Minister’s Report on Toxics Reduction 2014

Ontario’s progress in reducing toxic substances in our air, land and water from 2011 until 2013.

Minister’s message

People in Ontario value a clean environment and healthy communities. They want to know that the air they breathe and the water they drink is clean. The Ministry of the Environment is committed to protecting people’s health and the environment by promoting reductions in the use and creation of toxic substances. This report highlights our progress in this area from 2011 to 2013 under Ontario’s Toxics Reduction Strategy.

Ontario adopted the strategy in 2009, and the results to date are promising. Ninety-nine per cent of regulated facilities are meeting their obligations under the Toxics Reduction Act. In this first year, more than 40 per cent of facilities have voluntarily committed to implementing toxics reduction plans. Many of these companies have found they save money when they make changes to reduce toxic substance use. In 2012, we collaborated with industry to launch a user-friendly website that includes an interactive map detailing all of the regulated facilities across Ontario and direct access to raw data. I invite you to look and see what facilities in your community are doing to reduce their use and creation of toxic substances.

We continue to see positive results from the Cosmetic Pesticides Ban Act. Monitoring pesticides in urban streams show reductions of up to 92 per cent in the concentrations of three pesticides commonly used in lawn care products from pre-ban levels. We are also seeing steady growth in the development of “greener” pest control products and methods. Under Ontario’s cosmetic pesticides ban, only biopesticides and certain lower risk pesticides are allowed to be used for controlling weeds, insects and plant diseases on lawns and gardens. Since the ban was introduced, the number of alternate pesticides has increased from 29 to 65, providing more green options for lawn care operators and gardeners.

In 2013, Ontario introduced the proposed Ending Coal for Cleaner Air Act that would ensure coal facilities ceasing operation by the end of 2014 would remain closed. Coal-fired electricity generation was a major source of health-threatening smog, climate-destabilizing greenhouse gases, and toxic substances. The proposed legislation would ensure that dirty coal-fired electricity remains a thing of the past.

I look forward to working with all of our partners to reduce the use and production of toxic substances, while looking at new ways of providing the people of Ontario with information and data about toxics in the environment.

Jim Bradley

Minister of the Environment

Taking care of our environment

The toxics reduction program

Ontario’s toxics reduction program’s objectives are geared towards improving the health of the environment and the lives of people in Ontario. The program seeks to:

- improve the protection of the environment and human health by requiring regulated facilities to account, plan and publically report on their efforts to reduce the use and creation of prescribed toxic substances

- inform Ontarians about toxic substances in their communities

- help ensure Ontario is well positioned to compete in an increasingly green global economy

The toxics reduction program is intended to complement the traditional “end of pipe” management of discharges to the environment by including considerations of “front end” industrial processes. This can include:

- focusing on why toxic substances are used and how they are created

- looking at ways to make changes to processes and/or technologies to reduce the use and creation of toxic substances

- taking action beyond what is currently being done to reduce the use and creation of toxic substances and ultimately their discharge to our environment

The toxics reduction program requires regulated facilities engaged in manufacturing or mineral processing to examine how and why they use and/or create prescribed toxic substances and then consider opportunities for reduction. Reductions in use and creation of toxics can reduce discharges to air, land, water and in consumer products – thereby reducing risks to human health and the environment.

The purpose of the program is to ensure that in depth consideration is given to opportunities for reducing the use and creation of toxic substances while also recognizing that there may be essential and beneficial uses for some toxic substances. The intent of the program is to take a thoughtful approach to planning. The program does not restrict the use, creation, or release of toxic substances nor does it oblige facilities to implement reduction strategies.

Implementation is voluntary to allow each facility an opportunity to move forward at a rate that best reflects its unique economic and operational circumstances.

Nationally for the years 2008 – 2012, there has been a 17 per cent decrease in total releases for the National Pollutant Release Inventory (NPRI) substances also prescribed in Ontario under the Toxics Reduction Act.

Ontario’s registered nurses advocated for a Toxics Reduction Act because we see the ill effects of toxics in our daily practice. RNAO will continue to work with the ministry to help ensure all objectives of the act are met. Our goal is better protection for Ontarians from harmful chemicals in the environment, in the workplace, and in consumer products. Doris Grinspun, Chief Executive Officer of the Registered Nurses' Association of Ontario (RNAO).

The Canadian Cancer Society is pleased to see the development of what began from a point of wanting to reduce carcinogens in Ontario, to the implementation of a toxics reduction program where businesses are reporting what is being used and released. The Society strongly believes that as community members, workers and consumers, we all have the right to know about the environmental and occupational risks we are exposed to, allowing us to make informed decisions affecting our health. We look forward to seeing further efforts to promote innovation and the use of safer alternatives that will have a positive impact on cancer in Ontario. Canadian Cancer Society

Decreases were due to a combination of investments in emission control technologies; facility closures, and production decreases for certain substances in base metal smelters, in other manufacturing facilities, and coal-fired electricity generating stations. Similarly, the total reported releases of substances classified as toxics under the Canadian Environmental Protection Act (CEPA), and listed on the NPRI, decreased 23 per cent between 2008-2012. Further information may be found in Environment Canada’s Summary Report: Reviewed 2012 NPRI Facility Reported Data.

Further, there has been an upward trend in disposals and transfers for recycling for these years. The increase in disposals and transfers of substances for recycling was attributed to increased mining activity (e.g. tailings and waste rock) and higher rates of recycling of waste materials.

Assessing and managing the risks posed by some substances in the global market place means new challenges and opportunities to jurisdictions in Europe, Asia and North America, and to their citizens. As substances are evaluated and potentially restricted, Ontario companies are progressively positioning themselves to do business in this new global environment by developing new technologies, greening their practices, products, and services. Businesses around the world are recognizing the benefits of environmentally monitoring their products and supply chains, to reduce risks, improve consumer protection and increase profitability and best practices. As Ontario facilities undertake tracking, quantification and planning under the toxics reduction program, valuable information and options for reducing use and creation of toxics can be discovered. This information may be useful for those wishing to expand and/or access new markets in jurisdictions with trade agreements with Canada.

Achievements

The living list process

The science associated with toxic substances is continually evolving. In order to help ensure the toxics reduction program continues to meet its strategic objectives, the legislation requires the ministry to review and consult with experts and the public about potential changes to the list of toxic substances at least once every five years. The ministry’s approach to reviewing and making changes to the list of prescribed substances is called the Living List Framework.

To inform the development of the Living List Framework, the ministry formed a multistakeholder working group. This highly collaborative group was made up of representatives from industry, environmental non-governmental organizations, health organizations, academia, and labour groups bringing their skills, experience and perspectives to assist the ministry with developing a proposed Living List Framework. The multi-stakeholder group worked tirelessly over a two year period. The group was co-chaired by Yasmin Tarmohamed from the Canadian Vehicle Manufacturers Association and Dr. Miriam Diamond from the University of Toronto.

The proposed Living List Framework is posted on Ontario’s Environmental Registry for public comment until May 12, 2014.

The ministry invites people to comment on the proposed Living List Framework to suggest changes to the list of toxic substances covered by the Toxics Reduction Act.

Toxic substance planner

John McGeough is one of Ontario’s 280 licensed Planners. Prevention principles can be applied wherever there is risk, such as in fall prevention equipment, machine safeguarding, reduced toxicity or chemical concentrations, and reduced waste or noise generation. It was the preventive aspect of the Toxics Reduction Act that intrigued John and prompted him to share news of the toxics reduction program.

John McGeough prepared or reviewed 38 plans, of which 87 per cent have commitments to implement at least one toxic reduction option. Many of these have modest material and cost reductions, but most have secondary benefits, such as: improved environmental control; community safety improvements, and reductions in energy use and scrap/waste generation. These benefits underline the value of the program.

An initial concern identified by companies regarding the TRA program was the amount of information required for plan development. This was viewed as an unnecessary cost, considering continuous improvement teams were often already in place. John saw this as an opportunity! By involving the continuous improvement teams in the toxics reduction process, John was able to incorporate toxics reduction planning into current facility efforts concerning energy, waste, and scrap reduction. John facilitated the identification of toxics reduction options using the brain writing technique he learned while attending the toxics reduction planner training sessions. With the right mix of personnel, companies had no difficulty in filling the page with toxics reduction options.

In some cases the company seizes on the toxic reduction opportunity identified and runs with it. This is the approach that Procter and Gamble’s facility in Brockville, Ontario chose to take. The facility committed to optimizing the use of dust control systems to reduce the creation of particulate matter. This work led to additional secondary benefits including reduced particulate matter emissions, and anticipated energy savings of over $150,000 per year.

As a company, P&G is committed to regulatory compliance, while continuously striving to improve operational safety, efficiency, and environmental sustainability. John’s team-based approach to TRA planning helped us to identify and explore a number of opportunities to ultimately achieve our goals. Gary Thornhill, P&G Brockville Site Environmental Leader

Licensed toxic substance reduction planners

A toxic substance reduction planner plays an important role in the success of the toxics reduction program.

A licensed planner adds value to the toxic substance reduction planning process by:

- providing recommendations to improve the plan

- certifying the plan meets legislative requirements

- ensuring viable toxic substance reduction opportunities have not been missed or misrepresented

- encouraging and maximizing opportunities for implementing the plan

The planner plays an important role in ensuring public confidence that the goals of program will be met. The public can see summaries of certified plans for each substance, prepared by each facility, on the on-line interactive map.

A facility can realize a number of environmental, economic and social benefits through toxic substance reduction planning. A facility will look to the planner to help maximize these benefits.

The ministry worked with its partners to prepare and deliver the training and licensing program for toxic substance reduction planners, to ensure qualified people are available to certify plans and to offer advice in developing meaningful plans.

