Wind machines for minimizing cold injury to horticultural crops

Learn how to use wind machines to protect grapevines and tender tree fruits from cold temperatures. This technical information is for commercial fruit growers in Ontario.

ISSN 1198-712X, Published February 2026

Introduction

When plant tissue temperatures fall below critical values, sensitive perennial crops such as grapevines and tender tree fruits can suffer irreversible cold or freezing injury, causing malfunction or death of plant cells. One protection method is to use wind machines, which became widely popular in Niagara for grapes in the late 1990s. Today, wind machines are commonly used across Ontario. This fact sheet outlines best management practices (BMPs) for using wind machines to prevent cold injury in vineyards and other horticultural crops. They are practical, researched actions to improve efficiency and support long-term sustainability of farm operations, while minimizing the risk of causing disturbance to neighbours.

How wind machines work

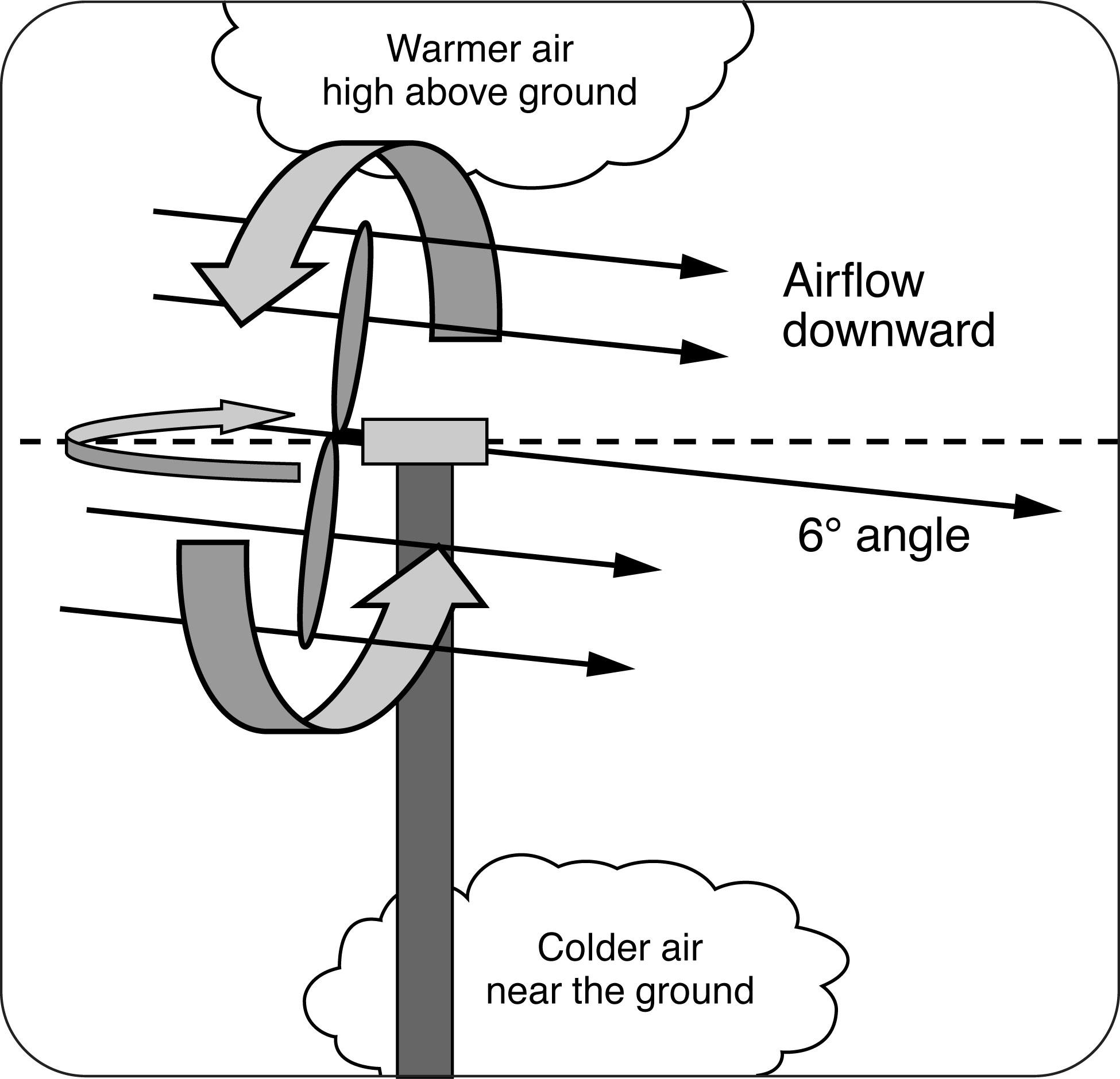

Wind machines are tall, fixed-in-place, engine-driven fans that pull warm air down from at least 15 m above ground during strong temperature inversions and draw cold air near target crops. This raises air temperatures around cold-sensitive perennial crops such as grapes (Figure 1). Wind machines are not the same as wind turbines and do not create electricity from wind energy.

