Heat stress in commercial layers

Learn how to mitigate the effects of high temperatures in poultry barns. This technical information is for commercial poultry producers in Ontario.

ISSN 1198-712X, Published April 2020

Introduction

While laying hens may occasionally die from heat stress in Ontario, the main economic consequence of heat stressing the bird is the impact on egg production, egg size and egg shell quality. This factsheet will discuss these impacts and some strategies that producers may use to mitigate the effects of high temperature in their barns.

Effect of heat stress on hens

Hens continually adjust their feed intake according to environmental temperature. The digestion of feed is the hen’s primary means of generating metabolic heat. If exposed to colder temperatures, the birds will normally eat more feed in order to generate more body heat to stay warm. Consequently, as the ambient temperature rises, the hen is more likely to reduce feed consumption to limit her body heat gain from digestion. Up to about 27°C, this fluctuation in feed intake does not affect production unless an important nutrient is marginally deficient. Above 27°C, the bird’s body temperature rises, and a much more dramatic reduction in feed intake can be expected.

A research project was undertaken by Mashaly et al. to study the effect of heat stress on production parameters and immune response in commercial laying hens. The project studied 180 31-week old commercial laying hens at peak production. The hens were divided into one of three groups of 60 hens, each housed in a separate environmental chamber for a 5-week period. All birds in the trial received the same feed ration and received the same light intensity. Commercial production parameters (egg production, egg weight, etc.) were recorded over the trial (Table 1).

| Parameter | Control | Cyclic | Heat stress |

|---|---|---|---|

| Daily feed consumption (per bird per day) |

86.7 g | 65.9 g | 41.6 g |

| Hen day egg production | 87.4% | 82.5% | 56.2% |

| Egg weight | 56.4 g | 53.5 g | 46.9 g |

| Shell weight | 5.06 g | 4.76 g | 3.50 g |

| Shell thickness (x 0.01 mm) | 34.8 mm | 33.9 mm | 28.3 mm |

One chamber was designated as the control group. The birds in this chamber were exposed to a temperature of 23.9°C and 50% relative humidity (RH) for the 5-week duration. The cyclic group was exposed to cyclic daily temperature and humidity ranging from 23.9°C–35°C and from 50%–15% RH to mimic natural cyclic temperatures during hot summer weather.

Birds were exposed to 23.9°C and 50% RH for approximately 8 hr/day, and to 35°C and 15% RH for approximately 4 hr/day to simulate the hot and dry conditions. For the balance of daily time (12 hr), the room conditions were transitioning up or down between these two points. The final chamber was identified as the heat stress group, and these birds were exposed to continuous temperature of 35°C and 50% RH during the 5-week trial.

Feed intake

Digestion of feed produces metabolic heat in the bird. To reduce heat load, the bird will reduce its feed intake. As shown in Table 1, the heat-stressed group reduced their feed consumption by over 50%.

As feed intake declines, the first production trait to respond is egg weight, which also shows up in the Mashaly experiment where the heat stress group produced eggs that were 17% smaller. Researchers speculate this is due to the reduction in the amount of protein ingested at the higher temperature. As temperatures rise above 32°C–35°C, egg production levels may decline (Table 1). This is often a result of insufficient nutrient intake to support normal rates of lay.

Shell quality

The most frequent result of heat stress is a decline in egg shell quality, making the eggs more prone to cracking or downgrading. Most of the shell quality problems arising from heat stress are not the result of dietary calcium deficiency. Rather, they result from extremely complex metabolic changes within the hen. As the bird pants to keep cool, excess carbon dioxide is exhaled. This causes the blood to become more alkaline, reducing its ability to hold and carry calcium for shell formation. Such a situation cannot be changed by increasing dietary calcium.

Vitamins and minerals

High temperatures may also result in less efficient utilization of vitamins. In addition, certain vitamins in the feed are themselves less stable in these conditions.

Various other blood minerals are affected by heat stress. One of the most important minerals to consider is phosphorus. The requirement for this element increases at high temperatures. Marginal phosphorus levels, when combined with heat stress, can lead to increased mortality rates, particularly among older birds.

Manure

As a result of the increased water intake, moisture content of droppings will increase in hot weather. This can create difficulties in the handling and storage of manure when the system depends on dry manure. It can also lead to increased soiling of egg shells.

Immune system and vaccination

There is considerable evidence that the immune system of the bird is hurt by heat stress. Therefore, administration of vaccines to pullets or layers is not usually recommended during very hot weather. Administering vaccines during hot weather can lower the effectiveness of the vaccine.