In 2012 and 2013, fifteen sessions were held across the province to train and license planners. As of November 2013, approximately 280 individuals have been licensed. A list of licensed toxic substance reduction planners is available at Licensed Toxics Planners page.

Informing Ontarians

Transparency

One of the toxics reduction program’s goals is to inform Ontarians about toxic substances being used and created in the province. This goal aligns with the Open Ontario initiative of making government more transparent. We are sharing information online from industry’s annual reports and summaries of plans to reduce their use and creation of toxics. A user friendly interactive map details all of the regulated facilities across Ontario is available on the Toxics Reduction Program page. Raw data is available on the Open Data Catalogue.

Facility annual reports - 2011 & 2012

Toxics reduction reports are prepared and submitted annually by regulated facilities for the previous calendar year. The reports track year-over-year toxics use and creation as well as progress made on toxic reduction plans. The reports include information on the annual quantities of toxic substances used, created, contained in product and released to the environment. Facilities are obligated to submit reports on a per substance basis to the ministry and make them publically available on the Internet.

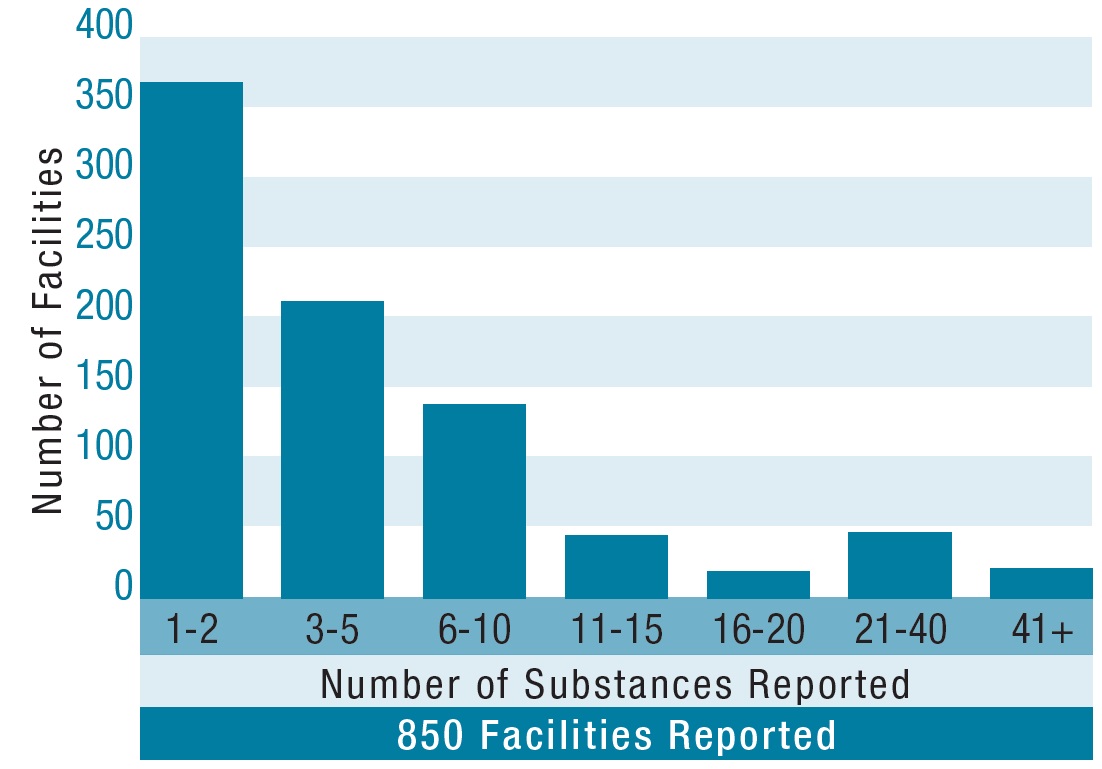

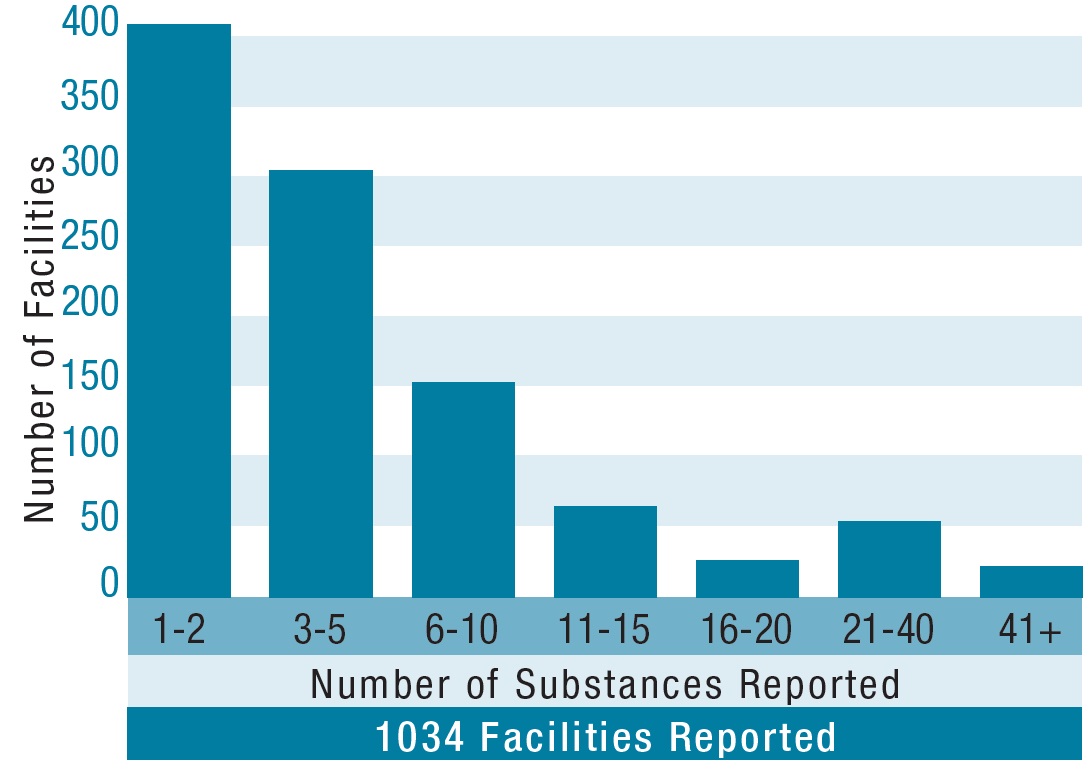

850 facilities submitted annual reports on 47 Phase I substances and substance groups for the 2011 reporting year. This number increased to over 1000 reports in 2012 due to the introduction of approximately 270 additional Phase II prescribed toxic substances.

The majority of facilities reporting were categorized as small or medium sized (500 employees or less) and on average reported on one to five toxic substances.

Number of facilities by number of substances reported in 2011

Number of facilities by number of substances reported in 2012

The following tables represent the provincial totals for substances as reported by facilities captured by the Toxics Reduction Act. If facilitates have any corrections or changes, they can be made through Environment Canada’s Single Window.

For 2011, metals were the most frequently reported toxic substances and along with solvents, made the top 10 used and created substances.

| Substances | Tonnes |

|---|---|

| Hydrochloric acid | 3,862,100 |

| Chromium (and its compounds) | 1,653,200 |

| Nickel (and its compounds) | 1,502,500 |

| Zinc (and its compounds) | 1,052,000 |

| Benzene | 489,500 |

| Copper (and its compounds) | 461,800 |

| Manganese (and its compounds) | 400,200 |

| Toluene | 290,100 |

| Methanol | 283,400 |

| Sulphuric acid | 247,300 |

| Substances | Tonnes |

|---|---|

| Sulphuric acid | 850,700 |

| Toluene | 515,500 |

| Xylene (all isomers) | 467,800 |

| Ethylbenzene | 445,200 |

| Benzene | 279,400 |

| 1,3-Butadiene | 90,800 |

| Naphthalene | 44,100 |

| Formaldehyde | 22,300 |

| Methanol | 18,500 |

| Hydrochloric acid | 8,300 |

For 2012, with the introduction of Phase II, the most frequently reported substances in Ontario were particulate matter (PM2.5 and PM10) as well as metals and solvents.

| Substances | Tonnes |

|---|---|

| Polymeric diphenylmethane diisocyanate | 1,853,100 |

| Methylenebis (phenylisocyanate) | 1,848,800 |

| Butane (all isomers) | 1,057,500 |

| Propane | 855,500 |

| Ethylene | 744,400 |

| Pentane (all isomers) | 682,300 |

| Butene (all isomers) | 649,200 |

| n-Hexane | 479,300 |

| Benzene | 458,700 |

| Nickel (and its compounds) | 447,100 |

| Substances | Tonnes |

|---|---|

| Ethylene | 1,026,900 |

| Sulphuric acid | 994,200 |

| Ethyl Alcohol | 653,300 |

| Toluene | 548,800 |

| Xylene (all isomers) | 524,000 |

| Octane (all isomers) | 520,000 |

| Ammonia (total) | 488,700 |

| Total Particulate Matter | 484,100 |

| Pentane (all isomers) | 464,500 |

| Propylene | 457,400 |

Bombardier

Bombardier Aerospace designs, manufactures and supports innovative aviation products for the business, commercial, specialized and amphibious aircraft markets. Bombardier Toronto is involved in the design, assembly and testing of the Q400 turboprop and Global family of business aircraft.

Bombardier is committed to operating our business in a way that maximizes the safety and environmental efficiency of our workplaces and of our products.

To reduce the use of toxics in its operations, the Toronto facility has concentrated on replacing cleaning solvents, namely Trichloroethylene, with less toxic alternatives. Trichloroethylene is used as a vapour degreaser for cleaning critical aircraft parts.