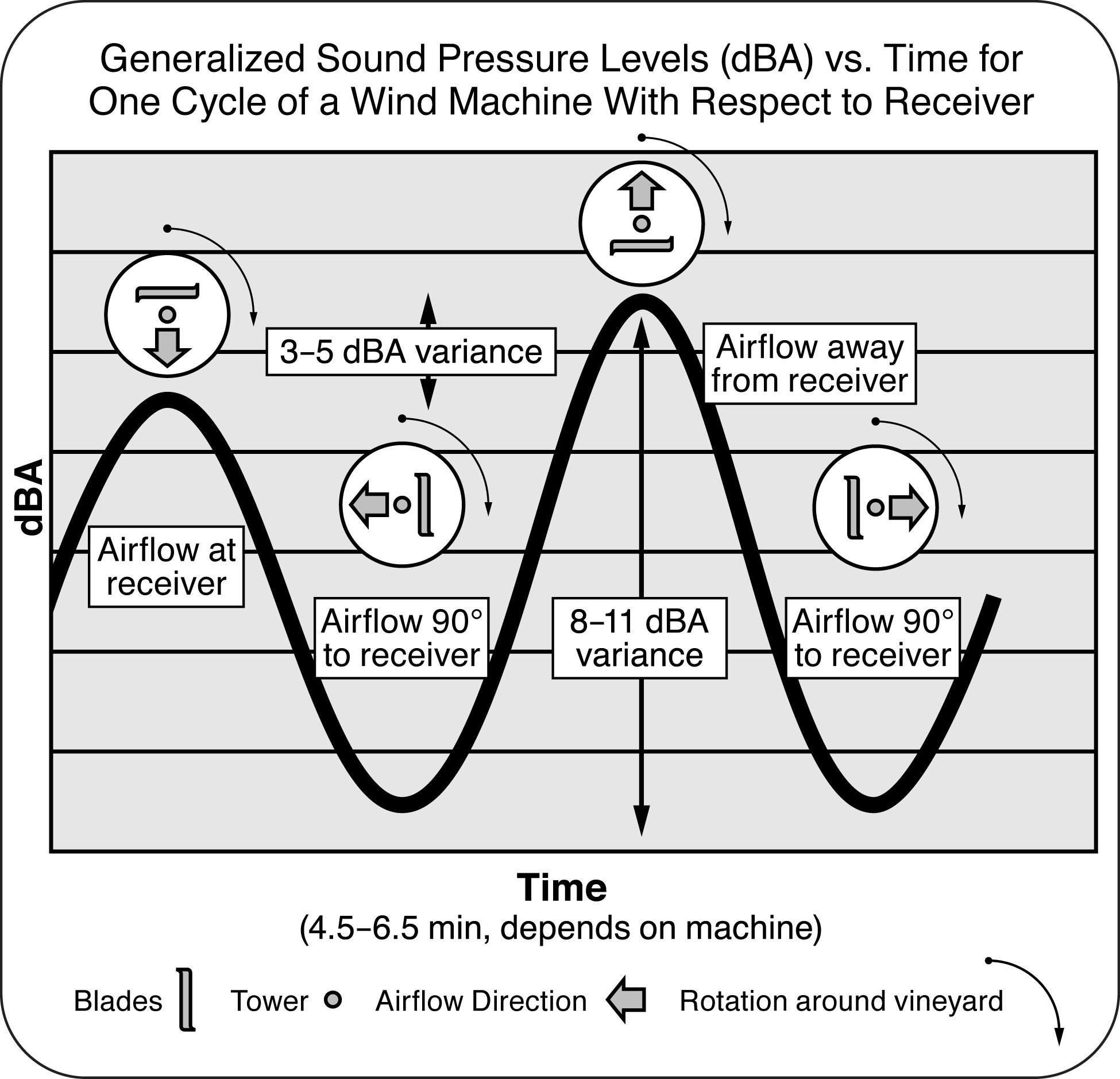

Wind machines break up micro-scale air boundary layers over plant surfaces, improving sensible heat transfer from the air to the plants. Wind machines transfer heat by forced convection. While the blades spin, the head of the fan rotates around the tower’s vertical axis. Air circulates north, east, south, west, then north again 4.5–6.5 min later, depending on the machine type (Figure 2). The area protected covers 3–5 ha, depending on topography, field layout, strength of the temperature inversion, time of year and drift due to slight winds. If a wind machine completes this circuit too slowly, cold air can resettle or drift in from cooler areas upstream or upwind of the machine, resulting in crop injury. It doesn’t take long for crop damage to occur at critical air temperatures.