Furthermore, when using a spray vaccine, closing the ventilation system to permit proper vaccine distribution is impractical in extremely hot conditions. If vaccinations cannot be avoided, they should be restricted to the coolest time of the day. This will help minimize the adverse effects of reduced ventilation and vaccination stress to the bird.

Overall

The effects of heat stress will be made worse by other environmental factors such as:

- increased bird density

- feed and/or water deprivation

- inadequate ventilation

- vaccine reaction

- the presence of diseases or parasites

How a hen tries to lose heat

A caged layer, housed in a barn environment between 24°C–27°C and eating a normal ration will produce about 182 kilocalories of heat every day

When the hen is in a comfortable environmental temperature (21°C–25°C), she will lose most of that heat by sensible means. Sensible heat loss occurs through three pathways:

- conduction, whereby a hen touches a surface cooler than her own surface, for example, the floor of the cage or the sides of a cool water trough

- convection, whereby a cool breeze carries heat from her body

- radiation, the electromagnetic process whereby heat moves from a warmer to a cooler surface without using a medium (heat flows to the earth from the sun by radiation)

When the laying hen is in a very warm environment (28°C–35°C), she must work at losing the heat she produces. Common ways she can lose heat include raising and spreading her wings or separating herself from other birds if possible.

Despite her best efforts, heat loss by sensible means decreases and loss by latent means (evaporation) increases. One reason for this change is that the difference between the temperature of the hen’s body (41°C) and the surrounding air, equipment and walls becomes very small. Thus, she cannot readily lose heat by sensible means and must do so by evaporation. A second reason is that the evaporation of water uses a lot of heat, making it an effective way for her to keep cool.

How does a hen evaporate water without having sweat glands? She does it by panting, like a dog. The hen can easily increase her respiration rate to 10 times normal and indulges in gular (throat) flutter to aid in evaporation. One can readily see the rapid throat movement in panting birds. This throat flutter moves air in and out of the throat, increasing evaporation without such air entering the lungs.

This technique is very efficient on a hot dry day but not as efficient on a hot humid day, as the barn air is less able to absorb as much evaporated water vapour. Because the hen is evaporating so much water from her body to help maintain her body temperature in the comfort zone, she must replenish the lost fluids. Continuous access to clean, fresh drinking water is vital.

Recommendations to reduce heat stress

There are several factors that can influence how a bird can manage high heat. The age of a bird and, indirectly, its feather coverage can influence its capacity. Older hens tend to have less feather coverage, letting them lose heat more efficiently. While the producer has no control over these two parameters, there are several barn management techniques that can help hens dealing with heat stress:

- Electrolytes: When temperatures are expected to peak over 30°C, add electrolytes to the drinking water, starting two days before the anticipated heat event and continue during the event. Remove electrolytes when the expected daytime temperature falls below 30°C so that this tool is available for the next heat stress event.

- Flushing water lines: This ensures that hens throughout the barn have access to cool water to help lose heat via conduction (ingesting cool liquid) and evaporation (through panting).

- Feed management: Some farmers will use a stack feeding program, i.e., limit feeding to the morning (before heat) and again at night before lights out (after heat) to avoid feeding during the heat of the day (digestion of feed creates heat within the hen as previously discussed). Another option includes the addition of a midnight feeding (1 hr in the middle of the night).

- Lower the minimum night time setpoint temperature: Cool the barn more than normal by using the temperature relief of the overnight hours during the heat spell. Instead of a 22°C setpoint, lower this to 19°C–20°C. This will allow the birds to lose more latent body heat so that they can manage the daytime temperatures better.

- Look for areas of poor airflow in the barn: These areas may require the addition of movable circulation fans.

Ventilation considerations

The heat from the laying hen, either in sensible or latent form, must be removed from the building as soon as possible.

The primary goal of the ventilation system during warm weather is to exchange enough outside air through the barn to expel all the animal heat being produced and keep the barn temperature within a comfort range for the animals, if possible. Once the temperature outside the barn exceeds 30°C, most systems are designed to limit the barn temperature rise to no more than 1°C–2°C above this temperature.

