Constructing a permanent concrete or steel liquid nutrient storage facility for agricultural source materials

Learn what factors to consider when expanding or constructing a permanent liquid nutrient storage facility made of steel, concrete or equivalent material to store agricultural source material (ASM). This technical information is for Ontario livestock producers.

ISSN 1198-712X, Published December 2021

Introduction

This fact sheet summarizes key factors to consider when expanding or constructing a permanent liquid nutrient storage facility made of steel, concrete or equivalent material to store agricultural source material (ASM). It applies to open tanks, as shown in Figure 1, and covered storages, including under-barn storage.

This fact sheet includes a general and simplified description of the Siting and Construction Standards under Part VIII of O. Reg. 267/03 (the regulation) applicable to farm units that generate more than 5 nutrient units of manure annually. Use it in conjunction with the regulation under the Nutrient Management Act, 2002 (NMA).

Under the regulation, permanent liquid nutrient storage facilities are structures that have:

- 14 or more days of storage capacity, or

- a depth of liquid nutrients of 100 mm or more

Liquid nutrients include agricultural and non‑agricultural source materials that have a dry matter content of less than 18% or have a slump of more than 150 mm using the slump test referred in the regulation. ASM include:

- manure produced by farm animals

- runoff from animal yards and solid manure storages

- washwater from agricultural operations that have not been mixed with human waste

Non-agricultural source materials (NASM) include:

- pulp and paper biosolids

- sewage biosolids

- materials that are not from agricultural sources that can be applied to land as a nutrient, such as washwater and organic residues from food processing plants

Anaerobic digestion output is another example of a liquid nutrient that can be an agricultural or non-agricultural source material, depending on the material treated in the digester. For example, anaerobic digestion output that meets the following criteria is considered an agricultural source material:

- the anaerobic digestion materials were treated in a mixed anaerobic digestion facility

- at least 50%, by volume, of the total amount of anaerobic digestion materials were on-farm anaerobic digestion materials

- the anaerobic digestion materials did not contain sewage biosolids or human body waste

Construction standards for new or expanding permanent liquid nutrient storage facility for NASM are similar to ASM with some exceptions. In addition to this fact sheet, read the OMAFRA fact sheet, Storage of Non-Agricultural Source Materials (NASM) in a Permanent Nutrient Storage Facility for details.

Key considerations

Consider the following when expanding or constructing a permanent liquid nutrient storage facility:

- All new and expanding liquid nutrient storage facilities must be designed by a professional engineer.

- A professional engineer must perform a general review of the construction or expansion to ensure that it is built in accordance with the engineer’s design specifications and the requirements of Part VIII of the regulation titled Siting, Construction and Storage.

- Construction of all permanent liquid nutrient storage facilities made of steel, concrete or equivalent material requires a building permit.

- You must have a nutrient management strategy, prepared by a certified nutrient management consultant and approved by OMAFRA, to obtain a building permit for the construction of all permanent liquid nutrient storage facilities made of steel, concrete or equivalent material.

- These storages require at least two levels of underground protection.

- Follow all proper setbacks from sensitive features such as wells, surface water and conflicting uses.

- Remove any perforated tile drain close to the storage unless it is required and properly installed as a foundation drain equipped with an observation and shut-off station [O. Reg. 267/03, s. 63 (5)].

- Contact your municipality to obtain a building permit and additional local requirements for construction of a permanent liquid nutrient storage facility.

Sizing considerations for storage facilities

The size of the storage depends on several factors:

- the amount of material generated at a time (daily, weekly basis)

- whether other materials, such as runoff and washwater, will be stored in the storage

- the number of days (or weeks) the facility has to store the material

- the net amount of precipitation entering the storage facility. For open tank, the amount is based on the number of days of storage required by the operation and the specified allowance of 0.83 m/year (that is, 2.27 mm per day of storage) referenced in Table 5.2 of the Nutrient Management Protocol.

- the freeboard requirements (0.3 m for open tanks and storages under slatted-floor barns, and 0.15 m for covered storages)

Note: Freeboard is an additional depth of storage required to deal with wave action due to wind and agitation and to provide a safety factor to address unexpected circumstances (such as excessive rainfall, leaks in water system). It is added to the calculated depth required for manure production and precipitation.

Amount of material generated

The amount of manure generated by farm animals varies between operations due to differences in herd management, including the amount of material used for bedding.