Temperature inversions

Temperature inversions are strong when air temperatures 20 m above the field are at least 3°C warmer than at crop level — about 0.625 m above ground. Strong, night-time radiative temperature inversions occur during periods when skies are clear and starlit, and there is minimal wind movement. These conditions favour the use of wind machines. Inversion conditions are common in Ontario winters; OMAFA research showed up to 10°C temperature inversions in Niagara.

For inversions to form, wind speeds must be less than 6 km/h; for inversions to break up, wind speeds must be greater than 6 km/h. This is because the wind mixes the air above the field with the air at ground level. This is like a house furnace fan mixing air throughout a house to keep air temperatures more uniform. When that fan is off, air stratification can occur with colder, heavier air settling in the basement, while warmer, lighter air rises and remains upstairs. Wind machines can raise air temperatures around plants by about a third to half the temperature inversion difference.

Field air temperatures are often very different from local or regional forecasts. Forecasts don’t predict air temperatures close to crop levels or low areas where air temperatures are often colder. Air temperatures can drop abruptly, sometimes many degrees in an hour and often at sunset or sunrise. Due to the variability in a forecast and temperature profile, it can be difficult to predict both the timing of when to operate a wind machine or whether it is needed at all.

Effects on air temperatures near the ground

The effect on air temperatures near the ground is almost instantaneous after a wind machine is turned on, but air temperatures will vary slightly throughout the area (Table 1). Note a strong temperature inversion of 4.8°C at 2:25 am just as the wind machine started (6.2–1.4 = 4.8°C), while air temperatures 20 m above the vineyard remained almost constant. The mass of warm air of an inversion is variable and will dictate how successful the wind machine can be.

| Time of day (am) | Wind machine status | Air temperatures 20 m above vineyard | Air temperatures at vine level 115 m north of wind machine |

|---|---|---|---|

| 2:20 | Off | 6.1°C | 1.5°C |

| 2:25 | Started | 6.2°C | 1.4°C |

| 2:30 | On | 6.1°C | 1.5°C |

| 2:35 | On | 5.8°C | 1.7°C |

| 2:40 | On | 5.8°C | 2.0°C |

| 2:45 | On | 6.1°C | 2.2°C |

| 2:50 | On | 6.0°C | 2.5°C |

There was a slight 4–5 km/h southwesterly wind causing air temperatures to rise higher on the northeast (downstream) side of the wind machine, while air temperatures rose more slowly on the southwest (upstream) side of the wind machine. The area protected by a wind machine is affected by topography, wind direction and speed, since cold air naturally drains downhill.

Noise

Wind machines create noise as they need large engines operating at high RPM and long-pitched blades to blow air a long distance. It is difficult to design them to be quieter. Sound comes from the engine and the blades. Because wind machines make a 360° sweep around the tower every few minutes, sound intensity varies in a sinusoidal fashion. The sound is loudest when airflow is directed away from a receiver (such as a neighbour), slightly less when directed toward a receiver and significantly reduced when airflow is perpendicular to a receiver (Figure 3). Some neighbours find this a nuisance, since they wait in anticipation for the sound to grow louder. Refer to the section Dealing with potential nuisances and normal farm practices for more information.

A slower blade speed reduces noise, but reduces airflow, so more machines are needed to cover the same area.

Unfortunately, it is often quiet in rural areas during temperature inversions, when wind machines operate during the spring, fall or winter nights. There are few other noises to mask the sound emitted by wind machines (for example, wind, cars). Conditions outside also complicate and affect sound movement from wind machines:

- lack of vegetation, grass on ground or leaves in woodlots to muffle sounds

- bouncing of sound waves off the warmer, temperature inversion layer high above ground

- hard, frozen, non-absorbing winter ground surfaces for sound waves to travel across

- source of sound being very high above ground, allowing it to travel greater distances

- simultaneous operation of multiple machines

- low relative humidity of the cold air

Conditions inside homes that complicate and allow external sound waves to penetrate or be amplified include large rooms, large windows, hard floors and light construction. Wind machine sound is generally quieter and less offensive in small, carpeted rooms with heavy, thick walls and in house areas opposite to the side where a wind machine is, or in basements. The sound is sometimes partially masked inside a house if there is white noise present, such as from a radio, television or ventilation fan.

Wind machine blades produce low frequency infrasound waves that travel long distances and may penetrate building components of residential structures. Low bass music sounds heard indoors originating from a neighbour’s stereo is an example of how low frequency sounds transmit.

Best management practices

Horticultural operations should implement the following best management practices for operating wind machines to use them effectively and minimize nuisance noise.

