Technical Bulletin: management approaches for industrial fugitive dust sources

This technical bulletin is an overview of best management practices for industrial sources of fugitive dust emissions. The information includes typical sources, their impact and the common technologies and techniques used to reduce the dust.

Management Approaches for Industrial Fugitive Dust Sources

The Procedure for Preparing an Emission Summary and Dispersion Modelling Report (Guideline A-10) (Chapter 7.4) sets out criteria for assessment of suspended particulate matter (SPM) from fugitive dust sources. In some cases, SPM emissions from fugitive dust sources may be excluded from an ESDM report if: 1) the fugitive dust emissions do not contain contaminants with health-based standards (i.e. metals); and 2) the emissions are negligible or the emissions are minimized through the effective implementation of a fugitive dust control plan, consistent with best management practices.

This technical bulletin is intended as an overview of best management practices for industrial sources of fugitive dust emissions. The information includes typical sources such as material handling and roads, their impact and the common abatement technologies and techniques considered to be effective at the time of issuance. If a facility has been issued a legal instrument with more specific requirements for fugitive dust control, is registered to a technical standard, or is operating under a site-specific standard under Ontario Regulation 419/05 (O. Reg. 419/051) that may have more specific requirements prescribed, then these other legal instruments shall take precedence over this technical bulletin.

1.0 Introduction

In this document, dust is defined as small solid particles which settle out under their own weight but which may remain suspended for some time

Once dust is emitted (particles put in suspension), it will travel away from the source again affected by various parameters, including meteorological conditions and particulate size distribution. Larger particles will likely settle closer to the source whereas smaller particles are likely to settle further away. Particulates that are less than 30 µm in size do not settle as easily and can travel even longer distances before deposition

Fugitive dust emissions are recognized as a significant issue by regulatory agencies such as the United States Environmental Protection Agency (USEPA)

Past reviews of facilities have shown that unless appropriately controlled, fugitive sources often contribute to the total site emissions as much as or greater than process sources. As a result it is important to include fugitive sources in the modelling assessment of off-site concentration levels of contaminants.

Best management practices (BMP) plans are normally in place for a wide variety of facilities where fugitive dust, also known as suspended particulate matter (SPM), is generated and emitted from open sources including roads, storage piles, on-site traffic (e.g. bull-dozers, grading, and parking lots) and other sources related to materials management. BMP plans may include the introduction of control or cleaning equipment and may also include implementation of new procedures. There is a significant amount of published information on the control of fugitive dust emissions[4][5][6]

2.0 Main sources of fugitive dust emissions

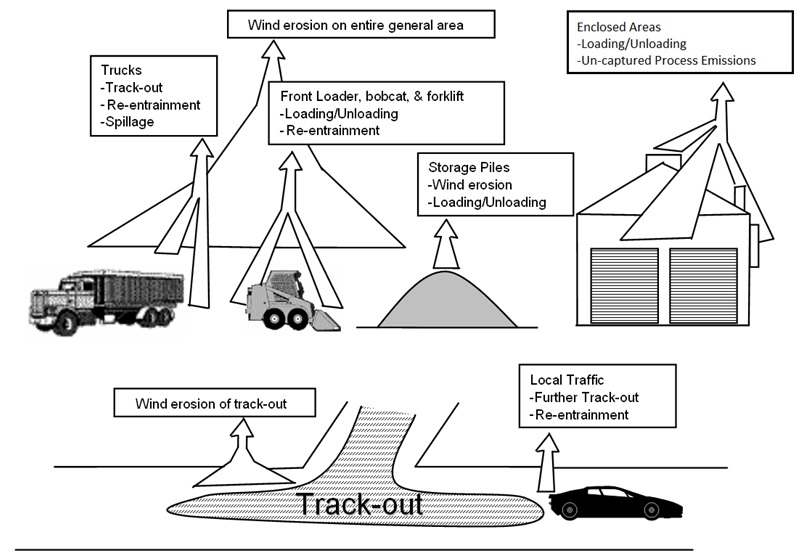

Fugitive dust can be emitted from vehicle traffic on paved or unpaved roads (or surfaces); blow-off from a load during haulage; loading and unloading of materials, products or packaging; handling of materials; screening and sorting; dry sweeping; and wind erosion of storage piles, berms and road surfaces[4][5][6][7][8][9][10].

