Providing feed and water to pigs

Learn about proper feed and water management for pigs of all sizes.

ISSN 1198-712X, Published February 2025

This fact sheet provides guidance on feed and water management for pigs of all sizes. For detailed information on the nutritional needs of pigs, refer to the Ministry of Agriculture, Food and Agribusiness (OMAFA) fact sheet, Nutrient requirements of pigs and considerations for making diets.

Water management and drinkers

Pigs should always be provided clean, palatable water. Water should be tested annually to ensure its quality is suitable for pigs to consume. Every farm should have a contingency plan in place to provide water in the event of a supply interruption or contamination. If you are using a liquid feeding system or wet/dry feeders, a separate source of water must be provided to the pigs.

Water disappearance can be much higher than actual water consumption by pigs. Wastage of water can occur regularly, so drinkers should be set to the correct height and flow rate to help reduce losses. Adjust heights as the pigs grow, and check flow rates weekly and during room fill. Use bowl‑style drinkers or a wet/dry feed system rather than nipple drinkers to reduce the amount of water wasted.

Refer to the OMAFA fact sheet, Water requirements of livestock, for information on water usage and quality.

The National Farm Animal Care Council’s Code of Practice for the Care and Handling of Pigs also provides guidelines on water usage, flow rates and drinker heights for different phases of pig production in Appendix G.

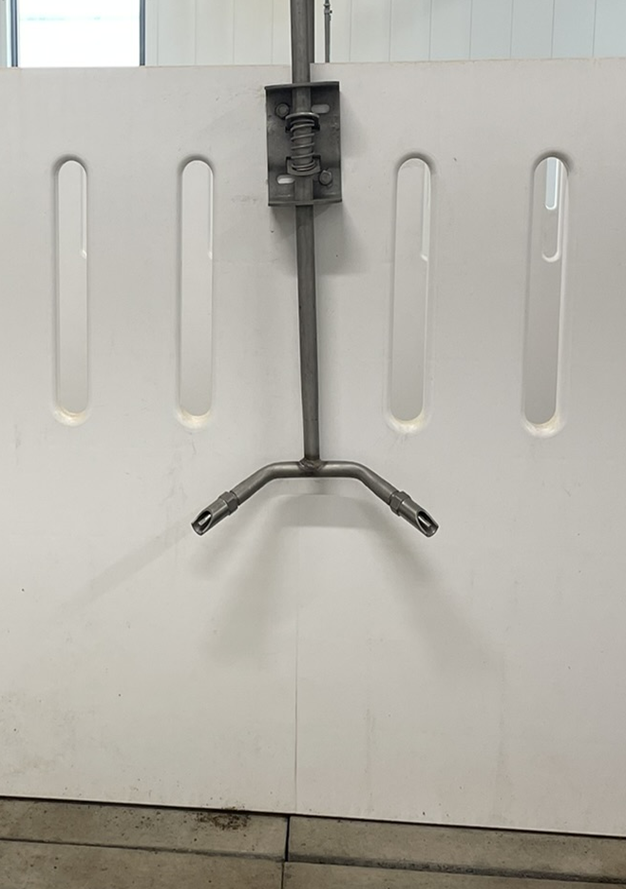

There are different styles of drinkers for livestock available on the market. For pigs, the most common styles of automatic drinkers are water nipples (Figure 1) and water bowls (Figure 2). Water troughs (Figure 3) can also be used successfully but will require more labour to keep them clean. If you are raising pigs outdoors, try to keep the water source in a shady place to prevent water from overheating. Regardless of drinker type, check equipment daily to ensure it is working properly.

Ensure there is enough water for the number of animals in the pen. Insufficient water can cause problems with feed intake, growth and reproduction, including milk production in sows. In a group setting, ensure that every animal always has access to enough water. It is recommended that there be no more than 10 to 15 pigs per water source: 10 for nursery pigs and 15 for larger animals. In nursery and grow/finish barns, drinkers should be located near feed sources to reduce the amount of walking that pigs need to do when eating and drinking.

Water consumption varies significantly between different sizes of pigs and can be impacted by the environment and dietary intake. For example, consumption can increase by 15% to 50% if barn temperatures are above the pig’s comfort zone. Young nursery pigs can consume 1 to 2.5 L of water per day. Growing pigs weighing about 50 kg can consume 5 to 7 L per day, with larger pigs consuming even more. A lactating sow needs significant amounts of water for milk production and can consume upwards of 20 L per day during lactation.

Feeders and feed management

Pigs need to be provided with daily access to feed that is adequate to meet their requirements and maintain their health. There are a variety of feed types one can provide. An example of a feeder is shown in Figure 4.