Crop hardiness

- Manage plants so they are as healthy as possible going into winter.

- Use the most up-to-date plant hardiness information and consider critical plant temperatures when decisions are made to operate a wind machine.

Location of wind machines

- Locate wind machines to account for expected skewing effects on their areas of influence by topography and wind direction.

- Locate wind machines to account for adjacent wind machines and features that might provide additional cold injury protection such as roads, warm buildings, streams or woodlots.

- Consider planting crops more sensitive to cold injury as far as practical from neighbours’ houses, so wind machines can be located further from their homes.

Monitoring

- Use the best local weather forecasts available.

- Monitor continually for strong temperature inversions, greater than 3°C, on or near the farm to determine if operating machine(s) might provide plant protection from cold injury. This includes a tower at least 10 m high to monitor air temperatures above the crop.

- Set start-up temperatures for wind machines based on sensors located below the fruiting wire and within 15 m of each machine.

- Monitor and automate start up/operation/shut down of wind machines, using a combination of real-time remote air temperature/wind speed/wind machine operation sensing devices and monitoring via mobile devices.

- Set wind machine start-up air temperatures as close as practical to expected critical air temperatures:

- Spring frost: 2°C–3°C

- Fall frost: 1°C–2°C

- Winter: variable based on latest bud hardiness data from local freezing trials.

- Set the differential (wind machine stop temperature) 2°C–3°C higher on wind machines than for start-up temperatures.

Wind

- Do not operate wind machines if wind speeds are much higher than 7 km/h as there is unlikely to be a strong temperature inversion or warmer air above the field anyway.

- Do not operate wind machines if wind speeds are 13 km/h or higher, as this can damage the long, thin blades.

- Never operate wind machines if wind speeds are 21 km/h or higher, as this can seriously damage them.

Maintenance

- Maintain wind machines in good condition with annual check-ups by changing the gearbox oil (at tower base and top), lubricating drive lines and inspecting seals, checking the tension of all bolts on the tower, inspecting blades and attaching hardware, performing regular engine maintenance and keeping booster cables handy for quick use.

Noise

- Locate wind machines as far as practical from neighbouring homes within agricultural areas, but not closer than 125 m unless best management practices are used.

- Explain to neighbours living within 125 m of a machine how and why wind machines operate. Consider creating an early warning system for neighbours about wind machine use and share contact information.

- Set wind machines closest to neighbours to be the last on and the first off.

- Be diligent operating wind machines on farms where you do not live, as you are not always there to hear them during times of operation.

- Install mufflers on all wind machines.

On-going learning

- Train and educate all employees operating wind machines on the best management practices to ensure the most effective and efficient machine operation.

Dealing with potential nuisances and normal farm practices

Respect and tolerance between farmers (including greenhouse operators) and their neighbours are essential for maintaining good community relations. Explaining to neighbours the importance of certain activities or devices required for farming operations that are prone to creating a nuisance will help build a better relationship.

To prevent nuisance complaints, farmers are encouraged to be proactive in communicating any activities or devices they are using as part of their agricultural operation that could result in a nuisance caused by a disturbance that is covered under the Farming and Food Production Protection Act, 1998 (FFPPA). Explaining the necessity of these activities for successful farming operations can help foster goodwill and reduce the likelihood of complaints. Similarly, neighbours of farming operations (including greenhouses) are encouraged to communicate with the farmers if they experience disturbances. Addressing concerns collaboratively before involving local authorities or the Ontario Ministry of Agriculture, Food and Agribusiness can lead to more effective and amicable resolutions.

Refer to the Resources section for more information on dealing with nuisance complaints.

Summary

Wind machines are used in Ontario vineyards and horticultural fields to protect crops from frost‑related and cold injury. These machines work by drawing warmer air from above the crop and mixing it with colder air near the ground, effectively increasing the temperature around the plants. It is important to follow best management practices for their effective use and operation, allowing the maximum coverage areas with minimum noise disturbance to neighbours. Timely operation of wind machines reduces the risk of crop loss.

Resources

OMAFA fact sheets:

- Responding to agricultural nuisance complaints

- The Farming and Food Production Protection Act, 1998 (FFPPA) and nuisance complaints

OMAFA video:

Author credits

This fact sheet was updated by Kevin Baines, P.Eng., horticulture and greenhouse, OMAFA, Craig Fowler, P.Eng., water management, OMAFA, and Gaganjyot Madanpotra, P.Eng., crop systems and environment, OMAFA. This fact sheet was originally written by Hugh Fraser, P.Eng., horticultural crop protection and post harvest, OMAFA, Ken Slingerland, tender fruit and grape specialist, OMAFA, Kevin Ker and Ryan Brewster, KCMS Consultants, Fenwick; and Helen Fisher, grape research scientist, University of Guelph.