A Guide to Using the Approved Model When Submitting a Modified Generic Risk Assessment

A step-by-step guide for using the Approved Model when submitting a modified generic risk assessment (MGRA) to the Ministry of the Environment and Climate Change for review.

Standards Development Branch

Ministry of the Environment and Climate Change

PIBS # 8450e

« Cette publication hautement spécialisée n’est disponible qu’en anglais en vertu du règlement 441/97, qui en exempte l’application de la Loi sur les services en français. Pour obtenir de l’aide en français, veuillez communiquer avec le ministère de l’Environnement au 416 327-6949. »

Disclaimer:

It should be noted that any description of the legislative and regulatory requirements given in this Guide is for convenience only. A copy of the relevant legislation and regulations should be obtained to determine the exact requirements, and a lawyer should be consulted on questions about the application or interpretation of them.

Prepared by:

Ontario Ministry of the Environment and Climate Change

Standards Development Branch

Toronto, Ontario, Canada

Original Publication Date: April 2011

Last Updated: September 2016

For more information:

Ministry of the Environment and Climate Change

Standards Development Branch

7th floor, 40 St. Clair Avenue West

Toronto, Ontario, M4V 1M2

Website: Ministry of the Environment and Climate Change

PIBS # 8450e

© Queen’s Printer for Ontario, 2016

1. Introduction to Modified Generic Risk Assessment

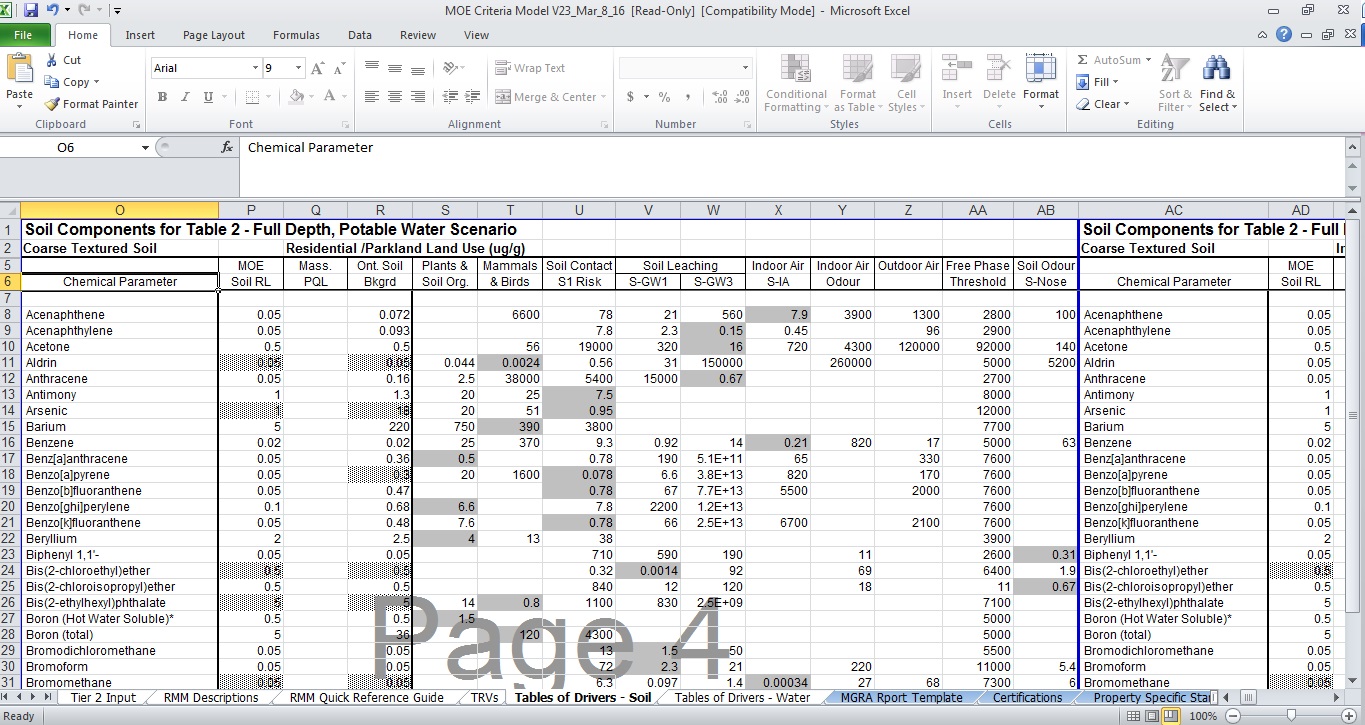

The Modified Generic Risk Assessment (MGRA; also referred to as “Tier 2”) provides a streamlined approach for developing property specific standards (PSS) under Ontario Regulation 153/04 (Records of Site Condition (RSC) – Part XV.1 of the Act), made under the Environmental Protection Act (the Regulation). This streamlined process uses the “Approved Model,” which is based on the model (a system of interconnected Excel spreadsheets) that was used to develop the generic site condition standards (Soil, Ground Water and Sediment Standards for Use Under Part XV.1 of the Environmental Protection Act - dated April 15, 2011).

The Approved Model enables a Qualified Person (QP) entitled to prepare or supervise a risk assessment (QPRA, as described in section 6 of the Regulation) to develop PSS quickly and easily. The Approved Model permits users a limited ability to modify physical site characteristics (e.g., distance to surface water body), modify certain pathways (e.g., ½ solubility and S3 for subsurface workers) supported by analytical results/data and opt into risk management measures (RMMs) (e.g., surface capping), which are developed by the Ministry of the Environment and Climate Change (ministry). For these reasons, the ministry provides a streamlined process for acceptance of PSS that are developed in risk assessments (RAs) that rely solely on the Approved Model.

2. Introduction to the User Guide for the Approved Model

The following is a suggested step-by-step guide for using the Approved Model when submitting an MGRA to the ministry for review. The updated Approved Model is available on the ministry’s website, and is dated (September 2016).

Although the Approved Model is relatively user friendly, there are some aspects for which guidance may assist the user considerably in generating the appropriate PSSs.

This User Guide assumes that a QP has already conducted or supervised and completed the phase one and two environmental site assessments (ESAs) in accordance with the requirements of the Regulation. Any work needed to modify an assumption within the model must be done in accordance with the Regulation (i.e., sections 41, 42 and Table 4 of Schedule E), and must be completed before the MGRA is submitted. The Approved Model may be used at various stages of an RA for other purposes, such as project planning.

2.1 New Features Introduced in Version 2

The Approved Model was first published for use in RAs in July, 2011. Users could modify 11 site specific parameters (e.g. distance to down-gradient surface water body, depth to highest annual water table, fraction of organic carbon, etc.). Specific phase two ESA work must be carried out (Schedule E, Table 4) to support modifying these parameters from the default values. Users could also opt into six (6) RMMs [three (3) caps and three (3) building restrictions] in order to develop higher PSSs, which would still provide the same protection for human health and the environment as the generic site condition standards (generic standards). Two (2) pathway modifiers (modified ecological protection and soil vapour screening levels) were also available in the original Approved Model.

In the years since the Approved Model was first published, the ministry has worked closely with a technical advisory body made up of experienced environmental professionals and industry representatives in order to develop new model features to promote more efficient brownfield redevelopment while maintaining the protection of the environment and human health. Version 2 is designed to allow a greater number of sites across the province to qualify for this streamlined RA process. These changes provide a greater number of options for modifying component values, make the model more user friendly, correct errors in the model discovered since the model was first published, and update the model to reflect current science while continuing to provide the same level of environment and human health protection.

For a summary of the effects of all Approved Model options now available, please see the following table.

| Name of RMM or Pathway Modifier | Effect of Pathway Modifier/RMM on Component Values | Requirements & Precluding Conditions | Applicability I/C/C | Applicability R/P/I (General) |

|---|---|---|---|---|

| Modified Ecological Protection (MEP) Pathway Modifier | Uses industrial values × 1.9 for plants and soil organisms (PSO) and 1000 × for mammals and birds (M&B) | Need to include statement in RSC that MEP is being used. | Yes | Yes |

| Shallow Soil Cap Barrier RMM (>50 cm) |

| Limited to I/C/C sites only | Yes | No |

| Fill/Hard Cap Barrier (1.0 metre or specified greater thickness) RMM |

| None | Yes | Yes |

| Modified Subsurface Worker Protection Pathway Modifier | Multiplies S3 by 100 × (if leachate comparisons meet criteria for any inorganic contaminant of concern (COCs)) | Cap must have a thickness of 1.5m. Complete the relevant part of the MGRA section in the RA Pre-Submission Form; For inorganic COCs: requires leachate testing for some COCs Must have HASP | Yes | Yes |

| Building with Storage Garage (intermittent 3.9 L/sec) RMM | R/P/I Property Use (Developmental COC): Multiplies S-IA and GW2 by 12× for Trichloroethylene (TCE) and by 2× for other developmental COC | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (intermittent 3.9 L/sec) RMM | R/P/I Property Use (Non-Developmental COCs): Multiplies S-IA and GW2 by 200× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (intermittent 3.9 L/sec) RMM | I/C/C Property or First Storey Use (Developmental COC): Multiplies S-IA and GW2 by 6× for TCE | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building with Storage Garage (intermittent 3.9 L/sec) RMM | I/C/C Property or First Storey Use (Non-Developmental COC): Multiplies S-IA and GW2 by 50× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building with Storage Garage (continuous 3.9 L/Sec) RMM - | R/P/I Property Use (Developmental COC): Multiplies S-IA and GW2 by 200× for TCE and by 30× for other developmental COCs | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (continuous 3.9 L/Sec) RMM - | R/P/I Property Use (Non-Developmental COCs): Multiplies S-IA and GW2 by 200× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (continuous 3.9 L/Sec) RMM - | I/C/C Property or First Storey Use (Developmental COC): Multiplies S-IA and GW2 by 30× for TCE and by 7× for other developmental COCs | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building with Storage Garage (continuous 3.9 L/Sec) RMM - | I/C/C Property or First Storey Use (Non-Developmental COC): Multiplies S-IA and GW2 by 100× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building with Storage Garage (continuous 10 L/sec) RMM- | R/P/I Property Use (Developmental COC): Multiplies S-IA and GW2 by 200× for TCE and by 70× for other developmental COCs | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (continuous 10 L/sec) RMM- | R/P/I Property Use (Non-Developmental COCs): Multiplies S-IA and GW2 by 200× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | No | Yes |

| Building with Storage Garage (continuous 10 L/sec) RMM- | I/C/C Property or First Storey Use (Developmental COC): Multiplies S-IA and GW2 by 70× for TCE and by 15× for other developmental COCs | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building with Storage Garage (continuous 10 L/sec) RMM- | I/C/C Property or First Storey Use (Non-Developmental COC): Multiplies S-IA and GW2 by 200× | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2). If there is a Storage Garage occupying the First Storey of the building, it cannot be double counted as both a “Building with No First Storey R/P/I Use RMM” and a “Storage Garage RMM” | Yes | No |

| Building Prohibition RMM |

| Cannot be combined with other building related RMMs; Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2) | Yes | Yes |

| Passive Soil Vapour Intrusion Mitigation System (SVIMS) RMM | Multiplies S-IA and GW2 by 100× | Limited to I/C/C with slab on grade built form; Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2) | Yes | No |

| Active Soil Vapour Intrusion Mitigation System (SVIMS) RMM | Multiplies S-IA and GW2 by 200× | Limited to R/P/I (with Property Management Oversight), and to I/C/C; Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2) | Yes | Only with Property Management Oversight as defined by the CPU |

| Building with No First Storey Residential, Institutional or Parkland Use RMM | Uses I/C/C S-IA and GW2 values | No R/P/I property use on first storey of building; No Industrial property use at the site; If the building also includes a basement or storage garage, the depth to ground water used in the model should reflect post-development conditions; Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2) | Yes | Yes |

| Soil Vapour Screening Level (met for soil source) Pathway Modifier | Multiplies S-IA by 1000× | Table 4 Sch. E requirements for Environmental Site Assessment (ESA) | Yes | Yes |

| Soil Vapour Screening Level (met for ground water source) Pathway Modifier | Multiplies GW2 by 200× | Table 4 Sch. E requirements for ESA; Complete the relevant part of the MGRA section in the RA Pre-Submission Form (re: modifying GW2) | Yes | Yes |

| Building with Minimum First Storey Ceiling Height Requirement RMM | Based on height of first storey, dilution factor for building (proportional to ceiling height); Example: 2 × S-IA & 2 × GW2 (for a building whose 1st storey is 2 × as tall as the default) | Limited to I/C/C | Yes | No |

| No Ground Water Use RMM | Uses non-potable component values (CVs); Example : Table 3 (non-potable) CVs replace Table 2 (potable) CVs | Complete the relevant part of the MGRA section in the RA Pre-Submission Form (requires pre-consult with District Office) | Yes | Yes |

| Modify Solubility Pathway Modifier | PHC F2 Solubility CV: 150 µg/L → 2,500 µg/L PHC F1 Solubility CV: 1,900 µg/L → 27,000 µg/L. | Complete the relevant part of the MGRA section in the RA Pre-Submission Form; See guidance in Appendix 6 | Yes | Yes |

Note: Where the RA includes use of the Passive SVIMS or the Active SVIMS RMM, as applicable, the RA should include a statement indicating that a Licenced Professional Engineer knowledgeable in the design and operation of such soil vapour intrusion mitigation systems has reviewed the requirements of these RMMs in the context of the conditions of the Property and agrees that the SVIMS RMM to be used can be properly implemented at the Property.

2.2 New MGRA Report Template Introduced in Version 2

A new MGRA Report Template has been added into the Approved Model (Excel spreadsheet) for Version 2. Adding the template tabs directly into the Approved Model means that many of the tables summarizing model inputs and outputs are now auto-populated by the model, once the QP has selected COCs, inserted site specific characteristics, RMMs and pathway modifiers. This new template was created in order to streamline reporting by the QP and reviewing by the ministry. To visually locate the tabs more easily, the tabs are highlighted blue.