Measure the amount of manure generated by an existing operation over the years, including bedding, during clean-out of barns and existing storage facilities. The Nutrient Management Tables that are associated with the regulation and the AgriSuite software also provide values of daily manure production for various livestock.

Size the storage facility based on the greater amount of manure measured at the farm or referenced in the regulation unless several years of reliable records of manure production demonstrate a lower manure production.

Storage capacity required

Under the NMA, farm operations subjected to the regulation because they are expanding or building a permanent nutrient storage facility or a structure to house livestock must provide a minimum storage capacity of 240 days for all nutrients generated and intended for storage at the farm (such as manure, washwater and runoff), with the following exceptions:

- Where a farmer sends some agricultural source material, generated on the farm, to a broker, the combined storage capacity provided by the broker and the farmer must total 240 days.

For example, a layer chicken operation that has an agreement with a broker who can provide 60 days of storage would only need a manure storage with a capacity of 180 days. - Where the period of use of the barn is less than 240 days.

For example, a beef feeder operation that houses the animals for 180 days from November 1 until they go to pasture on May 1 would only need a manure storage with a capacity of 180 days. - Where a farmer’s nutrient management plan (NMP) provides for the land application of nutrients to land on a schedule that reduces the storage requirements

For example, an operation with an NMP providing for land application of manure more often than every 240 days would not require a storage with a capacity of 240 days. Note: This is used for liquid manure storages, if the number of farm animals on the farm unit has not increased since September 30, 2003. - Where the farmer’s nutrient management strategy (NMS) includes transfers out of the farm unit

For example, a dairy farm that transfers its manure off-site every 3 months to another farm unit, only requires a manure storage with a capacity of 3 months.

Also, take into consideration the storage capacity of all prescribed material received on the farm unit that is not directly applied to land (such as manure from other agricultural operations, NASM).

Siting

When siting a new storage facility, or an expansion of an existing one, consider the potential impacts to surface and groundwater as well as neighbours. Setbacks to surrounding features must be respected. Refer to the fact sheet Siting requirements for permanent nutrient storage facilities to understand setbacks prescribed under the regulation, Minimum Separation Distance (MDS) to neighbouring properties and other considerations.

Qualified person involvement

To obtain a building permit for the construction of a permanent liquid nutrient storage facility made of steel, concrete or equivalent material, you must have a NMS, prepared by a certificate holder under Part X of the regulation and approved by OMAFRA.

The regulation has the following engineering requirements for new and expanding permanent liquid nutrient storage facilities:

Engineer’s Commitment Certificate — the professional engineer(s) must sign the Engineer’s Commitment Certificate to obtain a building permit [O. Reg. 267/03, s. 71 (1)]. This is to ensure that the project conforms to the engineering requirements under the regulation, where applicable. Download the Engineer’s Commitment Certificate from the Forms Repository, or by contacting an OMAFRA engineer or environmental specialist.

Design — a professional engineer must design the construction or expansion, including any monitoring system [O. Reg. 267/03, s. 71 (1)]. Where required, incorporate provision for a liner and transfer system in the design and specifications. For example, if a pipe associated with a transfer system enters the nutrient storage facility, the design and specifications must include special considerations such as a reinforced opening and required flexible watertight gasket. The engineer who designs the storage facility should confirm whether a transfer system will enter the facility. If the design of a storage facility and transfer system is not assigned to the same engineer, both engineers should communicate to ensure that the tank design take into consideration the transfer system requirements under the regulation.

Site investigation — a professional engineer or geoscientist must carry out a site characterization study [O. Reg. 267/03, s. 64].

Site review — a professional engineer must perform a general review of the construction or expansion project. This review process ensures that the liquid nutrient storage facility is built in accordance with the drawings and specifications of the engineer [O. Reg. 267/03, s. 71 (1)].

Other municipal or provincial requirements

Construction of a permanent liquid nutrient storage facility must also comply with all applicable requirements of Ontario’s Building Code and the National Farm Building Code for Canada, 1995.

Specific engineering criteria required by the regulation

Site investigation

All new or expanding permanent, liquid manure or nutrient storage facilities require a site characterization/investigation. The investigation involves a minimum number of test holes to identify soil types and the presence of any aquifer or bedrock to determine the suitability of a site for a storage facility and any specific design requirements under the regulation. For more details, read the OMAFRA factsheet, Siting characterization study for the construction of permanent nutrient storage facilities and the regulation [O. Reg. 267/03, s. 65, 67, 68].

