Incorporation of liquid and solid prescribed materials

Learn about the techniques and benefits of incorporating liquid and solid prescribed materials into crop production. This technical information is for Ontario producers.

ISSN 1198-712X, Published November 2009

Introduction

The evolution of farming systems over the last few decades has had considerable impact on how manure produced on livestock farms is managed. New technology is fostering a trend towards less tillage and improved residue management in crop production systems. This in turn is challenging conventional manure management systems.

Incorporation of agricultural and non-agricultural source materials (NASM) reduces nutrient and bacteria movement to surface water, places nutrients closer to the crop roots and minimizes odours. However, conventional methods to inject or incorporate manure and other materials can reduce surface residue, leaving soils more vulnerable to wind and water erosion. Fall application of these materials using these application methods only increases the risk by leaving soils vulnerable longer, resulting in potentially greater offsite movement of soil and nutrients.

Using both agricultural and non-agricultural source materials in today’s cropping systems is a trade-off between nutrient and pathogen retention, odour reduction and the potential for soil erosion due to reduced surface residue coverage. This fact sheet outlines management options to help meet goals of nutrient and pathogen retention, odour reduction and reduced soil erosion.

Incorporation

Incorporation involves mixing nutrients into soil through tillage. Till the soil to a minimum depth of 10 cm and for optimum retention, till either immediately after or during application of the nutrients. Direct injection of a liquid material into the soil is also a form of incorporation.

Incorporating manure or non-agricultural source materials

Three main reasons to incorporate or inject manure and NASM are:

- limiting odours

- reducing surface runoff

- improving nutrient and pathogen retention

Shallow incorporation and mixing these materials with crop residue also promotes the decomposition of the residue.

Odours

As the number of rural dwellers increases it is more important to be sensitive to odours. There are ways to minimize odours and maintain neighbour relations:

- incorporate or inject highly odourous materials immediately

- avoid applying during weekends and holidays

- apply when the wind is blowing away from neighbours

- spread in the morning when air is warming and rising, instead of late afternoon

- avoid spillage on public roads

Table 1 lists the odour thresholds for different methods of spreading manure. It shows that incorporation is an effective means of controlling odour as it results in essentially the same odour units as unmanured ground.

| Application Method | Odour Detectable Threshold¹ |

|---|---|

| Broadcast | 2818 |

| Plow | 200 |

| Harrow | 131 |

| Inject | 32 |

| Unmanured | 50 |

1. Ratio of fresh air to odorous air (fresh:odorous) to dilute the odour to where it is just detectable.

Source: Livestock and Poultry Environmental Stewardship Curriculum Lesson: 44 Emission Control strategies for Land Application

Nutrient retention

Nitrogen

Manure contains stable and unstable forms of nitrogen. Unstable nitrogen occurs in urine as urea and may account for more than 50% of the total nitrogen in manure. The more stable organic nitrogen occurs in feces and is slowly released.

The amount of nitrogen available from liquid manure to crops depends on how long it is exposed to the air before incorporation into the soil.

If incorporated directly as a side dress for corn during the growing season, 100% is available for plant growth.

If manure is spread during the spring prior to planting and incorporated immediately, roughly 65% of the nitrogen will be available (Figure 1).

If the manure is not incorporated the percentage lost increases by about 12% per day left unincorporated.

If not injected or incorporated, similar losses are anticipated for the volatile nitrogen sources found in NASM such as sewage biosolids.

Although general guidelines, these figures support a strong economic argument to incorporation, as well as an environmental one that it decreases surface runoff, reducing the threat of nitrogen and phosphorus to surface waters.

Phosphorus

Phosphorus is the least mobile of the major plant nutrients in the soil. It tends to bind within the soil matrix and is only slightly susceptible to leaching. The most significant water quality concern is generally in surface runoff and erosion situations.

Incorporating materials soon after spreading reduces contamination risks, yet continual tillage also has drawbacks, with increased erosion and compaction potential. For more detailed information on phosphorus erosion see OMAFRA fact sheet Determining the Phosphorus Index for a Field.