2.2.1 MGRA Report Template Organization

The new MGRA Report Template is broken up into several tabs (identified by blue shading):

- “MGRA Report Template” tab contains most of the fixed text previously included in the Word version of the template. There are several instances of bright green shaded cells meant for QP input (e.g., Checklist of Mandatory Appendices and Supporting Documents; current property use field). This tab maintains section numbering that corresponds to the headings and requirements contained in Schedule C, Table 1 (Mandatory Requirements for RA Reports).

- Certifications tab for printing and signing by the QP.

- Property Specific Standards tab through to RMM tab: these tabs include numbered tables corresponding to the sections in the “MGRA Report Template” tab. Wherever possible, the values in these tables are populated automatically by the model. There are also bright green shaded cells that are for direct user input, and paler green shaded cells that have pull down menus that pop up when the arrow on the right side of the box is clicked.

2.2.2 Printing of the RA Report and Supporting Documentation

Now that the MGRA Report Template has been incorporated into the Approved Model, there is no need to print out the Tier 2 Input tab as part of the MGRA submission.

The proponent should provide, as part of the RA submission, the following items electronically:

- Approved Model (including all site specific inputs and MGRA Report Template tabs completed by the QP).

- RA Pre-Submission Form.

The proponent should provide, as part of the RA submission, the following items in hard copy (4 copies):

- Report cover page.

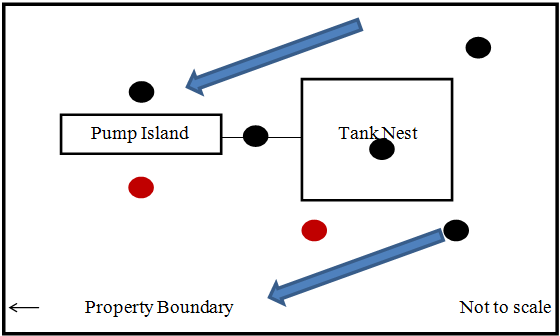

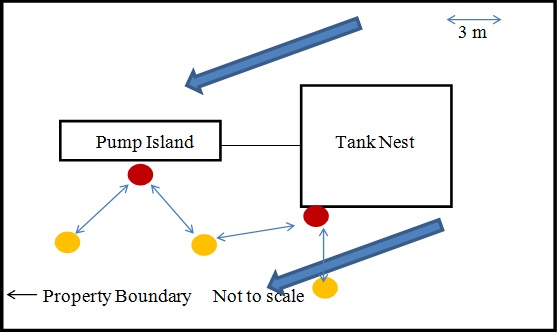

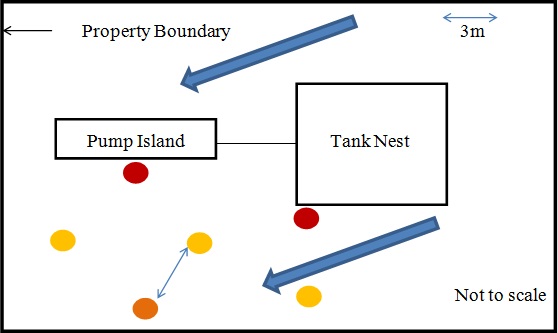

- Phase two conceptual site model (CSM).

- RA Pre-Submission Form signature page(s).

- MGRA Report Template certifications tab (with QP signatures).

The complete MGRA submission should be mailed to the ministry.

2.3 Amending the Approved Model

The amended version of the Approved Model came into effect September 2016 [method: Decision Notice Posted on the Environmental Registry]. The original version of the model will remain publicly available to view, but not to use.

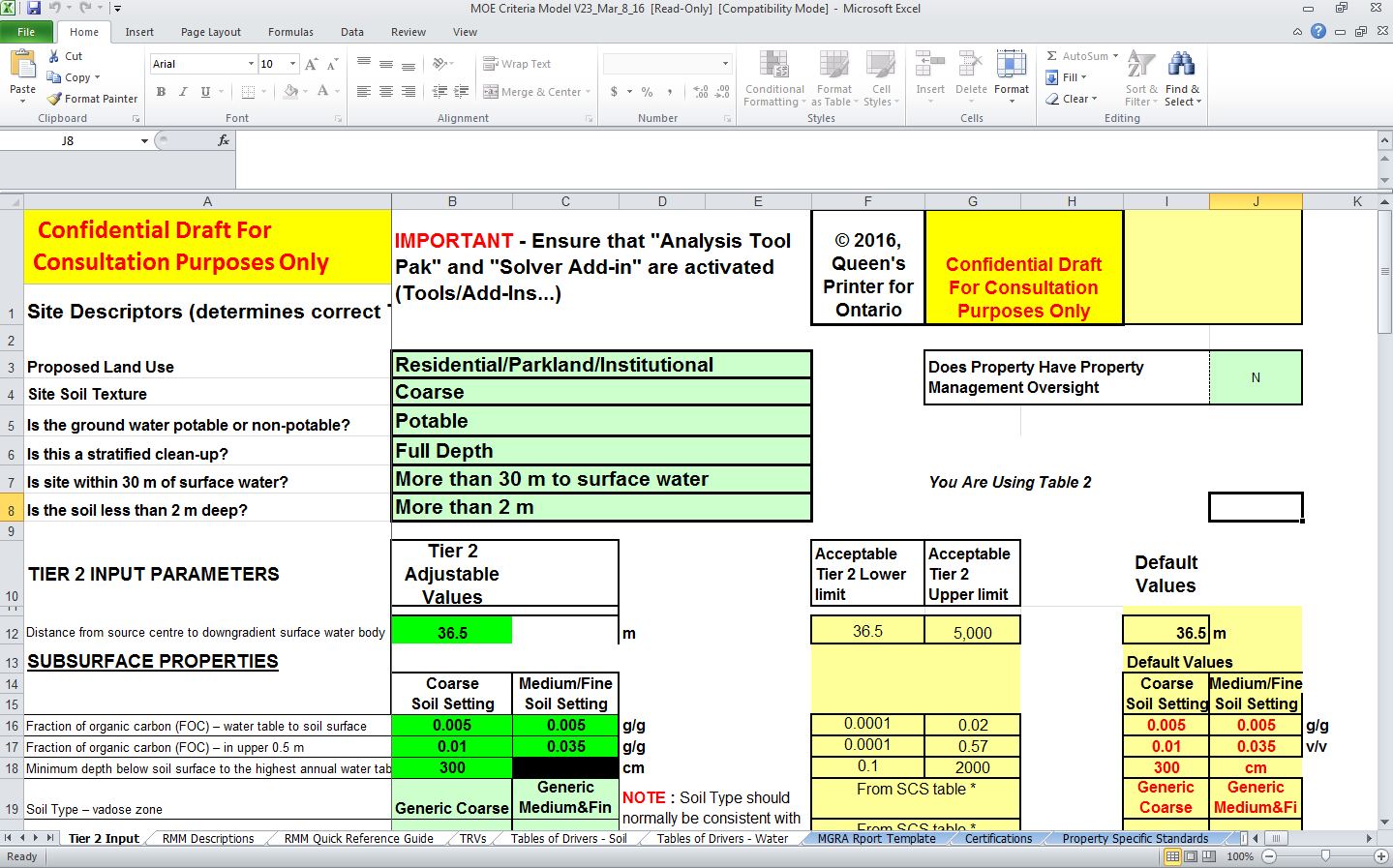

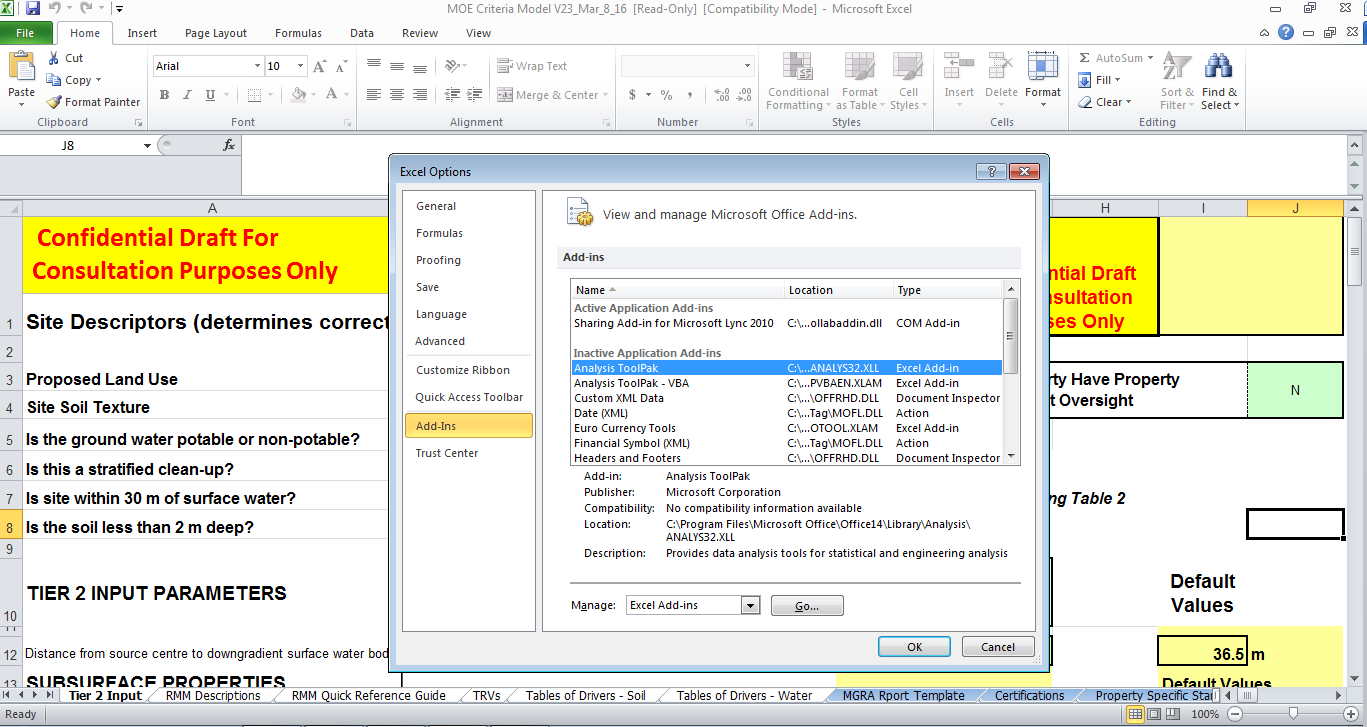

3. Downloading and Setting up the Model

The “Approved Model” can be downloaded from the Brownfields redevelopment website. The model is designed to work on Microsoft Excel 2003 (or later). Note that the print screen from this user guide is based on the Microsoft Excel 2010 version. The ministry cannot assure users that results from its use on other programs will be the same as those produced by Excel.

** Be sure that “Analysis Tool Pak” and “Solver Add-in” are installed in Excel

- Go to File → Options → Add-Ins (or in earlier versions of Excel: Tools → Add-Ins), then check the appropriate boxes, and click ok

** Also be sure to click the “Enable Content” box in the yellow security warning band at the top of the workbook when it opens.

4. Running the Model and Selecting Model Options

In the following sections you will find a sequence of steps that follows a progression from less to more complex MGRAs. For example, the least complex MGRAs change only measurable parameters such as the distance to the nearest surface water body, and do not require RMMs and are discussed first. More complex MGRAs can combine changes in site specific parameters, RMMs, and additional site investigation to support pathway modifiers. Once you are familiar with the model, you likely wouldn’t use the model in this step-wise fashion, but when you are learning the model’s features, it’s helpful to add layers of complexity in a logical way.

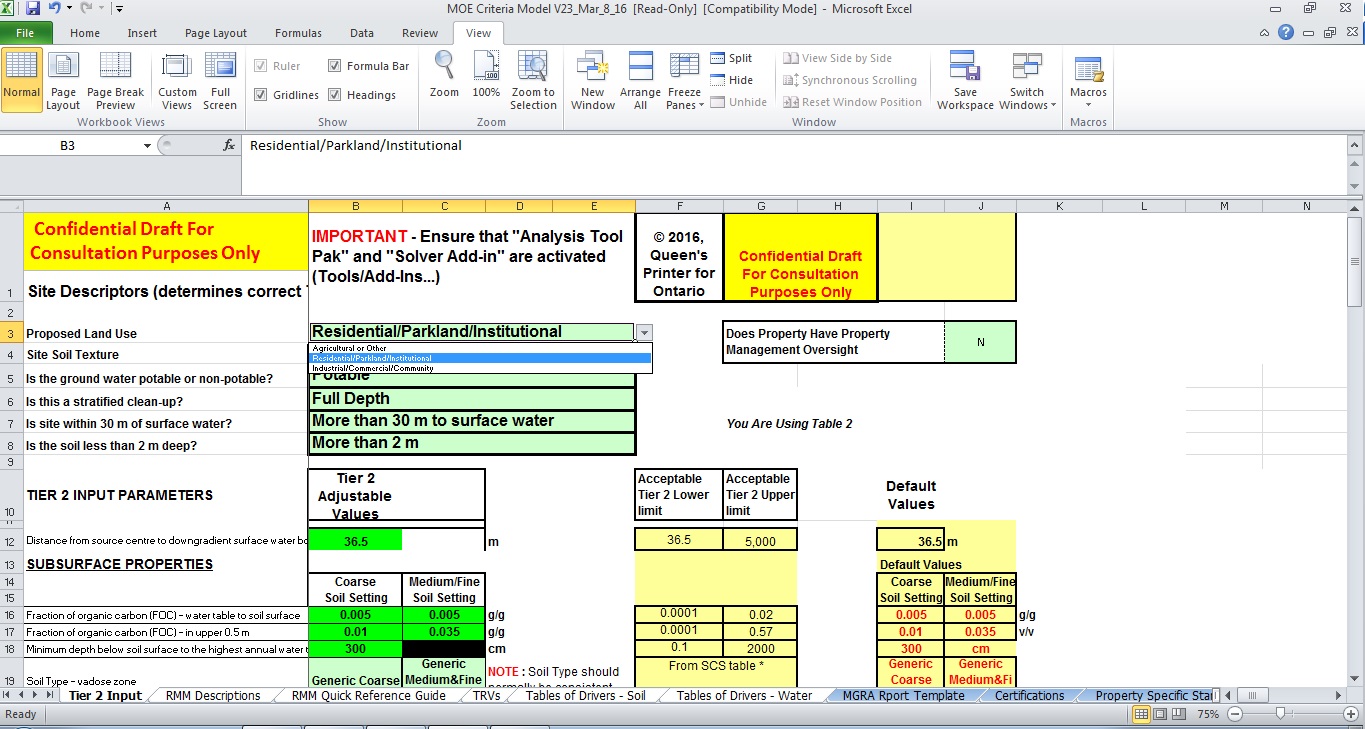

4.1 Entering Site Descriptors for Determining Table of Standards

Step 1. Open “Approved Model” and click on the “Tier 2 Input” tab

The cells that are highlighted in green are cells where the user can input information. The bright green shaded cells are for direct numeric user input, and the paler green shaded cells have pull down menus that pop up when the arrow on the right side of the box is clicked.

