Site characterization study for the construction of permanent nutrient storage facilities

Learn about the general requirements for a site characterization study under the Nutrient Management Act, 2002. This technical information is for Ontario producers.

ISSN 1198-712X, Published August 2015

Introduction

This fact sheet describes the general requirements for a site characterization study, conducting a Stage One investigation and the minimum soil conditions necessary for various types of permanent nutrient storage facilities that are considered acceptable under Ontario Regulation 267/03 (Regulation) of the Nutrient Management Act, 2002.

Understanding the requirements of a site characterization study and construction standards is crucial when constructing or expanding a permanent nutrient storage facility. It assists in the identification of sites suitable for permanent nutrient storage facilities that protect groundwater.

To protect groundwater, most new and expanding permanent nutrient storage facilities built in Ontario must provide two levels of protection — two physical barriers between the nutrients being stored and groundwater. Part 8 of the Regulation, Siting, Construction and Storage, sets out specific criteria for new or expanding permanent nutrient storage facilities.

The first barrier is achieved by the design of the engineered structure. The other barrier is achieved in two ways:

- by relying on the characteristics of the natural soil at the site

- by incorporating a liner in the engineering design of the structure if the natural soil at the site does not meet certain standards

The Regulation defines a “permanent nutrient storage facility” as a facility for storing agricultural source materials (ASM), such as manure and runoff and non-agricultural source materials (NASM) prescribed by the Regulation. It includes structures made of concrete, steel or those made of earth that are permanent structures or part of a permanent structure, but not the following:

- a permanent solid nutrient storage facility that has less than 14 days of storage capacity

- a permanent liquid nutrient storage facility that has less than 14 days of storage capacity and a maximum depth of liquid nutrient less than 100 mm

- nutrient application or irrigation systems used to deliver liquid fertilizer to crops

- a permanent nutrient storage facility used solely as part of a vegetated filter strip system

- a regulated mixed anaerobic digestion facility

The Regulation refers to two types of site characterization studies: a Stage One investigation and a Stage Two investigation. A Stage One investigation is usually enough for a new or expanding storage facility if the site and the structure meet certain minimum criteria. A Stage Two investigation must be developed by a professional engineer or geoscientist and accepted by the Ministry of Agriculture, Food and Rural Affairs (OMAFRA) when the site conditions do not meet the criteria identified in the Regulation. Due to the significant additional investigation required, a Stage Two investigation is often very costly.

General requirements

There are many factors that influence where a permanent nutrient storage is sited and where a site characterization may be conducted (Sections 63 and 67 of the Regulation). These sections address the proximity to wells, field tiles, surface water and desired locations. Most municipalities have bylaws that provide for minimum separation distances between manure storage facilities and neighbouring residences and other land uses. The layout of the farmstead may also dictate where a permanent nutrient storage is located. Good communication between all parties involved in the project is very important when siting a permanent nutrient storage facility and conducting a site characterization study.

Under Part 8 of the Regulation, a site characterization study must be performed if construction or expansion of the following storage facilities is planned:

- any permanent liquid nutrient storage for ASM or NASM

- certain permanent solid nutrient storage facilities without a concrete floor for ASM and NASM

The requirement for a site characterization study for a permanent solid nutrient storage facility depends upon a combination of factors including the floor material, the dimensions and capacity of the storage, and the number of animals present on the farm unit. Table 1 summarizes the requirements for storage facilities in various situations.

| Type of storage facility | Requirements |

|---|---|

| No site characterization study required under the Regulation for these structures. |

| Permanent solid nutrient storage facilities for ASM that do not meet all of the criteria listed above and are proposed at a farm unit that has, or is proposing to have, the capacity to generate at least 300 NU. | The site characterization study must demonstrate that there is at least:

|

| Permanent solid nutrient storage facility for ASM that does not meet all of the criteria listed above and is proposed on a farm unit that will generate less than 300 NU. | A site characterization study is not required, but the operation must demonstrate that the floor consists of at least 0.5 m of C or D type soil as defined by the Drainage Guide for Ontario. |

| Permanent solid nutrient storage facilities for NASM that do not meet all of the criteria listed above and located on a farm unit that requires a NASM plan. | The site characterization study must demonstrate that there is at least:

|

| Permanent solid nutrient storage facilities for NASM that do not meet all of the criteria listed above and located on a farm unit that DOES NOT require a NASM plan. | No site characterization study required under the Regulation for these structures. |