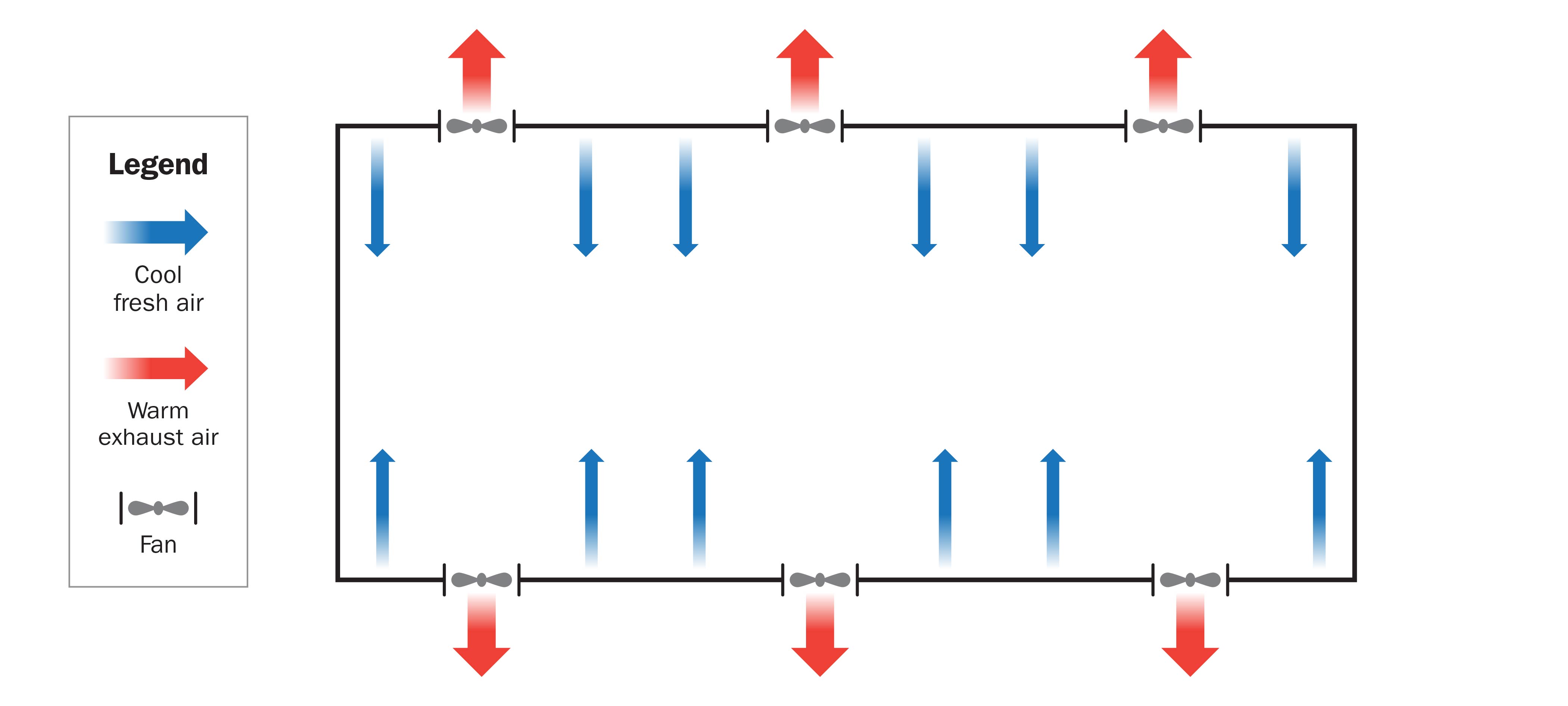

Adequate air exchange

In a typical cross-flow ventilation design where the inlets and exhaust fans are located on both the sidewalls along the long building axis (Figure 1), the exhaust fan capacity is sized using either a ventilation rate of 7 cubic feet per minute (CFM)/hen or 1.5–2 air exchanges/min, depending on the housing system and/or bird density. Higher density normally equates to higher air exchange to remove the greater heat load.

Select the appropriate size and number of fans to achieve the targeted 245,000 CFM. Fans are normally spaced along sidewalls to ensure even airflow and heat removal from the entire room.

In this configuration, the barn is operated as a negative pressure system, i.e., exhaust fans blow air out of the barn, creating a slight vacuum inside the barn to pull fresh air in through the inlet openings. Fans are selected to operate at approximately 24.91 Pa (0.10 in.) of static pressure, and air inlet openings are sized to provide a minimum of 2 ft2 of opening area for every 1,000 CFM of fan capacity.