Replacing solvents was achieved successfully despite strict aerospace requirements and increased costs. By replacing Trichloroethylene with a nonprescribed substance, Bombardier reduced its use by 100 per cent in 2012.

Further, Bombardier is currently working to reduce the use of hexavalent chromium by 50 per cent by 2020. Hexavalent chromium is used in the chemical treatment of aluminum for aircraft parts to increase corrosion resistance and paint adhesion. Reductions will be achieved through operator training, improved inventory management and material or feedstock substitution.

Bombardier has made significant reductions in the use of toxics and in some cases eliminated their use altogether by substituting with less hazardous alternatives.

Bombardier Toronto has adopted a structured system of continuous improvement and is constantly investigating further opportunities to reduce the use of toxics in order to improve operations and reduce its environmental footprint.

Bombardier sees beyond the current regulations on the reduction of toxic substances— employee safety and protecting the environment are key priorities for the company.Michael Anger, Sr. HSE Advisor

Toxic reduction plan and plan summary

A toxic reduction plan is a comprehensive document that identifies and assesses options to reduce the use and creation of a toxic substance. A facility must develop a plan for each identified toxic substance used or created at their facility—regardless of whether or not they intend to implement a reduction plan. These plans remain onsite and must be made available to ministry staff upon request.

A plan summary is a synopsis of a toxic reduction plan that must be submitted to the ministry and made public on the Internet. It is a valuable way to communicate with Ontarians. It tells the public:

- why the prescribed toxic substance is used or created

- of the facility’s intent to reduce the use and creation of the toxic substance(s), and

- how reductions will be achieved

2011 was the base year for Phase I plans prepared by facilities regulated under the Toxics Reduction Act. Facilities are required to make their toxics annual reports and summaries of their toxics reductions plans available online. In addition, detailed information can be found on a ministry hosted, user-friendly interactive map detailing all of the regulated facilities across Ontario as well as direct access to raw data.

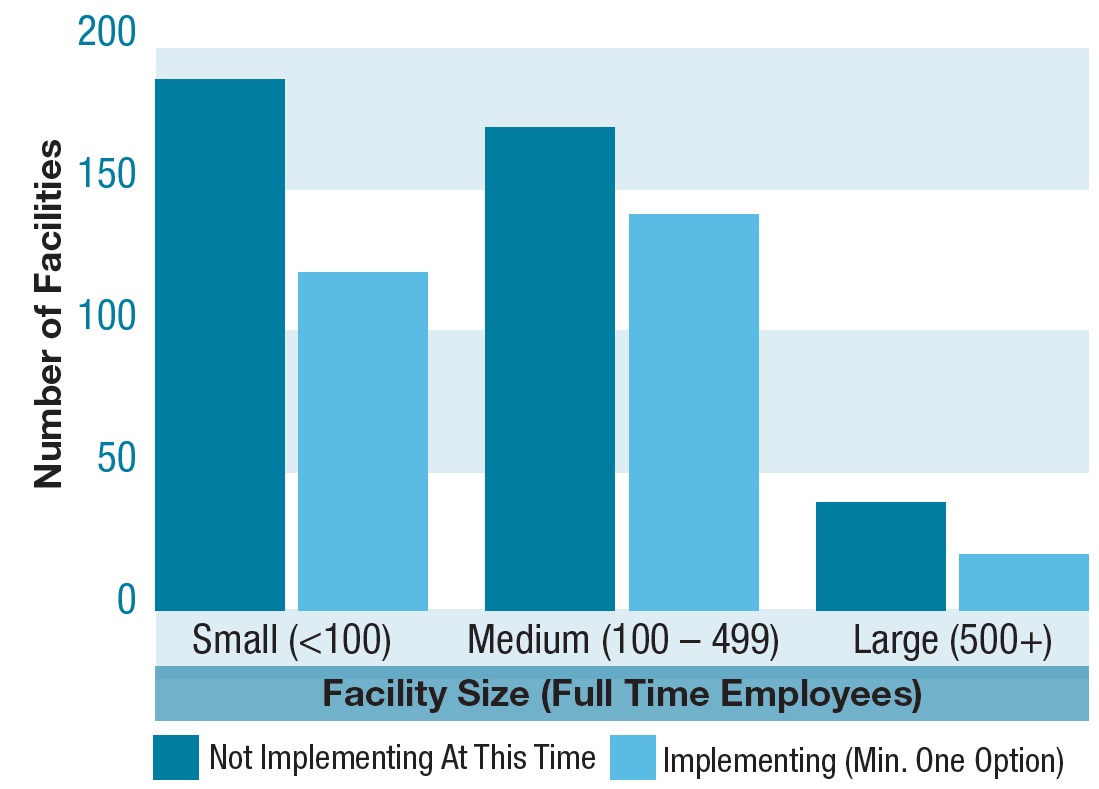

Over 680 facilities submitted plan summaries for 2011. Of those, 283 facilities committed to implementing at least one toxic reduction option. These facilities represent a wide range of sectors from chemical manufacturing to textiles to wood product manufacturing. Please see Appendix B for a list of facilities that are implementing toxics reduction plans for at least one toxic substance (based on submissions as of December 20, 2013). The top three toxics reduction categories that facilities referenced in their plans were:

- equipment or process modification

- good operator practice or training

- on-site reuse, recycling, or recovery

Small, medium, large facilities implementing 2011 toxic substance reduction plans

Size of facility was not a determining factor in the ratio of facilities implementing versus not implementing toxics reduction plans. For more information on plan implementation by small, medium and large facilities by sector, please see Appendix A.

Facilities indicating that they will not implement their toxic reduction plan at this time, most frequently cited the following reasons:

- no technically or economically feasible options

- facility will continue to investigate future opportunities

- best practices already implemented for leaner/ more efficient manufacturing

- toxic substance is a critical component of the manufacturing process or is the product itself

- toxic substance is naturally occurring in feedstock

- facility is focussing resources on the reduction of emissions

Compliance

The ministry uses a variety of tools designed to help ensure compliance with the act and regulation. Education, outreach and voluntary abatement have been the primary tools used to promote compliance. Education and outreach initiatives undertaken include:

- over 50 compliance and technical training sessions held across the province

- guidance documents including 6 technical guides and 1 industry specific guide prepared in partnership with the Canadian Vehicle Manufacturers Association

- 15 toxic substance reduction planner training sessions were held across the province

- emails to approximately 5500 recipients outlining their responsibilities under the act and regulation (including filing directions, reporting and planning deadlines); information on technical and planner training sessions as well as general updates and amendments

- speaking engagements and one-on-one meetings with numerous industry associations including more than 15 facility tours geared towards information sharing

- ministry client services staff respond to approximately 10 inquiries per day from both regulated facilities and licensed planners on a wide range of topics

- education and outreach during inspections where environmental officers provide toxics reduction outreach materials to facilities while conducting inspections under other program areas.

| Substance Name | Number of Facilities That Decided to Implement | Total Number of Facilities |

|---|---|---|

| Manganese (and its compounds) | 49 | 193 |

| Zinc (and its compounds) | 47 | 183 |

| Chromium (and its compounds) | 36 | 153 |

| Copper (and its compounds) | 45 | 153 |

| Lead (and its compounds) | 47 | 146 |

| Nickel (and its compounds) | 31 | 123 |

| Xylene (all isomers) | 54 | 120 |

| Methanol | 50 | 119 |

| Toluene | 54 | 119 |

| Sulphuric acid | 40 | 117 |

| Hydrochloric acid | 23 | 75 |

| Cadmium (and its compounds) | 17 | 66 |

| Hexavalent chromium (and its compounds) | 25 | 62 |

| Arsenic (and its compounds) | 10 | 42 |

| Ethylbenzene | 22 | 41 |

| Selenium (and its compounds) | 11 | 38 |

| Formaldehyde | 11 | 37 |

| Dioxins and Furans | 6 | 35 |

| Hexachlorobenzene | 5 | 35 |

| Mercury (and its compounds) | 11 | 32 |

| Benzene | 6 | 26 |

There are a number of resources available online for those who wish to learn more about toxics— websites include: Ontario’s website; Pollution Probe Primer website and, Canadian Partnership for Children’s Health & Environment (CPCHE) website.

The ministry is also conducting compliance activities to ensure facilities are complying with the requirements of the act and regulation. Compliance with the Toxics Reduction Act (TRA) reporting requirements are assessed following key compliance dates (e.g. June 1 annual report date) and involves a combination of data analysis and a graduated compliance approach.

An important factor in determining compliance involves identifying regulated facilities. This is achieved by reviewing historical facility and discharge data from the federal government’s National Pollutant Release Inventory for the manufacturing and mineral processing sectors. This information is then used to identify facilities with potential reporting irregularities with the TRA reporting requirements.

When a reporting irregularity is identified, facilities are contacted to confirm that the facility is subject to the TRA. Where confirmed that a facility has not met their TRA reporting requirements, follow up is initiated by Environmental Officers using a graduated compliance approach.

The graduated compliance approach begins with a letter sent to the facility and if required, may escalate to a site visit or inspection where Environmental Officers employ compliance and/or enforcement tools as set out in the Toxics Reduction Act, to ensure all requirements of the act and regulation are being met.

As a result of these efforts, 2010 and 2011 compliance rates show that 99 per cent of facilities met the requirements of the act and regulation.

Lac des Iles mine

North American Palladium LTD is an establi shed precious metals producer that has been operating its flagship Lac des Iles mine (LDI) located in Ontario, Canada since 1993. The mine employs 400 people and is 85km north of Thunder Bay.

LDI is one of only two primary producers of palladium in the world, and is currently undergoing a major expansion to increase production and reduce the cash costs per ounce of palladium extracted.