Open storage of granular materials and material handling can result in dispersion of the dust to a wider area, which may then be re-suspended by vehicle traffic or wind. Fugitive dust is also generated by wind erosion of exposed surfaces and piles. By reducing the primary emission source, less effort is required on the secondary sources, which typically result from re-entrainment or re-suspension.

Other common industrial activities that may contribute to fugitive dust emissions include, but are not limited to, trimming, blasting, drilling, crushing, grinding, sawing and screening.

Figure 1: Examples of Common Sources of Industrial Fugitive Dust

3.0 Elements of a best management practices plan

The key to an effective fugitive dust control program at a facility is the implementation of a BMP plan specific for the site. A BMP plan should include the following elements:

- Plan

- identify and characterize the sources of fugitive dust emissions within the facility

- identify nearby potential receptors that may be impacted by dust emissions

- develop a site map and/or figures to identify the locations of fugitive dust sources (such as storage piles and roadways) and potential receptors

- characterize applicable fugitive dust monitoring parameters such as silt loading, silt content, moisture content, metal content, dust fall, etc.

- review the composition and particle size distribution of fugitive dust generated by each significant fugitive dust source where available

- identify the contributing factors for each significant source that favour the generation of fugitive dust emissions (e.g. predominant wind direction, location of storage pile, frequency of activity, process operating parameters, control efficiency, etc.)

- prioritize the use of resources based on the relative contributions of fugitive dust sources

- describe how fugitive dust will be controlled from each significant source (e.g. the application of dust suppressants such as water or chemical suppressants)

- Do

- document how the control measures will be implemented with timelines (e.g. frequency of road cleaning or water application, etc.)

- describe proper operating, monitoring, sampling, record-keeping and best practice procedures of control and monitoring equipment (e.g. how to minimize drop height, etc.)

- include a program for site-wide training for facility personnel and contractors

- Check

- implement a regular inspection, maintenance and calibration program (e.g. visual inspections of storage piles, maintenance of water sprays, etc.)

- describe methods of reviewing information collected from inspections, monitoring, sampling and record-keeping to verify, and document ongoing implementation of the plan and to determine when to take additional action, if needed

- Act

- perodically review the effectiveness of control measures using available data from site inspections, silt loading and silt content analysis, dust fall jars, etc. on a regular basis to identify opportunities for continuous improvement

- update the BMP plan as required

4.0 Best management practices

For any source of fugitive dust, preventative measures should first be considered to eliminate or reduce the primary generation of dust emitted and the ensuing secondary re-entrainment. However, mitigation measures (such as dust collection, dust suppressant application, solid fence etc.) may be necessary to achieve the required level of control. In addition, other measures (such as monitoring and sampling, inspection etc.) may be required to determine whether the fugitive dust control program is effective.

4.1 Process sources

Fugitive dust generated from industrial processes varies significantly from sector to sector. In general, it may originate from an indoor process that emits dust to the natural environment through a door, window, opening, vent or stack, or an outdoor activity such as storage, transfer and handling of materials or products.

Fugitive dust emissions generated from an indoor or outdoor process source should be minimized by:

- Considering alternative processes/equipment to eliminate or minimize primary dust generation.

- Eliminating open burning

- Relocating an outdoor activity indoors for better fugitive dust control where feasible.

- Ensuring integrity of material transfer equipment.

- Wetting material prior to processing or loading where possible.

- Fitting silos with overfill detection using automatic shut-off valves.

- Installing and maintaining process containment and redirecting dust emissions to the dust collection system such as baghouse, scrubber etc.

- Implementing a preventative maintenance program for processes and control equipment.

