Stormwater management plan and SWMP design

Stormwater management plan and SWMP design (4.0)

4.1 General

The stormwater management plan is the means by which water resource concerns are addressed during development. It will provide the size and location of SWMPs and will demonstrate (through modelling and other techniques) that when integrated, the SWMPs will meet the criteria established to ensure that:

- groundwater and baseflow characteristics are preserved;

- water quality will be protected;

- the watercourse will not undergo undesirable and costly geomorphic change;

- there will not be any increase in flood damage potential; and ultimately,

- that an appropriate diversity of aquatic life and opportunities for human uses will be maintained.

Ideally, planning for stormwater management will have begun early in the environmental planning process (Section 2.3) and will have been integrated with subdivision/site planning (Appendix A). The stormwater management plan and SWMP design can then incorporate opportunities which have been identified and designs which have been developed.

If a subwatershed plan has not been completed, the stormwater management plan will include much of the information that otherwise would be included in the larger scale plan.

The recommended strategy for stormwater management is to provide an integrated treatment train approach to water management that is premised on providing control at the lot level and in conveyance (to the extent feasible) followed by end-of-pipe controls. This combination of controls is the only means of meeting the multiple criteria for water balance, water quality, erosion control and water quantity.

Stormwater management strategies that employ a combination of SWMPs are desirable because they yield the following benefits:

- more effective stormwater management;

- reduction in land area required to implement end-of-pipe solutions;

- enhanced opportunities to integrate SWMPs effectively as amenities;

- decreased total cost when land value is factored in; and

- increased level of public awareness and involvement in the implementation and management of stormwater management initiatives.