Structural systems

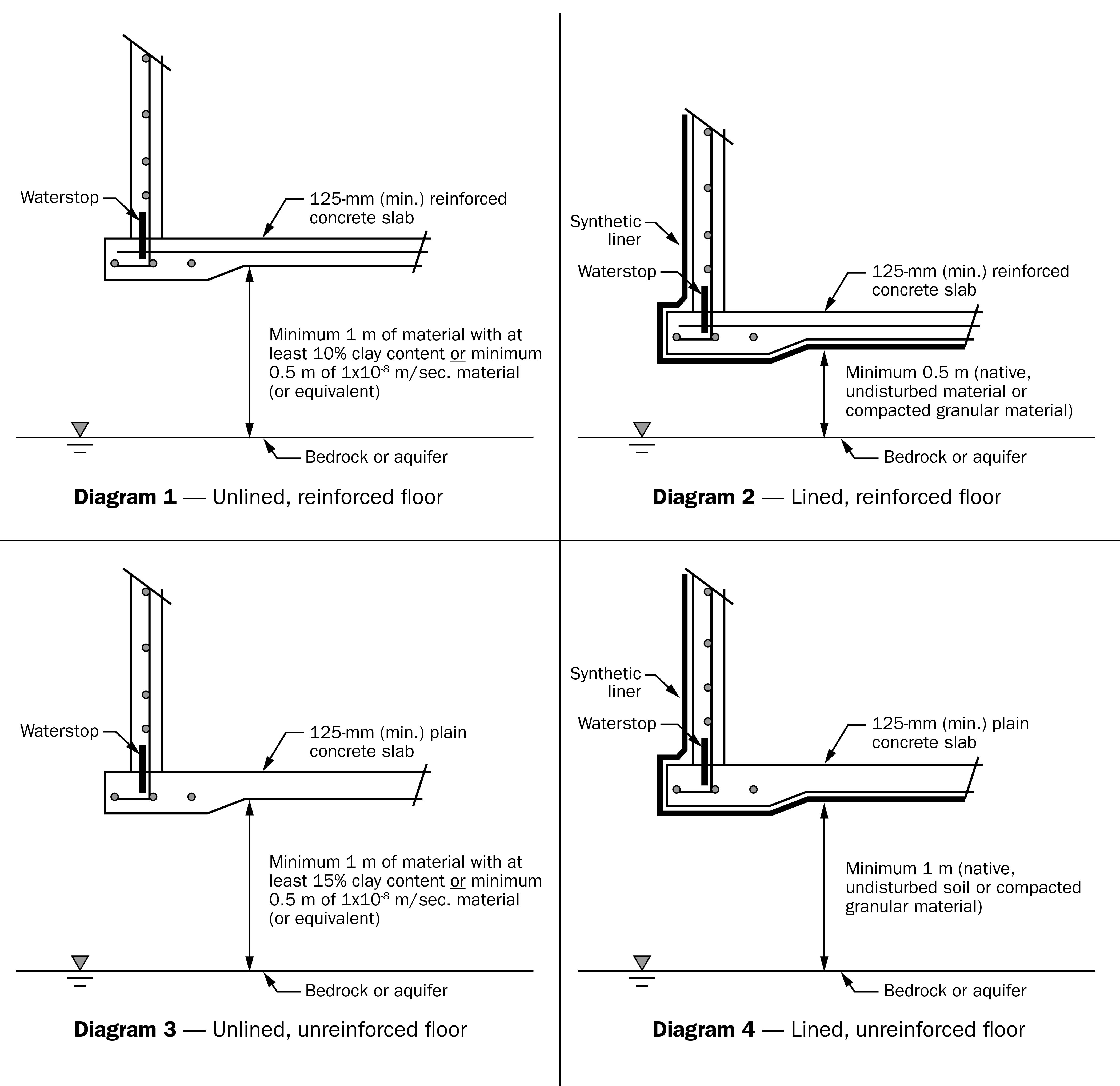

Figure 2 shows structural systems that are deemed acceptable under the regulation [O. Reg. 267/03, s. 65 (2)].