4.2 Storage piles

Emissions from storage piles of granular material can result from dust pick-up at certain wind speeds[11]. Emissions can also occur as material is dropped from a conveyor, loader or other equipment where there is an associated drop height onto the storage pile.

The dust control options for storage piles can include enclosures, barriers, shelters, proper layout, covers, water application, or other dust suppressant.

4.2.1 Enclosures

Covered storage of very fine materials with a high dust emitting potential should be considered especially where emissions may impact a human receptor. Silos, bunkers or hoppers should be used where feasible. Their doors should be kept closed. Properly designed ventilation and filtering systems should be used as appropriate.

Enclosures (full or partial) for inactive piles are effective in reducing wind erosion and controlling fugitive dust emissions from storage piles. Examples of enclosures include:

- A three-sided bunker that is at least as high as the storage pile: The length of the sides should be at least the length of the pile; the distance of the sides from the pile should be no more than twice the height of the pile; the height of the sides should be at least equal to the pile height; and the material of which the sides are made should be no more than 50% porous;

- A storage silo: Bulk cement, bentonite and similar fine dry materials (e.g. less than 3 millimetres in particle size) should be stored in silos. Facilities should consider dust control technology (e.g. fabric filters) for silos, where feasible;

- A half dome that is situated with consideration of the prevailing wind direction; and

- Buildings: Open-ended buildings or completely enclosing the pile within a building furnished with dust control technology[12].

4.2.2 Barrier and shelter

Wind erosion can be reduced by locating storage piles against one or more barriers made of durable materials such as cement block. Very fine materials should be stored in a sheltered area where feasible.

4.2.3 Location, Height and Slope of Piles

Storage piles should be located away from the prevailing downwind site boundaries where practical, or in designated areas with windbreaks and restricted traffic, and as far away from residents and other human receptors as possible. Where seasonal variability is significant for processes, wind direction or precipitation patterns, the worst case scenario should be considered where feasible.

Wind effects can be reduced by keeping the storage pile heights below the level of the windbreak. In addition, storage piles should be maintained so that the longitudinal axis is parallel with the prevailing wind.

Limiting the height and slope of storage piles can reduce wind erosion and entrainment. For example, a flat shallow storage pile is subject to less wind turbulence than one with a tall conical shape.

The number of piles should be kept to a minimum for the same material to minimize surface area (i.e. one pile instead of multiple piles will reduce fugitive emissions)[13].

4.2.4 Covers on Piles

Open storage piles may be covered with durable materials such as tarpaulins or plastic. Alternatively, soil or latex binders may be applied on the top of the pile to reduce wind erosion of the material. For piles that are inactive, a vegetative cover may also be used.

When covers are used, they should be anchored to prevent them from being blown away. Small or short-term inactive storage piles should be enclosed or kept under sheeting while larger inactive storage piles should be shrouded, capped or grassed over[13].

4.2.5 Water/Dust Suppressant Application

Water or dust suppressant that is compatible with the stored material can be applied to the surface of the storage pile to reduce wind erosion. Where feasible, smaller particulate matter or fines should be rinsed out prior to stockpiling.

This control measure also applies to other sources of dust including unpaved roads, conveyors, etc. This option is also discussed under Section 4.5 Yard Management.

4.3 Transport of Materials

Appropriate techniques for controlling fugitive dust along the haul roads include: paving roadways, covering loads in the bed of the truck, cleaning the bed of the truck after unloading and cleaning the wheels of the truck after unloading. These techniques are summarized below.

4.3.1 Paved Surfaces (including Paved Roads)

Dust deposits on paved surfaces (or hard unsurfaced material) can be re-dispersed by wind or by vehicle movements. Dust pick-up by wind is usually only significant at higher wind speeds (e.g. depending on factors such as the size of the material), but vehicle re-entrainment can occur under many conditions.

Dust emissions from paved surfaces can be minimized by following practices that include:

- Control movement and handling of fine materials to prevent spillages onto paved surfaces.