Potassium

Potassium is not presently considered a threat to water quality, partially due to its relative immobility in the soil. Manage potassium properly:

- to improve crop production

- reduce loss

- prevent excessive build up in the soil

Excessive potassium in soil may create feeds that are a risk to milk production and herd health.

Pathogens

Bacteria and other pathogens are potentially harmful to humans, livestock and other living organisms.

It is important to prevent pathogens from entering water. The best way to do this is to keep applied materials in the field where soil organisms and crops can breakdown and use the different components of these materials.

Preferential Flow

Preferential flow describes the movement of nutrients, pathogens and other substances taking the path of least resistance down the soil profile. Wormholes, root channels, cracks and other tunnels that run through the subsurface soil structure can provide a pathway to the drainage tiles.

The number of macropores and the depth of the tunnels leading from the surface to below ground are influenced by soil type and organic matter.

Higher organic matter and clay-loam to loam soils provide the best environment for soil life and allow stability of the macropores once formed.

Heavy clay soils, on the other hand, tend towards waterlogged, low oxygen conditions that are not favourable to worm tunnelling.

Coarse sands with low organic matter have significantly less stability, causing tunnels to collapse and coarse sands rub against soft bodied soil life dehydrating and killing these species.

Preventing preferential flow and tile drain interaction

Pre-tillage

Pre-tillage is recommended to break macropores. While pre-tillage may compromise no-till fields, shallow tillage deters the flow of liquid materials down macropores towards the field tile.

There are advantages to applying manure or NASM to wheat or spring grain fields after harvest followed by shallow incorporation. Shallow cultivation does not disturb earthworm channels below the depth of incorporation and the worms readily rebuild these channels to the surface. Also nitrogen in the manure and NASM helps straw to breakdown and material will be incorporated, limiting nutrient losses and odour.

According to the Nutrient Management Act, 2002, (NMA) materials are incorporated into land only if they are incorporated with a minimum depth of soil disturbance of 10 cm. Land is considered pre-tilled only if the tillage occurred not more than 7 days before the material is applied to it.

Methods of incorporation

The method of spreading and incorporating, or not incorporating, manure and NASM on crop acres influences the amount of nitrogen available for the crop.