"Lac des Iles mine has a long standing commitment to an Environmental Management System. For each of our activities (construction, operation, closure), all risks to the environment, to the health and safety of our employees and to the public are identified and minimized. Risks are identified through predevelopment impact assessments and regular monitoring."

Annual monitoring for physical and chemical stability of water surrounding the property is ongoing and will be continued years after the mine has closed. Every three years there is an extensive biological monitoring study that covers an area of 300 km2 around the mine site. This includes the monitoring of fisheries, plants, soils, water, and benthic invertebrates, as well as algae quality and assessment. To date, no negative trends have been associated with the Lac des Iles mine on the surrounding ecosystem. The Lac des Iles mine has all necessary approvals and licenses for the operation of the mine and for all planned expansion projects.

The successful Implementation of toxic substance reduction options has led to:

- testing of new, complementary reagents to allow for overall reduced reagent consumption

- continuous mill improvements have seen increases in recoveries upward of 3 per cent - additional mill improvement projects such as flash flotation (currently in the engineering stage) will allow for continued recovery increases while processing less tonnage

- improvements in overall concentrator recoveries and product grade that allow for reduced chemical consumption

- continued use of calcium chloride for dust suppression in the primary crushing of feed stock to eliminate airborne pollutants in the mine site

- implementation of a continuous training program for mine personnel on the fugitive dust best management practices

- constant spraying water truck on unpaved roads for dust suppression

- use of dust suppressant mixed with fertilizer and grass seed to re-vegetate decommissioned cells

- the replacement of assay lab equipment with more advanced, lead-free analytical equipment making all of our equipment lead free

- mill feed being blended resulting in final product impurities below threshold limits

- careful and efficient clarifier operation has reduced toxic substances in final effluent discharge to below regulation limits

- continuous testing of mill reagents to improve overall metallurgy

“Our efforts in toxics reduction are part of an ongoing effort to reduce overall waste and increase operational efficiency. The successes achieved in these areas have minimized the environmental impact of our operations, increased production yields and, reduced the cash cost per ounce.”

Our Employees actively benefit from our efforts in toxics reduction. Many employees use the surrounding areas for various recreational activities including fishing and snowmobile riding. We can enjoy these recreational activities knowing our efforts in toxics reduction create a safe place for us to work and enjoy. Mike Wanecki, North American Palladium

Supporting industry

Clean and greener manufaturing program

The ministry provided funding to Canadian Manufacturers & Exporters (CME) in partnership with The Bloom Centre for Sustainability to develop and deliver “Cleaner and Greener Manufacturing” technical training and a site-specific financial assistance program on toxics reduction. Through this program 15 small and medium sized manufacturing facilities received 50 per cent of the costs (up to a maximum of $7000) associated with:

- conducting an integrated pollution prevention and energy efficiency assessment

- accounting for toxic substances, and

- planning to reduce the use and/or creation of toxic substances

These facilities found opportunities to reduce toxic substances, hazardous waste, greenhouse gas emissions, as well as water, gas and electricity use. They also discovered that they could save money and gain operational efficiencies by implementing toxics reduction options.

For more information please see Cleaner greener case studies.

Toolkits and training resources

As part of the ministry’s commitment to support industry and to help them understand their obligations, the ministry has developed a number of guidance documents.

These plain language and technical documents provide provide clarification and examples on toxic substance accounting, reporting, and the development of toxic substance reduction plans.

Additional guidance material has been developed to help industry evaluate chemicals as safer alternatives—to help replace prescribed toxic substances with greener options.

Toolkits and training resources can be found on Ontario’s website using key words such as “toxics accounting” and “toxics planning.”

Technical assistance information sessions

In addition to toolkits and training materials, ministry staff delivered technical training sessions to more than a 1000 people. Over 50 sessions were held across the province between 2011 and 2013. These sessions were held to assist facilities with their understanding of the goals and objectives of the program, as well as the accounting, reporting and planning requirements of the act and regulation.

Growing the green economy

Green chemistry and engineering

Green Chemistry is the design of chemical products and processes that are safe, energy efficient and environmentally sustainable. Sometimes referred to as a form of molecular-level pollution prevention, Green Chemistry provides industry with sustainable products and process alternatives to help meet advancing market demands. This in turn leads to enhancements in sustainability, improvements to human health and drives Ontario’s economy forward.

To help achieve growth in this key area, the ministry provided assistance in building echnical knowledge skills and capacity to become leaders in developing this field of expertise.

The ministry provided funding over five years to support two research Chairs at Trent University and Queens University. The Chairs were funded to:

- build research capacity,

- build skills by supervising/mentoring graduate students

- develop green chemistry and engineering solutions for industry, and

- address barriers to commercialization to position Ontario to compete in a greening global economy.

Dr. Suresh Narine, Department of Physics & Astronomy and Department of Chemistry, Trent University

The objective of his research is to develop alternatives to petroleum-based products such as :

- development of non-toxic, biodegradable, vegetable-oil replacements for waxes for various commercial uses (e.g. car wax or commercial floor wax),

- development of non-toxic, biodegradable vegetable-oil lubricants to replace petroleum based chemical lubricants (e.g. car engine lubricants), and

- production of polymers from vegetable-based feedstock, which can potentially be used in drug delivery systems or in fertilizers to slow the release of nutrients to soils

Dr. Michael Cunningham, Department of Chemical Engineering, Queen’s University

Dr. Cunningham, is leading four major research projects which include:

- developing water-based processes for new polymerization chemistries

- switchable surfactants for preparation of “smart” polymer nanoparticles

- modification of natural polymers and biomass treatment using ionic liquids

- switchable water, which can be “switched” from hydrophilic to hydrophobic simply by bubbling either carbon dioxide or air through the liquid, thus allowing organic solvents to be efficiently separated from water

Green Chemistry and Engineering hold keys to our future for economic prosperity, sustainable growth, sustainable utilization of our natural resources and a proactive, preventative approach to health care. Dr. Michael Cunningham

Since their establishment in 2010, the chairs have built capacity in the specific areas of their research:

- Dr. Narine published 37 research papers, 4 chapters in books and filed 8 patent applications

- Dr. Cunningham published 57 papers and filed 2 patent applications

- built skills by supervising/mentoring graduate and undergraduate students

- Dr. Narine: 24 MSc student-years and 6 PhD student-years

- Dr. Cunningham: 19 MSc student-years and 17 PhD student-years

- Dr. Narine: developed chemical additives that lower the crystallization temperature of biodiesel (so it won't freeze as easily in the winter); developed nano-scale derivatives of cellulose in a wide variety of applications including food, packaging and antimicrobials; developed methods for the green conversion of vegetable oils for uses in new chemicals, additives, monomers, lubricants cosmetics and waxes, as well as polyurethanes, polyesters and polyamides.

- Dr. Cunningham: Expanded the range of switchable surfactants; discovered how to make water viscous by bubbling air or CO2 when particles are re-dispersed; demonstrated that metal catalysts can be removed from polymerization reactions; commenced work on making solid surfaces switchable (e.g., selfcleaning windows, biofilm) in order to reduce the use of cleaning solvents.

The International Group

The International Group, Inc. (IGI) is headquartered in Toronto, Ontario and operates five wax manufacturing facilities in North America. The Toronto plant employs approximately 150 people and is capable of producing scale and semi refined waxes, fully refined paraffin waxes, microcrystalline waxes as well as petrolatum. The facility operates under both ISO 9001 quality management and ISO 14001 environmental management standards. The waxes produced at IGI are compostable and biodegradable.

Based on IGI's corporate governance, the Toxics Reduction Act, 2009 (TRA) and the requirements of the ISO 14001 environmental management standard, IGI has focused on reducing the use and release of chemical substances, namely solvents used in the crystallization process.

IGI has, as a result of adopting TRA methodologies, implemented a number of programs geared towards environmental sustainability. These programs include: implementation of a Leak Detection Repair Program (LDAR); the review and upgrade of a Preventative Maintenance Program (PM) for the operating equipment; and, a state of the art leak detection Optical Gas Imaging (OGI) camera survey was instituted and will be performed on a yearly basis. Further, in addition to regular capital expenditures, over $2.5 million was recently spent on upgrading the wastewater system that has essentially removed all VOCs from entering the sanitary sewer.

These improvements have allowed IGI to reduce the use, creation and release of volatile organic compounds (VOCs) by 44 per cent from 2009 to 2012. IGI has completed seven TRA reports to date.

Every year, through our corporate and department objectives, the continuous improvement program motivates us to focus on all of our environmental aspects and impacts at the facility. This allows us to reduce our environmental foot print while lowering operational costs and consequently enhancing our business profileRichard Manka, Plant Manager.

Recognizing success in green chemistry and engineering

Recognizing success

The Ministry of the Environment sponsored the Ontario Green Chemistry and Engineering Awards. The annual awards were presented over a three year period to individuals and organizations that have made significant contributions to the field of green chemistry and engineering— including technical, economic, human health and environmental benefits.

Ontario Green Chemistry and Engineering Awards

2011 Individual Award: Franco Berruti

Mr. Berruti is a professor at the University of Western Ontario, Department of Chemical Engineering and the Director of the Institute for Chemicals and Fuels from Alternative Resources.

Mr. Berruti holds three patents and is the cofounding editor of the International Journal of Chemical Reactor Engineering. He is one of the technology developers for a company that develops and markets an innovative technology for converting agricultural residues into valuable biofuels, biochemicals and biopharmaceuticals. Further, Mr. Berruti has contributed more than 200 publications to prestigious journals, books and conferences.

2011 Organization Award: EcoSynthetix

EcoSynthetix is a global supplier of innovative biopolymers which are used to produce paper and paperboard products, architectural coatings, adhesives, carpet backing and more.

The company’s flagship product line–EcoSphere® Biolatex® binders, is made from renewable raw materials such as corn or potato starches. It can replace traditional petroleum-based products.