- Regular cleaning of paved surfaces, using a mobile sweeper in conjunction with vacuuming, or a water truck (see Section 4.3.4).

- Reducing unnecessary traffic volume where practical (see Section 4.3.3).

- Limiting vehicle weight where practical.

- Windbreak measures (see Section 4.5.1)11.

4.3.2 Unpaved Surfaces (including Unpaved Roads)

For the control of fugitive dust emissions from truck traffic on haul roads and parking lots, paving of these areas must be considered. Hard surfaces of asphalt or concrete may be applied. Paving can be highly effective but it may be unsuitable for surfaces used by very heavy vehicles or subject to spillages of material in transport.

If paving is not practical, the high traffic areas of unpaved roads should be covered with large aggregates or lower silt materials (such as gravel) to reduce track-out. The use of gravel can be moderately effective, but repeated additions will usually be required.

Dust emissions from unpaved surfaces can be controlled using the following practices:

- Wet suppressant should be applied during dry periods using a water truck and/or fixed sprinklers. As a general guide, the typical water requirements are up to 1 litre per square metre per hour and vary depending on the precipitation. Water requirements may vary based on temperature, humidity, solar insolation, or soil moisture content.

- Speed control on vehicle movements on unpaved roads.

- Chemical stabilization can be used in conjunction with wet suppression, and is best suited for permanent site roads. This involves the use of chemical additives in the water, which help to form a crust on the surface and bind the dust particles together. Chemical stabilization reduces the watering requirements, but any savings can be offset by the cost of the additives. Repeat treatments are usually required at intervals of 1 – 4 weeks. (Note: chemical additives used for dust suppression must also be shown to not have adverse effects on the environment) [11].

- Mud and dust track-out from unpaved roads should be minimized by the use of wheel wash facilities or simple wheel shakers.

4.3.3 Truck Travel Route

Truck traffic should be monitored where feasible and restricted to defined roads. The travel routes for haul trucks should be established and demarcated in order to minimize vehicular disturbances of erodible surfaces. Travel distances can be minimized through effective site layout and design.

4.3.4 Road Maintenance/Cleaning

Any mud, dirt, or debris on paved roads should be removed on a regular basis. A dry street sweeper/vacuum system can be used, although it is more effective to use water flush in combination. (Note: for dust with metal content, a vacuum system should be used). If water is used, runoff should be controlled in order not to enhance track-out by saturating the surface of adjacent roads.

For unpaved roads, dry sweeping is generally not recommended. This measure may cause elevated dust emissions and should be avoided unless there is no other option.

Water or dust suppressant should be applied on unpaved roads to reduce fugitive dust emissions caused by traffic and track-out. Since this control measure also applies to other sources, it is discussed in detail under Section 4.5 Yard Management.

4.3.5 Freeboard for Truck Loads

To prevent air entrainment and spillage during transportation, bulk materials must be transported in trucks with adequate freeboard, so that no part of the load should come within a safe distance of the top of any side board, side panel or tail gate of the truck. If feasible, trucks should be loaded such that the freeboard is at least 7 cm[12].

4.3.6 Covers on Truck Loads

All vehicles entering and leaving the site and carrying a load that may generate dust should be covered whenever feasible, except during loading and unloading of materials. Bulk materials transported by trucks may be covered with durable materials such as tarpaulins or screening material that are extended over the truck bed and secured to the truck.

4.3.7 Cleaning of Trucks and Covers After Each Load

After each hauling trip, particulate adhering to the wheels, tires, roof, undercarriage, and other exterior surfaces of the vehicle should be removed before leaving the site. This can be accomplished by installing a wheel washing station and maintaining replenishment of the wash water. Other mechanical equipment such as truck shaker may also be effective for removing the larger particles. In addition, all surfaces that are in contact with the bulk materials should be regularly cleaned to prevent the buildup of excessive dust in and on the truck over time. As an additional measure, the truck cover should be regularly replaced with a cleaned one as applicable.