General design

The facility, including any associated monitoring systems, must be “designed to minimize leakage, minimize corrosion and to be structurally safe and sound” [O. Reg. 267/03, s. 71 (1)].

Type of concrete

If used, concrete must be strong and durable enough to resist environmental conditions and protect the reinforcing steel (if used) from potentially corrosive environments [O. Reg. 267/03, s. 72 (1)]. Review Ontario’s Building Code for the type of concrete to use.

Concrete floors

Concrete floors must be a minimum of 125 mm thick unless an engineer specifies otherwise [O. Reg. 267/03, s. 72 (2)].

Liners

Some site conditions require that the engineer use a liner as shown in Figure 2 (Diagrams 2 and 4). The regulation specifies some details on synthetic and compacted soil liners. For example, the regulation indicates that the liner must be continuous under the floor and footings of the facility and must extend up the wall to the level of the top of the ground surface. Read Sections 73, 74 and 75 of the regulation for more details on the installation and requirements of synthetic and compacted soil liners.

Secondary containment

If the liquid level in the storage facility is partially or wholly above the surface of the surrounding soil, the following options apply:

- an engineer can apply a load factor of 1.5 or another value that he or she specifies, to increase the overall factor of safety for the structure

- an engineer can determine that the storage and landscape features around the facility are adequate to ensure that a secondary containment system is not required

- the above-grade portion of the facility can have a secondary containment system with a capacity equivalent to 110% of the above-ground portion of the facility [O. Reg. 267/03, s. 76]

Structural calculations

A designer must apply an importance factor of 1.0 to a permanent liquid nutrient storage facility. An importance factor of 0.8 is commonly applied by an engineer in the design of other farm structures of low human occupancy [O. Reg. 267/03, s. 77].

Ventilation

All covered storage systems must have a ventilation system that is either a powered system or a natural system to prevent the accumulation of corrosive or noxious gases [O. Reg. 267/03, s. 78].

NASM storages

Read the OMAFRA fact sheet, Storage of Non-Agricultural Source Materials (NASM) in a Permanent Storage Facility, for additional specific requirements for NASM stored in a permanent liquid nutrient storage facility.

Transfer systems

A nutrient storage facility often includes a liquid nutrient transfer system. A transfer system includes, for example, the sump pit, pump and associated piping to move manure from a barn to a storage facility. Such a system can also be used to transfer other agricultural source material (such as washwater, runoff) or NASM. All liquid transfer systems, other than floor transfer systems defined in the regulation, must be designed by an engineer.

Transfer systems rely on gravity or mechanical devices (such as manure pumps and piping) to move the material. Regardless of the conduit used, it is important to make secure connections.

Rubber gaskets and bell and spigot connections are commonly used to make the transfer piping watertight. Proper connectors ensure that the integrity of the system is maintained. Figure 3 shows a PVC transfer piping system being assembled during barn construction.

The regulation states that no person shall construct or expand a liquid nutrient transfer system when constructing a permanent liquid nutrient storage facility unless:

- the system is designed and constructed or expanded in accordance with Part VIII of the regulation

- a professional engineer designs the construction or expansion

- a professional engineer performs a general review of the construction or expansion to ensure that it is done in accordance with the engineer’s design specification and Part VIII of the regulation

All connections in a liquid transfer system must be installed using specifically designed fittings and gaskets that are compatible with the pipe material [O. Reg. 267/03, s. 87]:

- All pipes entering a liquid nutrient storage facility must have a flexible, watertight gasket or membrane installed between the pipe and the floor or wall of the storage facility to serve as an anti-seepage collar.

- Any transfer system having an opportunity to backflow to the pump or pump-out chamber must have both a primary and secondary shutoff valve.

For more information on transfer systems, read the OMAFRA fact sheet, On-farm liquid nutrient transfer systems.

Resources

For the applicable requirements under the NMA for a facility or any component of a facility that is constructed of earth, read the OMAFRA fact sheet, Constructing an earthen liquid nutrient storage facility for agricultural source materials.

Disclaimer

The information in this factsheet is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was originally written by Don Hilborn, P. Eng., by-products/manure (retired), OMAFRA, and John Johnson, P. Eng. (retired), OMAFRA. Revised by Benoit Lebeau, P. Eng., non-agricultural source materials, OMAFRA, and Richard Brunke, P. Eng., nutrient management, OMAFRA.