2012 Individual award: Dr. Paul A. Charpentier

Dr. Charpentier is a professor at Western University, Department of Chemical and Biochemical Engineering.

Dr. Charpentier received his award for research on green nanotechnologies and their applications in alternative energy conversion. His research on nanotechnology is currently being tested for use in solar cells that could harvest sunlight in a more efficient and cost-effective way.

2012 Organization Award: Xerox Research Centre of Canada

The Xerox Research Centre of Canada (XRCC) is Xerox’s global materials research centre located in Mississauga. The Centre researches, develops and manufactures green materials and processes used in Xerox’s laser printers, solid ink printers and other imaging products.

Xerox’s innovations include the development of a toner that uses 50 per cent less material and a solid ink printer that eliminates the need for traditional toner cartridges and reduces waste generation by 90 per cent.

Cosmetic pesticides ban

Ontario’s lawns, gardens, school yards and parks are much healthier spaces since the province’s cosmetic pesticides ban came into effect on Earth Day, April 22, 2009. The pesticide ban is part of the government’s commitment to protect families, especially children from pollution and toxic chemicals through tough new environmental laws and is one of the most comprehensive restrictions on cosmetic use pesticides in North America.

The ministry listened to medical experts – like the Canadian Cancer Society – who made a convincing case for reducing Ontarian’s exposure to pesticides, particularly for children who are generally more susceptible to the potential toxic effects of pesticides.

The provincial ban establishes one clear and understandable set of rules across the province.

Levels of herbicides in Ontario’s streams have decreased as a result of the Cosmetic Pesticides Ban Act. The ministry worked in cooperation with Environment Canada and Ontario’s Conservation Authorities to measure concentrations of pesticides in streams in cities across Ontario, including the Greater Toronto Area, London, North Bay, Ottawa and Sudbury. The study focused on three herbicides (2,4-D, dicamba, mecoprop) that were amongst the most used pesticides in urban settings before the ban. It was determined that concentrations decreased following the ban anywhere from 16 per cent to 92 per cent depending on the stream and herbicide. These findings were published in a science journal and can be accessed at MDPI Open access publishing.

Although the ban on the use of Class 9 pesticides contains exceptions such as for public health and safety, golf courses, specialty turf, maintaining trees and the protection of natural resources, certain conditions must be met.

For example, golf courses must obtain Integrated Pest Management (IPM) accreditation to minimize pesticide use on the golf course. As well, owners or operators of golf courses must establish public reporting requirements and hold an annual public meeting to present the annual report on Class 9 pesticide use in order to increase public transparency.

IPM Accreditation is a phased process which requires golf courses to successfully pass an annual desk review audit of mandatory pesticide use records to reach Level 1 Accreditation, and pass an onsite audit to verify pesticide use practices to reach Level 2 Accreditation. As of 2012, golf courses must be accredited by the IPM Council of Canada. Approximately 80 per cent of the almost 700 golf courses registered with the IPM Council of Canada have achieved and maintained Level 2 accreditation.

The IPM Accreditation Program has allowed Trafalgar Golf and Country Club to standardize the manner in which it documents pest monitoring and pesticide applications. In addition, it has helped us to establish baseline measurements which can be used in future years for comparing pesticide use trends, as well as measuring the success of our goal of minimizing the use of pesticides.Mark Prieur, Golf Course Superintendent, Trafalgar Golf and Country Club, Milton

Pesticides Allowed for Cosmetic Use

Under Ontario’s cosmetic pesticides ban, only biopesticides and certain lower risk pesticides - Class 11 - are allowed to be used for controlling weeds, insects and plant diseases on lawns and gardens.

Biopesticides are designated by Health Canada’s Pest Management Regulatory Agency. Lower risk pesticides have characteristics such as low toxicity to humans, minimal impact to the environment, and act in a non-toxic way in controlling intended pests.

Recognizing Ontarians would like more options, the ministry provided funding to the Agricultural Adaptation Council to encourage the development of biopesticides and lower risk pesticides for pest management in turf and on ornamentals through the Cosmetic Use Pesticides Research and Innovation (CUPRI) program.

The ministry looks forward to hearing about the results of further research and development of new pesticide products to maintain lawns and gardens over the next few years.

Normac Kitchens

Founded in 1968, Normac Kitchens is a leading kitchen cabinet manufacturer with offices in Canada and the United States. The facility, located in Thornhill, Ontario has committed to reducing the use of toxic substances.

The implementation of toxics reduction and pollution prevention plans coupled with excellent staff participation has led to positive changes in workplace culture. These changes include increased awareness, higher levels of motivation and conscientiousness and greater attention to detail – all of which result in better quality products.

Environmental sustainability is a part of our everyday lives and factors in to many of the choices we make, including the products we buy. The construction industry has been moving towards green-certified projects and it is the responsibility of all sub-contractors, like Normac Kitchens, to produce high quality products that help to reach the industry’s green-certification goals. The adoption and implementation of toxics reduction and pollution prevention methodologies will certainly lead to increased opportunities.

The greatest reduction has been achieved in the amount of lacquer thinner used during painting and finishing. This has resulted in a 30 per cent reduction over one year in the amount of toluene purchased. These reductions were made possible by: increasing the level of lacquer recycling, better management of the application of recycled material, and by maintaining the seals on storage containers.

The implementation of these reduction strategies coupled with additional training and the use of high efficiency spray guns has resulted in considerable reductions in the use of toluene and xylene by approximately 15 per cent. Further, these enhancements have made paint booth clean-up and tool maintenance less onerous. Overall, these changes represent significant cost savings for the company.

Normac Kitchens is committed to taking on a leadership role in the promotion of environmental stewardship through innovation. The environment is everyone’s concern and it is only through broad-based collaboration that society can move toward an environmentally sustainable future. This commitment to sustainability is visibly apparent in the enthusiastic effort put forth by our employees. Alfonso Mendez, Plant Manager

What’s new

Air standards

Ontario’s local air quality regulation (O. Reg. 419/05 Air Pollution – Local Air Quality) works within the province’s air management framework by regulating air contaminants released into communities by various sources, including local industrial and commercial facilities.

In 2011, Ontario introduced new and/or updated air standards for nine contaminants. These new and/ or updated air standards will be phased in over five years and will take effect on July 1, 2016.

The ministry continues to review the science on the remaining contaminants prioritized under its standards plan for the purpose of developing new and/or updated air standards.

In addition, the ministry continues to work with industry through the site-specific and technical standards processes which consider technical and/ or economic issues. These compliance approaches provide a means of improving environmental performance and reducing risks to the local community over time.

The goal is to have a more efficient tool to better manage air emissions and reduce overall exposure from various industrial and commercial facilities in a manner that is publicly transparent.

Drive clean

Smog is a serious health problem in our province that has contributed to almost 9,500 premature deaths per year, according to the Ontario Medical Association.

Vehicle emissions in particular are a major source of domestic air pollution in the province.

Drive Clean, Ontario’s mandatory vehicle emissions inspection program, plays an important role in keeping our air clean. Drive Clean protects public health by reducing smog causing emissions by more than a third every year. The program has removed 335,000 tonnes of smog-causing pollutants, including nitrogen oxides and hydrocarbons, from the air since 1999.

On January 1, 2013, Ontario introduced an improved Drive Clean test that is faster, more accurate and better at protecting our air than the old tailpipe test. The on-board diagnostic test works on most 1998 and newer light-duty vehicles in Ontario. These vehicles have an on-board computer that monitors the engine and emissions system during every day driving conditions. The new test reads the emissions information from the vehicle’s computer. It can detect problems that lead to poor performance, high emissions or poor fuel economy. The new test is also less costly, with the test fee reduced from $35 to $30 on April 1, 2014.

LPP manufacturing

LPP Manufacturing Inc. (LPP), located in Guelph, is part of the Linamar Corporation—Canada’s second largest automobile parts manufacturer. The facility employs 280 people and manufactures precision machined components and assembles automotive parts for Ford, General Motors and Chrysler.

Copper is an integral part of the alloys we use in the manufacture of automotive components. As a result, any reduction of copper in the composition of our alloys would significantly affect the safety and quality of our products. As a result, we have looked at alternative ways to reduce our use of copper which include:

- equipment or process modifications

- improved inventory management and purchasing techniques

- training or improved operating practices

Based on a 5 year plan, implementing the above mentioned toxic reduction options, could save LPP approximately $242,500.

LPP believes that pollution prevention and waste reduction coupled with a commitment to a robust environmental management system increases employee morale and motivation resulting in improved productivity and better quality products – this ultimately leads to both increased sales and market share. For many of our customers, having an ISO 14001 Environmental Management System Certification in good standing is a prerequisite to continued and future business.

In addition to the Toxics Reduction Act, the Linamar Corporation has committed to Social Responsibility and Sustainability by implementing the strategies below:

- product research – improve vehicle fuel economy

- resource consumption – decrease the usage of municipally supplied water, and reduce electricity usage by using low- energy lighting

- renewable solar energy – installed solar panels on facility to utilize natural energy to decrease total electricity usage and supply power back to local grid

In order to help ensure that LPP Manufacturing remains an industry leader in pollution prevention and waste reduction, employees are encouraged to participate in environmental outcome-based continuous improvement. Our Lean Suggestion Program is an integral part of corporate key performance indicators.

We are committed to an environmental management system that protects human health and the environment. Decreasing our environmental footprint will not only help us, but will help upcoming generations. Exploring different avenues for environmental sustainability is a part of LPP's annual objectives and targets, which is reviewed by a Plant Operating Committee on a regular basis and annually by external auditors.LPP Manufacturing

Environmental objectives/targets set on annual basis ensure continuous improvement in reducing consumption of precious resources at LPPR. Rajagopal, GM

Great lakes

On December 17, 2012, the province released Ontario’s Great Lakes Strategy. The Strategy articulates Ontario’s vision of healthy Great Lakes for a stronger Ontario – Great Lakes that are drinkable, swimmable and fishable.