4.3.8 Sampling of Fugitive Sources

The Procedure for Preparing an Emission Summary and Dispersion Modelling Report (Guideline A-10) (Chapter 7.4) sets out criteria for assessment of suspended particulate matter (SPM) from fugitive dust sources. Sectors listed in Table 7-2 of Guideline A-10 are required to include metal emissions in their dispersion modelling. This may require an analyses of road dust, storage piles or other fugitive sources to determine the metal content.

Samples of road dust should be collected and analyzed for the silt loading, particle size distribution and metallic composition as required. The recommended protocols for sampling and analysis of road dust can be found respectively in USEPA AP-42, Compilation of Air Pollution Emission Factors, Appendix C.1 Procedures for Sampling Surface/Bulk Dust Loading

4.4 Material Handling/Transfer Activities

Control of dust emissions generated during material handling activities is primarily accomplished by preventing dust emissions due to loading, unloading and transfer activities in the open air.

Where feasible, activities that take place at an existing storage pile (i.e., loading and unloading) should be confined to the downwind side of the storage pile.

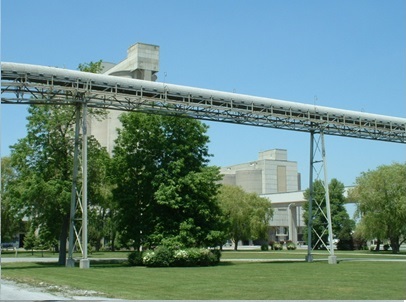

Continuous transport such as conveyors (see 4.4.1) should be used whenever feasible because it generates less dust emissions than discontinuous transport such as shovel or truck.

4.4.1 Use of Conveyors and Enclosures

Dust emissions from conveyors can be caused by wind pick-up and through losses during loading, discharge, and at transfer points, depending on the particle size distribution of the material.

In general, conveyors should be designed to minimize material overflow or spillage. Where feasible, they should be enclosed and filtered through a dust collection system.

Dust emissions from conveyors can be controlled using the following practices[11][13]:

- Optimize the conveyor speed with the use of an adjustable speed conveyor;

- Avoid loading conveyor belt up to its edges;

- Use enclosures or housings for conveyors for fine material;

- Use water sprays or sprinklers at conveyor transfer points;

- Minimize drop heights at transfer points, including use of conveyors that can be raised and lowered; and

- Perform regular clean-up of spillages around transfer points.

4.4.2 Transfer Techniques

Material handling using front-end loaders or mechanical grabs is another potential source of fugitive dust emissions. These mainly occur when the load is dropped into a truck or hopper, but can also be caused by spillages during handling. Similar problems can occur when dusty loads are transferred by gravity discharge from hoppers into trucks[13].

There are numerous techniques that can reduce dust emissions from the transfer and handling of solid materials. Below are a few examples[13]:

- Empty a truck in a roofed or partly enclosed unloading station;

- Minimize the speed of descent;

- Minimize the free fall height (drop height);

- Optimize the use of mechanical grabs (geometric shape, load capacity, smooth surface);

- Use sprinklers or water sprays around hoppers and other transfer points;

- Install hooding or enclosure for significant fugitive dust sources such as hopper load systems, with the emissions being ducted to bag filters or other dust control equipment;

- Conduct regular maintenance of hydraulic grabs to ensure complete closure; and

- Design hopper load systems to ensure a good match with truck size.

4.4.3 Water Application

Water spray can be applied to the materials on the conveyor belt and at transfer points to reduce wind erosion by keeping the material moist. Since this control measure also applies to other sources, it is discussed in detail under Section 4.5 Yard Management.

4.4.4 Scheduling of Loading/Unloading Activities

Where feasible, the loading and unloading activities should be conducted when the wind speed is low in order to minimize fugitive dust emissions. In very high wind conditions, these activities should be suspended where practical.

4.5 Yard Management

4.5.1 Windbreak Measures

Wind is a major cause of fugitive dust emissions from industrial sites. Wind speed near the pile surface is the primary factor affecting particle uptake from storage piles.