Shallow tillage implements

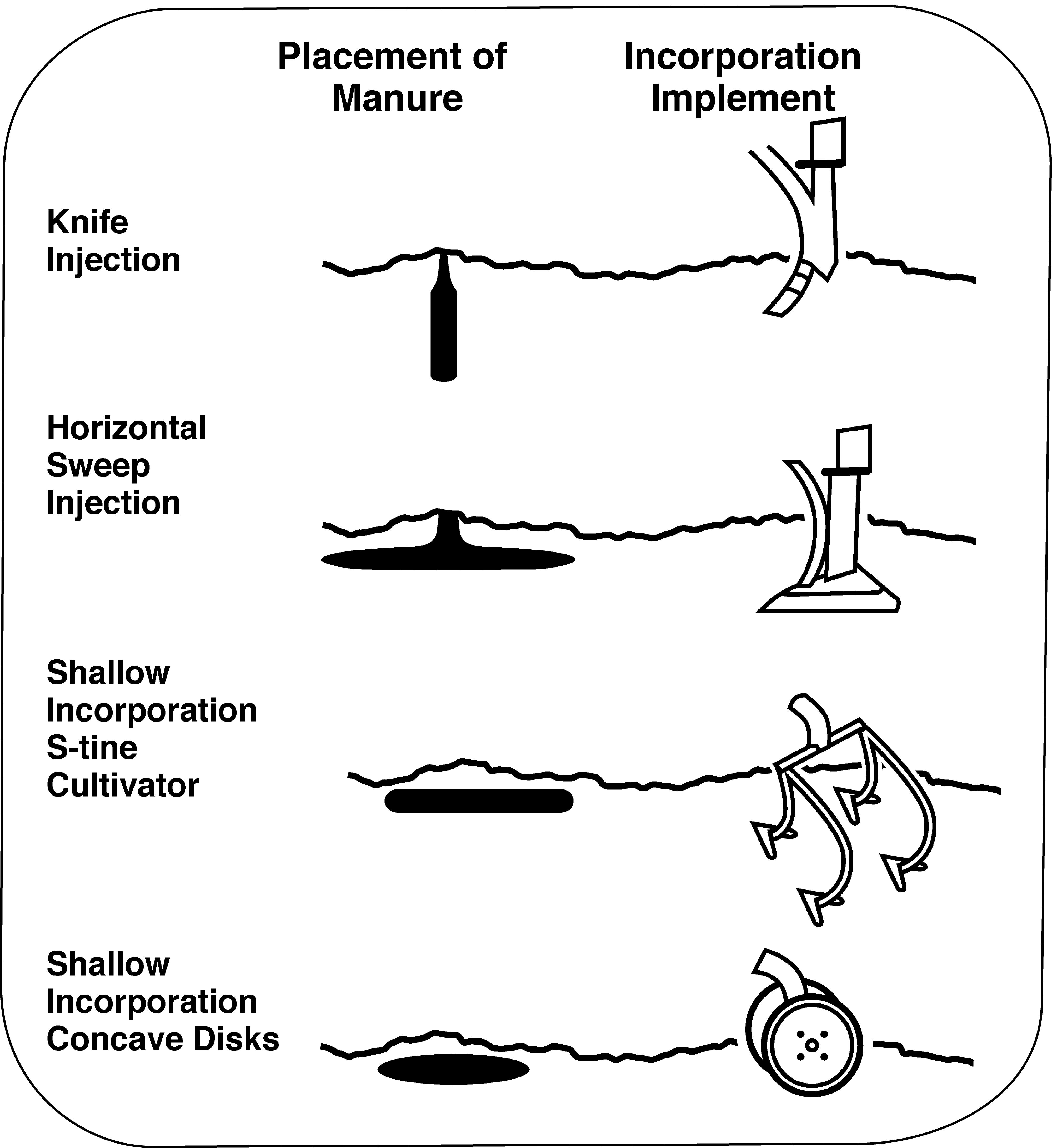

Incorporation may involve turning the soil over by plow or chisel plow so surface soil, plus any applied materials, are buried. Incorporation is most effective when the material is mixed with soil, instead of being buried. Less aggressive methods of incorporation include disc ripping or cultivating that mixes the soil and applied material within the top few inches of the surface of the soil. Still less aggressive tools for disturbing the soil surface are equipment such as a rolling knife-blade injector or a less aggressive shallow cultivation (Figure 2).

Source: University of Nebraska, Institute of Agriculture and Natural Resources.

Other shallow incorporation tillage implements (s-tine cultivators and concave disks) are options on many liquid manure tank wagons. These systems are most commonly used for pre-plant applications. Materials are applied near the tillage tool that immediately mixes the materials into the soil. Speed of application, low power requirements and uniform mixing into the soil are advantages of this approach. In addition, such systems are being used to side-dress manure on row crops. However, extra attention is necessary. S-tines can trap and drag residues and, in some cases, have taken out a long row of corn when plugged tines behind the tanker were not noticed. Side dressing expands the season during which manure can be applied and improves the use of manure nutrients.

Shallow tillage of the soil prior to manure or other material applications disrupts the soil surface, decreasing the flow of nutrients down wormholes, cracks and other macropores towards the field tile. Soil cultivation before material application greatly increases the soils ability to absorb applied materials and resist immediate runoff.

Liquid methods

In the past, application on grassland, legume crops and cereal grains was limited to surface broadcasting. But alternative application methods are now appearing.

Flexible drop hoses supported on a boom can apply liquid manure and NASM beneath the crop canopy on the soil surface. A variation is a sliding metal shoe to which the drop hose is attached. The shoe rides on the surface, scraping it free of residue and creating a depression for the liquid. This method reduces ammonia losses and minimizes odour since there is reduced mixing of air and applied liquid. Yield improvements suggest that side-dressing nutrients into the crop can more than offset any crop damage by the sliding shoe.

