Heavy equipment and soil compaction

Learn how large tires and low inflation pressures may reduce soil compaction caused by heavy equipment.

Can large tires and low inflation pressures solve all your problems?

Producers view soil compaction as a prevalent problem — a problem to be avoided, if possible. There are several main theories on how to avoid or manage soil compaction.

- Confine traffic to permanent lanes within the field in order to provide traffic-free zones for crop production.

- Avoid wheel traffic on wet soils which are susceptible to compaction, use equipment with lower axle weights.

- Increase the size of the "foot print" by employing radial tires, larger tires, more tires, or tracks.

- Reduce tire inflation pressures.

Considerable effort has been taken on the part of equipment manufacturers to do two of these, by increasing tire size and reducing inflation pressures. This lowers ground contact pressures so there is less soil rutting and compaction. Figure 1 illustrates where a loaded manure tanker with radial tires at 18 PSI (left) resulted in a larger foot print and a rut which was 10 cm shallower than bias play tires at 32 PSI (right).

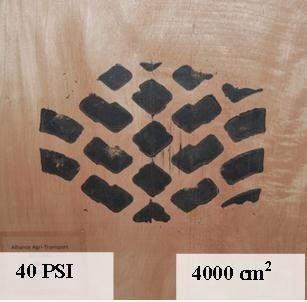

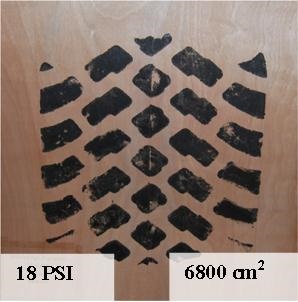

In well publicized compaction studies done at Ohio State University, the four wheel drive tractor operating at inflation pressures of 6 and 7 PSI resulted in less soil compaction than two belted track tractors. However, when this same tractor was operated at inflation pressures of 24 PSI, it caused the worst compaction in the experiment. Certainly the use of larger foot print tires, with inflation pressure adjusted correctly for axle load, has been an important tool in reducing compaction risks. Figure 2 illustrates where the inflation pressure of a radial tire on a fully loaded manure tanker is reduced to meet minimum load bearing requirements from road speed (40 PSI at 25 MPH) to field spreading speed (18 PSI at 5 MPH). Being able to adjust tire inflation pressures at the field edge to maximize tire floatation for the slower in-field operating speeds has been common in Europe for years, but is just starting to get traction in Ontario.

Figure 2. Tire footprints for an Alliance Agri-Transport 35.5LR32 radial tire fitted on a fully loaded 8,000 gal Husky manure tanker (~ 21,000 lbs/tire) at tire inflation pressures of 40, 28 and 18 PSI. (Equipment courtesy of Husky Farm Equipment and the Alliance Tire Group).

Total axle weight

What might get lost in this discussion is that soil compaction, particularly at depths a few centimeters below the surface, is also a function of total axle weight. Large tires with low inflation pressures cannot eliminate the potential for very heavy axle loads to cause compaction. Rutting or smearing may indeed be reduced by this type of running gear, but pressure distribution under these large tires can still negatively affect soil structure.

Soil compaction can be a yield limiting, expensive problem. Efforts should be made to avoid causing it in the first place. Proper tires with correctly adjusted inflation pressures can significantly reduce surface compaction. They are at least part of the solution for subsoil compaction threats as axle loads continue to climb.