Check Site Descriptors in cells B3-B8 to be sure that the descriptions match the RA property. These fields are used to select the applicable table of site condition standards (SCS). To change a description, click on the appropriate cell, then click on the down arrow on the right end of the box and choose the description that is appropriate for the site. Explanations of these site descriptors are available in the document “Records of Site Condition: A Guide on Site Assessment, the Cleanup of Brownfield Sites and the Filing of Records of Site Condition“, which can be found at Brownfields redevelopment website.

(4728e)

4.2 Entering Site Specific Input Parameters

Step 2. Once the appropriate site descriptors are selected, start entering the relevant site data in cells B12 – B26. If the data entered is outside of the acceptable range (cells in yellow, F12-G26), the warning “invalid” will be displayed and the cell will be highlighted in red. The Tier 1 (SCS) default values are given in cells I12 to J26 (also in yellow highlight). Once a value changes from the default, so long as it is within the acceptable range, it is displayed in italics.

* If there are site properties described in cells A12 – A26 of the Tier 2 Input tab for which no measurements have been conducted, you may wish to check Appendix 3 to determine if you can benefit from measuring them and using them in the Tier 2 process. The possibility of producing a less stringent Tier 2 number exists if there is a check mark in Appendix 3 against the measured parameter for the particular driver that is driving your PSS.

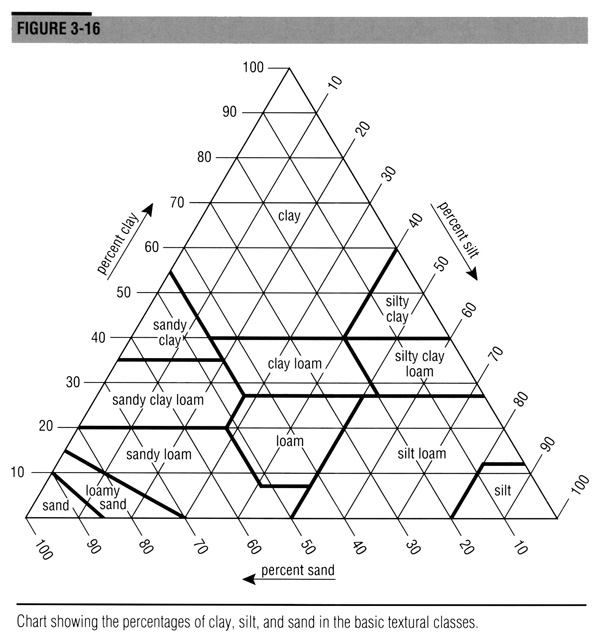

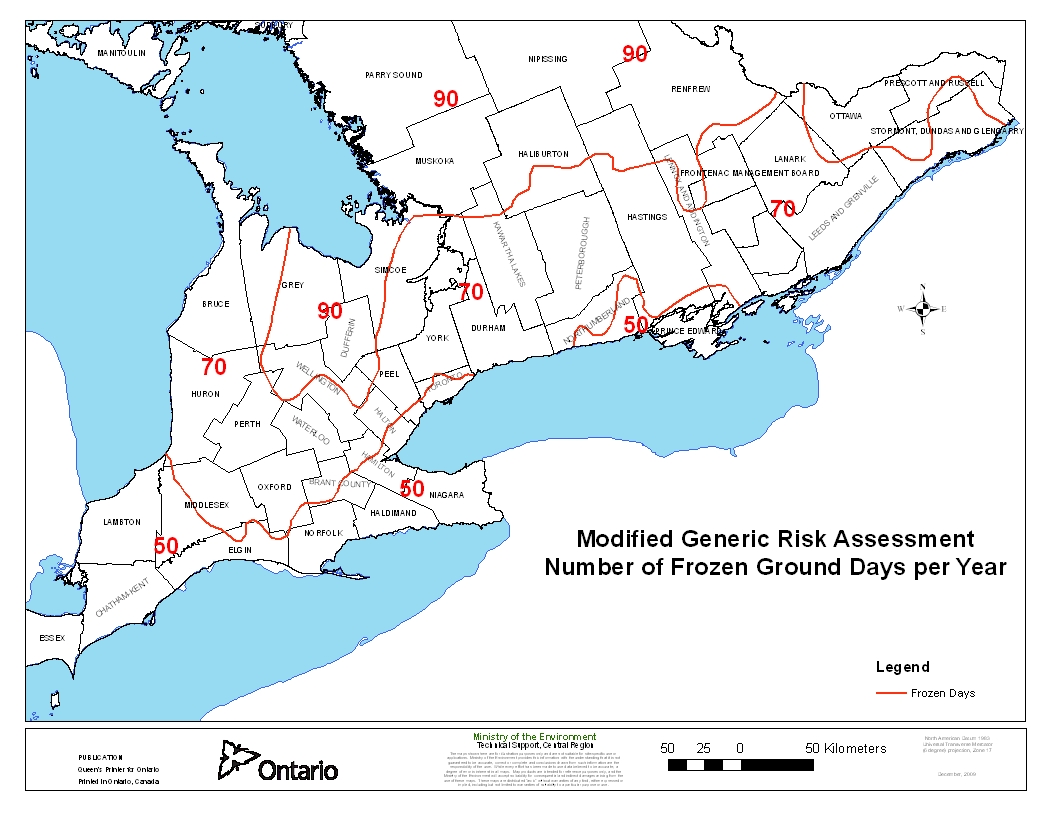

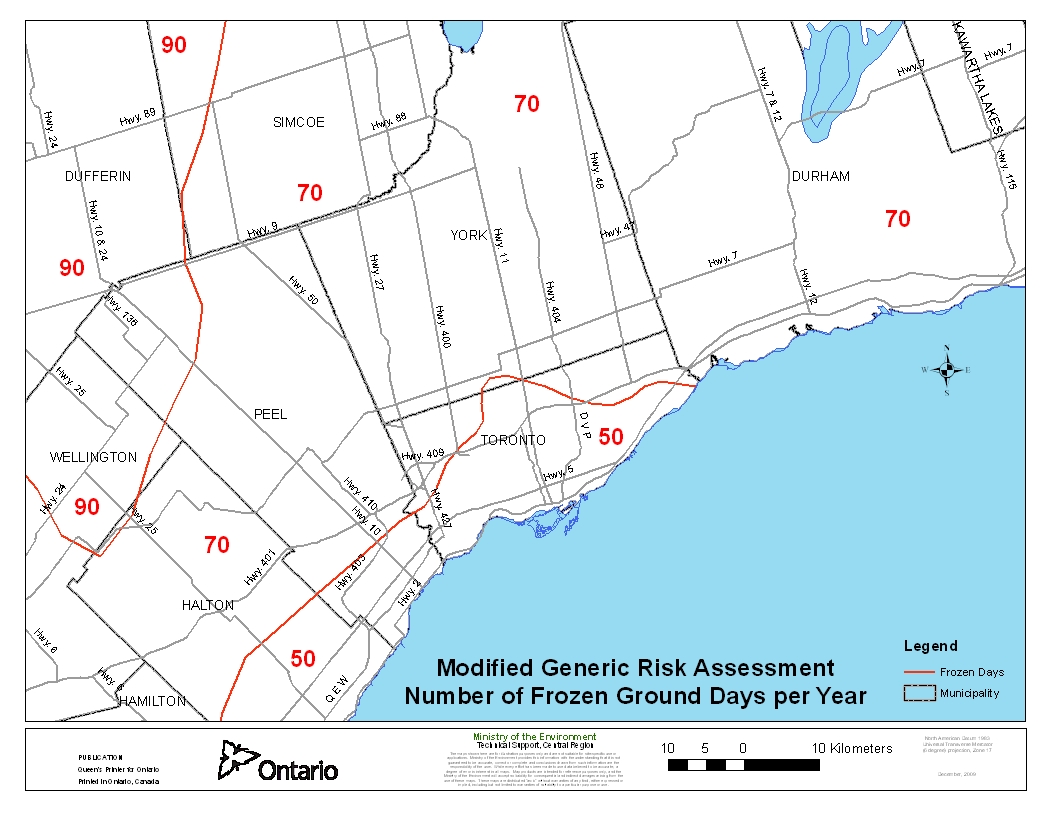

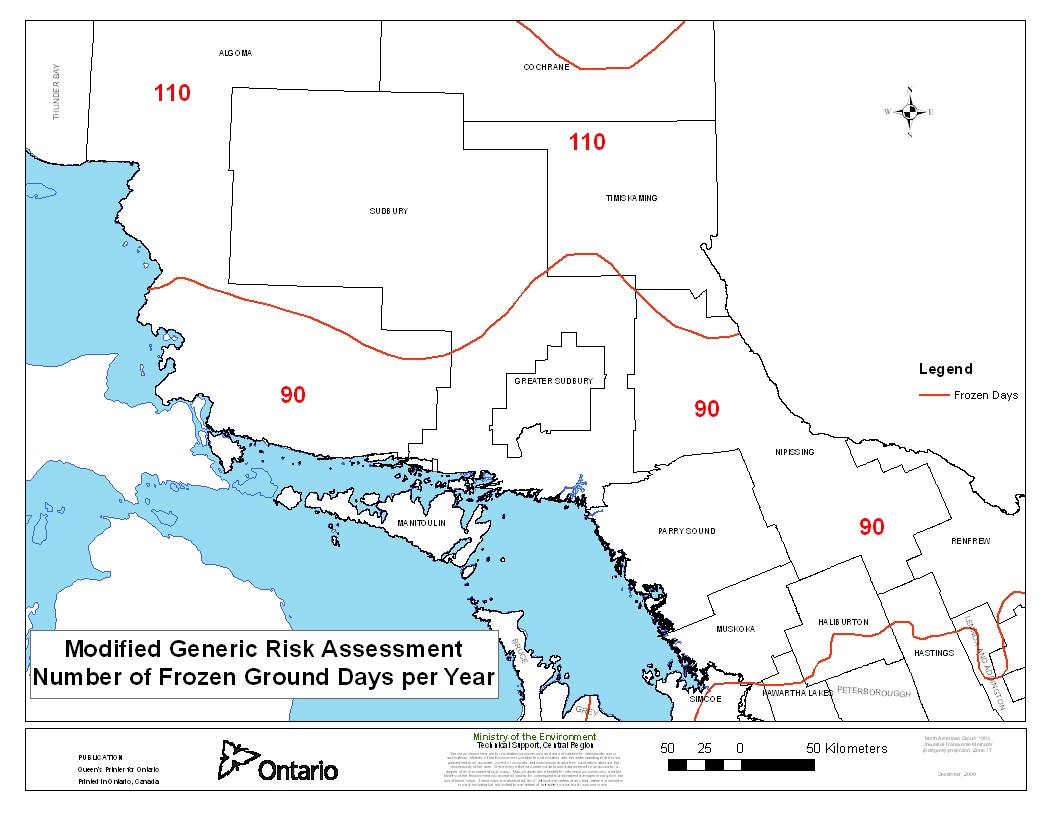

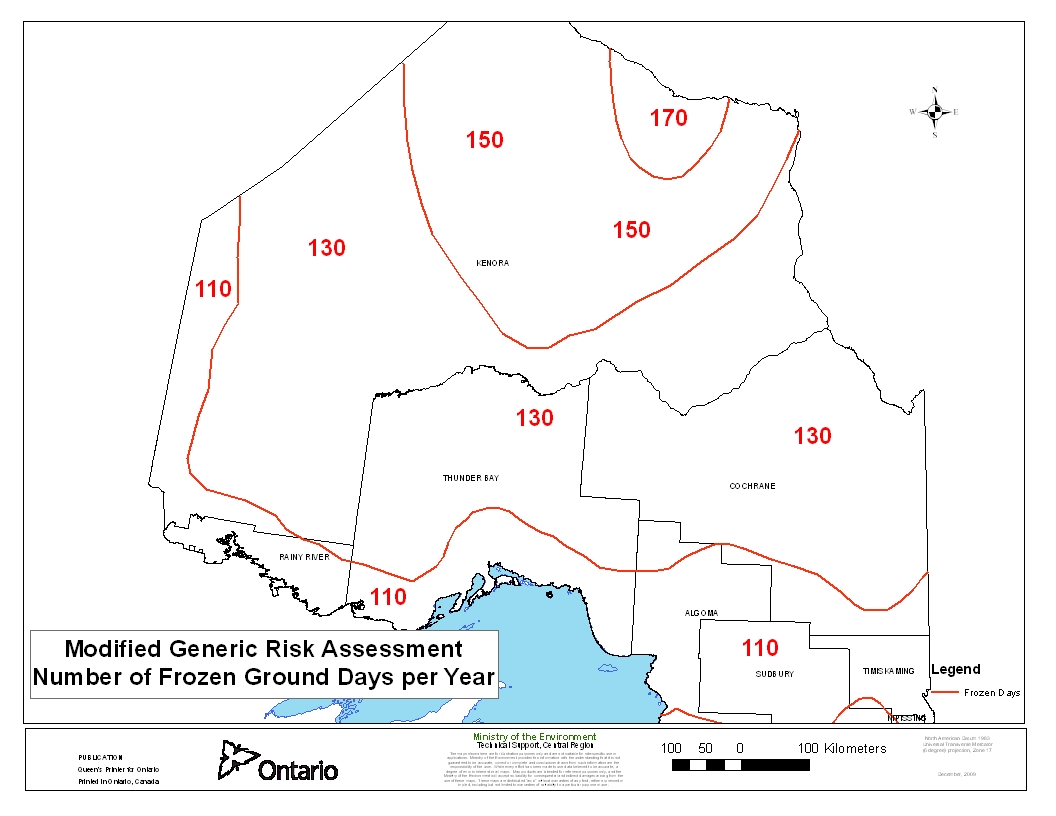

For sites where the overall soil texture is medium/fine, be sure to enter the appropriate data in Cells C16 – C20 (rather than B16 – B17 and B19 – B20, which are for coarse texture soils). Note that cells B19 - C20 and B21 are changed using the pull down menus to choose the appropriate soil type or frozen days. For determination of the Soil Type, use the measured sand, silt and clay contents from the site in conjunction with the information in Appendix 1 of this document. If your goal is to develop PSS (as opposed to calculating soil vapour screening levels) be sure to enter the appropriate value for the “Property Soil Type”, as opposed to “Area Soil Type”. For determination of which value to use for Frozen Ground Days, follow the requirements set out in sections. 41, 42 and Table 4, Schedule E of the Regulation, and round it to the nearest tens or use the maps included in Appendix 2 of this document. When using Appendix 2, if it is uncertain as to which of two zones your site falls, use the higher (more conservative) of the two numerical values.