Regardless of pig size or production stage, check feeders daily to ensure they are functioning properly. If feeders are damaged, repair or replace them quickly to prevent feed spillage or injury to the animals. Keep feed storage areas and bins clean and rodent-free.

Feed systems can be classed as dry, wet-dry or liquid.

With a dry system, a pelleted or mash feed is provided to the animals in a feeder, and a water source is provided in a separate location.

With a wet-dry system, a water nipple is located in the feeder trough, allowing the pig to mix water and dry feed together. Wet-dry systems have been shown to reduce feed wastage and increase feed consumption.

A liquid feed system mixes feed and water in a tank and then delivers a liquid feed mixture to the pigs. A potential benefit of a liquid system is the ability to include high moisture corn or high moisture by-products into feed rations.

Sows

Sow feeder styles can vary depending on how sows are housed (stalls versus groups versus individual farrowing crates/pens) and their stage of production (breeding, gestation, lactation). Feeders can be electronically controlled or manually calibrated using a drop system to deliver precise amounts of feed to each animal. The feeding system chosen will ultimately depend on the producer’s preferred management style, comfort level with electronics and the desired outcome for each animal.

Sows that are currently in the gestating phase of their reproductive cycle are limit-fed to prevent over conditioning, which can lead to difficulty with farrowing and lactation. These sows should be fed 1 to 2 times per day. The amount of feed will vary depending on animal size, production level and whether they are consuming any forage in addition to their grain diet. On average, these sows should consume 2 to 2.5 kg (4.5 to 5.5 lb) of concentrate feed per day if no forage is provided. If forage is provided, 1 to 1.4 kg (2.5 to 3 lb) of concentrate feed should be provided per day. Forage, which is a fibre source, can help the sow feel fuller while she is on a restricted amount of feed.

There are different strategies that can be implemented when feeding gestating sows. These include:

- standard feeding: Sows are fed one diet at the same amount throughout their entire gestation period. The amount can be tailored for each sow if the feed system allows.

- bump feeding: Feed allowance is increased towards the end of gestation.

- top dressing: Sows are provided with an additional supplemental diet during late gestation or for thin sows.

- phase feeding: Different feeding levels or diets are fed, based on the stage of gestation and/or parity of the sow.

- precision feeding: Blending 2 or more diets to precisely match the sows’ daily nutrient requirements as she progresses through gestation (electronic system with blending capabilities required).

Regardless of which feeding program you are using, assessing the sow’s body condition score will help guide feeding amounts. To understand the importance of sow body condition and how to evaluate it, refer to the OMAFA fact sheet, Determining the size of finisher pigs, replacement gilts and sows.

Lactating sows should be fed as much as they are willing and able to eat. Higher feed intake leads to increased milk production and thriving litters. Their feed intake will increase over the first few days of lactation and can reach 6.8 kg (15 lb) or more per day during peak lactation. It is important to keep lactating sow feeders clean and not let feed spoil in the feeder, as this may cause the sow to reduce or stop intake. If you are feeding forages, lactating sows should not be getting large amounts, as this takes up space in their gastrointestinal system and reduces the amount of usable nutrients available for milk production by reducing the intake of concentrated feed.

There are several strategies used to maximize lactating sow feed intake, and success varies from farm to farm. Some producers provide the sow with ad libitum feed just before or after farrowing, whereas others ramp up the amount of feed given over the first few days of lactation. Determine what system works best on your farm. Some other tips to remember with lactating sows:

- Feeding sows frequently instead of filling their feeder once a day encourages them to get up more often and keeps feed fresh and less likely to spoil.

- Gilts and younger sows will consume less feed than older ones.

- The body condition of the sow at the time of farrowing will impact her feed consumption throughout lactation. Overweight sows will consume less feed post-farrowing and rely more on their own body fat to supply nutrients in milk. This will cause them to lose a significant amount of body weight. Poor body condition of sows can also lead to lower conception rates and longer wean-estrus intervals than with well‑conditioned sows.

- Using a pelleted feed can increase feed intake compared to a mash diet.

- During the summer when temperatures are high, sows will consume less feed. Work with your nutritionist to make a summer ration that is more nutrient dense so she can consume more nutrients with less volume of feed.

- Having a water nipple in the feeder can help increase feed intake.