The effects can be partially mitigated through the use of shelter belts or temporary screening. It may also be possible to make use of natural land features, or artificial features such as noise barriers, to provide a degree of wind protection. This option should be considered in the initial development of the site layout and design[11].

Berms, tree lines or vegetation should be used in the surrounding areas of the yard where practical. Professional horticultural advice should be sought regarding suitable species for any specific site[11]. A windbreak can be effective when designed specifications[11] such as:

- Minimum height equal to the pile height or drop height.

- Minimum length equal to the pile length at the base.

- Located at a maximum distance of one pile height from the base of the pile.

Windbreaks can be constructed using horticultural cloth supported on poles. Solid or fabric fences may also be used as an effective wind protection measure. This type of windbreak can be effective when the design considers things such as:

- A horticultural cloth with 50% or less porosity[12].

- The bottom of wind fences should be sufficiently anchored to the ground to prevent material from blowing underneath the fence.

Barriers placed at right angles to prevailing wind currents at intervals of 15 times the barrier height are suggested to be the most effective in controlling wind erosion.

- Windbreaks and fabric fences should be maintained in an upright and functional condition at all times.

- All accumulated material on the windward side of the windbreak should be periodically removed to prevent failure of the windbreak[12].

4.5.2 Re-vegetation

Re-vegetation of exposed surfaces should be conducted wherever practicable at mines, quarries and construction sites, and any other similar activities subject to ongoing site development.

A progressive re-vegetation plan should be implemented to reduce wind and rain erosion of berms or disturbed areas within 10 days after active operations have ceased, where feasible. This plan should include consideration for a downwind shelter belt, identification of plant species mix, a planting schedule and maintenance program. Techniques such as hydro-seeding and the use of geotextiles should be used on sloping ground and other difficult surfaces.

Ground cover should be of sufficient density to expose less than 30% of unstabilized ground within 90 days of planting, and all times thereafter. Such restoration control measures should be maintained[12].

4.5.3 Water/Dust Suppressant Application

Application of water or approved dust suppressant is a common practice used on wind exposed storage piles, conveyor belts, connection points, drop points, truck loads, unpaved roads, and excavation areas. Water can be applied by a variety of methods, for instance water trucks, water pulls, water cannons, hoses, fire hydrants, sprinklers, etc.[12] However, application of this control measure may be limited by the risk of freezing, slippery situations or water shortage. In addition, there are also potential environmental consequences resulting from over-application of water that must be considered. These include: runoff problems, soil instability, spreading of contaminants (e.g. oil or coolant from engines), and erosion.

Chemical dust suppressants can be more effective than water in controlling dust with less frequent applications. However, the selection of chemical dust suppressant must take into consideration the hazardous, biodegradable and water-soluble properties of the substance and the effect of its application on the surrounding environment[12].

The rate of water or suppressant application varies with the site and material, and should be determined by the local weather conditions such as rainfall, relative humidity, temperature, evaporation rate and wind speed.

The control efficiency of water or suppressant application depends on the traffic volume, application rates, wind direction and other weather conditions. In addition, the equipment such as water trucks and sprinkler systems must be properly maintained to be effective.

4.5.4 Weather Monitoring

The local weather forecast including wind direction, wind speed, rainfall, relative humidity, temperature and evaporation rate should be monitored using available resources or meteorological instruments such as an anemometer (or wind meter), in order to optimize the application rates of water or dust suppressant.

Continuous monitoring of wind conditions should be considered when dust generating activities are to be carried out in a sensitive location. The information can be used as a trigger for increased dust control activities or even as a signal for work to cease at higher wind speeds[11].

4.5.5 Spillage/Overflow

Good housekeeping is the key to reducing wind erosion and track-out. Limiting the load size, and controlling the movement and handling of fine materials can avoid spills. Any material spillage or overflow at loading/unloading areas or on roads should be cleaned up immediately before they are picked up by high winds or disturbed by vehicle traffic. Off-site spillage should be collected and returned to the site for proper disposal.