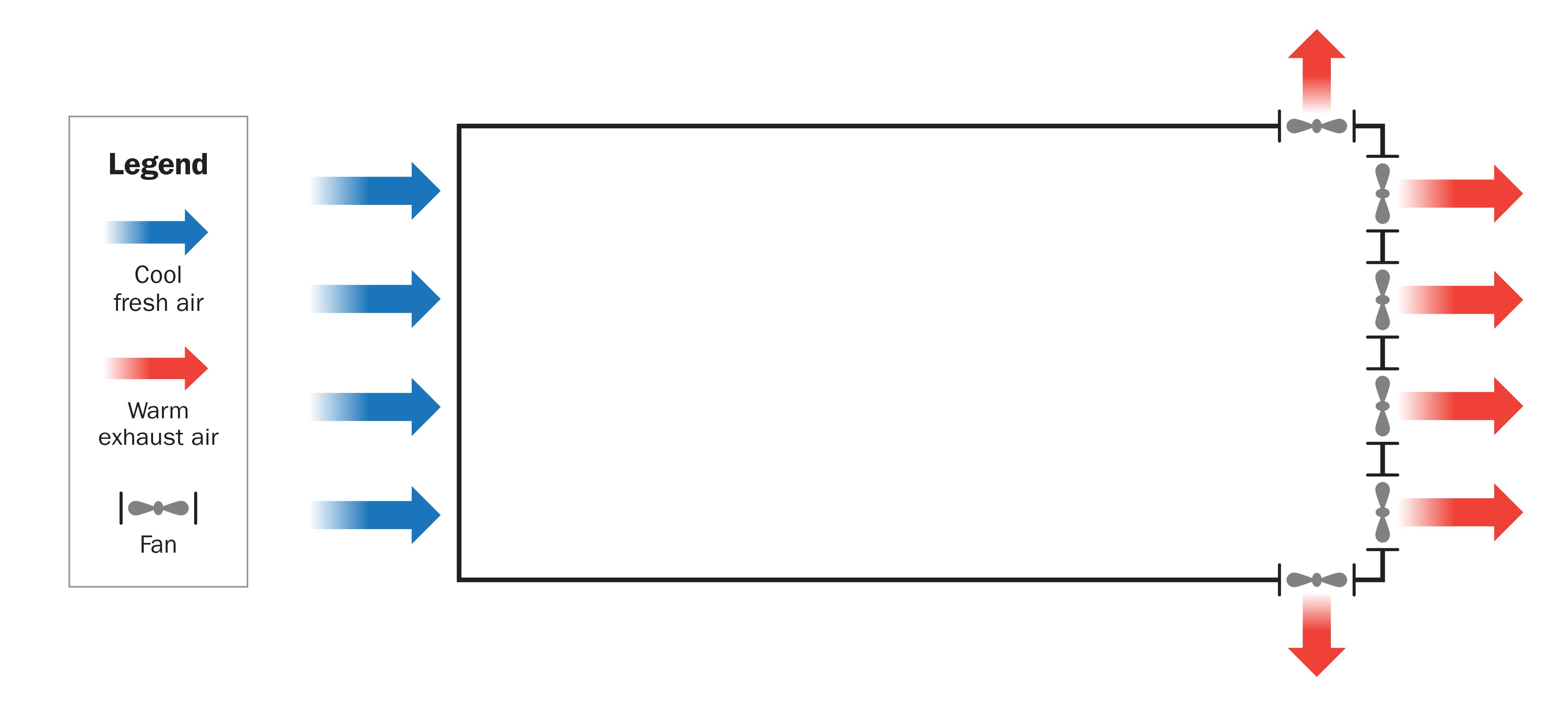

Windchill/increased airspeed — tunnel ventilation

Another option is to use tunnel ventilation to increase the airspeed the birds are exposed to and create a wind chill type effect. Tunnel ventilation has been used in the broiler sector for many years, but there is starting to be some adoption of this system in layer barns.

In this system the exhaust fans and the air inlets are placed in the short axis end walls (Figure 2). This barn design has a narrower barn cross-section. This will create an increased air velocity through the barn, so the bird feels cooler. This concept mimics a person standing outside on a hot 33°C day — if they are standing in a windy location, they do not perceive the temperature to be as hot.

Target airspeeds of 1.0–2.5 m/s (200–500 ft/min) or higher are used for designing tunnel ventilation systems. Research with broilers has shown that an airspeed of 2 m/s (400 ft/min) creates a wind chill effect of 3.7°C for the birds.

The required number of tunnel fans are selected to provide the calculated airflow and the inlet area at the opposite end of barn is sized to provide at least 2 ft2 of inlet opening area per 1,000 CFM of calculated fan capacity.

There are several advantages with tunnel ventilation systems including:

- Birds feel cooler. The birds and people working in the barn feel cooler due to the wind chill effect from the fast-moving air stream running down the length of the barn.