Suckling piglets

Most suckling piglets perform well by consuming colostrum and milk from their dam. Colostrum is the first milk the sow produces, which is especially rich in antibodies and other immune cells. Unlike in humans, antibodies cannot cross the placental membrane to the piglets during gestation, so piglets must consume colostrum after they are born to receive this essential immune protection from their mothers. Sows will only produce colostrum for the first 24 to 48 hours after farrowing, and the ability of piglets to absorb antibodies from colostrum begins to decline rapidly after birth. Research has shown that in order to survive and perform optimally before and after weaning, piglets need to consume at least 100 mL of colostrum within the first 24 hours of life. Sows will nurse their litter approximately once an hour throughout the lactation period.

In some instances, piglets may need some extra care throughout their suckling period. This can be because the sow isn’t producing enough milk, the sow had more piglets than teats to nurse from or the piglet has a low birthweight and just needs extra help. There are several nutritional and management strategies that producers can use to help high-risk piglets and increase the likelihood of them becoming a full-value pig down the road. Refer to the OMAFA fact sheet Helping high-risk piglets in the farrowing room for details on these management and nutritional strategies, including the use of milk replacers and gruel feeding.

Producers can implement nutritional strategies, such as creep feeding, for suckling pigs with the aim of helping them successfully transition from liquid to solid feed at the time of weaning. To learn about creep feeding, refer to the OMAFA fact sheet Creep feeding to improve piglet performance.

Weaned (nursery) piglets

Piglets undergo a significant amount of stress around the time of weaning. This includes social, environmental, immunological and nutritional stressors. This contributes to a common phenomenon called the “post-weaning growth lag.” This is characterized by:

pigs going off feed for 24 to 48 hours post-weaning

- reduced (or negative) body weight gain

- increased susceptibility to disease

- negative impacts to gut development

It is extremely important to get piglets onto feed as fast as possible at the time of weaning to ensure optimal welfare and performance.

If the average weaning weight of piglets is 6 kg, the range of weights for 92% of weaning piglets in a group will likely be about 4 to 8 kg. Piglets with below‑average, average and above-average weights have different growth curves. It can take up to 20 days post-weaning for the below-average piglets to reach 6 kg and up to 26 days to reach 8 kg. Managing feeders and feed is critical to help get weaned piglets off to a good start. Nursery pigs should be fed ad libitum feed at all times.

Nursery pigs can be fed using dry, wet-dry and liquid systems. The number of pigs per feeder space depends on the type of feed system and, if a dry feed is used, the type offered (mash versus pellets). In the nursery, the recommended number of pigs per feeder is between 6 (mash) and 10 (pellets). Utilizing a wet-dry system allows for additional pigs per feeder space as pigs can consume feed faster. With a liquid feeding system, all pigs must have access to the feed trough at the same time, as the feed is delivered in small batches several times a day.

When providing dry feed, feeder gaps should be adjusted to achieve 65% to 70% feeder pan coverage to optimize feed conversion ratio (FCR) and reduce the amount of time each pig spends at the feeder. The Kansas State University Animal Sciences and Industry extension team offers feeder adjustment cards to help nursery producers ensure they are achieving the correct feeder pan coverage.

Feeding mats are recommended for the first week post-weaning. Mats take advantage of the normal social feeding behaviour of young pigs, allowing them to eat as a group and consume small amounts more frequently. If a creep feed is provided in the farrowing room, the same feed for the first few days post-weaning should be used, as pigs will recognize the smell and taste of the feed.

The overall amount of feed consumed per pig will vary from pig to pig, farm to farm and between genetic lines. Pigs under 8 kg will consume approximately 0.3 kg/day of complete feed. Pigs 8 to 15 kg will consume approximately 0.5 to 0.8 kg/day and pigs 15 to 25 kg will consume approximately 1 to 1.5 kg/day.

Grow-finish pigs

Like nursery pigs, grow-finish pigs can be fed using dry, wet-dry and liquid systems. The recommended number of pigs per feeder in the grow-finish barn is between 11 (mash) and 17 (pellets). Utilizing a wet-dry system allows for additional pigs per feeder space, as pigs can consume feed faster. With a liquid feeding system, all pigs must have access to the feed trough at the same time, as the feed is delivered in small batches several times a day.

When providing dry feed, feeder gaps should be adjusted to achieve 40% to 50% feeder pan coverage to optimize the FCR and reduce feed wastage. As pigs grow, feeder pan coverage can be decreased slightly to help reduce wastage. If feed accumulates in the corners, you may need to reduce the gap setting. Cleaning corners daily will allow you to better determine if the gap setting requires changing.