4.5.6 Record-keeping

Procedures should be implemented to ensure that any documentation and information recorded as a result of any activity included in the BMP plan are retained at the facility and available to the ministry upon request. This can include but not limited to monitoring, measurement, sampling, maintenance, analysis, activity logging, site inspection, training and community feedback. This information should be retained at the facility for a minimum period of two years, or as required by a facility specific Environmental Compliance Approval or other legal instrument, and is made available to the ministry upon request as soon as practicable.

4.5.7 Site Inspections

A site inspection plan should be developed that includes procedures for visual inspections of fugitive dust emission sources throughout the site. Appropriate control measures should be applied promptly to address any excessive emissions, with follow-up observations to ensure the effectiveness of the measures. A formal inspection form should be used (example shown in Appendix A) for listing the inspection items and recording any observations of potential issues and/or corrective actions for follow-up.

Site inspections should include sources such as storage piles and open un-vegetated areas that should be observed for fugitive dust emissions. Water or dust suppressant application should be conducted as required. Plant equipment, conveyors and enclosures should be inspected for physical integrity and proper operation. Any equipment or seal leaks should be repaired as soon as practicable.

Site inspections should be conducted according to need, with special emphasis on the dry season. Observations for the conditions that contribute to generation of fugitive dust emissions should be made. Issues identified through the site inspection may necessitate a revision to the BMP plan.

4.5.8 Other Monitoring

There are other forms of monitoring that should be considered when sources are located near human receptors. For example, an ambient monitoring program could be considered. The program should be appropriate for the situation and consider a number of factors such as the proximity of human receptors, the contaminants and predicted point of impingement (POI) concentrations. Monitoring strategies could range from dustfall monitors to continuous monitoring that is publically reported in real time.

4.5.9 Training

A formal training program should be developed for all personnel including contractors. This training should include training personnel on their roles and responsibilities in terms of developing and implementing actions with respect to the facility’s BMP plan. The training frequency, topics, and methods, as well as record-keeping procedures should be clearly identified.

All staff responsible for site inspections should be appropriately trained on the inspection criteria, including the proper completion of inspection forms, and response procedures to excessive visible dust.

Surveys should be conducted regularly to solicit feedback from site personnel and contractors on the effectiveness of dust control measures in order to identify opportunities for continuous improvement.

4.5.10 Community Feedback

When regular complaints occur, procedures for regular consultation and communication with the affected community should be set up. One option could be to post signs with the contact information of someone in the facility that can take action when the community sees excessive fugitive dust emissions. Where appropriate, a dust monitoring program with trigger levels for actions should be considered.

Prompt responses to complaints can be important in developing strong communications with the surrounding community. Effective complaint investigation is important for identifying areas of the operation where dust control procedures need improvement.

5.0 Continuous Improvement

A BMP plan should be a comprehensive site-specific document that identifies all fugitive sources of dust emissions from the site and the best management practices for controlling these sources. This plan must be reviewed and updated on a regular basis. It should build on current and known practices with a commitment to continuous improvement. In addition, consideration should be given to process changes or material substitution that would result in reduction of fugitive dust. Where justified, the plan should be adjusted where improvements in other areas may have made a control measure unnecessary.

For more information on this technical bulletin, please contact:

Ontario Ministry of the Environment and Climate Change (MOECC)

Standards Development Branch, Local Air Quality Section

40 St. Clair Avenue West, 7th Floor

Toronto, Ontario, Canada M4V 1M2

Telephone: 416-327-5519

This Bulletin is provided for information purposes only and should not be used to interpret any policy of the ministry nor any statute, regulation or other law. Further, this Bulletin does not provide any advice or permission in respect of any statute, regulation or law, nor does this Bulletin relieve any user from compliance with any statute, regulation or other law. The ministry makes no warranty respecting the accuracy of the information contained in this Bulletin. Any use or application of the information contained in this Bulletin is at the sole risk of the user. The ministry assumes no liability for any damages or other loss or injury which may result from the use or application of information contained in this Bulletin.