Priorities for future action to achieve that vision are described around the following six Great Lakes Goals:

- engaging and empowering communities

- protecting water for human and ecological health

- improving wetlands, beaches, shorelines and coastal areas

- protecting habitats and species

- enhancing understanding and adaptation

- ensuring environmentally sustainable economic opportunities and innovation

Under Goal 2, protecting water, a key priority under this Strategy is protecting water quality by continuing to reduce toxic chemicals. There are five future actions in the Strategy associated with reducing toxic chemicals:

- making publicly available online, information on toxic substances used and created by regulated facilities, and summaries of facilities' plans to reduce toxics

- reporting on the progress in implementing Ontario’s toxics reduction program

- continuing to promote reduction initiatives and to support research on safer alternatives

- bringing academics, industry and technology experts together through GreenCentre Canada, to create green chemistry innovations

- reviewing lists of substances at least once every five years in consultation with experts and the public

On February 25, 2013, the government introduced the proposed Great Lakes Protection Act. (Bill 6). On October 9, 2013, the proposed Great Lakes Protection Act passed second reading in the Ontario Legislature. Bill 6 has now been referred to Standing Committee and public hearings on the Bill commenced in fall 2013.

The proposed Great Lakes Protection Act, if passed, would help to restore and protect the Great Lakes so they are drinkable, swimmable and fishable. The purposes of the proposed Great Lakes Protection Act are to:

- protect and restore the ecological health of the Great Lakes-St. Lawrence River Basin

- create opportunities for individuals and communities to become involved in the protection and restoration of the ecological health of Basin. The proposed act, if passed, would protect human health and well-being through the elimination or reduction of harmful pollutants, including toxics.

Great lakes and toxics reduction

The Toxics Reduction Act is supplemented by other programs and initiatives that are in place to reduce toxics in Ontario, and in particular, to protect the Great Lakes.

For over four decades, governments and the Great Lakes community have worked together to reduce harmful pollutants in the Great Lakes, dating as far back as the 1978 Canada-U.S. Great Lakes Water Quality Agreement which called for the virtual elimination of inputs of persistent toxic substances to the lakes. Working through a series of subsequent bi-national and domestic agreements, along with a focus on pollution prevention, safer alternatives and technologies, significant accomplishments have been achieved in reducing the presence of a number of persistent toxic substances within the Great Lakes basin. For example, these include a more than 90 per cent reduction in the Canadian releases of mercury, dioxins and furans, and a more than 90 per cent reduction in the amount of high-level PCBs in storage in Ontario. Recent monitoring and research indicates that the overall levels of concentrations of many chemicals are significantly lower in the sediments, offshore waters and fish from the Great Lakes.

While progress has been made, much work remains to be done to better understand the sources, impact and management of chemicals within the Great Lakes ecosystem. The 2012 amended Canada-United States Great Lakes Water Quality Agreement (GLWQA) commits both governments to "develop cooperative and coordinated measures to reduce the anthropogenic [man-made] release of chemicals of mutual concern into the waters of the Great Lakes". A new Canada-Ontario Agreement (COA) on the Great Lakes is also currently being negotiated. The new COA will help Ontario in achieving its goals under Ontario’s Great Lakes Strategy and Canada in meeting its commitments under the GLWQA.

Cleaning Up Great Lakes Areas of Concern

Our Great Lakes Watershed is particularly vulnerable to toxics for several reasons. The lakes are home to most of the province’s urban, industrial and agricultural activity and more than 98 per cent of Ontarians live in the Great Lakes-St. Lawrence River watersheds.

One of our Great Lakes initiatives is the clean-up of hot spots, or Areas of Concern (AOCs). Under the 1987 Canada-U.S. Great Lakes Water Quality Agreement, 43 AOCs were identified across the Great Lakes for targeted clean-up and restoration. These are areas where the environment has been harmed to the point that it affects the use and enjoyment of that area of the lake or may be affecting the health of the lake.

Randle Reef is an area of contaminated sediment located in the Hamilton Harbour AOC. Ontario committed $46.3 million to help cap sediment leftover from past industrial activity, improving water quality and helping to ensure the health of the harbour’s natural habitat. The clean-up for this project begins in Spring 2014 and is a major step toward improving the health of the Hamilton Harbour ecosystem and delisting it as a Great Lakes Area of Concern.

Another sediment remediation project occurred in the Peninsula Harbour AOC located on the northeastern shore of Lake Superior. In 2012, the contaminated sediment was capped to reduce plant, animal and fish exposureto chemicals in the sediment. Ontario’s funding for the Peninsula Harbour sediment capping project included a $3 million settlement from a pulp mill owner and $1.6 million in provincial funding. This project is the last major stepin the plan to restore Peninsula Harbour AOC to a healthy state.

We have made considerable progress in restoring AOCs. Three AOCs in Ontario have been delisted including Wheatley Harbour, Collingwood Harbour and Severn Sound. In 2011, Jackfish Bay AOC was designated as "Area of Concern in Recovery" where all clean-up actions are complete. It is the second AOC in Ontario to be designated "in recovery", along with Spanish Harbour.

Ongoing monitoring programs for the Great Lakes also help to determine the status of toxics in given areas.

Kuntz electroplating Inc. (KEI)

Kuntz Electroplating Inc. (KEI) is one of North America’s largest and most advanced finishing operations for original equipment manufacturers of premium interior and exterior components. Located in Kitchener, ON we are a third generation family owned and operated business established in 1948.

We have fully established quality and environmental management systems in accordance with the ISO-9001:2008 and the ISO-14001:2004 International Standards, respectively. Our quality mission is to “continuously evaluate and improve our processes and services to meet or exceed our customer’s quality expectations” plus, “we have an ongoing commitment to sustainable development, protecting human health and preservation of natural resources, and the environment through sound business practices”.

In this regard, we are committed to continuous improvement (CI), and we strive to reduce the use of toxic substances in our workplace. Our toxic substance reduction team, through the development of toxic substance reduction plans and, through our CI process were able to reduce the usage of the following toxic substances: hexavalent chromium (10 per cent); nickel (2.5 per cent); and copper (2 per cent). This was accomplished by:

- installing a purification system, and by modifying the racking structure and drain pans/tank covers to reduce splashing and material lost through drag out;

- adding auxiliary equipment to help stabilize the process and reduce the amount of material lost through maintenance activities; and

- lowering the solution level in the tanks to reduce material lost from splashing or through drag out

KEI embraces sustainability as a key corporate strategic pillar. These initiatives have helped us to reduce our costs and the amount of material being shipped offsite for recycling and/or disposal and help us in our goal towards a sustainable manufacturing future. As a result, these reductions demonstrate our commitment to continuously improve, and promote good environmental stewardship.

For KEI sustainability is about making a commitment… a commitment to the environment…to our neighbours and our community…to our employees and our customers… that we will continue to embrace sustainable thinking as a means to improving our business, while recognizing and balancing the needs of growth and profitability, environmental integrity and social equality.” Michael Kuntz, VP Sales & Marketing

How to stay informed

Ontario’s commitment to protect clean and safe air, land and water is exemplified by the growth and success of the toxics reduction program. Program partnerships that support innovative work in the field of green chemistry and engineering continue to support industry as they transition toward a greener economy and improved environmental awareness and action.

As part of the government’s continued commitment to transparency and open government, information is being made available to all Ontarians by both industry and the ministry on toxics used, created and contained in product by manufacturing and mineral processing companies for the very first time.

These efforts, combined with initiatives to improve the Great Lakes, reduce the use of pesticides and improve air quality through programs like Drive Clean and the elimination of coal-fired electricity all contribute to achieving healthy communities, environmental protection and sustainable development for present and future generations of Ontarians.

News Updates

In order to stay informed of new developments and information, please visit ministry’s website.

Appendices

| Subsector | Small (<100) 308 Facilities – Implementing (Min. One Option) 120 Facilities |

Small (<100) 308 Facilities – Not Implementing At This Time 188 Facilities |

Medium (100 – 499) 316 Facilities – Implementing (Min. One Option) 143 Facilities |

Medium (100 – 499) 316 Facilities – Not Implementing At This Time 173 Facilities |