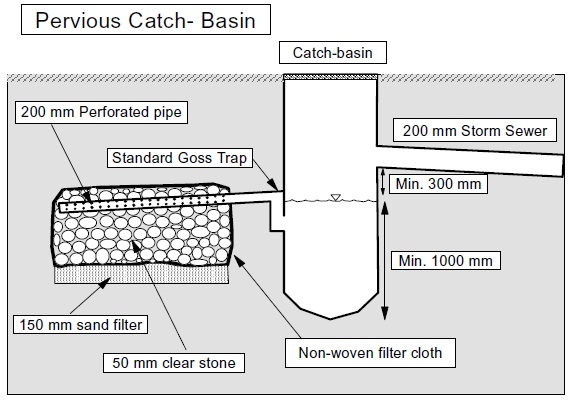

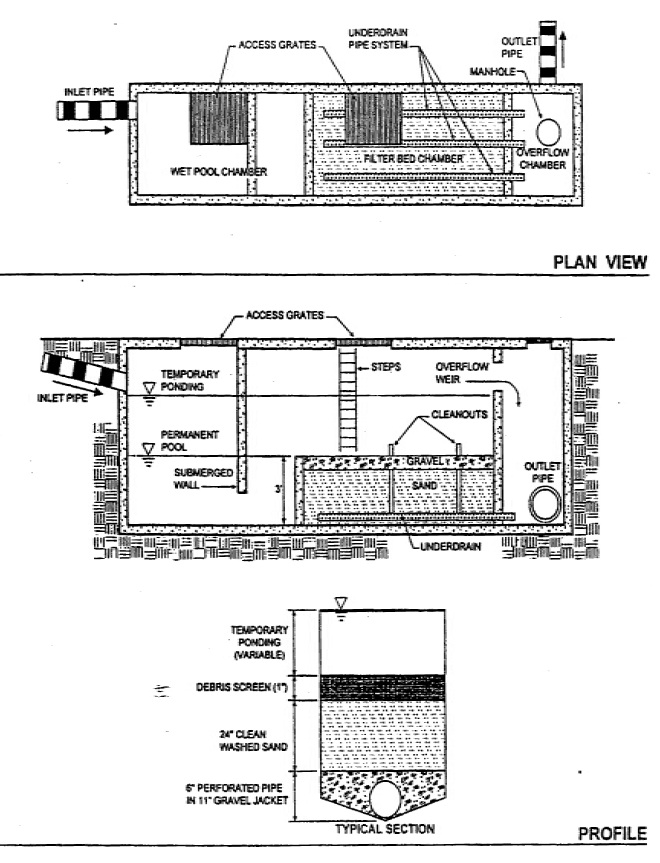

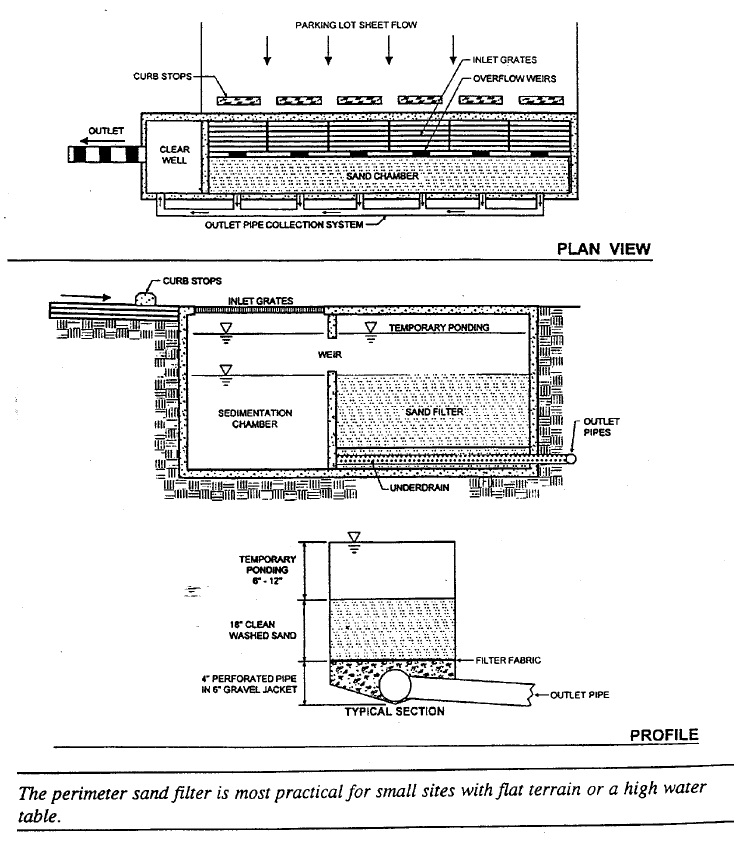

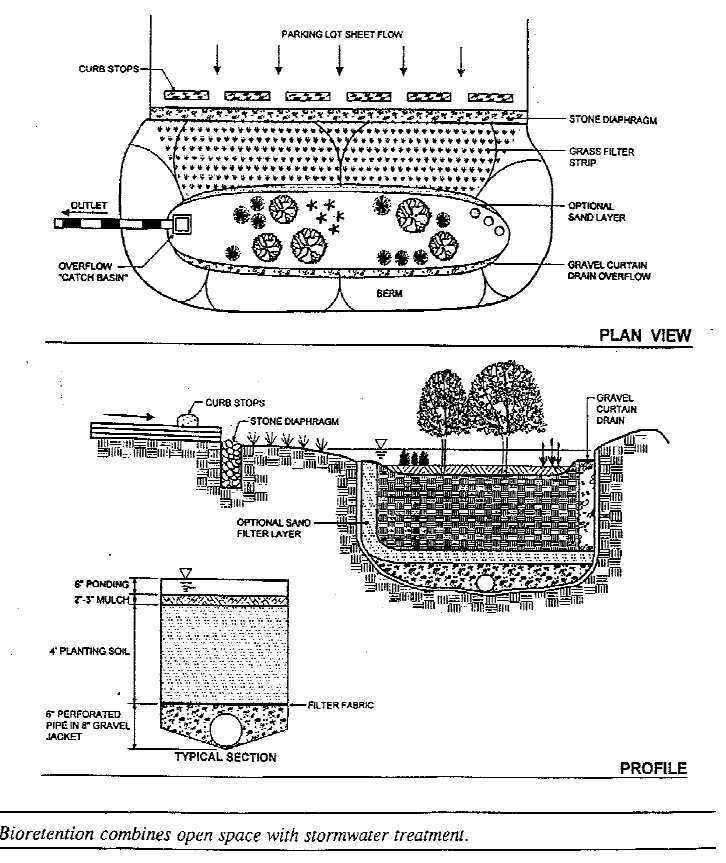

To meet water quality objectives, a multi-component approach, in which there is a series of stormwater quality measures, may be used. If in a given situation no single measure is considered sufficient, then two or more controls in series may be expected to provide a higher level of water quality improvement. SWMPs used in a multi-component approach often include oil/grit separators, soakaway pits, sand and bioretention filters, vegetated filter strips, and grassed swales. If special concerns such as recreational activities involving water contact have been identified, additional water quality controls such as ultra violet disinfection units may be required.

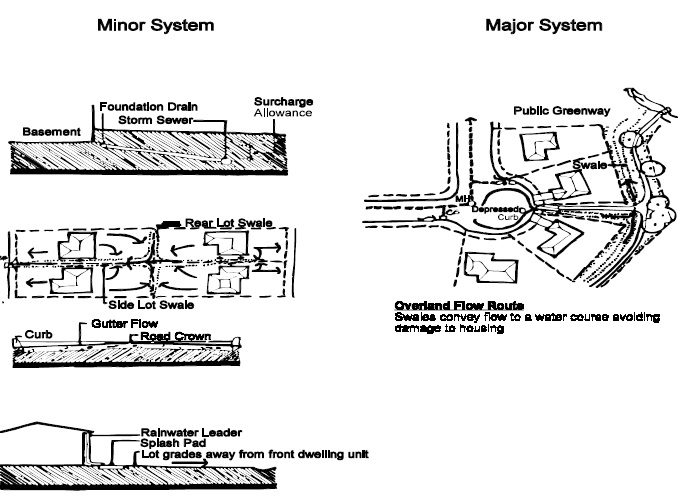

Modelling techniques which may be used to develop the system of stormwater management practices are discussed in Section 4.9. The stormwater management plan will also include designs for the major and minor systems that convey the runoff from infrequent and frequent storm events, respectively (Section 4.8).

4.1.1 Lot level and conveyance controls

Lot level and conveyance controls include those that are applied at the individual lot level, those which form part of the conveyance system, and controls which typically serve multiple lots but are only suitable for small drainage areas (< 2 hectares). They can be divided into two categories according to their primary function: storage controls and infiltration controls. Storage controls include:

- rooftop storage – restricting the discharge rate from roof drains to provide rooftop detention of stormwater

- parking lot storage – implementing catchbasin restrictors or orifices in the storm sewer to detain stormwater on parking lots

- superpipe storage – oversizing storm sewers and implementing orifices in the sewer to create pipe storage

- rear yard storage – implementing catchbasin restrictors in rear yard catchbasins to create rear yard storage

All of these measures were designed to detain stormwater to reduce peak runoff rates. In some cases there may be increased opportunity for evapotranspiration. However, detention times are typically short and these measures are not intended to reduce the volume of stormwater runoff. Further, they do not address water balance, erosion, or water quality issues. In addition, there are devices such as oil/grit separators which are suitable as lot level controls but which are also potentially suitable as end-of-pipe controls for small drainage areas with physical constraints. These devices are described in section 4.6.

Infiltration-based controls include:

- reduced grading to allow greater ponding of stormwater and natural infiltration;

- directing roof leaders to rear yard ponding areas, soakaway pits, or to cisterns or rain barrels;

- sump pumping foundation drains to rear yard ponding areas;

- infiltration trenches;

- grassed swales;

- pervious pipe systems;

- vegetated filter strips; and

- stream and valley corridor buffer strips.

The primary function of infiltration controls is to mitigate the impacts that urbanization normally has on the water balance (i.e., increased surface runoff, reduced soil moisture replenishment and groundwater recharge). Concentrated infiltration of stormwater collected from larger areas (e.g., infiltration basins, an end-of-pipe infiltration type control) will not match the characteristics of distributed infiltration which occurred under pre-development conditions. The natural hydrologic cycle can be maintained to the greatest extent possible by lot level infiltration controls.

Infiltration technologies can achieve water quality enhancement; however, stormwater containing high concentrations of suspended solids will tend to clog these controls. Further, infiltration of contaminated water can impair groundwater quality. Therefore, these measures are ideally suited to the infiltration of relatively clear stormwater, such as stormwater from rooftops which contains only atmospheric contaminants (i.e., contaminants deposited on the rooftop by precipitation or dryfall) or foundation drainage.

If the quality of the stormwater is such that there may be a problem with clogging in the system or degradation of groundwater quality, pre-treatment is required. Infiltration controls are not appropriate for applications with the potential for highly contaminated stormwater (e.g., industrial land uses).

By reducing the size of storm sewer infrastructure and end-of-pipe facilities, lot level and conveyance controls provide economic benefits. Section 4.8 provides guidance with respect to the reductions in end-of-pipe storage requirements which various lot level and conveyance controls allow.

The successful implementation of many lot level and conveyance measures require innovative subdivision design. In addition to the measures which are the focus of this manual, there are complementary controls which can be undertaken by home owners. For example, cisterns or rain barrels may be used in combination with bioretention gardens. Lot grading can be used to direct runoff to garden areas. Trickle irrigation systems may be used to make use of captured runoff in soils with lower infiltration capacities. Public education programs within municipalities can help to educate the public on the role they can play in the application of complementary measures.

A significant challenge in designing and implementing a stormwater management strategy which incorporates lot level techniques and other source controls is that many of these initiatives will be implemented on lands held in private ownership. Consequently, maintenance and the long-term effectiveness of the system is contingent on the actions of the landowner. Landowner education is the key to ensuring that systems remain effective over time. The successful application of lot level landscape solutions therefore requires the commitment of the municipality and the establishment of creative partnerships between the developer, municipality and landowner to realize consistent benefits over the long term.

4.1.2 End-of-pipe controls

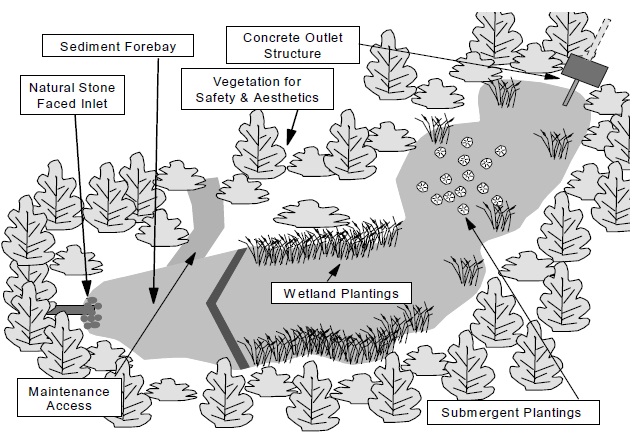

End-of-pipe stormwater management facilities receive stormwater from a conveyance system (ditches, sewers) and discharge the treated water to the receiving waters. The purpose of end-of-pipe SWMPs is to control the impacts of urbanization which remain after lot level and conveyance controls have been applied. In most cases, new urban developments (unless they are small or of very low density) will require some sort of end-of-pipe SWMP. Some SWMPs that have been applied as end-of-pipe SWM facilities include:

- wet ponds;

- wetlands;

- dry ponds; and

- infiltration basins.