* Note that none of the four cells (B19-C20) for Soil Type can include either of the terms “Generic Coarse” or “Generic Medium/Fine” if you want the soil vapour screening levels (SVSLs) to be calculated. These two Soil Types are not options for Tier 2 when SVSLs are being generated. There should be a reasonable correspondence between the Soil Types and the Site Soil Texture, or the QP should have a full understanding and explanation as to the reasons why they do not correspond reasonably well. All Phase Two ESAs upon which MGRA are based should follow sections 41, 42 and Table 4 of Schedule E of the Regulation.

* Note that if the Area Soil Type for the SVSL is considered “fine/medium” textured soil based on grain size analysis, the QP will need to ensure that the “Site Soil Texture” in Cell B4 is changed to correspond to “medium/fine” texture for property SVSL calculations.

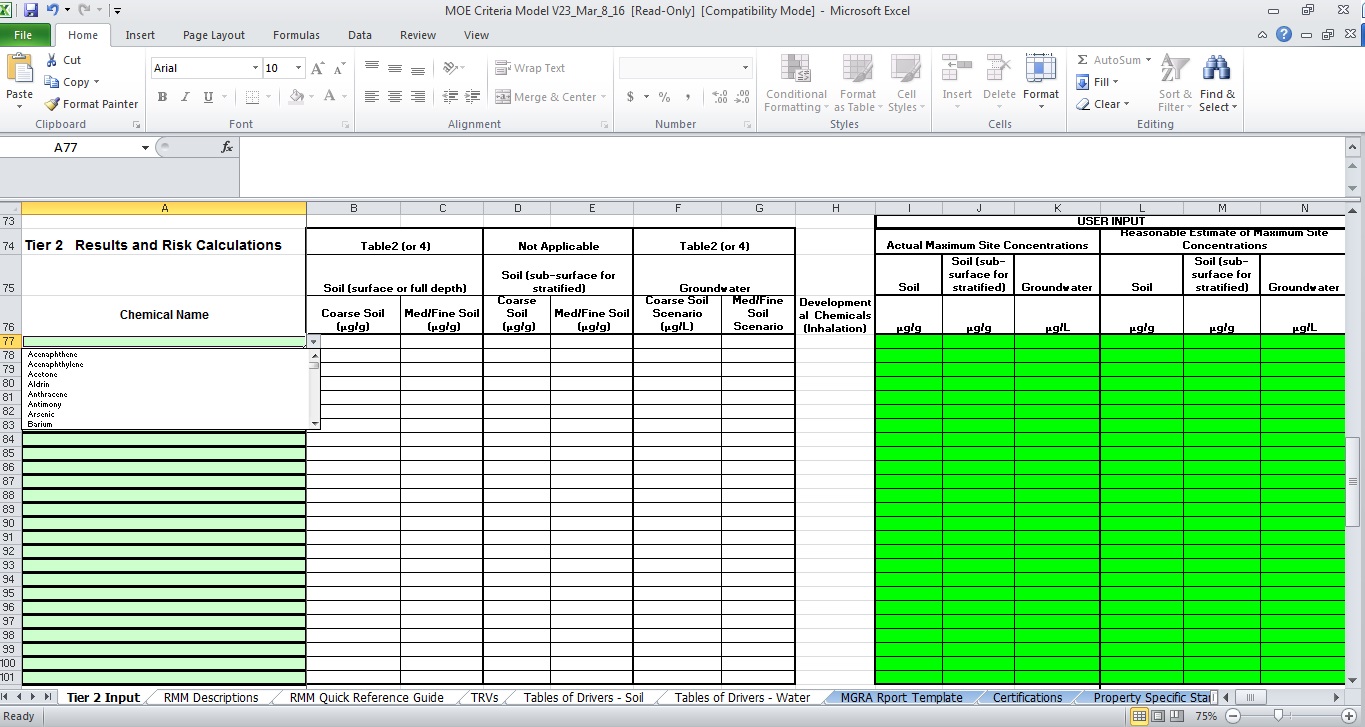

4.3 Viewing Modeling Results and Comparing with Site Concentrations

Step 3. After all of the available Tier 2 inputs have been populated, you can review the results that the spreadsheet has generated and compare them with the maximum concentrations measured on the site

- Note 1 – This spreadsheet allows for 25 COCs. If there are more than 25 COCs at the site, you should consider whether an MGRA approach is appropriate given the potential complexity of the site. If needed, you can run the model again for the remainder of the COCs, saving with a different file name.

- Note 2 – rather than entering all COCs manually using the drop-down menu, you may prefer to try these tips to help populate your COC list more quickly:

- Tip 1: enter a space before and after the COC name, e.g. _benzene_, and make sure you type the same name as indicated in the MGRA, e.g. “Dichlorobenzene, 1,2-” not “1,2, Dichlorobenzene”

- Tip 2: just copy and paste the COC name from the other tab, e.g. “Phys_chem &Tox”

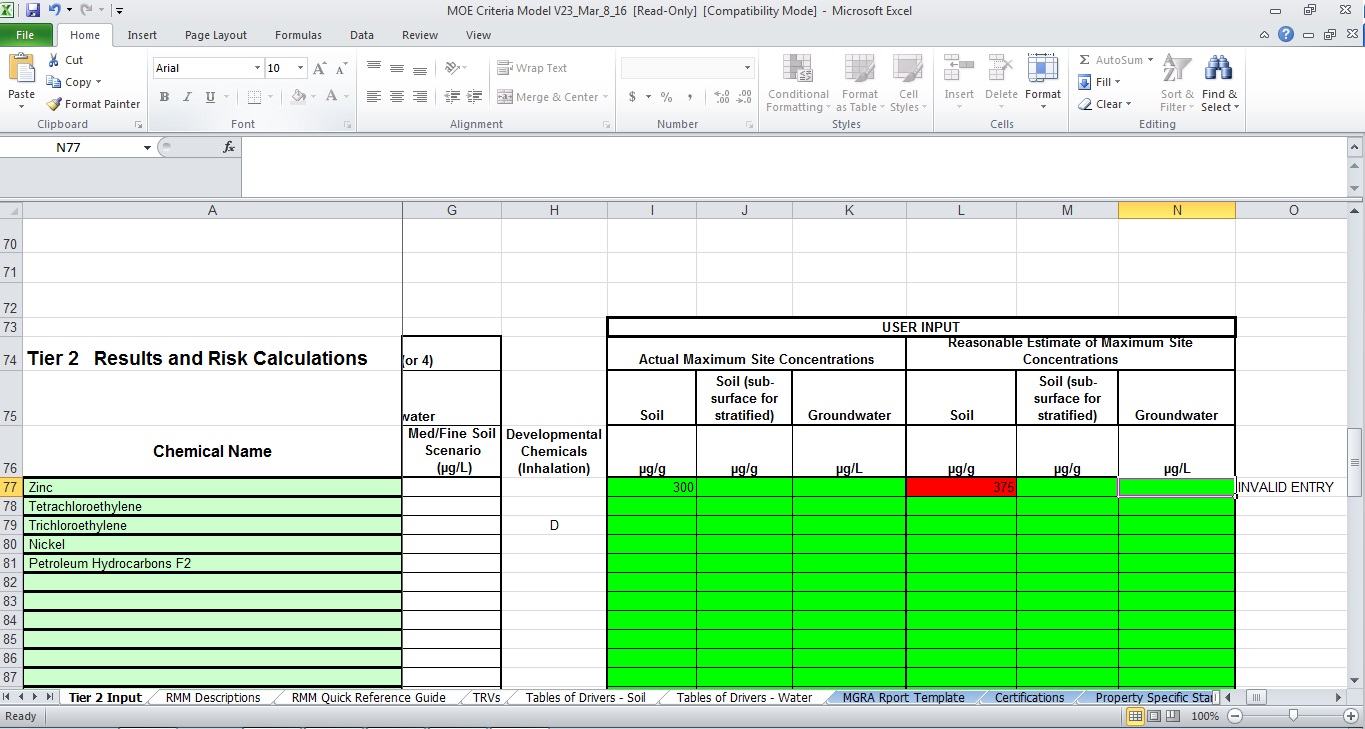

The initial soil and ground water criteria generated by the spreadsheet will appear in cells B77-G101.

Step 4. Your actual (measured) site concentrations for soil and groundwater are added to the spreadsheet in cells I77-K96, and your calculated reasonable estimate of the site maximum (REM) are inputted into Cells L77-N101. Note that the estimate of the site max cannot exceed 1.2 times the actual measured site max in an MGRA (a warning will pop up if it does). Also note that delineation for all COCs must be complete before the MGRA is submitted. If all COC REM concentrations are numerically lower than the respective values calculated by the spreadsheet (B77-G101), then your site meets the Tier 2 PSSs, and you may submit the RA to the ministry for review. The PSSs that you can use for submitting the RA are displayed in Cells B108-D132. These values account for the REM.

4.4 Adding Risk Management Measures and other Pathway Modifiers

Step 5. If your site doesn’t meet the Tier 2 standards, then you may wish to take a look at the Tables of Drivers (see screen shot below) to determine which component value is limiting the PSS value

No Possibility of Change in Tier 2:

Solubility (with the exception of PHC F1 and F2, for which there is now site characterization work that the QP can complete to modify this component value. This site characterization work is described in Appendix 6).

Change from Measured Parameters (see Appendix 3)

- S-IA, S-Odour, S-GW1, S-GW3, S-OA, GW2, GW2-Odour, GW3, Free Phase Threshold

- Note that meeting the Soil Vapour Screening Level (SVSL) generated for soil and ground water could affect S-IA and GW2

Change from Pathway Modification (step 11)

- Modified Ecological Protection: Plants and Soil Invertebrates, Mammals and Birds

- Modify Solubility Component Values (PHC F1 and F2): solubility

- Soil Vapour Screening Levels: S-IA, GW2 (described below)

- Modified Subsurface Worker Protection: for addressing S3

Change from Risk Management; CPU typically issued (Appendices 5 to 8)

- S-IA, S-IA (Odour), S1, S2, S-Odour, Plants and Soil Invertebrates, Mammals and Birds, S3, GW1, GW2, GW-Odour.

Step 6. If the driving component is “Mammals and Birds” or “Plants and Soil Organisms”, then you may wish to consider whether it would be appropriate for your site to use the “Modified Ecological Protection” (MEP) option (by picking “Y” from the pull-down menu in cell B30). This option will generate a higher number for the “Plants and Soil Organisms” component, and effectively eliminate the “Mammals and Birds” component. An acknowledgement that the option has been chosen must be placed on the RSC. For a full description of this option, read Appendix 4 of this document.

Step 7. If your measured concentrations (for PHC F1 and F2) in ground water still exceed the Tier 2 PSS, and the driver is the solubility component value, then you may wish to opt into the “Modify Solubility Component Values” (cell B40). Note: please see Appendix 6 for guidance to assist proponents in conducting site characterization that is effective in demonstrating that there is no evidence of free product, so that the solubility CV can be modified in the MGRA. You may then answer the questions related to this option that are found in the MGRA section of the RA Pre-Submission Form and provide supporting documentation as part of the MGRA submission.

Note: To this point, none of the options chosen would typically result in the issuance of a Certificate of Property Use (CPU), so if your property meets the Tier 2 PSSs at this stage and the ministry accepts the RA, then a RSC could generally be filed without a CPU. However, all other Tier 2 options (with the exception of Soil Vapour Screening Levels) described from the next step-on would typically be associated with a CPU.

Step 8. If your site soil still doesn’t meet the Tier 2 standards and the driving component is any of “Mammals and Birds”, “Plants and Soil Organisms”, S1, or S2, then you may wish to consider the use of either a “Shallow Soil Cap (Cell B31)” (for industrial/commercial sites) or a “Fill Cap” or “Hard Cap” (Cell B32). These RMMs are described on the “RMM Descriptions” tab of the Approved Model (Excel). In the “Tier 2 Input” spreadsheet, clicking on one of the RMMs hyperlinked in blue (A31-A43) will take you to the appropriate description. Choose the option appropriate for your site by picking “Y” on the pull down menu in Cells B31-B37 & B41- B43 of the Tier 2 Input spreadsheet.