Large (500+) 58 Facilities – Implementing (Min. One Option ) 20 Facilities |

Large (500+) 58 Facilities – Not Implementing At This Time 38 Facilities |

Total 682 Facilities |

|---|---|---|---|---|---|---|---|

| Chemical Manufacturing | 43 | 44 | 14 | 12 | 2 | 3 | 118 |

| Transportation Equipment Manufacturing | 1 | 13 | 28 | 40 | 6 | 20 | 108 |

| Fabricated Metal Product Manufacturing | 26 | 41 | 19 | 16 | 2 | 2 | 106 |

| Primary Metal Manufacturing | 12 | 32 | 12 | 23 | 2 | 4 | 85 |

| Plastics and Rubber Products Manufacturing | 8 | 9 | 12 | 11 | 1 | 1 | 42 |

| Non-Metallic Mineral Product Manufacturing | 2 | 17 | 6 | 5 | 0 | 0 | 30 |

| Food Manufacturing | 2 | 6 | 6 | 9 | 0 | 1 | 24 |

| Furniture and Related Product Manufacturing | 1 | 2 | 10 | 8 | 0 | 2 | 23 |

| Wood Product Manufacturing | 5 | 5 | 7 | 5 | 0 | 0 | 22 |

| Electrical Equipment, Appliance and Component Manufacturing | 3 | 3 | 5 | 8 | 0 | 0 | 19 |

| Mining (except Oil and Gas) | 1 | 1 | 4 | 7 | 1 | 2 | 16 |

| Machinery Manufacturing | 0 | 5 | 1 | 7 | 1 | 2 | 16 |

| Paper Manufacturing | 2 | 1 | 6 | 5 | 0 | 0 | 14 |

| Computer and Electronic Product Manufacturing | 2 | 0 | 6 | 3 | 2 | 0 | 13 |

| Miscellaneous Manufacturing | 2 | 5 | 0 | 3 | 2 | 0 | 12 |

| Petroleum and Coal Products Manufacturing | 1 | 2 | 3 | 5 | 0 | 0 | 11 |

| Printing and Related Support Activities | 4 | 0 | 2 | 3 | 1 | 0 | 10 |

| Other primary NAICS codes | 3 | 1 | 0 | 1 | 0 | 0 | 5 |

| Textile Mills | 2 | 0 | 2 | 0 | 0 | 0 | 4 |

| Beverage and Tobacco Product Manufacturing | 0 | 0 | 0 | 2 | 0 | 1 | 3 |

| Textile Product Mills | 0 | 1 | 0 | 0 | 0 | 0 | 1 |

| Total | 120 | 188 | 143 | 173 | 20 | 38 | 682 |

| Percent of Total | 18% | 28% | 21% | 25% | 3% | 6% | 100% |

(Data from Plan Summaries submitted on Phase I substances, as of December 20, 2013)

| Facility NPRI ID | NAICS | Company Legal Name | Facility Name | Town/City |

|---|---|---|---|---|

| 5874 | 331 | Victaulic Company Of Canada | 115 Newkirk Road | Richmond Hill |

| 11811 | 331 | Alloy Casting Industries Limited | 374 Hamilton Road | New Hamburg |

| 11219 | 332 | Blastech - A Div. Of TF Warren Group | 57 Old Onondaga Rd. W., Brantford | Brantford |

| 8522 | 337 | A. Potvin Construction Ltd. | A. Potvin Construction | Rockland |

| 5914 | 326 | ABC Group Inc. | Abc Inoac Exterior Systems Inc. | Etobicoke |

| 2541 | 332 | Acadian Platers Co. Ltd. | Acadian Platers | Toronto |

| 423 | 324 | The International Group Inc. | Agincourt Plant | Toronto |

| 286 | 325 | E. I. Du Pont Canada Company | Ajax Performance Coatings Division | Ajax |

| 10412 | 313 | Ajax Textile Processing Co. Ltd. | Ajax Textile Dyers And Finishers | Ajax |

| 5619 | 325 | Akzo Nobel Wood Coatings Ltd. | Akzonobel Wood Coatings (Port Hope) | Port Hope |

| 1485 | 325 | Allcolour Paint Limited | Allcolour Paint Ltd. | Oakville |

| 5757 | 337 | Allwood Products Ltd. | Allwood Products Ltd. | Vaughan |

| 5655 | 325 | Honeywell Asca Inc. | Amherstburg Plant | Amherstburg |

| 3266 | 327 | Anh Refractories Canada Inc. | Anh Refractories Canada Inc. | Smithville |

| 11419 | 332 | Anti-Friction Enterprises Ltd. | Anti Friction Enterprises (1985) Ltd. Plant 3 | Brampton |

| 11209 | 336 | A.P. Plasman Corporation | A.P. Plasman Tecumseh | Tecumseh |

| 11210 | 336 | A.P. Plasman Corporation | A.P. Plasman Tilbury | Tilbury |

| 111 | 325 | Apotex Inc. | Apotex Inc. 150 Signet Drive | Toronto |

| 10731 | 325 | Apotex Inc. | Apotex Inc. Etobicoke Site | Toronto |

| 5965 | 325 | Apotex Pharmachem Inc. | Apotex Pharmachem Inc. | Brantford |

| 5691 | 331 | Arcelormittal Tubular Products Canada Inc. - Woodstock | Arcelormittal Tubular Products Canada Inc.- Holtby | Brampton |

| 4545 | 331 | Arcelormittal Tubular Products Canada Inc. - Woodstock | Arcelormittal Tubular Products Inc. - Woodstock | Woodstock |

| 1687 | 325 | Arclin Canada Ltd. | Arclin Canada Ltd. - North Bay | North Bay |

| 10429 | 336 | Arnprior Aerospace Inc. | Arnprior Aerospace Inc. | Arnprior |

| 1109 | 325 | Atotech Canada Ltd. | Atotech Canada | Burlington |

| 7119 | 336 | Autocom Manufacturing | Autocom Manufacturing | Guelph |

| 3279 | 334 | Autoliv Electronics Canada Inc. | Autoliv Electronics Canada | Markham |

| 3116 | 332 | Ball Packaging Products Canada Corp. | Ball Packaging Whitby | Whitby |

| 5771 | 313 | Barrday Inc. | Barrday | Cambridge |

| 15 | 332 | Baycoat Ltd. | Baycoat Ltd. | Hamilton |

| 2670 | 335 | Belden (Canada) Inc. | Belden Canada | Cobourg |

| 11796 | 212 | Lake Shore Gold Corp. | Bell Creek Complex | Porcupine |

| 4496 | 326 | Durabla Canada Ltd. | Belleville, Ontario | Belleville |

| 11700 | 325 | Biox Canada Ltd. | Biox Biodiesel Plant 01 - Hamilton | Hamilton |

| 3657 | 325 | Cameco Corporation | Blind River Refinery | Blind River |

| 3845 | 332 | Blount Canada Ltd. | Blount Guelph | Guelph |

| 1845 | 311 | Parmalat Canada Inc. | Brampton | Brampton |

| 4833 | 325 | Sun Chemical Ltd. | Brampton | Brampton |

| 25027 | 332 | Brampton Processing | Brampton Processing | Brampton |

| 3430 | 325 | Colortrend Canada Inc. (Changed To Chromaflo Technologies Canada Inc. On May 1 2012) | Brampton Site | Brampton |

| 11436 | 332 | Brant Corrosion Control Inc. | Brant Corrosion Control Inc. | Brantford |

| 10242 | 311 | Aryzta Canada | Brantford Production Facility | Brantford |

| 11743 | 212 | Brigus Gold | Brigus Black Fox Mill | Matheson |

| 2122 | 324 | Shell Canada Limited | Brockville Lubricants Plant | Brockville |

| 7174 | 331 | Outokumpu Stainless Tubular Products Ltd. | Brockville Plant | Brockville |

| 11434 | 335 | Cam Tran Co. Ltd. | Cam Tran | Colborne |

| 4475 | 332 | Cambridge Brass Inc. | Cambridge Brass | Cambridge |

| 11094 | 332 | Court Galvanizing Ltd. | Cambridge Plant | Cambridge |

| 10942 | 336 | Camtac Manufacturing | Camtac Manufacturing | Guelph |

| 10631 | 323 | Canadian Bank Note Co. Ltd. | Canadian Bank Note Company, Limited Richmond Division | Ottawa |

| 5759 | 335 | Voith Hydro Inc. (Voith Siemens Hydro Power Generation) | Canadian Coil Operation | Mississauga |

| 3475 | 326 | Canadian General-Tower Ltd. | Canadian General-Tower Ltd. | Cambridge |

| 4400 | 322 | Canadian Technical Tape Ltd. | Canadian Technical Tape - Cornwall Plant | Cornwall |

| 11452 | 335 | Mersen Canada Dn Ltd. | Carbon Brush Division - Toronto | Toronto |

| 743 | 326 | KN Rubber | Cawthra Plant | Toronto |

| 92 | 331 | CCL Container Canada | CCL Container - Aerosol Division Penetanguishene | Penetanguishene |

| 1169 | 334 | Celestica International Inc. | Celestica Toronto Site | Toronto |

| 2233 | 325 | Terra International (Canada) Inc. | CF Industries Courtright Nitrogen Complex | Courtright |

| 10397 | 321 | Tembec | Chapleau Sawmill | Chapleau |

| 5739 | 325 | Greenfield Ethanol Inc. | Chatham Plant | Chatham |

| 1951 | 325 | Chemfil Canada Ltd. | Chemfil Canada Ltd. | Windsor |

| 11181 | 334 | Chubb Edwards A UTC Corporation | Chubb Edwards Canada A UTC Corporation | Owen Sound |

| 11583 | 332 | Cleaver-Brooks Of Canada Ltd. | Cleaver-Brooks Of Canada Limited | Stratford |

| 11580 | 325 | Cloverdale Paint Inc. | Cloverdale Paints Inc. - Mississauga | Mississauga |

| 11597 | 331 | Canadian Metal Rolling Mills | CMRM - Cambridge | Cambridge |

| 2545 | 332 | Coatings 85 Ltd. | Coatings 85 Ltd. | Mississauga |

| 11068 | 321 | Tembec | Cochrane Sawmill | Cochrane |

| 4131 | 323 | Colwell Canada Corp. | Colwell/Canada Corp. | Toronto |

| 5741 | 337 | Waterloo Furniture Components Ltd. | Compx Waterloo | Kitchener |

| 10105 | 336 | Linamar Corp. | Comtech Mfg. | Guelph |

| 5772 | 325 | Brenntag Canada Inc. | Cornwall / Conpak (Ow06) | Cornwall |

| 1353 | 325 | Valspar Inc. | Cornwall Facility | Cornwall |

| 4635 | 311 | Sensient Flavors Canada Inc. | Cornwall Facility | Cornwall |

| 7259 | 336 | Linamar Corp. | Corvex Manufacturing | Guelph |

| 177 | 322 | Coveright Surfaces Canada Inc. | Coveright Surfaces Canada | Cobourg |