Other SWMPs applied in some cases as end-of-pipe facilities for smaller areas include filters and oil/grit separators.

Designs are possible which form a continuum from wetland to wet pond. The main criteria for differentiating between the types of facilities are the proportions of deep (> 0.5 m) and shallow areas (< 0.5 m). A wet pond has the greatest percentage of its volume provided in deep water zones. Aquatic plants are concentrated on shallow shelves around the perimeter. These shallow zones typically comprise less than 20% of the surface area of the facility. In contrast, wetlands are dominated by shallow zones (typically > 70% of the volume). Hybrid wet pond-wetland systems combine the two types in series with a minimum of 50% of the volume being provided in deep water areas.

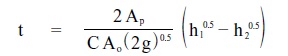

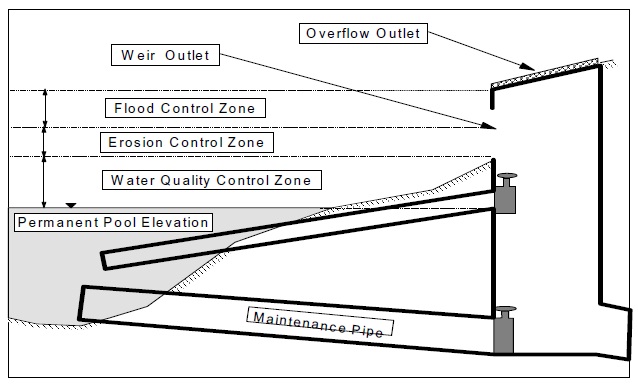

Virtually all new wet facilities (i.e., those having a permanent pool) designed in Ontario have an extended detention storage component, in part due to the guidance provided in this document and its predecessor, but largely because of their multi-purpose design (i.e., water quality, quantity and erosion control). Extended detention storage refers to the active storage which is used during and after a runoff event, but which subsequently drains. The extent to which the active storage is filled by an event depends upon the volume of runoff. Section 3.3 provides a more detailed description of the functions of the permanent pool and active storage elements of ponds and wetlands.

Other jurisdictions draw a distinction between "wet ponds" and "extended detention wet ponds." In the former, water is discharged at the same rate as water is received, while in the latter, water is released more slowly.

Concerns are sometimes expressed regarding the ancillary aviary, terrestrial, and aquatic habitat provided by ponds and wetlands. While the design of these stormwater facilities does not specifically seek to create habitat conditions, habitat is usually created (as a natural consequence). Hence, there are often concerns relating to bio-accumulation of stormwater contaminants and the destruction of habitat during maintenance.

The loss of natural wetlands is, in itself, a major issue which has led to a provincial wetland policy. Some view stormwater wetlands as a replacement for lost natural wetlands; however, stormwater facilities will not have the same attributes as natural systems. It must be recognized that stormwater ponds and wetlands are first and foremost stormwater management facilities that must be maintained. They should not be considered as significant natural areas which require environmental protection. Equally important is that the use of natural wetlands for stormwater quality enhancement is not allowed since the introduction of stormwater may alter the hydrologic regime and chemical/biological composition of the wetland.

4.2 Siting of stormwater management facilities

Site conditions must be addressed in the development of a stormwater management plan. Physical factors may suggest the use of particular SWMPs and preclude the use of others, or they may point to special design requirements (e.g., lining a pond). Factors which should be considered in the evaluation of the physical feasibility of SWMPs include:

- topography;

- soil type;

- depth to bedrock;

- depth to seasonally high water table; and

- drainage area.

Table 4.1 summarizes the physical constraints which could limit the use of lot level, conveyance, and end-of-pipe controls, and further detail is provided in the subsequent sections.

End-of-pipe SWMPs should normally be located outside of the floodplain (above the 100 year elevation). If the facility is multi-purpose in nature (e.g., providing quantity control in addition to quality and erosion control) it must be located above the highest design flood level. In some site- specific instances, SWMPs may be allowed in the floodplain if there is sufficient technical or economic justification and if they meet certain requirements:

- The cumulative effects resulting from changes in floodplain storage and balancing cut and fill do not adversely impact existing or future development;

- Effects on corridor requirements and functional valleyland values must be assessed. SWMPs would not be allowed in the floodplain if detrimental impacts could occur to the valleyland values or corridor processes;

- The SWMPs must not affect the fluvial processes in the floodplain; and

- The outlet invert elevation of the SWMP should be higher than the 2 year floodline and the overflow elevation must be above the 25 year floodline.

| SWMP | Topography | Soil | Bedrock | Groundwater | Area |

|---|---|---|---|---|---|

| wet pond | none | none | none | none | > 5 ha |

| dry pond | none | none | none | none | > 5 ha |

| wetland | none | none | none | none | > 5 ha |

| infiltration basin | none | loam (min. inf. rate ≥ 60 mm/h) | > 1 m below bottom | > 1 m below bottom | < 5 ha |

| infiltration trench | none | loam (min. inf. rate ≥ 15 mm/h) | > 1 m below bottom | > 1 m below bottom | < 2 ha |

| reduced lot grading | < 5% | loam (min. inf. rate ≥ 15 mm/h) | none | none | none |

| soakaway pit | none | loam (min. inf. rate ≥ 15 mm/h) | > 1 m below bottom | > 1 m below bottom | < 0.5 ha |

| rear yard ponding | < 2% | loam (min. inf. rate ≥ 15 mm/h) | > 1 m below bottom | > 1 m below bottom | < 0.5 ha |

| grassed swales | < 5% | none | none | none | < 2 ha |

| pervious pipes | none | loam (min. inf. rate ≥ 15 mm/h) | > 1 m below bottom | > 1 m below bottom | none |

| vegetated filter strips | < 10% | none | none | > 0.5 m below bottom | < 2 ha |

| sand filters | none | none | none | > 0.5 m below bottom | < 5 ha |

| oil/grit separators | none | none | none | none | < 2 ha |

In most cases, online facilities (those located within a watercourse) are discouraged because of concerns for wildlife movement, fish passage and disruption of energy inputs. On-line stormwater quantity facilities may be acceptable if designed such that the bank full flow, and hence fish movement, is not impeded/obstructed, and provided the foregoing requirements are met. On-line quality ponds can only be approved if issues of aquatic habitat can be resolved. An on-line facility can only be proposed in the context of a subwatershed plan.

In all development submissions, there should be a concerted effort to preserve the existing watercourse in its natural state. In cases where watercourse alterations are deemed necessary, the alterations should be designed using natural channel design techniques. This will require that the current stream reach be assessed using a stream classification system and that any alterations must account for hydrologic and hydraulic changes as a result of urbanization and the preferred stream function/morphology. Guidance on natural channel design techniques is provided in "Natural Channel Systems: An Approach to Management and Design" (Ministry of Natural Resources, 1994). Alterations to watercourses will, in most cases, require authorization under Section 35 (2) of the federal Fisheries Act.

The location of end-of-pipe stormwater management facilities is a contentious issue since the use of tableland reduces the overall area available for development. In an effort to minimize the loss of developable land, some municipalities allow the use of parkland dedication for SWMPs which offer recreational opportunities such as trails and playing fields. By offsetting the potential loss of land area available for development, the stormwater management facility, designed in whole or in part as usable parkland, may be considered acceptable.