Appendix A

Get a sample fugitive dust site inspection form.

Appendix B - Examples of Best Management Practices in Ontario Facilities

Figure 3. Wetting of Storage Pile using Water Cannon

Figure 4. Immediate Clean-up of Overflow/Spills

Figure 5. Installation of Environmental Barrier

Figure 6. Wetting of Material

Figure 7. Vacuum Sweeping

Figure 8. Wind Protection for Unloading of Fine PM

Figure 9. Truck Washing

Figure 10. Well Vegetated Grounds

Figure 11. Pneumatic Loading

Figure 12. Water Truck on Unpaved Road

Figure 13. Shelter for Storage Pile

Figure 14. Barrier for Storage Piles

Appendix C - Examples of Improvement Opportunities

Figure 15. Dry Sweeping Piles

Figure 16. Unprotected Storage

Figure 17. Large Un-vegetated Surfaces

Figure 18. Poor Housekeeping

Figure 19. Open Loading

Figure 20. High Drop Height

Footnotes

- footnote[2] Back to paragraph World Health Organization, WHO/SDE/OEH/99.14, Hazard Prevention and Control in the Work Environment: Airborne Dust, August 1999.

- footnote[3] Back to paragraph Ontario Ministry of the Environment and Climate Change, The Procedure for Preparing an Emission Summary and Dispersion Modelling Report, as amended from time to time

- footnote[4] Back to paragraph United States Environmental Protection Agency, EPA-600/7-78-071, Particulate Control for Fugitive Dust, April 1978

- footnote[5] Back to paragraph United States Environmental Protection Agency, AP-42 Compilation of Air Pollution Emission Factors, Section 13.2 Introduction to Fugitive Dust Sources, January 1995; Section 13.2.1 Paved Roads, January 2011; Section 13.2.2 Unpaved Roads, November 2006; Section 13.2.4 Aggregate Handling and Storage Piles, November 2006; and Section 13.2.5 Industrial Wind Erosion, November 2006

- footnote[6] Back to paragraph C. Cowherd et al., Control of Fugitive and Hazardous Dusts, 1991

- footnote[7] Back to paragraph United States Environmental Protection Agency, EPA/625/6-91/014, Handbook: Control Technologies for Hazardous Air Pollutants, June 1991

- footnote[8] Back to paragraph United States Environmental Protection Agency, EPA/600/2-87/066, A Method for Estimating Fugitive Particulate Emissions from Hazardous Waste Sites, August 1987

- footnote[9] Back to paragraph United States Environmental Protection Agency, EPA/600/8-86/023, Identification, Assessment and Control of Fugitive Particulate Emissions, August 1986

- footnote[10] Back to paragraph United States Environmental Protection Agency, Contract 68-D-98-026, Stationary Source Control Techniques Document for Fine Particulate Matter, October 1998

- footnote[11] Back to paragraph Ministry of the Environment, Wellington, New Zealand, Good Practice Guide for Assessing and Managing the Environmental Effects of Dust Emissions, September 2001

- footnote[12] Back to paragraph Cheminfo Services Inc., Best Practices for the Reduction of Air Emissions From Construction and Demolition Activities, March 2005

- footnote[13] Back to paragraph European Commission, Integrated Pollution Prevention and Control, Reference Document on Best Available Techniques on Emissions from Storage, July 2006

- footnote[14] Back to paragraph United States Environmental Protection Agency, AP-42 Compilation of Air Pollution Emission Factors, Appendix C.1 Procedures For Sampling Surface/Bulk Dust Loading, July 1993

- footnote[15] Back to paragraph United States Environmental Protection Agency, AP-42 Compilation of Air Pollution Emission Factors, Appendix C.2 Procedures for Laboratory Analysis of Surface/Bulk Dust Loading Samples, July 1993