Step 9. If your measured concentrations still exceed the Tier 2 PSS, and the driver is either S-IA or GW2, then you may wish to consider:

- “Building with Storage Garage” (i.e. ventilated parking garage) (cells B33);

- “Building Prohibition” (if no enclosed buildings will be constructed at the site) (choose cell B34 for either);

- “Passive Soil Vapour Intrusion Mitigation System” (cell B35);

- “Active Soil Vapour Intrusion Mitigation System” (cell B36);

- “Building with no First Storey Residential, Institutional or Parkland Use

footnote 5 ” (cell B37); or - “Building with Minimum First Storey Height Requirement” (cell B41).

- Soil Vapour Screening Levels (not an RMM; described below)

Please see the summary table in Section 2.1 to see requirements and precluding conditions for these options.

Step 10. If your measured concentrations still exceed the Tier 2 PSSs, and the driver is GW1 (for potable ground water site conditions), then you may wish to consider the “No Ground Water Use” RMM (cell B42). Note however, that in order to check the “Y”, you must answer the questions related to this RMM that are found in the MGRA section of the RA Pre-Submission Form. Your responses to these questions should be used in pre-consultation with the local District Office. Typically, answers to questions 2, 4 and 5 on Page 26 of the RA Pre-Submission Form must be “yes” in order for this RMM to be used in an MGRA. Note that when you select this option, you must return to cell B5 to change the potability to “Non-potable”, which should now be the only option available in the dropdown list. Please also note that one of the outcomes of the ministry’s review of the RA may still be the conclusion that groundwater monitoring is warranted for the RA property, and that the RA cannot, therefore, be classified as an MGRA, and may need to proceed as a traditional “Tier 3” RA. The Approved Model can continue to be relied upon to develop PSS, but the Director will review whether any selected RMMs are appropriate for the property, as the RA is no longer considered an MGRA.

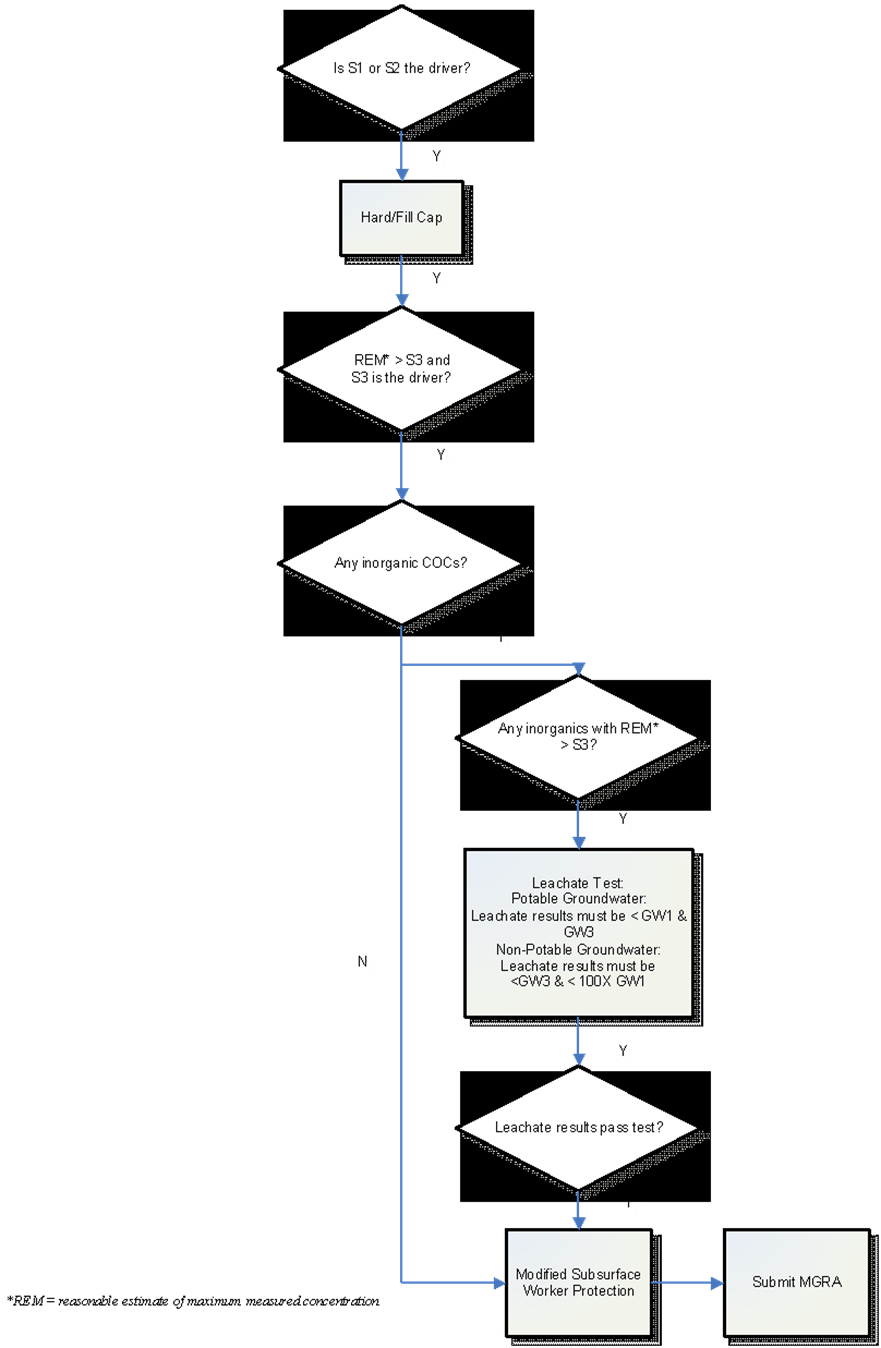

Step 11. If your measured concentrations still exceed the Tier 2 PSSs, and the driver is S3, you may wish to opt into the “Modified Subsurface Worker Protection” pathway modifier (cell B43). Note however that for inorganics (COCs without Koc values), in order to check the “Y”, you must answer the questions related to this RMM that are found in the MGRA section of the RA Pre-Submission Form, and should provide leachate testing results as part of the MGRA. For details on the use of this pathway modifier, please refer to Appendix 5.

For inorganics, select the COCs from the drop down list in cells A62-A66. The corresponding leachate criteria are generated in row B. Next, enter the leachate analysis results in row C for comparison.

5. Consideration of Off-Site Receptors

If you have used RMMs affecting the ground water for protection of drinking water pathway (GW1 pathway), or the ground water for protection of indoor air pathway (GW2 pathway) or soil vapour screening for a ground water source, you should carefully consider the potential impact of ground water travelling from the RA site to downgradient sites. The following MGRA options modify GW1 and GW2:

- Options that modify GW1:

- No Ground Water use RMM

- Options that modify GW2:

- Building with Storage Garage RMMs

- Building Prohibition RMM

- Building with No First Storey Residential, Institutional or Parkland Use RMM

- Soil Vapour Intrusion Mitigation System RMMs

- Building with Minimum First Storey Ceiling Height Requirement RMM

- Soil Vapour Screening Level met for ground water source (pathway modifier)

Table 4-5 of the Human Health RA MGRA Report Template (Off-site – HH tab) is provided in accordance with Mandatory Requirements for RA Reports (Schedule C, Table 1 of the Regulation) and this section requires the QP to assess whether the proposed human health standards will likely result in an exceedance of the applicable full depth Site Condition Standard at the nearest off-site human receptor. You must also answer the questions related to options that modify GW1 and GW2 found in the MGRA section of the RA Pre-Submission Form, and should use these questions as a basis to consult with the local District Office about your assessment of the likelihood of off-site impacts.

6. Combining Risk Management Measurements and other Pathway Modifiers Options in the Model: Guidelines and Restrictions

Here are restrictions on how RMMs, Modified Ecological Protection (MEP) and Soil Vapour Screening Levels (SVSLs) can be combined. In general, most options can be combined in the model, but there is not always an advantage to combining them in terms of generating less stringent standards. Please see the bullets and summary table below to see the effects of (and restrictions for) combining options in the Approved Model.

- MEP can be combined with anything, but would provide no extra benefit if a cap is selected

- SVSLs can be combined with anything. There is no numerical advantage in the proposed PSS to doing so; however, the screening level that the measured soil vapour concentration are compared to will be increased if soil vapour RMMs are selected

- “Fill Cap Barrier” & “Hard Cap Barrier” can be combined with one another

- If a “Shallow Soil Cap Barrier” is combined with other caps at a site, only the “Shallow Soil Cap Barrier” multipliers can be used

- “Shallow Soil Cap Barrier” can only be used if the intended and actual property use is industrial/commercial/community

- Caps can generally be combined with other RMMs such as the RMMs affecting the vapour intrusion pathway (subject to the restriction for “Shallow Soil Cap” given above)

- “Active Soil Vapour Intrusion Mitigation Systems (SVIMS)” can only be used if (a) the intended and actual property use is industrial/commercial/community, or (b) if the intended and actual property use includes residential/parkland/institutional, the Building must be multi-storey and multi-unit, and must have Property Management Oversight. (For more information, please see the description of this RMM and the relevant Definitions).

- “Passive Soil Vapour Intrusion Mitigation System (SVIMS)” can only be used if property use is industrial/commercial/community and the building type is slab on grade.

- “Building Prohibition” cannot be used at sites that will have buildings, so it cannot be combined with other building restrictions (e.g.: “Building with Storage Garage,” “Building with no First Storey Residential, Institutional or Parkland Use,” “Building with Minimum First Storey Ceiling Height Requirement.”)

Abbreviations used in the tables below:

- COC

- Contaminant of Concern

- GW2

- Ground water for the protection of Indoor Air

- I/C/C

- Industrial / Commercial / Community (refers to least sensitive property use category)

- M&B

- Mammals & Birds

- PSF

- Pre-Submission Form

- PSO

- Plants and Soil Organisms

- R/P/I

- Residential / Parkland / Institutional (refers to a more sensitive property use category)

- RSC

- Record of Site Condition

- S-IA

- Soil for the protection of Indoor Air

- S-OA

- Soil for the protection of Outdoor Air

- SVIMS

- Soil Vapour Intrusion Mitigation System

- SVSL

- Soil Vapour Screening Level

Effect on Multiplier Ceilings when MGRA Options are Combined

| MEP | Shallow Cap | Hard/Fill Cap | |

|---|---|---|---|

| Modified Ecological Protection (MEP) | Uses industrial values × 1.9 for PSO and 1000× M&B; Need to include statement in RSC that MEP option is used. | No value in combining MEP with caps (but CPU typically required for caps) | No value in combining MEP with caps (but CPU typically required for caps) |

| Shallow Soil Cap Barrier RMM | No value in combining MEP with caps (but CPU typically required for caps) | Uses industrial values × 1.9 for PSO and 1000× M&B; Limited to I/C/C sites | Where shallow and hard/fill caps are present on different areas of a property, the shallow cap multiplier ceilings are applied. |

| Hard/Fill Cap Barrier RMM | No value in combining MEP with caps (but CPU typically required for caps) | Where shallow and hard/fill caps are present on different areas of the property, the shallow cap multiplier ceilings are applied. | Uses industrial values × 1000 for PSO & 1000 × M&B for R/P/I and I/C/C |

| Shallow Cap | Hard/Fill Cap | MSWP | |

|---|---|---|---|

| Shallow Soil Cap Barrier RMM | S3 replaces S1/S2 Limited to I/C/C sites | Where shallow and hard/fill caps are present on different areas of the property, the shallow cap multiplier ceilings are applied. | 100× S3 |

| Hard/Fill Cap Barrier RMM | Where shallow and hard/fill caps are present on different areas of the property, the shallow cap multiplier ceilings are applied. | S3 replaces S1/S2 | 100× S3 |

| Modified Subsurface Worker Protection (MSWP) | N/A | 1.5 m Fill/hard Cap RMM or stratified standards must be in place in order to use MSWP as well as a HASP | 100× S3 |

| Building Prohibition | Storage Garage | Passive SVIMS | Active SVIMS | No First Storey Residential | Min First Storey Ceiling Height | Soil Vapour Screening Level | |

|---|---|---|---|---|---|---|---|

| Building Prohibition RMM | Effectively S-OA replaces S-IA; 200× GW2 | Building Prohibition cannot be combined with any building | Building Prohibition cannot be combined with any building | Building Prohibition cannot be combined with any building | Building Prohibition cannot be combined with any building | Building Prohibition cannot be combined with any building | SVSL would not be used for a site with no buildings |

| Storage Garage RMMs | Building Prohibition cannot be combined with any building | 1-200× S-IA and GW2 (depending on property use and whether any COCs are developmental) | 200× S-IA and GW2 (with the exception of developmental COCs for I/C/C Storage Garage (intermittent 3.9 L/sec) RMM | 200× S-IA and GW2 | 1-200× I/C/C S-IA and I/C/C GW2 (depending on property use and whether any COCs are developmental) | 1-400× S-IA and GW2 (depending on property use and whether any COCs are developmental) | SVSL is multiplied by 1-200× (depending on property use and whether any COCs are developmental, but S-IA and GW2 remain at 1000× & 200×) |

| Passive SVIMS RMM | Building Prohibition cannot be combined with any building | 200× S-IA and GW2 (with the exception of developmental COCs for I/C/C Storage Garage (intermittent 3.9 L/sec) RMM | 100× S-IA and GW2 | These would not be combined | 100 × I/C/C S-IA and I/C/C GW2 | ~100-200 × S-IA and GW2 | SVSL is multiplied by 100× (but S-IA and GW2 remain at 1000× & 200×) |

| Active SVIMS RMM | Building Prohibition cannot be combined with any building | 200× S-IA and GW2 | These would not be combined | 200× S-IA and GW2 | 200 × I/C/C S-IA and I/C/C GW2 | ~200-400 × S-IA and GW2 | SVSL is multiplied by 200× (but S-IA and GW2 remain at 1000× & 200×) |

| No First Storey Residential, Institutional or Parkland Use RMM | Building Prohibition cannot be combined with any building | 1-200× I/C/C S-IA and I/C/C GW2 (depending on property use and whether any COCs are developmental) | 100 × I/C/C S-IA and I/C/C GW2 | 200 × I/C/C S-IA and I/C/C GW2 | I/C/C component values replace R/P/I component values (new baseline) | ~1-2 × I/C/C S-IA and I/C/C GW2 | I/C/C SVSL |

| Building with Minimum First Storey Ceiling Height RMM | Building Prohibition cannot be combined with any building | 1-200× ~1-2× S-IA and GW2 (depending on property use and whether any COCs are developmental) | ~100-200 × S-IA and GW2 | ~200-400 × S-IA and GW2 | ~1-2 × I/C/C S-IA and I/C/C GW2 | ~1-2 × S-IA and GW2 [multiplier is proportional to ceiling height (new baseline)] | SVSL is multiplied by ~1-2×; ~1-2 × S-IA and GW2 |

| Soil Vapour Screening Level (SVSL) | Would not be used for a site with no buildings | SVSL is multiplied by 1-200× (depending on property use and whether any COCs are developmental, but S-IA and GW2 remain at 1000× & 200×) | SVSL is multiplied by 100× (but S-IA and GW2 remain at 1000× & 200×) | SVSL is multiplied by 200× (but S-IA and GW2 remain at 1000× & 200×) | I/C/C SVSL | SVSL is multiplied by ~1-2×; ~1-2 × S-IA and GW2 | 1000 × S-IA 200 × GW2 |

| No Ground Water Use | |

|---|---|

| No Ground Water Use RMM | Uses non-potable component values (GW2 or GW3 rather than GW1) |