4.3 Design modifications for cold climates

An extensive review of cold climate design considerations was undertaken by the Centre for Watershed Protection (1997). Much of the information contained in the document is based on the results of a survey conducted among practitioners operating in cold climates. The major recommendations relating to cold climate design include:

- Increased storage volumes to account for volume reductions due to ice and effects of multi-day spring melt;

- Sizing and location of inlets and outlets to avoid ice clogging and freeze-up; and

- Prohibition of early spring drawdown for maintenance (avoid discharge of water with low oxygen or high chloride levels).

Many of the study’s recommendations address depth of cover and backfilling practices which are standard in Ontario. However, the recommendations regarding storage volume increases and designs to limit problems due to freezing warrant consideration and are discussed further below.

4.3.1 Volume modifications

A number of factors combine to make water quality treatment of winter runoff more difficult. Typically, a finer range of particles is washed off in winter due to the lower flow rates associated with melt events. Finer particles require longer to settle and so the relative removal efficiency may be expected to drop in winter. In many situations, ice formation will reduce the effective volume of a permanent pool (causing more frequent overflows or reduced event capture). Ice formation may eliminate a permanent pool entirely so that only active storage is available for treatment.

The Centre for Watershed Protection (CWP) design supplement suggests increasing the water quality volume provided in order to accommodate multi-day snowmelt events. This is not necessary for the volumes recommended in Table 3.2 of this manual because they were derived using a continuous modelling approach which accounts for snow accumulation and melt.

CWP also suggests adding compensatory volume to account for the expected maximum ice thickness and setting the minimum active storage volume to 25% of the total volume (active and permanent pool). The latter measure ensures that some treatment will continue to occur when the pool is completely frozen over. In most cases where water quality and erosion control storage are provided in the same facility, the minimum active storage volume for water quality will be met without the need for additional volume.

The former measure may be particularly important in more northern portions of the province where temperature regimes are such that ice cover may persist into the spring when runoff rates and contaminant washoff are more of a concern than they typically are during the winter. In these areas of the province, it is recommended that the permanent pool volume be increased by an amount equal to the expected volume of the ice cover.

The thickness of ice can be estimated using Stefan’s Equation (Ashton, 1986):

Equation 4.1: Stefan’s Equation

h = α(Df)0.5

where:

- h

- ice thinkness in millimeters

- α

- coefficient of ice growth

- Df

- the sum of freezing degree-days

Table 4.2 indicates values for the coefficient of ice growth. Work done at a pond in Kingston, Ontario, indicated that a coefficient value of 15 produced results close to measured values (Marsalek, 1997). The pond operated with a constant subsurface inflow, which tended to limit the build-up of ice. In general, it is expected that most ponds will be small enough and will receive sufficient inflow to behave more like a river (in terms of ice build-up) than a lake. Where possible, however, the designer should consult with the local municipality or conservation authority concerning local knowledge on ice depths.

| Condition | α(mm°C-0.5d-0.5) |

|---|---|

| Theoretical Maximum | 34 |

| Windy lakes with no snow | 27 |

| Average lake with snow | 17-24 |

| Average river with snow | 14-17 |

| Shelter river with rapid flow | 7-14 |

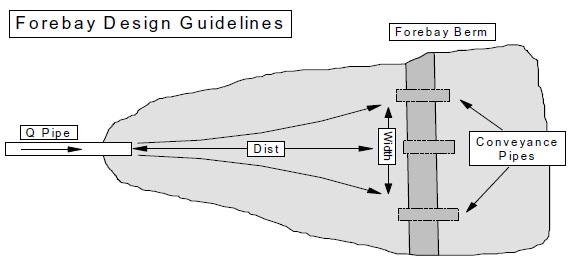

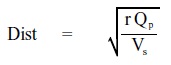

4.3.2 Modifications to inlet and outlet design

A number of the recommendations of the Centre for Watershed Protection (1997) study regarding inlets and outlets should also be considered:

- Slopes of inlet and outlet pipes should be > 1%;

- Minimum diameter of inlet and outlet pipes should be 450 mm;

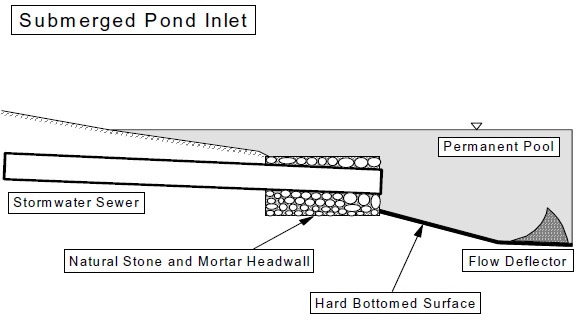

- Submerged or partially submerged inlets should be avoided where possible; where a submerged inlet is required, its obvert should be located 150 mm below the expected maximum ice depth;

- Where a submerged berm is used to separate the forebay from the remainder of the pond, the crest of the berm should be set to ensure that there is adequate capacity to pass the design flow (accounting for the expected maximum ice depth);

- Submerged outlet configurations (reverse sloped pipe, baffle plate) should be set 150 mm below the expected maximum ice depth; reverse sloped pipes should have a minimum diameter of 150 mm; and

- Where a very small orifice (e.g., 75-100 mm) is required for discharge control, the design should provide for overflow caused by freezing (i.e., provide a secondary high-level orifice of larger diameter or other appropriate design feature.)

Specific recommendations for cold climate design are provided in the subsequent sections describing each SWMP.

4.4 Mitigation measures for increased temperature

There are a number of reports which indicate that urban development end-of-pipe SWM facilities increase the temperature of water before it is discharged to the receiving waters (Beland, 1991, Galli, 1990, Schueler, 1992). Galli (1990) found that there is an increase in water temperature with all types of urban development SWMPs. These reports also stress, however, that an increase in water temperature is inevitable if an area is developed (i.e., urbanization causes stormwater temperature increases). This observation is based on current development practices. It is anticipated that employing the integrated approach to stormwater management described in Section 2.3 and Appendix A, and incorporating some of the techniques presented, will minimize the temperature increase associated with urbanization.

Literature values of temperature increases with different types of end-of-pipe stormwater management facilities have been recorded (Galli, 1990) and are provided in Table 4.3.

| SWMP Type | Temperature Increase |

|---|---|

| Infiltration Basin | 1.4°C |

| Wetland (extended detention) | 3.4°C** |

| Dry Pond (extended detention) | 2.9°C |

| Wet Pond (extended detention) | 5.1°C |

* Guideline based on monitoring – detailed calculations supersede this table.

** Original report value modified since the wetland design permanent pool was undersized resulting in a low ΔT

Wet ponds and wetlands can compound the temperature increase due to urbanization by maintaining water in the facility between storms and allowing it to acclimate to the air temperature. There are several techniques that can be used to reduce thermal impacts.

Pond configuration

The configuration of a pond will affect its temperature. The length-to-width ratio should be maximized to prevent the occurrence of large open areas of water which cannot be shaded by riparian vegetation. Planted berms and islands can be used in ponds that have a poor configuration due to site specific topography/land availability.

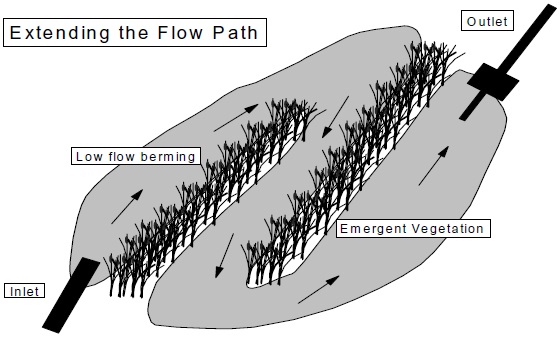

Riparian planting strategy

Planting in the shoreline fringe and flood fringe zones of a wet pond help to shade the pond and minimize temperature increases during inter-event periods. The planting strategy should incorporate designs which shade open water areas when the vegetation reaches maturity.