If a site characterization study is required under the Regulation, it must be conducted under the supervision of a professional engineer or a professional geoscientist licensed to practise in Ontario. As part of the approval of a nutrient management strategy (NMS) for the construction of any structures referred to above, the investigating professional is required to complete and sign the site characterization section of an Engineer’s Commitment Certificate. This demonstrates that a qualified professional has committed to conduct the investigation prior to construction.

Stage One investigation procedures

A site characterization study involves soil boring or a test pit investigation to identify critical subsurface elements. These include water table levels, depth to the uppermost bedrock layer or aquifer, as well as geotechnical and hydraulic soil characteristics.

A Stage One investigation requires a minimum of one test hole per 1,000 m2 (10,760 ft2) of the footprint of the proposed structure. The test holes must be located 3–10 m (10–33 ft) outside the perimeter of the footprint, thus protecting the integrity of the soil at the site by leaving it undisturbed.

The minimum required investigation depth for a Stage One investigation varies, depending on the type of storage facility selected:

Permanent liquid nutrient storage facility:

- earthen storages: 2.5 m (8 ft) below the lowest elevation of proposed excavation (below the excavation for the floor).

- concrete or steel storages: 1.5 m (5 ft) below the lowest elevation of proposed excavation (below the excavation for the floor). Note: The professional engineer may choose other equivalent materials for the floor of the structure, as long as they offer the same level of protection as concrete or steel.

Permanent solid nutrient storage facility:

- 0.5–0.9 m (1.64–2.95 ft) below the bottom of the proposed facility, depending on the type of soil material as indicated in Table 1.

Equipment to conduct a site characterization study

Use exploratory equipment such as soil-boring machines, backhoes, excavators or other equipment to perform the site characterization study. Leave the choice of equipment, which may depend on the nature of the site being investigated, to a professional engineer or professional geoscientist. Figure 1 shows a boring machine used to obtain soil samples.

Log and analysis

The site characterization study should include a field log that describes soil characteristics such as texture, colour and moisture conditions in the soils as a borehole is being drilled or a pit excavated. Collect soil samples, intended for laboratory analysis, at 1-m intervals, and for every soil layer encountered that consists of a different soil material. Experienced technical personnel can estimate soil texture by observing a small handful of soil when moistened and kneaded between the thumb and forefinger. This technique is known as hand-texturing. Record the depths at which soil samples are taken, with an estimate of the soil texture. Note the depth to any soil anomalies and their characteristics, as well as depth to water table. Geotechnical companies use standard field log forms to document investigations.

Geologic anomalies

Geologic or soil anomalies are layers of coarse material lenses, stringers, bedrock drift, large rocks and roots or other organic debris that are imbedded within the subsoil. These irregularities can create seepage paths to groundwater from the nutrient storage facility where they contact the floor or walls of the structure. Permeable anomalous features can also transfer water toward the structure, creating unexpected hydraulic loads that may cause structural complications. Where irregularities are encountered during site excavation, the engineer or geoscientist must develop a strategy to compensate for any potential impacts related to these soil and geologic conditions.

Interpretation of test data

All soil analyses must be carried out by a laboratory qualified to analyze geotechnical soil samples in Ontario. The completed field and laboratory tests must be interpreted by a professional engineer or a professional geoscientist.

Resource information

To aid in the analysis for the site, the professional supervising the site investigation can make use of the following additional sources of information:

- topographical maps

- quaternary geology maps

- hydrogeological or septic suitability reports

- provincial soils maps

- Ontario Ministry of the Environment and Climate Change (MOECC) well-construction records

- Source water protection at Conservation Ontario

- well-water quality data

Subsurface condition requirements for permanent nutrient storages

The subsurface conditions found at a particular site will confirm whether the site is suitable and provide sufficient protection to the groundwater. The minimum subsurface conditions required for a solid nutrient storage facility are listed in Table 1.