The depth of the feed pans and width of the feeder are also important to ensure optimal performance. For pigs nearing the end of the finishing stage (> 95 kg), the feeder pan depth should be approximately 30 cm, which prevents the head of the pigs from pushing against the feeder as they eat. The width of the feeder should be 1.1 times the shoulder width of the pig and should be sized for the largest pigs that will use the feeder. With market weights of around 130 kg body weight, this equates to a shoulder width of approximately 32.5 cm (12.8 in.) and a required feeder width of 35.6 cm (14 in.). Many older facilities use feeders with 30.5 cm (12-in.) widths, which limit the growth performance of the animals. Newer facilities are often opting to install feeders with 40.6-cm (16‑in.) widths.

Like nursery pigs, grow-finish pigs should be provided with ad libitum feed. The overall amount of feed consumed per pig will vary from pig to pig, farm to farm and between genetic lines. On average, pigs in the growing stage of production (25 to 70 kg) will consume approximately 1.4 to 2.2 kg of feed per day, and pigs in the finishing stage (70 to 135 kg) will consume 2.5 to 3 kg per day.

Phase feeding

Phase feeding is typically used throughout the grow‑finish phase of a pig’s life. It allows for adjustment to the ration of dietary nutrient concentration as the pigs grow, so that over- or under-feeding of nutrients to the pigs is reduced. In turn, this reduces nutrient losses to the environment and the cost of production for the producer, while improving animal welfare and performance. The more phases there are, the closer the requirements of the pig can be matched. However, the number of phases must be balanced with practicality and cost. While the number of diet phases can vary, there are typically 2 or 3 diet phases in the nursery barn and 3 or more in the grow-finish barn.

Feed budgets

A feed budget is a tool that producers can use to help manage feed costs. A feed budget determines how much of each phase of diet is given to a group of pigs, removing the need to weigh pigs or use visual observations to estimate the weight of the group. Feed budgets are customized for your farm and should account for genetics, target market weight, dietary energy and nutrient levels, health status, intake and growth history. The more data used to develop the feed budget, the more precise the delivery of the right feed to the right pigs at the right time. In general, a feed budget estimates how much feed each pig will consume during a weight range. Feed budgets are used successfully in many nursery and grow-finish barns.

To determine the feed budgets for your farm, first decide on the number of dietary phases you plan to feed. Once the dietary phases are set, the target start and end weights for each phase will be known. If possible, using data from the farm, including genetic growth potential and historical information, the FCR for pigs within those weight ranges can be used to determine how much feed each pig needs to consume. For example, if nursery pigs are expected to gain 5 kg of weight with an FCR of 1.4, 5 multiplied by 1.4 kg of feed per pig will be needed, or 7 kg of feed per pig for that phase. Table 1 shows an example feed budget for nursery and grow-finish pigs. After determining the feed consumption for each dietary phase, multiply the feed budget per pig with the total number of pigs being fed, to provide the total amount of feed needed to be delivered.

| Diets | Initial pig weight (kg) | Ending pig weight (kg) | Feed:gain (kg) | Feed budget (kg/pig) | Estimated gain/day (kg) | Days on feed | Kg/day |

|---|---|---|---|---|---|---|---|

| Starter 1 | 5 | 7 | 1.10 | 2.2 | 0.21 | 10 | 0.2 |

| Starter 2 | 7 | 11 | 1.40 | 7.0 | 0.34 | 12 | 0.6 |

| Starter 3 | 11 | 25 | 1.70 | 20.5 | 0.59 | 24 | 0.9 |

| Grower 1 | 25 | 30 | 1.84 | 9 | 0.75 | 7 | 1.4 |

| Grower 2 | 30 | 45 | 2.20 | 33 | 0.75 | 20 | 1.7 |

| Grower 3 | 45 | 70 | 2.60 | 60 | 0.90 | 28 | 2.2 |

| Finisher 1 | 70 | 90 | 2.88 | 66 | 0.92 | 22 | 3.0 |

| Finisher 2 | 90 | 110 | 3.35 | 64 | 0.90 | 22 | 2.9 |

| Finisher 3 | 110 | 130 | 3.63 | 73 | 0.87 | 23 | 3.2 |

Adapted from Nutrient Requirements of Swine (National Research Council, 2012).

Additionally, feed budgets can be matched with practical things such as feed bin capacity, feed truck capacity or mixer capacity. Feed budget numbers can be adjusted up or down to line up with capacities. For example, if routinely using a 20-tonne feed truck to haul feed, you can make sure your feed budget uses 20-tonne increments. By doing this, partial load deliveries can be reduced, which can save money and improve the efficiency of feed mixing and delivery.

Author credits

This fact sheet was authored by Dr. Jaydee Smith, swine specialist, OMAFA, and Dr. Laura Eastwood, (former) swine specialist, OMAFA.