Injection methods

Injecting liquid materials is another way of incorporating (Figure 3). Here liquid flows through a tube attached to a knife that places the material in a band below the soil surface.

While this method is effective, be careful to prevent soil smearing and compaction when the soil is too wet.

Exercise caution in soil conditions susceptible to macropore flow. In these situations, place the liquid material higher than the depth the injection knife is traveling through the soil. The soil disturbance the knife action causes below the applied material helps to seal off the macropores, so the material does not reach the tiles.

Injector knives, the traditional injecting option, cut 30–40 cm deep into the soil. The result is high power requirements and little mixing of the soil and applied materials. Injector knives with sweeps that run 10–15 cm below the soil surface allow liquid placement in a wider band at a shallower depth. The materials mix with the soil better than straight injector knives and the material is higher in profile, minimizing potential leaching and reducing power requirements. Use sweeps to apply a higher rate of material than a conventional injector knife.

Alternatives to incorporation

Incorporation is not always possible. Examples include when:

- loose soil is blown by the wind or washed from the field by water

- saturated soil becomes too compacted under the weight of equipment tires

- injection into saturated soils containing clay may smear in the seedbed, limiting root development and growth of next season’s crops

Alternatives to incorporation include using high residue (over 30%) on the soil surface or live crops to reduce wind and water erosion. Residues, cover crops and live crops can also absorb and trap nutrients that otherwise wash off the soil surface or leach down to tile drains. High crop residues left to trap nutrients can be a feasible alternative to tillage.

Incorporating nutrients: best management practices and nutrient management protocol

Timing

In general, apply materials containing nitrogen as close as possible to planting time, as this ensures greater availability of nutrients for plant growth.

Early spring application before planting is the best for crop production, as this allows mineralization of organic nitrogen.

Fall application, even with incorporation, can increase nitrogen losses due to the time between application and the next growing season.

Application rates

The maximum application rates determined by each nutrient management program may be increased as the risk of material flowing over the soil surface is decreased. For example, the maximum single application rate for liquid materials (agriculture or non-agricultural) may be increased when the materials are injected or incorporated into the land or if the land is pretilled. [See O. Reg. 267/03 and the specific nutrient management plan.]

Methods of decreasing surface runoff include:

- Injecting or incorporating applied materials. This mixes soil and nutrients together so nutrients have a greater chance of staying where applied.

- Pre-tilling soil. This destroys cracks and macropores in the soil thereby blocking the pathways used by nutrients to leach through to field tiles. Land is considered pre-tilled only if the tillage occurred not more than 7 days before the application of the liquid prescribed materials.

Set back distances

The NMA regulates set back distances from surface water. The distance required for a set back from the top of the nearest bank of surface water may be decreased under certain conditions such as those listed:

- Incorporation or placement of materials in a band below the soil surface such that the materials cannot travel over the soil toward surface water.

- Land is pre-tilled before application to reduce macropore flow and to have higher absorption potential, compared to surface application on to untilled soils.

- When materials are applied to live crops or to land with crop residue covering at least 30% of the soil. Examples are wheat stubble and/or a red clover cover crop, standing corn stalks, alfalfa, grassy hay and growing row crops.

Set back distances for NASM differ from those for agricultural source material such as manure and are determined by the quality of the material. Refer to the regulation for details.

Conclusion

Crop production can reap the benefits of agricultural and non-agricultural source materials through added nutrients and organic matter, but with benefits come responsibilities to manage these resources with care for soil, air and water quality.

Different farming systems require adjustments to conventional methods. For manure and NASM incorporation this may mean adopting new technology that replaces or adds to the plow and other conventional tillage tools. Each generator and user of these materials must evaluate alternative management techniques and make choices that are most positive for Ontario’s natural resources.

Disclaimer

The information in this fact sheet is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was written by Michael Payne (retired), environmental management specialist, OMAFRA.