- Energy savings, due to fewer fans being required to achieve a similar level of cooling in the barn. In this case, 53,000 CFM less fan power is required. This is equivalent to operating two 1.2-m (48-in.) and two 0.61-m (24-in.) exhaust fans.

| Date | Maximum ambient temperature | Maximum temperature Barn #1 | Maximum temperature Barn #3 | Feed intake (/bird/day) Barn #1 | Feed intake (/bird/day) Barn #3 | Water consumption (/1,000 birds) Barn #1 | Water consumption (/1,000 birds) Barn #3 |

|---|---|---|---|---|---|---|---|

| July 3 | 30.5°C | 29°C | 27.5°C | 101.5 g | 113.7 g | 186.9 L* | 188 L* |

| July 4 | 36°C | 32°C | 29.5°C | 96.7 g | 99.8 g | 192.1 L* | 205.3 L* |

| July 5 | 34.5°C | 32.5°C | 31°C | 83.7 g | 97.3 g | 182.5 L | 206.3 L |

| July 6 | 30.5°C | 29°C | 29°C | 97.1 g | 102.4 g | 161.5 L | 181.1 L |

| July 7 | 28°C | 26°C | 25.5°C | 107.5 g | 101.4 g | 156.3 L | 167.3 L |

| July 8 | 28°C | 26.5°C | 26°C | 97.8 g | 103.7 g | 156.3 L | 174.2 L |

| July 9 | 32.5°C | 29.5°C | 28°C | 112.6 g | 104.4 g | 178.2 L | 182 L |

*Electrolytes added to drinking water.

A monitoring project was undertaken in Ontario in 2019 (Table 2) to compare conditions between a barn with a conventional ventilation system (Barn #1) versus another barn with a tunnel ventilation system (Barn #3) on the same farm property. The site chosen for the project had hens that were roughly the same age (1-week difference in age), and both barns were fed the exact same diet.

Birds in Barn #1 were housed in a conventional cage system with a space allowance of 574 cm2/bird (89 in.2/bird). The birds in Barn #3 were housed in an enriched colony cage system with a space allowance of 748 cm2/bird (116 in.2/bird). The farm manager noted that birds in Barn #3 normally eat 3–5 g/day more feed than their counterparts in Barn #1 simply because they are more active.

Results and discussion

In this example, Barn #1 had slightly over two complete air exchanges per minute when all the fans were operating. While Barn #3 had a little more than one complete air exchange per minute with all of the fans operating, it was developing an airspeed of approximately 485 fpm down the length of the barn.

As shown in Table 2, the birds in Barn #3 were exposed to the wind chill effect so they did not perceive the heat as much and their feed consumption did not fluctuate significantly during short-term exposure to temperatures above 28°C.

An interesting note as discussed previously is the difference in ventilation operating costs between these two barns, which was quite dramatic. Barn #1 was operating a total of 41 fans during times of peak heat while Barn #3 had only 22 fans operating. The hottest time of the day normally occurs during peak electrical pricing rates so these operating costs could be significant to the farm if a heat wave persisted for more than a couple of days.

Summary

Layers in Ontario will experience heat stress at some point during their production cycle. Preparing for heat events by making sure that your ventilation system has capacity and having heat stress management techniques ready to implement will minimize the negative impact on the birds. It will also help the birds' recovery after the heat event and hopefully minimize any production issues.

After a heat stress event you should evaluate how well your heat stress strategy worked and look for areas where it could be improved. There are always ways to improve an existing barn and if you are building a new barn, make sure your ventilation system has the required capacity and will work well with the layer housing system you will install.

This factsheet was written by Al Dam, Poultry Specialist, OMAFRA, Guelph; Daniel Ward, P.Eng., Agricultural Engineer, OMAFRA, Stratford; and Cecelia Creighton, Poultry Assistant, OMAFRA, Guelph.

Footnotes

- footnote[1] Back to paragraph Mashaly, M.M., Hendricks III, G.L., Kalama, M.A., Gehad, A.E., Abbas, A.O., and Patterson, P.H. 2004. Effect of Heat Stress on Production Parameters and Immune Responses of Commercial Laying Hens. Poult. Sci. 83:889–894.

- footnote[2] Back to paragraph Chepete, H.J., Xin, H., Mendes, L.B. & Li, H. 2011. Heat and Moisture Production of W-36 Laying Hens at 24°C to 27°C Temperature Conditions. ASABE 54, no.4 (2011) pp. 1491–1493.