Bottom-draw outlet

There are temperature benefits from a bottom-draw facility, although this is dependent on the size of the permanent pool and the release depth. There is a minimal difference in water temperature within the top metre of a permanent pool. Lower temperatures (in the order of several degrees Celsius) occur several metres below the permanent pool surface. Ponds with permanent pool depths greater than 3 metres, however, are likely to become thermally stratified during the summer months. The water at depth can become anoxic, and there is a potential for metals and nutrients to be remobilized. Although the oxygen deprivation can be solved by re-aeration at the outlet (e.g., discharge over rocks), the discharge of the polluted water would be undesirable. Accordingly, ponds with a very deep release (> 3 m) should consider re-aeration in the pond itself to prevent thermal stratification from occurring. However, this may reduce sedimentation and resuspend sediment collected at the pond bottom.

Subsurface trench outlet

Treatment of water, by routing the discharge through a subsurface trench filled with clear stone, has also been suggested to reduce temperature. As the water flows through the trench, heat is transferred to the stone. It is purely a conveyance system which does not rely on infiltration; however, there is relatively little knowledge with respect to the success of these systems.

The dimensions of the system depend on the intended range of release rates, and the proximity of the pond to the watercourse. The length of the trench should be maximized to increase the opportunity for heat transfer. The cross-sectional area of the trench should be sized based on the design conveyance flow which does not necessarily have to match the design release rate from the pond (especially if the pond will accommodate the runoff from relatively large storms; i.e., > 25 mm). The trench should be designed to accommodate frequent events (i.e., ≤ 10 mm) which will have a greater effect on the thermal regime of the receiving water.

The trench should be wrapped with non-woven filter fabric to prevent the native material from blocking the pore space in the stone/rock. The stone should be relatively small (13 mm - 25 mm) since smaller stones will have a greater total surface area available for heat transfer.

Night time release

Monitoring evidence (Beland, 1990 unpublished) suggests that the water in stormwater ponds cool during the night as a result of ambient temperature fluctuations that can be up to 5°C. Generally, the lowest pond temperatures were recorded during the early morning (5 A.M. - 7 A.M.) indicating that very early morning releases should be targeted for facilities which are designed with real time controls.

Outlet channel design

In cases where there is a lengthy outlet channel from the end-of-pipe SWM facility to the receiving waters, natural channel design techniques can be employed. Guidance on natural channel design techniques is provided in "Natural Channel Systems: An Approach to Channel Management and Design" (Ministry of Natural Resources, 1994). The outlet channel from an end-of-pipe SWM facility to the receiving waters should be shaded by plantings to minimize the temperature of the water discharged to the receiver.

4.5 Lot level and conveyance controls

4.5.1 Rooftop storage

Flat building roofs can be used to store runoff to reduce peak flow rates to storm sewer systems. Rooftop storage is economical and requires little extra cost during construction. It is generally applicable to large flat commercial and industrial rooftops. Residential roofs are usually peaked with few opportunities for storage. Rooftop storage is widely applied for infill development scenarios to mitigate the need for downstream storm sewer size increases. Few regulatory agencies allow rooftop storage to reduce downstream post-development peak flow rates for new sites. Local regulatory agencies should be consulted to determine what is allowable.

Design guidance

Storage volumes and release rates

Plates or weirs are used in rooftop drainage hoppers to control the rate of discharge and depth of storage. Drainage hoppers can discharge to the internal building drainage system or externally to the ground.

Discharge rates for pre-manufactured rooftop drainage hoppers are specified by the manufacturer. Typically, discharge values for each hopper can range from 1 to 15 L/s. Storage is user determined for dead level or slightly sloped roofs. Large commercial roofs can store 50 mm to 80 mm of runoff. The 100 year 24 hour rainfall amount for southern Ontario is approximately 100 mm. Detention times are usually between 12 and 24 hours. Structural/mechanical engineers should supervise the detailed design of rooftop storage to ensure that loadings are not exceeded.

Emergency overflows

Openings must be designed in the roof parapet walls to ensure loading requirements are not exceeded during excessive runoff events or in case roof hoppers are blocked. Openings will limit the depth of ponding and the loading to the building. Rooftop storage requires periodic inspections and prompt maintenance. More frequent inspections for blockages should be made during the winter and fall months.

Hopper location

The location of hoppers is a function of the building roof length, width and slope. The manufacturer commonly supplies guidelines for determining the location of the hoppers. Typically, hoppers are located 10 m to 15 m from the roof parapet and the distance between hoppers is approximately 30 m.

Drain pipe sizing

Vertical drain pipes should be sized to convey the maximum flows discharged from the roof hoppers. Vertical pipe capacities range from 2 L/s for 50 mm diameter pipes to 40 L/s for 150 mm diameter pipes.

Leakage

Improved waterproofing techniques are required during construction to prevent leakage of ponded runoff.

Technical effectiveness

Rooftop storage is highly effective in reducing downstream peak flow rates. However, the volume of stormwater runoff to the sewer system is not reduced.

4.5.2 Parking lot storage

Parking lots can be used to store runoff to reduce peak flow rates in storm sewer systems. Parking lot storage is economical with slightly increased costs for construction. It is generally applicable to commercial and industrial lots. Parking lot storage is not used in residential areas due to the small parking areas. It has been widely applied for infill developments to mitigate the need for downstream storm sewer size increases. Few regulatory agencies allow parking lot storage to reduce downstream post-development peak flow rates for new sites. Local regulatory agencies should be consulted to determine what is allowable.

Design guidance

Storage volumes and release rates

Storage is created when runoff rates are greater than the outflow allowed by the restricted capacity of inlet control devices (ICDs) placed in maintenance holes or catchbasins. Pre-manufactured ICDs can take the form of an orifice plate or plug over the pipe to a catchbasin or maintenance hole. Specialty ICDs can be orifice plates under catchbasin grates.

Generally, ponding depths are limited to 300 mm with durations less than 1 hour. Design criteria can vary significantly between municipalities. Some municipalities require sizing of the control to the pre-development 2 year peak runoff rate for all (2 through 100 year) post-development runoff rates.

Pre-manufactured ICDs have patentable dimensions and discharge rating curves. Simple spreadsheet calculations can be used to size parking lot storage, or computer simulation programs can be used. Calculations may be complicated when building roof storage discharges to surface ponding areas or when storm sewers are used to control ponding levels at catchbasins.

Parking lot grading

Storage at a catchbasin or manhole is limited by the maximum ponding depth and the grade of the parking lot. Generally, grades are greater than 0.5% and less than 5%. Storage capacities are reduced for increasing grades assuming a constant ponding depth.

Emergency overflows

Overland flow paths must be designed to accommodate runoff that exceeds the storage capacity at the catchbasins. Debris blocking at the catchbasin grate can reduce outflow rates and create overflows. Overland flow paths can be sewers, swales or the roadway system.

Control location

ICDs can be located in catchbasins or at maintenance holes located on the property boundary. Controls at the property boundary allow the municipality to check the operation of the control at its convenience. Controls at the property boundary will likely result in constant water levels at all catchbasins within the site. Controls at the catchbasins allow for different ponding levels and maximize storage on steeply graded sites.

Ponding locations

Frequent ponding areas should be located away from buildings within the site. Storage of runoff during an event can be a nuisance to parking lot users.

Technical effectiveness

Parking lot storage is highly effective in reducing downstream peak flow rates; however, the volume of storm runoff to the sewer system is not reduced. Normal parking lot maintenance procedures are suitable for parking lot storage areas.