| 7075 | 332 | Crosby Canada, Div of | Crosby Canada | Brampton |

| 10665 | 326 | Crosslink Technology Inc. | Crosslink | Mississauga |

| 538 | 332 | Crown Metal Packaging Canada Lp. | Crown Metal Packaging Canada Lp. - Plt. 245 | Weston |

| 25051 | 332 | Cyclone Manufacturing Inc. | Cyclone Manufacturing Inc. | Mississauga |

| 5727 | 336 | Dana Canada Corp. | Dana Mount Forest | Mount Forest |

| 4756 | 336 | Dana Canada Corp. | Dana Oakville Kerr | Oakville |

| 577 | 325 | Dextran Products Ltd. | Dextran Products Limited | Scarborough |

| 3713 | 331 | Arcelormittal Dofasco Inc. | Dofasco Hamilton | Hamilton |

| 928 | 322 | Domtar Inc. | Dryden Mill | Dryden |

| 7602 | 326 | Shawcor Ltd. | DSG-Canusa | Toronto |

| 4862 | 339 | Rockwell Automation | Dundas Facility | Cambridge |

| 656 | 325 | Durez Canada Company, Ltd. | Durez Canada | Fort Erie |

| 11602 | 335 | Hammond Manufacturing Co. Ltd. | Edinburgh Road | Guelph |

| 2322 | 325 | Chemtura Canada Co. Cie. | Elmira | Elmira |

| 5964 | 332 | Emirfi Shield Plating Inc. | Emirfi Shield Plating Inc. | Englehart |

| 4559 | 321 | GP North Woods Lp. | Englehart Oriented Strand Board Plant | |

| 315 | 331 | Esco Limited | Esco Limited | Port Hope |

| 3886 | 336 | Essex Manufacturing | Essex Engine Plant | Windsor |

| 4535 | 311 | Parmalat Canada Inc. | Etobicoke | Etobicoke |

| 5658 | 326 | Fabricushion Ltd. | Fabricushion Ltd.- Markham | Markham |

| 11360 | 326 | Multy Home Lp. | Fenmar Plant | Toronto |

| 5800 | 337 | Fileco A Division Of Teknion Limited | Fileco a Division of Teknion Limited | Concord |

| 11221 | 331 | Fischer Canada Stainless Steel Tubing Inc. | Fischer Canada Stainless Steel Tubing Inc. | Waterloo |

| 4990 | 336 | Fleet Canada Inc. | Fleet Canada Inc. | Fort Erie |

| 3890 | 325 | Flextile Ltd. | Flextile Ltd. | Etobicoke |

| 452 | 332 | IMT Partnership - PC Forge | Forge Division | Port Colborne |

| 1931 | 325 | Sherwin-Williams Canada | Fort Erie Plant | Fort Erie |

| 917 | 322 | Resolute FP Canada Inc. | Fort Frances Division | Fort Frances |

| 4465 | 323 | FPC Flexible Packaging Corp. | FPC Flexible Packaging Corp. | Toronto |

| 10101 | 332 | Frazier Industrial Co. Ltd. | Fracan | Trenton |

| 5912 | 337 | Frendel Kitchens Limited | Frendel Kitchens Limited | Mississauga |

| 10698 | 336 | General Dynamics Land Systems | General Dynamics Land Systems London | London |

| 4412 | 326 | Cooper Standard Automotive Canada Ltd. | Georgetown Sealing | Georgetown |

| 3824 | 331 | Gerdau Ameristeel Corporation | Gerdau Ameristeel Corporation, Whitby Mill | Whitby |

| 1322 | 326 | Goodyear Canada Inc. | Goodyear Canada Inc. Napanee Plant | Napanee |

| 7435 | 323 | Atlantic Packaging Products Ltd. | Gran Packaging | Toronto |

| 5954 | 332 | Greif Bros Canada Inc. | Greif Stoney Creek | Stoney Creek |

| 10079 | 325 | Sherwin-Williams Canada | Grimsby | Grimsby |

| 11733 | 326 | Eaton Industries (Canada) Company | Guelph Facility | Guelph |

| 3287 | 327 | Owens Corning Composite Materials Canada Lp. | Guelph Glass Plant | Guelph |

| 2560 | 321 | Stella-Jones Inc. | Guelph Utility Pole Company Ltd. | Guelph |

| 7080 | 331 | Magellan Aerospace Limited | Haley Industries Limited | Haley |

| 7106 | 325 | Halton Chemical Inc. | Halton Chemical Inc. Plant/ Warehouse | Burlington |

| 2660 | 325 | Columbian Chemicals Canada Ltd. | Hamilton | Hamilton |

| 4939 | 326 | Hamilton Kent, Inc. | Hamilton Kent, Inc. | Toronto |

| 7365 | 332 | Walters Inc. | Hamilton Plant | Hamilton |

| 2161 | 331 | Hamilton Specialty Bar Corporation | Hamilton Specialty Bar | Hamilton |

| 2984 | 331 | U.S. Steel Canada Inc. | Hamilton Works | Hamilton |

| 4738 | 336 | Hastech Manufacturing | Hastech Manufacturing - Guelph | Guelph |

| 7232 | 321 | Tembec | Hearst Sawmill | Hearst |

| 10893 | 334 | Hi-Q.A. Inc. | Hi-Q.A. Inc. | Carleton Place |

| 11675 | 332 | Hodgson Custom Rolling Inc. | Hodgson Custom Rolling Inc. | Niagara Falls |

| 818 | 326 | Canusa-CPS | Huntsville | Huntsville |

| 11696 | 325 | Integrated Grain Processors Co-Operative Incorporated | IGPC Ethanol Inc. - Aylmer Plant | Aylmer |

| 11042 | 325 | Ingenia Polymers Corp. | Ingenia Polymers Corp. | Brantford |

| 488 | 311 | Ingredion Canada Incorporated | Ingredion Canada Incorporated - Cardinal Plant | Cardinal |

| 2695 | 311 | Ingredion Canada Incorporated | Ingredion Canada Incorporated - Port Colborne Plant | Port Colborne |

| 485 | 311 | Ingredion Canada Incorporated | Ingredion Canada Incorporated - London Plant | London |

| 5753 | 337 | Inscape Corp. | Inscape Corp. | Holland Landing |

| 7109 | 325 | Iogen Corp. | Iogen Corporation | Ottawa |

| 978 | 322 | Resolute FP Canada Inc. | Iroquois Falls Division | Iroquois Falls |

| 1520 | 331 | Ivaco Rolling Mills 2004 Limited Partnership | Ivaco Rolling Mills | L'orignal |

| 7325 | 331 | John Zubick Ltd. | John Zubick Ltd. | London |

| 11684 | 325 | Greenfield Johnstown Limited Partnership | Johnstown Plant | Prescott |

| 10613 | 331 | Joseph Robertson Foundries Ltd. | Joseph Robertson Foundries Limited | Toronto |

| 2173 | 322 | Tembec | Kapuskasing Operations | Kapuskasing |

| 5684 | 212 | Agrium Inc. | Kapuskasing Phosphate Operations | Kapuskasing |

| 7658 | 321 | Weyerhaeuser Company Limited | Kenora Timberstrand | Kenora |

| 5702 | 325 | KIK Operating Partnership | KIK Operating Partnership D/B/A KIK Canada | Concord |

| 4462 | 332 | Kilian Canada ULC | Kilian Canada ULC | Etobicoke |

| 477 | 325 | Kleen-Flo Tumbler Industries Ltd. | Kleen-Flo Tumbler Industries Ltd. | Brampton |

| 3111 | 332 | Kuntz Electroplating Inc. | Kuntz Electroplating Inc. | Kitchener |

| 7369 | 212 | North American Palladium Ltd. | Lac Des Iles Mine Ltd. | Thunder Bay |

| 10424 | 332 | Savage Arms (Canada), Inc. | Lakefield | Lakefield |

| 10751 | 332 | Larsen & Shaw Ltd. | Larsen & Shaw Limited | Walkerton |

| 11073 | 332 | Linamar Gear | Linamar Gear | Guelph |

| 11378 | 336 | Linamar Performance Centre | Linamar Performance Centre | Guelph |

| 2216 | 325 | Stepan Canada | Longford Mills Plant | Longford Mills |

| 10118 | 336 | LPP Manufacturing Inc. | LPP Manufacturing | Guelph |

| 1568 | 212 | Kirkland Lake Gold Inc. | Macassa Mine | Kirkland Lake |

| 4536 | 337 | The Raywal Limited Partnership | Main Plant | Thornhill |

| 1207 | 325 | Invista (Canada) Company | Maitland Site | Maitland |

| 5816 | 325 | Evonik Canada Inc. | Maitland Site | Maitland |

| 10206 | 325 | Brenntag Canada Inc. | Malton (OS62) | Mississauga |

| 5881 | 337 | Krug Furniture Inc. | Manitou Casegoods | Kitchener |

| 11317 | 332 | Massilly North America Inc. | Massilly North America Inc. Cap Plant | Brantford |

| 10568 | 331 | Mauser Canada Ltd. | Mauser Canada Limited - Burlington | Burlington |

| 4527 | 332 | Continuous Colour Coat Limited | Metal Koting Continuous Colour Coat Ltd. | Rexdale |

| 4752 | 337 | Knoll North America Corp. | Metals Plant | Woodbridge |

| 11504 | 323 | Metro Label Company Ltd. | Metro Label Company Ltd. | Toronto |

| 4785 | 331 | Groupe Canam Inc. | Mississauga | Mississauga |

| 11512 | 336 | O.E. Quality Friction Inc. | Mississauga | Mississauga |

| 1096 | 418 | Nexeo Solutions Canada Corporation | Mississauga - Distribution | Mississauga |

| 2182 | 327 | Holcim (Canada) Inc. | Mississauga Cement Plant | Mississauga |

| 800 | 325 | Siltech Corporation | Mississauga Plant | Mississauga |