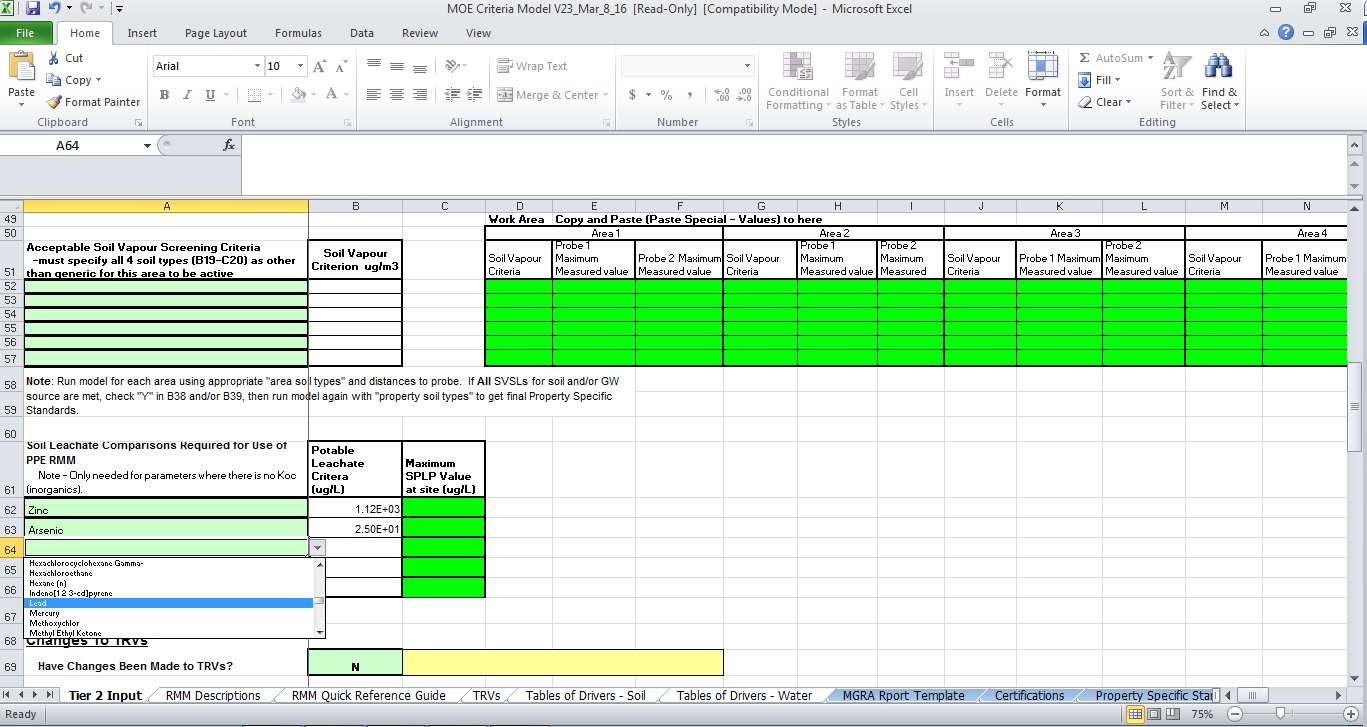

7. Calculating Soil Vapour Screening Levels

This method offers an alternative approach to address exceedences of the S-IA and GW2 pathways for volatile COCs. If any of the calculated reasonable estimate of the site maximum (REMs) (L77-N101) for volatile chemicals exceed the respective values calculated by the spreadsheet (B77-G101) and the driver is either S-IA or GW2, then you can calculate soil vapour screening levels and compare them to your actual soil vapour measurements. Make sure that you have fulfilled all of the requirements of the Regulation in relation to soil vapour sample collection, including the MGRA-specific requirements found in Schedule E, Table 4. For general guidance on soil vapour assessment, the QP should refer to the draft Technical Guidance: Soil Vapour Intrusion Assessment, dated 2013 (or the most recent ministry guidance available).

Step 1. Begin by entering the names of the volatile chemicals for which soil vapour measurements are available into cells A52-A57, and entering the depth to soil vapour measurement (B26) and the corresponding Area Soil Type – vadose zone (B19 or C19) for one of the soil vapour sampling locations on the site where soil vapour measurements were made. The soil vapour screening levels, appropriate for the soil vapour sampling location at a given depth to soil vapour measurement and to the site inputs currently in the spreadsheet, will then appear in row B (that is, if the Area Soil Type cells (B19-C20) do not contain either of the two generic Soil Types). These soil vapour criteria are specific to the particular soil vapour sampling location and depth from which the soil vapour samples were taken, and which is represented by the current Tier 2 input data that you have entered in the spreadsheet. Be sure to separate areas that are ground water source areas from those that are soil source areas such that you can properly later choose the appropriate measures in cells B38 or B39. Repeat this process as many times as needed. You must develop soil vapour screening levels for each sampling location and depth to soil vapour measurement (as specified in Table 4, Schedule E of the Regulation) in which soil vapour measurements were taken at the RA property.

* Note that if the Area Soil Type for the SVSL is considered “fine/medium” textured soil based on grain size analysis, the QP will need to ensure that the “Site Soil Texture” in Cell B4 is changed to correspond to “medium/fine” texture for property SVSL calculations.

Step 2. Check to be sure that the input parameters (especially soil type and depth below soil surface to soil vapour measurement (B26)) are correct for that specific soil vapour sampling location. You can consult Appendix 1 of this guide for determination of soil type. Within the scope of MGRA, the depth below soil surface to soil vapour measurement should meet the following:

- To minimize the influence of atmospheric short-circuiting, the minimum depth below soil surface to soil vapour measurement is 150 cm, as per Table 4 of Schedule E; and,

- To ensure that the collected soil vapour measurements are appropriate to assess the vapour intrusion pathway for both existing building(s) (if present) and future building(s) (e.g. with respect to vapour accumulation and increased advection near/below the building foundation), soil vapour samples should be collected at least 100 cm below the base of the building foundation. For example, if the depth of the subsurface structure (e.g. basement) is similar to the R/P/I default value (158 cm below soil surface), soil vapour should be collected at 258 cm below soil surface or deeper.

- For future building(s), if the built form is unknown, it is unlikely that reliance on soil vapour measurements is appropriate to support modification of vapour intrusion component values.

If depths that are shallower than those noted above are entered, the cell (B26) will be shaded red and the message “invalid” will be shown.

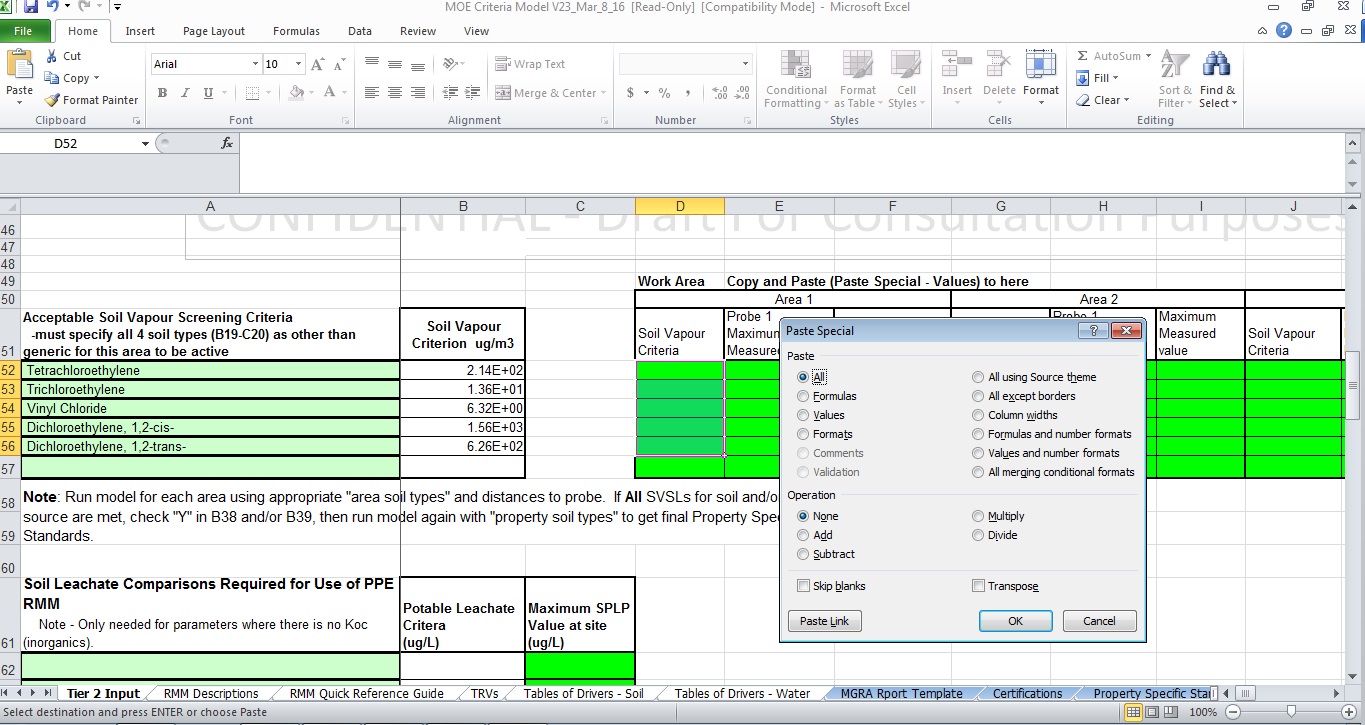

Step 3. For the first sampling location (Area 1), copy the soil vapour screening level (Cells B52-B57) to Cells D52 to D57 (highlight cells to be copied, right click, choose copy, move pointer to D52, right click, choose “Paste Special”, then “Values”( this last part is critical, otherwise you will get formulae rather than numbers, or you may alter the formatting).

Step 4. Now enter the maximum soil vapour measurement recorded for that specific soil vapour sampling location and depth for the appropriate chemical in cells E52-E57. If a maximum measured concentration exceeds the soil vapour screening level, it will be highlighted in red.

Step 5. For the next sampling locations (Area 2 to 6), revise the Soil Type – vadose zone and the depth to soil vapour measurement fields to match the identified characteristics at the soil vapour sampling location and depth where soil vapour samples were taken and repeat the previous steps, putting the results in the section of the spreadsheet for appropriate sampling location (e.g., “Area 2”). Then repeat for other sampling locations. (This spreadsheet allows for up to six (6) sampling locations at a time)

Step 6. If, for a given COC, all soil vapour measurements, at all the required sampling locations and depths, meet the appropriate calculated soil vapour screening levels, then you may change the value in cells B38 and/or B39 (“soil vapour screening levels are met”), as appropriate for the source of the soil vapours (soil source or ground water source), to a “Y” (on the pull down menu). In most cases this effectively allows for the removal of the S-IA and the GW2 pathways from the Tier 2 PSSs.

** You will have to keep track as to which COCs meet the soil vapour screening levels, and be sure to use the results from checking “Y” in B38 or B39 only for those COCs that meet all the soil vapour screening levels. You would need to uncheck the “Y” to derive the PSS for those COCs which do not meet the soil vapour screening level.