4.5.3 Superpipe storage

A superpipe, consisting of pre-manufactured pipe requiring on-site assembly, can reduce peak flow rates by providing subsurface storage. There are marginal water quality benefits as some of the coarse sediment may settle. Generally, superpipes are utilized for small development sites which lack sufficient surface space to construct detention facilities. Design and construction standards for superpipes are defined by the local municipality or township.

Superpipes are equipped with small outlet pipes. As inflow rates are much larger than outflow rates, runoff is detained. Generally, detention times are on the order of a few hours. Compared to traditional surface facilities, land requirements for superpipes are small while material costs are high.

Design guidance

Inlets and outlets

Inlets and outlets must be sized for each site. Outflow rates may have been previously defined in master drainage plans or storm sewer analyses. Generally, inlets are the on-site storm sewer system that has been designed to convey frequent runoff events from impermeable surfaces. Outlets are much smaller pipes that may discharge to watercourses or existing storm sewer systems.

Length and diameter

The length and diameter of the superpipe will be a function of the storage required to meet off-site discharge rates. Maximum pre-manufactured diameters are approximately 3 m. However, the maximum pipe size that can be transported to the site due to constraints, such as bridge height, must be considered. Some municipalities have established minimum sizes to facilitate cleaning. Generally, pipes with diameters less than 1.8 m are difficult to clean.

Slope

Minimum slopes are approximately 0.5% as a slope must be maintained to completely drain the pipe. Slopes should be kept to the minimum as steep slopes will reduce the amount of storage available within the pipe.

Emergency overflows

Emergency surface overflow paths should be located and sized to convey the 100 year runoff in case the superpipe (inlet/outlet) becomes plugged or inoperable.

Location

Superpipes should be installed where the pipes can be easily excavated for maintenance. Suitable locations include parking lots and grassed swales adjacent to property boundaries. Superpipes should be located in close proximity to fire hydrants that supply flushing water for the removal of sediments.

Maintenance

Personnel access points should be located at the upstream and downstream ends of the superpipe. For safety precautions, confined space entry procedures will be required for maintenance personnel when flushing or removing sediments. Upstream removal of sediments will extend the maintenance interval (oil/grit separators and/or other pre-treatment devices can be used for this purpose).

Technical effectiveness

Superpipes are very effective in reducing site peak flow rates; however, they do not significantly improve water quality. Special maintenance considerations are required for clearing.

4.5.4 Reduced lot grading

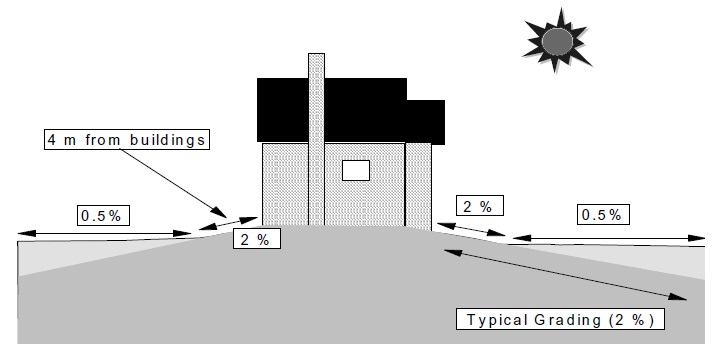

Typical development standards require minimum lot grades of 2% for adequate drainage of stormwater away from a building. Alternative Development Standards (Ministry of Municipal Affairs and Housing, 1995) suggest reducing minimum lot grades from 2% to 0.5%. Despite this, the designer should check the acceptability of this practice with the local municipality.

Design guidance

Soils

Reduced lot grading can be implemented where soils have a percolation rate ≤ 15 mm/h. This generally includes all soils coarser than a loam (Table 4.4). Table 4.4 should be used as a screening tool to determine if site conditions may be suitable for infiltration type controls. However, site testing should be undertaken to confirm actual soil percolation rates. Scarification, or tilling of the soil to a depth of approximately 300 mm, will enhance infiltration; thereby helping to overcome the soil compaction that normally occurs during construction.

| Soil Type | Percolation Rate (mm/h) |

|---|---|

| sand | 210 |

| loamy sand | 60 |

| sandy loam | 25 |

| loam | 15 |

Topography

A reduction in the lot grading should be evaluated if the land is naturally flat. In hilly areas, alterations to the natural topography should be minimized (as indicated in Appendix A).

Setbacks

In order to ensure that foundation drainage problems do not occur, the grading within 2 metres - 4 metres of a building should be maintained at 2% or higher (local municipal standards should be reviewed to ensure that the grading around a building is in compliance). Areas outside of this boundary may be graded at less than 2% to create greater depression storage, and promote natural infiltration (Figure 4.1).

Figure 4.1 Lot Grading Changes

Roof leaders

In areas where reduced lot grading is implemented, roof leaders which discharge to the surface should extend 2 metres away from the building.

End-of-pipe benefits

End-of-pipe extended detention requirements will be reduced by decreasing lot grades. The benefits of reduced grades can be assessed based on an increase in pervious area depression storage in hydrological modelling. It is recommended that the pervious depression storage (or initial abstraction) be increased by 1.5 mm for a change in lot grades from 2% to 0.5% (based on a typical lot of 12 m × 30 m). Section 4.8 provides further guidance with respect to adjusting end- of-pipe SWM facility storage to account for lot level and conveyance controls.

Technical effectiveness

There is little experience with reduced lot grading as a standard practice on a subdivision scale. The largest impact this practice will have is on the homeowner’s utility of his or her land. The water ponded on lots may take 24 to 48 hours to drain which may restrict the active use of the land. This impact will be greatest in spring, but negligible during the summer. It is anticipated that the public will be receptive to this alternative standard if they understand its benefits.

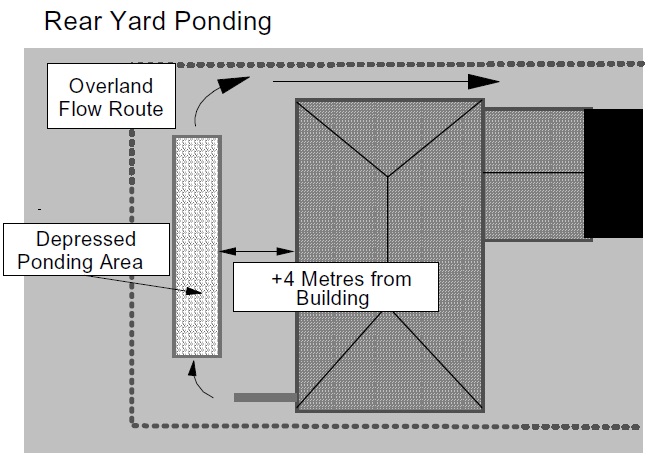

4.5.5 Roof leader to ponding areas

An area for ponding can be created in the rear yard or along the rear lot line. Roof leaders are discharged to the surface and directed to the ponding area. Water is detained in the ponding area until it either evaporates or infiltrates.

A variation on this SWMP adds rainbarrels or cisterns, so that water can be stored for later use in the garden or on the lawn. This is particularly useful in areas with impermeable soils, where infiltration is slow and ponding areas may remain wet for an extended period of time.

Design guidance

Soils

Ponding can be implemented for soils having a percolation rate ;;. 15 mm/h. Infiltration can be improved by tilling the ponding area to a depth of approximately 300 mm before sod is laid.

Storage volume

A minimum storage volume of 5 mm over the rooftop area should be accommodated in the rear yard without overflowing. The maximum target storage volume should be 20 mm over the rooftop area since 90% of all daily rainfall depths are less than this amount.

Ponding depth

The area for ponding should be a shallow depression with a maximum depth of 100 mm. An overland flow path should be established for depths greater than this amount.

