fawning/calving

- newly weaned fawns/calves will try to reunite with their dams. Make sure their paddocks are properly fenced or are as far away as possible from their dams

- a rotational grazing system requires a series of paddocks of 0.6-2 ha (1.5-5 ac) each

- holding paddocks for either sick animals, or for sorting purposes, should be located close to the handling facility for easy access

- if possible site the paddocks close to the house so deer become accustomed to humans

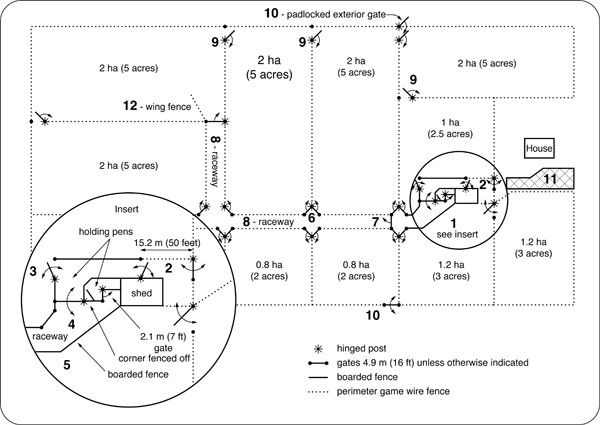

Paddocks can be many shapes: rectangular, square or pie-shaped. Partial fences, known as wing fences, (see feature 12 in Figure 1), funnel deer towards the gates. This works well in rectangular or square paddocks, particularly for fallow deer.

Raceway

A raceway links all paddocks to each other and to the handling facility. Ideally each paddock needs at least one gate that provides direct access to the raceway. But if this is not possible, then access to the raceway can be obtained through an empty paddock.

Locate the raceway gates to allow as much flexibility as possible when moving deer. Stop gates (see feature 7 in Figure 1) are useful to prevent deer from breaking back or from going in an unintended direction. Gateways placed at an angle to the fence, rather than parallel to the fence will make for easier access for equipment (see feature 6 in Figure 1).

The raceway must be wide enough, usually 5-10 m (16-33 ft), to allow movement of machinery, feed and deer to all paddocks and the handling facility, even when snow drifts become a problem.

When being herded, deer like to move around corners and out of sight of their handlers. Incorporating gentle bends and turns in the raceways allows the deer to do this. If possible, avoid building straight raceways that are longer than 100 m (330 ft).

A turn from the raceway into the handling facility, as well as a visual barrier of solid wood or wood battens in these areas, will reduce the likelihood of deer running into the fences or gates while under pressure. Gradually narrowing a very wide raceway as it approaches the handling facility improves handling.

Deer can leap over very high barriers, particularly if given a downhill run. Avoid placing a gate from the raceway into a handling area at the bottom of a hill as stress could cause them to jump over the gate or fence.

Features of figure 1:

- handling facility within, but not abutting, the perimeter fence (enlarged in the insert)

- double-gate pass-through at main entry

- option to take equipment directly into the field without using the raceway

- turn into handling facility from the raceway

- boarded or slatted fence in the last 10-20 m (33-66 ft) of raceway and around the handling facility

- angled gate entrances to give maximum manoeuvrability

- stop gate in the raceway

- raceway width 5-10 m (16-33 ft)

- gates between paddocks

- locked gate on the perimeter fence to facilitate recovery of escaped deer

- driveway

- wing fence to help funnel deer towards raceway

Handling facility

A facility for sorting and handling deer increases the speed and ease of doing routine management and veterinary procedures such as applying ear tags, vaccinating, weighing and removing velvet antler.

A site where water and electricity are available, and that is well drained to allow for year-round use, is essential for the handling facility. Level ground simplifies construction of fences and gates.

The key elements of the handling facility are holding and sorting pens, a covered area equipped with a work area and a restraint device (squeeze), and a ramp for loading/unloading animals.

A covered shed will be more comfortable to work in and has a calming effect on the deer. It can be quite small if enough sorting and holding pens are located in close proximity.

Access of vehicles and machinery

Vehicles and machinery with trailers or wagons must be able to move easily into and around paddocks, raceways and storage areas. Gates must be conveniently located and be wide enough to allow machinery to get through comfortably.

Vehicles must also have year-round access to the loading/unloading ramp. Installation of two or three different heights of hinge pins on the gatepost allows for raising the gates when snow becomes packed around the gateways.

Water, feed and shelter

The layout of the farm must include a plan for feeding and watering the deer, and for providing shelter.

Year-round access to clean water in each paddock is essential. Frost-free water hydrants or heated water bowls are some of the essential equipment.

Installing grain troughs on the inside of the fence adjoining the raceway is an easy method of feeding deer while ensuring owner safety, since deer can be dangerous, especially during the rut and calving seasons. Another option is to put the grain feeders inside each paddock. Paddocks should also have hay or other forage feeders to provide supplemental forage during periods when pasture is not available. When entering a paddock take measures to ensure personal safety and always have an escape plan.

Deer need access to natural or constructed shelter areas that provide protection from weather extremes. Simple shelters provide wind protection and will reduce undue stress on the deer. Keep in mind that although wooded areas provide shelter, the deer will eventually destroy the trees.

Summary

It is important to have a plan before the first fence post is installed to ensure a workable and efficient deer farm layout and handling facility is developed.

Established deer farmers are great resources. Take the time to learn from their experiences by visiting existing facilities. Invite the farm operator to see your farm and to offer advice based on your situation.

This factsheet was written by Brian Tapscott, Alternative Livestock Specialist, Elora, OMAFRA.