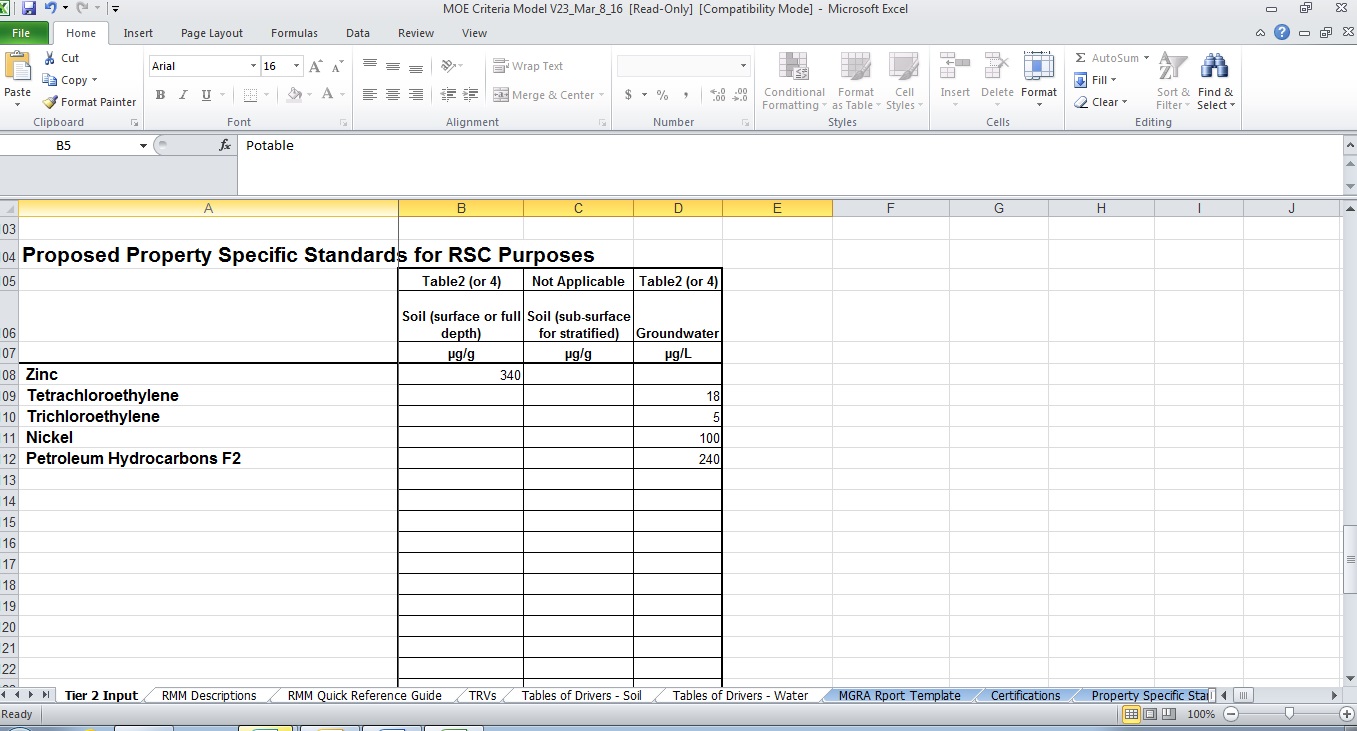

** Before determining your PSSs, you must now go back and re-enter the “Property-wide Soil Types”. If at this point all your REMs at the site meet the calculated criteria in cells B77-G101, then your site meets the appropriate Tier 2 PSSs, and you may submit the RA to the ministry for review. The “Proposed Property Specific Standards” that you can use for submitting the RA are displayed in Cells B108-D132.

8. Using Updated TRVs Provided by the Ministry

This option allows QPs to use ministry-provided toxicity reference values (TRVs) in an MGRA, as soon as they are updated and available. Only TRVs provided by the ministry may be used in place of the existing TRV. The ministry will make new TRVs available to QPRAs.

Step 1. Check for the new ministry TRV.

Step 2.Change the TRV and its reference in the appropriate cells in the TRV tab (columns C to V) of the model. The changes will be highlighted in red.

Step 3.Go back to the Tier 2 Input tab, which will be displaying an error that notes the number of changes that have been made in the TRV table. Change cell B69 to “Yes” from the pull down menu to indicate that you have intentionally changed a TRV, at which point the error note disappears.

Step 4.You can now view the updated PSS, which take into account the updated TRV.

9. COCs with Hazard Quotient (HQ) other than 0.2

Source allocation is applied in the derivation of human health component values (HHCVs) in order to account for exposures to the same substance via multiple pathways of exposure. The use of source allocation helps to prevent potential exposure from exceeding a tolerable daily intake (TDI) or tolerable concentration (TC). A default Source Allocation Factor (SAF) of 0.2 is applied in the derivation of most HHCVs for non-cancer. This means that one-fifth of the TDI or TC was allocated for most component values, which translates to a target HQ of 0.2. There are some exceptions, however, for which the target risk levels for HQ are set at different levels or applied in a different way.

9.1 Trichloroethylene (TCE) at Non-Potable Sites

Trichlorethylene (TCE) is now recognized as having developmental effects, as well as carcinogenic effects, and this is reflected in updated TRVs in Version 2 of the Approved Model. PSSs generated based on the updated TRVs are lower than those generated using Version 1 of the Approved Model. For this reason, the ministry undertook a review of assumptions, (specifically the potential for concurrent exposure from multiple pathways) used in calculating CVs for TCE. The review examined multimedia intakes of TCE for an adult and led to the conclusion that TCE intake from ingestion of food, ingestion of ground water, and ingestion and dermal contact with soil are negligible at non-potable sites when compared to TCE exposure via inhalation of indoor air (and possibly also outdoor air). Given that the background indoor air concentration is estimated at approximately half the inhalation TRV (e.g. 2.0 µg/m3), the use of an HQ of 0.5 is considered appropriate for calculating vapour intrusion CVs for non-potable sites.

The updated HQ of 0.5 applies only at sites where a non-potable ground water condition is applied (i.e. site ground water is not used as drinking water), or for sites using the “No Ground Water Use” RMM. This is because the drinking water pathway is a significant pathway for potable drinking water sites, and an HQ of 0.2 is still applied for S-IA and GW2 at potable drinking water sites.

9.2 Petroleum Hydrocarbons (PHC)

An HQ of 0.5 is used for all PHC fractions. This has not changed since Version 1 of the Approved Model. For more information, please see the ministry’s Rationale for the Development of Soil and Ground Water Standards For Use At Contaminated Sites in Ontario dated April 2011, Section 2.4.

10. Using the Approved Model in a Tier 3 Risk Assessment

Where there is a need to go beyond the approaches permitted within the Approved Model, a Tier 3 RA approach can be used to supplement the Tier 2 PSS. A proponent will be required to complete and submit a Tier 3 RA to the ministry for review as per the traditional process. The Tier 3 RA can utilize the PSS generated by the Approved Model, including the methodology and/or RMM’s relied upon to develop the PSS by appending the Tier 2 RA report to the Tier 3 submission when submitting to the ministry for review.

11. Risk Characterization

When an RMM has been used, it is necessary to report what the risk level would be if the RMM were to fail. These risk levels are calculated in the Tier 2 spreadsheet in cells P77-BA101. Please note that they no longer need to be calculated with all the RMMs turned off (set at N), unlike in Version 1. Cells B36 and B37 can be set to Y for the risk calculations only if all of the Soil Vapour Screening Levels were met for all soil vapour samples. The screenshot below shows the user input area (note the invalid entry where a reasonable estimate of the site maximum entered is higher than 1.2 times the actual measured value) and the first part of the risk calculations. Determine the risk level by looking under the appropriate risk management measure in Row 72. The cancer risk level is given for carcinogens and the Hazard Quotient from each particular exposure component (e.g. soil contact) for non-carcinogens.

The next screenshot shows the area of the Tier 2 Input spreadsheet that displays the final Proposed PSSs. There is also an area (cells B108-B132) that gives a quick reference comparison for some common contaminants such that you can quickly see the effects of your Tier 2 changes in comparison to the Generic Table 2 Residential coarse soil standards.

12. Limitations of the Approved Model

12.1 Limitations Related to Generic Assumptions

Any of the conditions for which the generic assumptions may not hold would result in a violation of the assumptions behind the Approved Model as well. These conditions are reproduced from the introduction to the Soil, Ground Water and Sediment Standards for Use under Part XV.1 of the Environmental Protection Act, dated April 15, 2011 below.

Conditions can exist at a site for which the assumptions used to develop the generic criteria may not be valid. The QP must ascertain that the site conditions are appropriate for use of the generic standards such that he/she can be comfortable with signing the certifications on the RSC. To assist the QP in recognizing the types of conditions that may be important in this respect the following examples are given:

- if the contaminated zone has a volume larger than 340 m3 or a source length or width greater than 13 metres then all pathways which employ source depletion or ground water transport (Soil to Nose, S-GW1, S-IA, S-GW3 and GW3 components of the standards) may be affected.

- if a high permeability zone is present in the vadose zone which provides a direct preferential pathway to the building then the soil properties assumed in the generic J&E modelling to determine the S-IA and GW2 components of the standard may change.

- if the annual average of the capillary fringe of the water table is < 0.8 metres from the outer edge of the gravel crush of the building foundation or when there is less than one (1) meter of between the top of the water table or soil contamination and the gravel crush layer, then the 10 × biodegradation factor assumed in the GW2 pathway for some VOCs may be non-conservative.

- if the average Organic Carbon content (foc) of soil above the water table is < 0.002 then more contaminant may be in the water and gas phases than assumed in the generic standards.

- if there is a continuous source of the contaminant then the pathways which assume a depleting source (i.e., S-IA, S-GW1, and Soil to Nose) might be non-conservative.

- if there is a surface water body that could be affected by the property from contaminant migration via ground water, and the surface water has total hardness less than 70 mg/L (as CaCO3) and/or has pH less than 6.7, the aquatic protection values for some metals and pentachlorophenol may be non-conservative. In such cases, the QP may need to consider whether a site-specific estimate of hardness and pH resulting from mixing of ground water and surface water is needed to estimate an appropriate aquatic protection value for this site.

The existence of any of the above conditions does not necessarily indicate that the Tier 2 PSSs are not valid for a given site. There are many interrelated parameters and factors that were used in the development of the generic standards, and in many cases one factor, such as any of those above, can be outweighed by differences in other factors in a manner that, overall, there is sufficient natural protection provided by the site. In addition, it must also be considered that the component that drives the standard may not be affected by the particular limiting condition described above (e.g. a terrestrial ecological driver, but there are high permeable zones in the vadose zone). The QP should consider these types of factors in assessing the appropriateness of the use of the Tier 2 PSSs.

12.2 Limitations Related to MGRA Conceptual Site Model (CSM)

- The Approved Model does not include a “ground water to plants and soil invertebrates” pathway. When you have selected pathway modifiers that multiply ground water component values (GW2 and GW3), consider whether the CSM used to develop the generic SCS is appropriate. The generic GW3 value is a considered to be a reasonable surrogate for protection of plant roots from ground water impacts. At greater distances to the nearest surface water body, the GW3 can increase significantly in relation to the generic GW3 value.

- The Approved Model does not include a vapour inhalation pathway for ground dwelling mammals (such as groundhogs) or soil dwelling organisms (such as earthworms). When using RMMs with large multipliers for S-IA (such as the “Building Prohibition” RMM), the QP should consider whether or not ground dwelling mammals or soil dwelling organisms could be adversely affected by the concentrations of volatiles substances remaining in the soil. The ecological component values in the CSM used to develop the generic SCS do not have a specific mechanism of protection for this pathway, and the assumption that the human health vapour exposure pathways are adequate for ecological receptors is less likely to be valid at higher multiples of the S-IA and GW2 component values.

13. Submitting the MGRA

Once you have completed the above steps and are satisfied with the RA you can submit it to the ministry. Please see Section 2.2 regarding the MGRA report template.

For more information on Tier 2, contact the Streamlined Risk Assessment Coordinator at Standards Development Branch of the Ontario Ministry of the Environment and Climate Change (E-mail: SDB-Tier2RAReview@ontario.ca; Phone 416-327-5519).

Appendix 1 - Determination of Soil Type

Use the results of the soil texture analyses to determine which soil type is appropriate by placing the % sand and % silt (or clay) in the following triangle. The point of intersection of the two lines gives the Soil Type. The triangle is from Figure 3-16 of the Soil Survey Manual, United States Department of Agriculture, Natural Resources Conservation Service, as published at its website (see the USDA website for more information and for a calculator).

USDA classification:

- Sand - Soil particles between 0.05 and 2.0 mm in size

- Silt - Soil particles between 0.002 mm and 0.05 mm

- Clay - Soil particles smaller than 0.002 mm (2 microns) in size

Appendix 2 - Maps Showing “Number of Frozen Ground Days Per Year”

A1 – Southern Ontario

A2 – Greater Toronto Area

B – Central Ontario

C – Northern Ontario

Appendix 3 Chart to identify which Tier 2 input parameters affect which pathways (subsurface transport components)

| Pathway\Tier2 Input Parameters | S-IA* | S-Odour | S-GW1 | S-GW3 | S-OA | GW1 | GW2 | GW2-Odour | GW3 | Free Phase Threshold |

|---|---|---|---|---|---|---|---|---|---|---|

| Distance to surface water | NA | NA | NA | ✔ | NA | NA | NA | NA | ✔ | NA |

| Soil FOC – water table to soil surface | ✔ | NA | ✔ | ✔ | ✔ | NA | NA | NA | NA | ✔ |

| Soil FOC – upper 0.5m | NA | ✔ | NA | NA | NA | NA | NA | NA | NA | NA |

| Depth to water table | NA | NA | NA | NA | NA | NA | ✔ | ✔ | NA | NA |

| Property Soil Type – vadose zone | ✔ | ✔ | ✔ | ✔ | ✔ | NA | ✔ | ✔ | NA | ✔ |

| Property Soil Type – capillary fringe | NA | NA | NA | NA | NA | NA | ✔ | ✔ | NA | NA |

| # Frozen Days | NA | ✔ | NA | NA | NA | NA | NA | NA | NA | NA |

| Aquifer horizontal hydraulic conductivity | NA | NA | NA | ✔ | NA | NA | NA | NA | ✔ | NA |

| Aquifer horizontal hydraulic gradient | NA | NA | NA | ✔ | NA | NA | NA | NA | ✔ | NA |

| Aquifer dry bulk density | NA | NA | NA | ✔ | NA | NA | NA | NA | ✔ | NA |

| Aquifer FOC | NA | NA | NA | ✔ | NA | NA | NA | NA | ✔ | NA |

* Best method to do Tier 2 on S-IA pathway is using soil vapour screening methods as described in the body of this document or by selection RMMs that mitigate the vapour intrusion pathway.