Configuration

The configuration of the ponding area will depend on the site-specific layout of the development. The depth of ponding should be minimized as a goal. If possible the length of ponding should be maximized compared to the width to prevent short-circuiting to reduce the potential for groundwater mounding, and to maximize the potential for infiltration.

Location

The area of ponding should be at least 4 metres away from any building foundations to ensure that the ponded water does not increase the amount of foundation drainage (Figure 4.2).

Figure 4.2: Roof Leader Discharge to Rear Yard Areas

In general, surface ponding areas should not be located over sewage system leaching beds to minimize the potential for compaction of the leaching bed and groundwater mounding problems. A hydrogeologist should be consulted with respect to the necessity for mounding calculations and the requirements for a setback from the tile field in areas where surface ponding is proposed.

In general, surface ponding areas should not be located adjacent to highways or major roads.

Common ponding areas

Ponding areas can be created along the rear lot lines by raising rear yard catch-basins such that they are used as an overflow system. Infiltration in the ponding areas can be enhanced by providing an infiltration trench system underneath the swale (see Sections 4.5.6 and 4.5.8).

Roof leader

The roof leader should discharge into the ponding area via a splash pad and overland flow route.

End-of-pipe benefits

An increase in impervious depression storage is the simplest way to assess the benefits of rear yard storage on the end-of-pipe extended detention requirements. If modelling is performed, this would require the rooftop area to be modelled separately from the other areas. The increased depression storage would be equivalent to the depth of storage provided over the entire rooftop area. Further guidance is provided in Section 4.8.

Technical effectiveness

This technique has similar benefits and drawbacks to flatter lot grading. The benefits of this practice outweigh its drawbacks, and therefore, this stormwater lot level control is recommended.

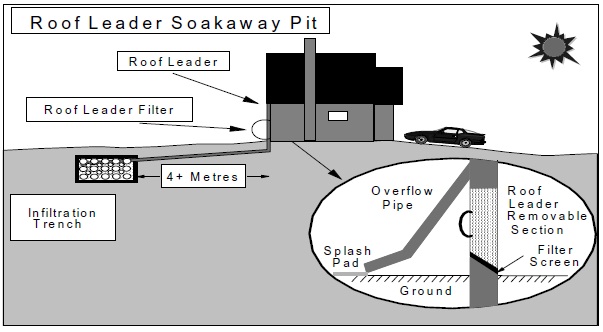

4.5.6 Roof leader discharge to soakaway pits

This stormwater lot level control infiltrates roof drainage via an underground infiltration trench (soakaway pit). The roof drainage is conveyed directly to the trench by the roof leader (Figure 4.3). The term soakaway pit is typically used to describe an infiltration trench which serves a single lot and which does not receive road runoff. Since the runoff is relatively clear, pre-treatment is not needed.

Figure 4.3: Roof Leader Discharge to Soakaway Pit

Design guidance

Water table depth

The depth from the bottom of the soakaway pit to the estimated seasonally high water table should be greater than or equal to 1 metre.

Depth to bedrock

The depth from the bottom of the soakaway pit to the bedrock should be greater than or equal to 1 metre.

Soils

Soakaway pits can be used where soils have a percolation rate ;;. 15 mm/h. This generally includes all soils coarser than a loam.

Storage volume

A minimum storage volume of 5 mm over the rooftop area should be accommodated in the soakaway pit without overflowing. The maximum target storage volume should be 20 mm over the rooftop area since 90% of all daily rainfall depths are less than this amount.

Storage configuration

The length and width of a soakaway pit are dependent on the configuration of the development. The length of trench (in the direction of inflow) should be maximized compared to the width to ensure the proper distribution of water into the entire trench and to minimize the potential for groundwater mounding.

The permeability of the native soil will dictate the maximum allowable underground storage depth as indicated by Equation 4.2. Storage depths greater than 1.5 m are generally not recommended for soakaway pits from both a cost, and a compaction perspective. The weight of the water in a deep soakaway pit will compact the surrounding native soil and decrease the infiltration capacity.

There are exceptions, however, to this maximum depth recommendation. In areas with deep sand lenses or significant horizontal soil stratification, deep soakaway pits may be preferred. If, for example, a sand lens is located at a depth of 2 metres, it would be advantageous to construct a deep soakaway pit which drains into the lens. Soils investigations should be undertaken to determine whether these conditions exist.

Equation 4.2: Maximum Allowable Soakaway Pit Depth

d = PT ÷ 1000

where

- d

- maximum allowalbe depth of teh soakaway pit (m)

- P

- percolation rate (Table 4.1) (mm.h)

- T

- drawdown time (24-48 h) (h)

It is recommended that a conservative drawdown time (24 h) be chosen recognizing that the percolation rates into the surrounding soil will decrease over time and that there will likely be a lack of maintenance in some cases.

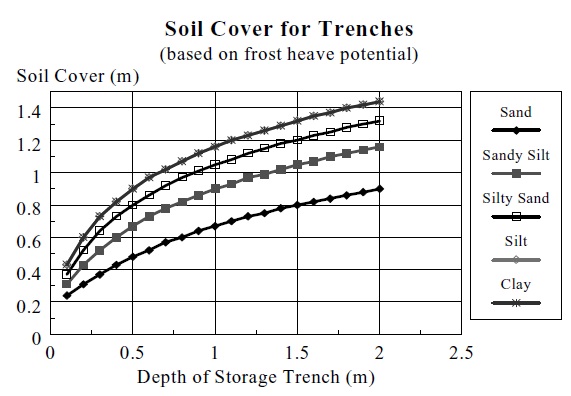

Soil cover

Typically, the pit should be located close to the ground surface; however, this will depend on the depth of storage in the trench, the potential for frost heave, and the stratification of the surrounding soil. The potential for frost heave is dependent on the native soils and the volume of water in the trench which may freeze. Figure 4.4 provides guidance on the recommended minimum soil cover for various subsurface trench depths and native soils. It is based on professional opinion, the expansion of water because of freezing, and the potential availability of water to freeze. Ice lens formation is not anticipated to occur within the trench because of the size of the pores in the storage media.

Figure 4.4: Soil Cover for Trenches

Location

The roof leader is extended underground to an excavated infiltration trench. The trench should be located at least 4 metres away from the foundation of the nearest building to prevent excessive foundation drainage.

Groundwater mounding calculations may be required to ensure that soakaway pits do not interfere with sewage system leaching beds. A hydrogeologist should be consulted with respect to the necessity for mounding calculations and the requirements for a setback from the tile field. It is anticipated that calculations will be required in areas where the soils are marginally acceptable for infiltration.

Common soakaway pits

Common soakaway pits may be viable in areas with compact built forms. The common soakaway pit can be located in neighbourhood park areas or along rear lot lines.

Storage media

The trench is comprised of clear stone (50 mm diameter). Non-woven filter cloth should be used to line the trench to prevent the pore space between the stones from being blocked by the surrounding native material.

Conveyance pipe

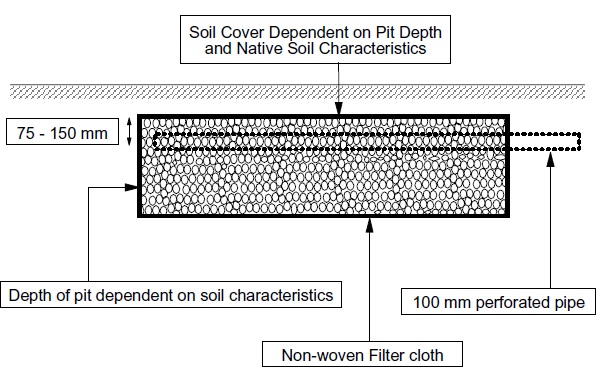

The roof leader should extend into the soakaway pit for the full length of the pit. The extension of the roof leader should be perforated to allow water to fill the pit along the length of the pipe. The perforated pipe should be located near the surface of the trench (75 mm - 150 mm from the top of the pit). A typical trench detail is shown in Figure 4.5.