Table 2 shows the minimum subsurface conditions for various types of permanent liquid nutrient storage facilities that are considered acceptable under the Regulation. In general, more secure storage facilities must be used where the natural soil and geologic characteristics provide a lower level of groundwater protection. The professional conducting the site characterization study will determine what type of storage to use to ensure adequate protection of the groundwater.

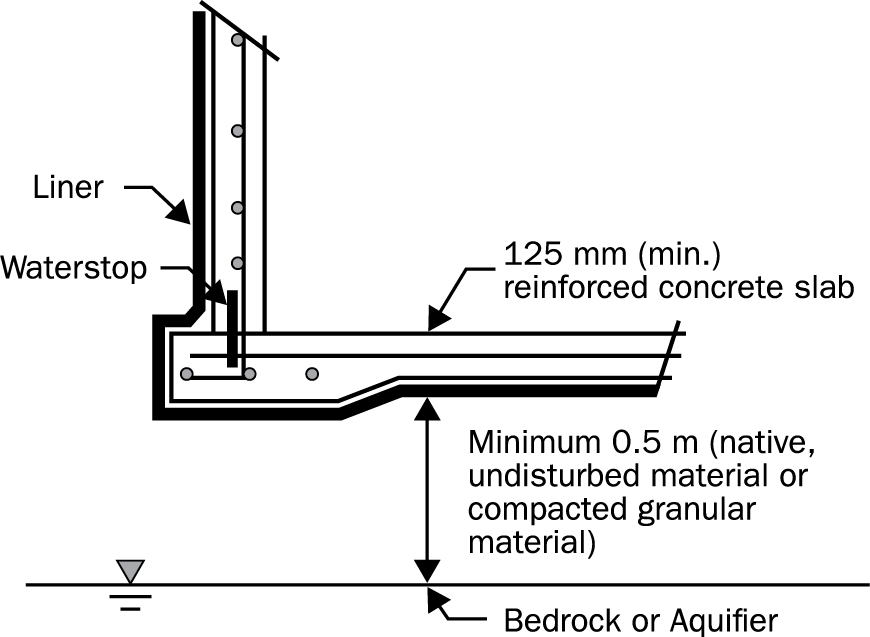

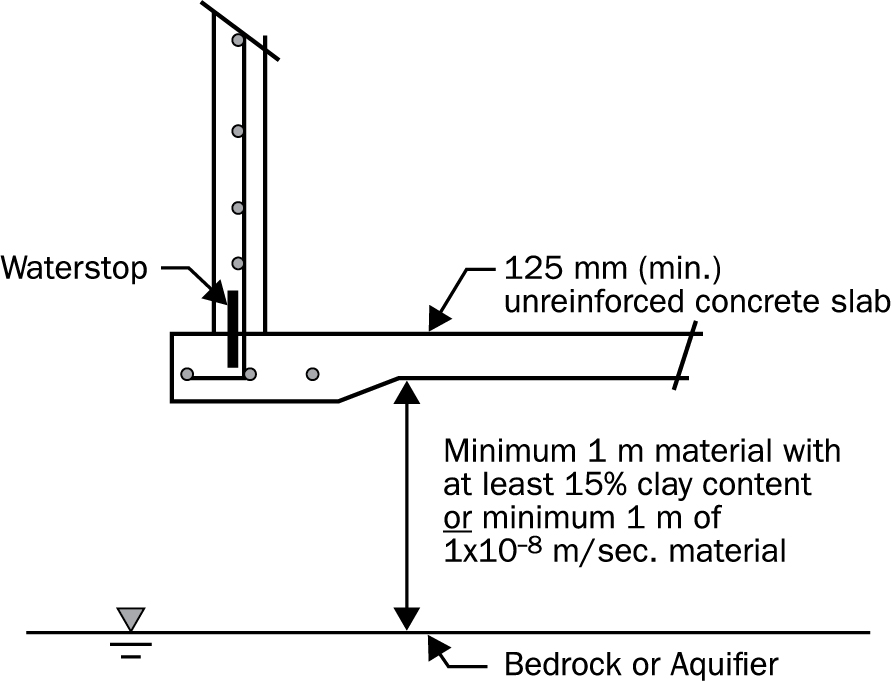

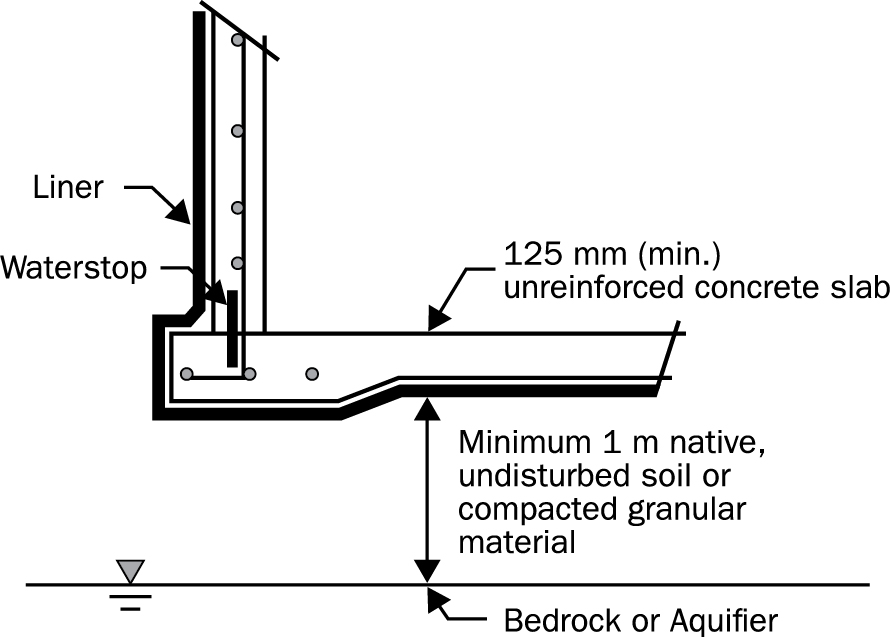

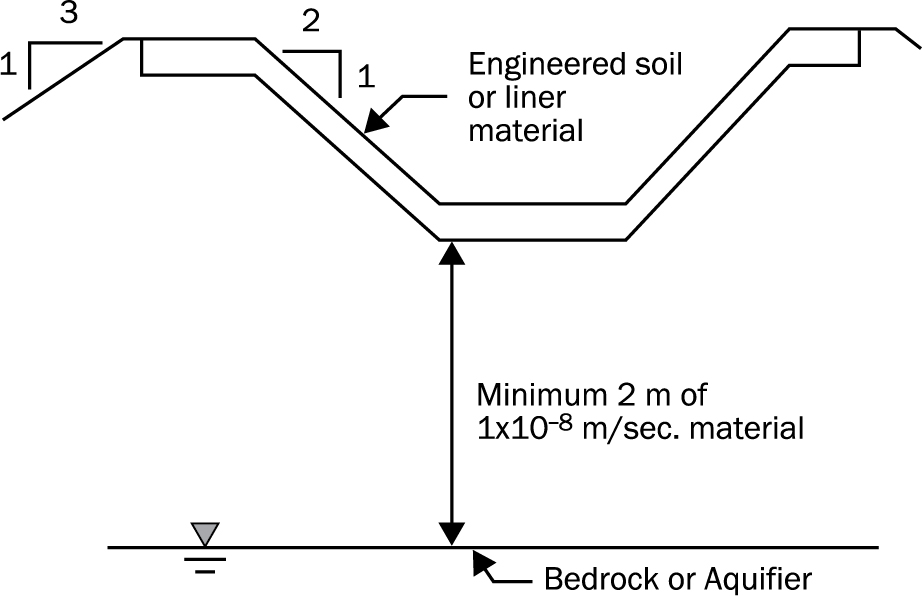

| Type of storage | Subsurface condition requirements | Storage types for permanent liquid storage facilities |

|---|---|---|

| Unlined concrete or steel storage facilities with reinforced concrete floors | Must have, between the bottom of the storage facility and the uppermost identified bedrock layer or aquifer, a minimum of:

Note: A hydraulically secure soil is a natural soil, consistent in nature and able to meet a maximum saturated hydraulic conductivity of 1x10–8m/s. |  |

| Lined concrete or steel storage facilities with reinforced concrete floors | Must have a minimum of:

|  |

| Unlined concrete or steel storage facilities with unreinforced concrete floors | Must have, between the bottom of the storage facility and the uppermost identified bedrock layer or aquifer, a minimum of:

|  |

| Lined concrete or steel storage facilities with unreinforced concrete floors | Must have a minimum of:

|  |

| Lined storage facilities made of earth | Must have a minimum of:

|  |

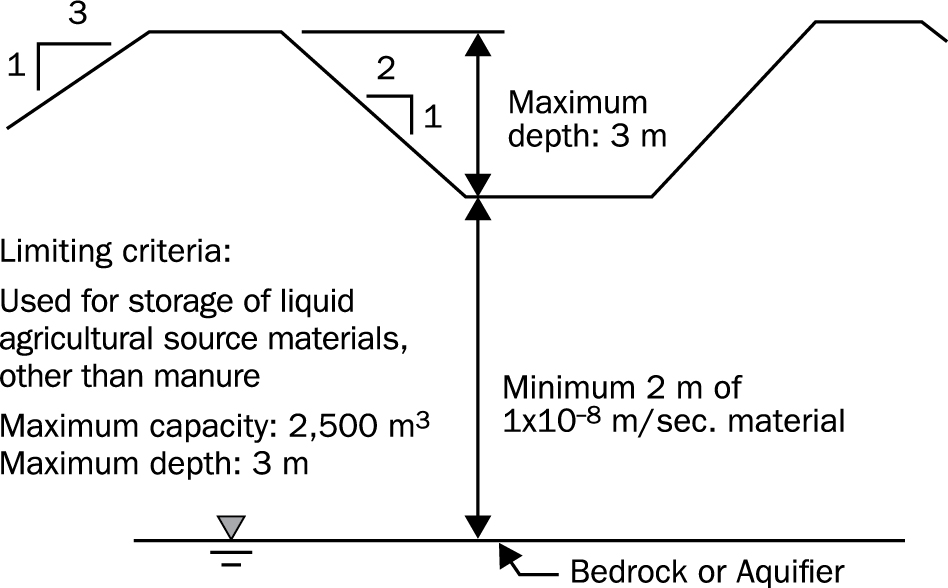

| Unlined storage facilities made of earth used to store agricultural source materials, other than manure and materials produced by intermediate generators. Also not suitable for NASM. | Must have at least:

Note: The facility must have a maximum storage depth of 3.0 m and a maximum storage volume of 2,500 m3. |  |

The site characterization study must conclusively determine that the site characteristics meet the minimum criteria for the type of storage structure proposed. In combination with the required setback distances from water wells, these minimum criteria provide excellent protection against groundwater contamination.

Consider the proposed nutrient storage facility only if the subsoil conditions meet or exceed the requirements set out in the Regulation. If the requirements are not met for a given site, the options are:

- evaluate another site

- propose a facility that is suitable for the site

- perform a Stage Two investigation as determined by the professional engineer and accepted by a director as outlined by the Nutrient Management Act, 2002 and its associated Regulation.

Summary

Protection of surface and groundwater resources is important. The type of nutrient storage facility and a study of the natural characteristics of the site are used to determine if additional measures are needed to assure protection for groundwater.

Disclaimer

The information in this document is provided for informational purposes only and should not be relied upon to determine legal obligations. To determine your legal obligations, consult the relevant law. If legal advice is required, consult a lawyer. In the event of a conflict between the information in this fact sheet and any applicable law, the law prevails.

This fact sheet was written by Benoit Lebeau, P.Eng., non-agricultural source material specialist and Dale McComb, nutrient management specialist, OMAFRA.