NA = not applicable for pathway

✔ = applicable for pathway

Descriptions of all Components:

- GW1

- Ground water for drinking water purposes

- GW2

- Ground water for protection from movement to indoor air

- GW2-Odour

- Ground water for protection from excessive odours

- GW3

- Ground water for protection of aquatic life

- S1

- Soil for protection of a residential receptor from direct contact with surface soil

- S2

- Soil for protection from direct soil contact for a lower frequency and intensity exposure than residential surface soil, such as for commercial or industrial scenarios where children are not frequently present.

- S3

- Soil for direct soil contact for a low-frequency, high-intensity, human health exposure scenario without children present that is protective of a worker digging in the soil.

- S-IA

- Soil for protection of movement to indoor air and human exposure.

- S-OA

- Soil for protection of movement to outdoor air and human exposure

- S-Odour

- Soil for protection from excessive odours

- S-GW1

- Soil for protection from movement to ground water for drinking water purposes

- S-GW3

- Soil for protection from movement to ground water and then to aquatic life

- Plants and Soil Organisms

- Soil for protection against adverse effects to plants and soil dwelling organisms

- Mammals and Birds

- Soil for protection against adverse effects through direct soil and food ingestion to mammals and birds

Appendix 4 - Tier 2 Option: Modified Ecological Protection (MEP)

1) What is the Tier 2 modified ecological protection (MEP) option?

In order to allow the development and application of less stringent PSS, current practice in Ontario may be to remove ecological habitat to ensure no ecological species are present or exposed to contamination. This practice results in the removal of habitat which, although degraded, could and often does support a variety of ecological species. While redevelopment needs may drive the removal of habitat, the ministry’s intent is to provide another option that will allow for greater preservation of ecological habitat. The ministry has developed a “modified ecological protection (MEP)” option within the Approved Model, which is intended to both promote brownfield redevelopment and preserve existing and potential future ecological habitat. This means getting more brownfield properties developed and providing developers a greener alternative to paving over ecological habitat. The ministry will continue to look at new ways of promoting ecological habitat preservation as part of brownfield redevelopment.

MEP is an option available to risk assessors within the MGRA process in Ontario that uses less stringent ecotoxicity values to develop PSS. The use of the MEP option will allow for the maintenance or establishment of natural habitat; habitat that is not comparable in quality to habitat in an uncontaminated setting, but instead is habitat comprising of assemblages of species that are adapted or less sensitive to the contaminants of concern at the property. Use of the MEP option may result in impacts to some plants, soil organisms and wildlife that might reside in or frequent the site. The MEP option does provide the same degree of protection to humans as the Tier 1 generic standards.

Under the MEP option, ecotoxicity values for mammals and birds are removed from the modified generic model for both residential/parkland and commercial/industrial land uses. Therefore no protection is provided for those ecological receptors under the MEP option. For plants and soil invertebrates under both residential/parkland and commercial/industrial land uses, the Tier 2 MEP option utilizes a multiplier (1.9 × industrial component value) that is equivalent to the 75th percentile value for each dose-response data set (developed for generic model values using the CCME protocol weight-of-evidence procedure where resulting No Observable Effect Concentration (NOEC) and Lowest Observed Effect Concentration (LOEC) data are ranked and ranked percentiles are determined for each data point).

2) What is the purpose of the MEP option?

The ministry recognizes that maintaining natural environments on remediated brownfield sites should be encouraged wherever possible. Soil standards at a brownfield site can often be driven by ecological risks to soil-dwelling invertebrates, plants and wildlife; therefore, “paving” a site as a means of removing potential ecological risks is one option that is exercised by property owners. However, paving a site provides no opportunity for any current or future natural habitat to exist on a property.

The MEP option in MGRA will provide the property owner with a viable alternative to RMMs such as “paving”. The MEP option will allow the property owner to use ecotoxicity values that will yield less stringent PSS values that can support a natural but relatively degraded environment; however it also may result in adverse effects to some plants and soil organisms. As a result, some species may not thrive as they would have at a site that is uncontaminated or which meets the more stringent generic site condition standards. However, more robust species will have the opportunity to populate this habitat which provides a more ecologically sustainable alternative to paving a site and promotes the redevelopment of brownfield properties.

3) Degree of protection provided by the MEP option

It is important to note that unlike other options for modifying the generic assumptions in the Approved Model (i.e. through the input of site-specific parameters into model inputs or the use of standardized RMMs) use of the MEP option does not provide the same degree of ecological protection that is provided by the Tier 1 generic standards. Instead a lower degree of ecological protection is permitted under the MEP option and impacts to some portions of ecological receptor populations may be anticipated in many cases. However, the MEP option does provide the same degree of protection to humans as the Tier 1 generic standards.

The ministry acknowledges that at some sites the higher soil concentrations allowed under the MEP option might not cause adverse ecological impacts due to ameliorating site-specific conditions (e.g., decreased bioavailability due to soil physicochemical characteristics or due to the site-specific speciation of the contaminant(s), differential sensitivity of species at a site relative to those used to generate ecotoxicity values, plasticity or adaptation of the species at the site, etc.). Therefore, use of the MEP option may not result in adverse ecological impacts. Should a property owner need to demonstrate that no adverse ecological impacts have resulted from leaving concentrations of contaminants using the MEP option a Tier 3 RA could be utilized.

Note on human health exposure pathway through ingestion of plants

The Tier 2 MEP option is available for all land uses except agriculture. The model under the Tier 2 MEP option incorporates all of the same assumptions and exposure pathways for soil contaminants for the protection of human health as the Tier 1 generic model. Therefore, the MEP option provides the same degree of protection to humans as the Tier 1 generic standards. However, the Tier 1 model (and therefore the Tier 2 spreadsheet) does not incorporate the soil-to-plant uptake-to-human ingestion pathway. This is because the current state of the science is very uncertain and excessive conservatism may be required in order to cover all uncertainties, especially with respect to modelling soil-to-plant uptake values in a scientifically defensible manner. There is an enormous amount of variability in the rate of bioaccumulation of individual contaminants in plants in the scientific literature. Uptake factors can vary by orders of magnitude among species and even within subspecies and varieties. Under the Tier 2 MEP option, soil concentrations at the 75th percentile are not in a range anticipated to cause significant phytotoxicity. Therefore, plants grown at these concentrations would likely survive and have the potential to be used as a food item (the same is true for plants grown in soil under generic Tier 1 conditions). Because there is a potential that plants that might be ingested by humans accumulate higher concentrations of contaminants under the Tier 2 MEP option compared to plants grown in soil with contaminant concentrations at the Tier 1 generic standards, the Tier 2 MEP option is not permitted under agricultural land uses. It is also not permitted for agricultural land uses because decreased protection of plant life is incompatible with agricultural land use. The exclusion of the soil-to-plant uptake-to-human ingestion exposure pathway in the generic model is an acknowledged gap and will be re-evaluated at a future date once the scientific data supporting the development of this pathway into the generic model becomes available.

How is the MEP option used within Tier 2?

MEP is an option available to the QPRA in a similar fashion as the Tier 2 adjustable input parameters and RMMs options. If a QPRA wishes to invoke the MEP option for a site, they simply select the “Modified Ecological Protection” option in the Tier 2 spreadsheet. The Tier 2 spreadsheet then recalculates the PSS based on the modified ecological values under the MEP (as well as any other changes in the model if other Tier 2 adjustable parameters have been modified by the QPRA).

How is the MEP option reported?

Any RSC that utilizes standards that were developed with the MEP option will state such on the RSC itself, which will be posted on the Brownfields Environmental Site Registry for public viewing.

Appendix 5 - Modified Subsurface Worker Protection

This option offers a proponent the ability to modify the subsurface worker exposure scenario. The Approved Model includes protection from direct soil contact for a worker exposed to contaminants in the subsurface (known as the “S3 pathway”). The proponent, as part of the MGRA process, may choose to modify the subsurface worker protection S3 value. Selecting this approach results in S3 being multiplied by 100×, effectively removing the protection provided by the S3 pathway. Selecting this approach will also mean that the Hard/Fill Cap RMM will be included as a requirement at the property, and that hard/fill cap must be a depth of at least 1.5 m (see Hard and Fill Cap RMM descriptions and definitions). Selecting this approach will also mean that a Health and Safety Plan (HASP) will be required for the property (see HASP description). The HASP ensures appropriate protection is in place if a subsurface worker carries out intrusive work in the soil below the 1.5 m cap. The development of the HASP should take into account the presence of the site specific contaminants of concern and consider direct exposure through dermal contact, soil and ground water ingestion, and inhalation of soil particles or vapours. The combination of a hard/fill cap and a HASP, is intended to ensure that subsurface workers are protected where the Modified Subsurface Worker Protection approach has been utilized to develop PSS.

Requirement for a Leachate Test for Inorganics

In order to opt into the Modified Subsurface Worker Protection and get the associated relief for S3 with respect to an inorganic (no Koc value) contaminant of concern in soil that remains at the RA property, an acceptable leachate test result should be submitted as part of the RA. Please see the questions for this option in the MGRA section of the RA Pre-Submission Form.

It is expected that the soil sample(s) collected for the leachate testing will be from the area where the highest concentrations of the contaminant(s) of concern are found. At sites where the distribution of contaminants is across the entire site, the QP should use their best judgement to determine the number of samples that should be collected; the expectation, however, is that in this scenario more than one (1) sample will be collected and sent for leachate testing. To support the use of this pathway modifier, the QP should provide a rationale, in the form of a sampling analysis plan, to justify the number of samples collected and their locations.

Multiplying the S3 component value by up to 100 allows higher soil concentrations to be left at the RA property. For most contaminants, the concentrations remaining at the RA property pose no additional risk to people, plants or animals, due to the RMMs in place. In the case of metals, however, the Approved Model does not model how metals may move from soil into ground water, as this pathway is too site-specific to include in a generic or MGRA. The unmodified S3 value provides an upper bound. If the S3 pathway is to be modified, assurance is needed that the ground water will be protected from contamination by these inorganic contaminant(s) of concern.

A leachate test is carried out to provide this assurance. A leachate test mimics how metals in soil are carried into the ground water through rainfall. The leachate test is to be performed by an accredited laboratory (as defined in Section 47(1)(c)(i) or (ii) of the Regulation), and the results would be entered into the Approved Model for comparison with appropriately protective ground water component values. For sites at which potable ground water site condition standards apply, the leachate results would need to be less than both the GW1 (drinking water protection value) and GW3 (aquatic protection value). For sites at which non-potable ground water site condition standards apply, the leachate results would need to be less than both GW3 and 100 × GW1 (as 100 times the Ontario Drinking Water Standards has been used to characterize leachate as being hazardous). If this comparison test is passed, then the Modified Subsurface Protection option could be used to yield relief for metal contaminants of concern in soil at the RA property.

The leachate test to be used for this comparison is the Synthetic Precipitation Leaching Procedure (SPLP; Method 1312 in the United States Environmental Protection Agency (US EPA) publication SW-846 entitled “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods”).

Some proponents may already need to carry out a similar test called the Toxicity Characteristic Leaching Procedure (TCLP; Method 1311 in US EPA SW-846) to characterize waste materials. In order to avoid duplication of testing, and since the TCLP is generally more conservative, a proponent may use either the SPLP or the TCLP.

The flow diagram below (Figure 1) is intended to help the reader understand the process for modifying the subsurface component in the Approved Model.

Process for Developing Property Specific Standards (PSS) using the Modified Subsurface Protection (MSP):

- Check if the S1 or the S2 components are driving the standard to be sure that the MEP RMM will be helpful in generating a numerically higher standard.

- If yes, then the hard or fill cap RMMs become a potentially helpful option as they will remove the S1 and S2 components from driving the standard.

- Check to see if the Reasonable Estimate of the Maximum Concentration (REM) is greater than the S3 component value and that S3 is the new driver for the standard?

- If yes, then the Modified sub-surface Protection RMM can help to modify the S3 value and may be utilized.

- Then determine if there are any inorganic contaminants of concern?

- If no, you can proceed directly to using the MSP without any additional requirements.

- If yes, determine if any of those inorganic contaminants are greater than the S3 component value?

- If yes, then a leachate test will be required to utilize the MSP RMM in order to modify the S3 value.

- The leachate test results must be less than the GW1 and GW3 in the potable situation and less than the GW3 and 100×GW1 in the non-potable situation.

- Determine if the leachate results pass the test?

- If yes, you may utilize the MSP RMM for the inorganic contaminants.

Appendix 6 - Process for Modifying the Solubility Component Value for Petroleum Hydrocarbons (PHCs) F1 and F2 in the Modified Generic Risk Assessment (MGRA) Approved Model

1. Why Modify the Solubility Component Values for PHCs F1 and F2?

The solubility of PHC fractions F1 and F2 is one of the parameters used in the Approved Model to develop ground water standards. These generic solubility component values (CVs) are estimated values and are intended to be an indicator that free product may be present at a RA property. The Approved Model is not appropriate for use at sites where free product is present. In some situations, it is possible that site-specific ground water sampling finds no evidence of free product, even though the solubility CV for PHC F1 and/or F2 is exceeded. In these cases, it may be appropriate to modify the solubility CV within the Approved Model to reflect the fact that site-specific information does not indicate the presence of free product on site. In effect, the absence of evidence of free product on site supersedes the prediction that free product may exist based on the generic solubility estimates.

2. Who is this Guidance for?

This guidance is for proponents of brownfield redevelopment projects at properties with PHC contamination. The ability to modify the solubility CV by demonstrating that there is no evidence of free product on site will permit the development of numerically higher PSS for PHC F1 and F2, thereby offering proponents greater ability to use the streamlined Tier 2 RA process for such properties.

3. When Does this Guidance Apply?