Figure 4.5: Soakaway Pit Details

Overflow by-pass

An overflow pipe should be installed from the roof leader that discharges to a splash pad. A removable filter should be incorporated into the roof leader below the overflow pipe. The filter should have a screened bottom to prevent leaves and debris from entering the soakaway pit. It should be easy to remove so that a homeowner can clear the filter. Frequent use of the overflow pipe will indicate the need for filter screen maintenance.

Technical effectiveness

Soakaway pits for roof leader drainage have been implemented in numerous areas (e.g., Toronto, Maryland). Lindsey et al. (1992) indicated that of 25 soakaway pits monitored, 60% were operating as designed.

Soakaway pits have both benefits and drawbacks compared to rear yard ponding. The benefits include greater recharge (less evapotranspiration) and less inconvenience to the homeowner (less surface water ponding). The drawbacks include greater maintenance and uncertain longevity.

For soakaway pits accepting only roof drainage, the potential for clogging is low as is the risk of groundwater quality degradation. Accordingly, this SWMP is recommended for general implementation.

4.5.7 Sump pumping of foundation drains

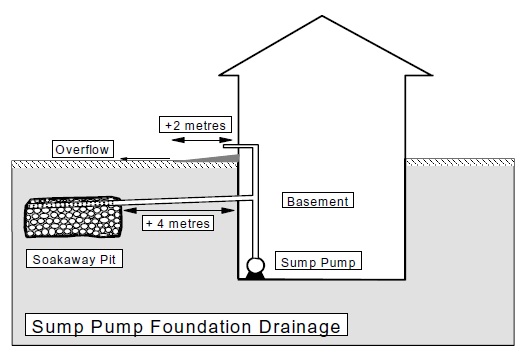

Development standards allow foundation drains to be connected to the storm sewer. Alternative standards (Ministry of Municipal Affairs and Housing, 1995) allow the use of sump pumps to discharge foundation drainage to the surface or soakaway pits (Figure 4.6). Because foundation drainage is relatively clear water, the cost of stormwater management and sewage treatment can be reduced by keeping it separate from storm and sanitary sewers. The municipality should be contacted before recommending this type of control as its use may not be permitted.

Figure 4.6: Foundation Drainage Options

Design guidance

Water table depth

In areas where the seasonally high water table is within 1 metre of the building foundation drains, sump pumps should not be utilized. This requirement is imposed to prevent excessive sump pump operation and to prevent a looped system whereby the sump pump discharges maintain the foundation drainage. Where the use of sump pumps is not feasible, a "third pipe" may be used to convey foundation drainage to the receiving water.

Depth to bedrock

In areas where the depth to bedrock is within 1 m of the foundation drain elevation, foundation drainage by sump pumps is not feasible. This requirement is imposed to prevent excessive sump pump operation and a looped system.

Location

Figure 4.6 demonstrates foundation drainage to a soakaway pit using a sump pump. If a soakaway pit is used, it should be located a minimum of 4 metres away from all building foundations to minimize the contribution of soakaway pit drainage to foundation drainage. If the foundation drains are being discharged directly to the surface, the discharge point at the ground surface should be located at least 2 metres away from all building foundations, and there should be sufficient grade from the foundation wall away from the building (≥ 2%) for 2 metres to 4 metres to convey the foundation drainage away.

Overland flow

Discharges to the surface should be directed to the rear yard to minimize the amount of surface drainage over sidewalks during the winter. Sump pumps discharging to the surface should discharge approximately 0.5 m above the ground surface to prevent blockages in the winter due to ice and snow.

4.5.8 Infiltration trenches

Infiltration trenches in this manual refer to infiltration systems with a subsurface storage component that treat stormwater runoff from several lots as opposed to soakaway pits which are primarily used for a single lot application. Infiltration trenches can be implemented at the ground surface to intercept overland flows, or underground as part of a storm sewer system.

The acceptability of infiltration trenches should be confirmed because of potential concerns for aquifer contamination. In most cases, infiltration trenches will provide marginal flooding and erosion control benefits because they are sized for recharge and water quality.

Design guidance

Drainage area

Infiltration trenches can be implemented for small drainage areas (< 2 ha). The use of trenches for larger drainage areas is inappropriate due to the problems associated with infiltrating a large volume of water in a relatively small area of land. Groundwater mounding problems, compaction, and sealing of the native soil material have a higher potential of occurrence as the volume of water to be infiltrated increases. Further, in terms of the natural hydrological cycle, concentrated infiltration of stormwater collected from large areas will not match the characteristics of pre-development distributed infiltration.

Land use

Infiltration trenches can be implemented for residential land uses. Trenches are best implemented for compact housing (cluster housing, townhouses) in small parks/greenspace areas where several households can drain to a single trench.

Infiltration trenches are not suitable for industrial land uses since there is a high potential for groundwater contamination and/or dry weather spills. Similarly, infiltration trenches are not suitable for commercial parking lots since there is a high potential for dry weather spills and for chloride to enter the trench, and subsequently, the groundwater system.

Water table depth

The seasonally high water table depth should be > 1 m below the bottom of the infiltration trench.

Bedrock depth

The depth to bedrock should be > 1 m below the bottom of the infiltration trench.

Soils

Infiltration trenches are not suitable if the native soil has a percolation rate less than 15 mm/h.

Storage configuration

The depth of the storage layer should be sized to ensure a 24 to 48 hour drawdown (a 24 hour drawdown is recommended) of the stored water based on the percolation rate determined in the field. Equation 4.2 can be used to calculate the maximum allowable storage depth in the trench.

A maximum storage volume equal to the runoff from a 4 hour 15 mm storm should be provided in the trench storage media if the trench accepts runoff from several lots. The length and width of the trench will be determined by the characteristics of the site in question (topography, size and shape).

If a surface trench is designed, the dimensions of the trench will depend on the path of influent water. If stormwater is conveyed to the trench as uniform sheet flow, the length of the trench perpendicular to the flow direction should be maximized. If stormwater is conveyed as channel flow, the length of trench parallel to the direction of flow should be maximized.

In a subsurface trench, the water is conveyed into the trench via a pipe system. In this arrangement, it is recommended that the trench length (parallel to the incoming pipe) be maximized compared to the trench width. This will encourage the uniform distribution of water in the storage layer.

The appropriate bottom area of the trench can be calculated using Equation 4.3. This equation assumes that all of the infiltration occurs through the bottom of the trench.

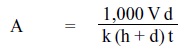

Equation 4.3: Infiltration Trench Bottom Area

A = 1000V ÷ PnΔt

where:

- A

- bottom area of the trench (m²)

- V

- runoff volume to be infiltrated (Table 3.2)

- P

- percolation rate of surrounding native soil (mm/h)

- n

- porosity of the storage media (0.4 for clear stone)

- Δt

- retention time (24 to 48 hours)

Location/setbacks

Groundwater mounding calculations may be required to ensure that infiltration trenches do not interfere with sewage system leaching beds. A hydrogeologist should be consulted with respect to the necessity for mounding calculations and the requirements for a setback from the tile field. It is anticipated that calculations will be required in areas where the soils are marginally acceptable for infiltration.

The setbacks from wells specified in the Building Code for leaching bed systems shall also be observed for infiltration trenches.

Storage media

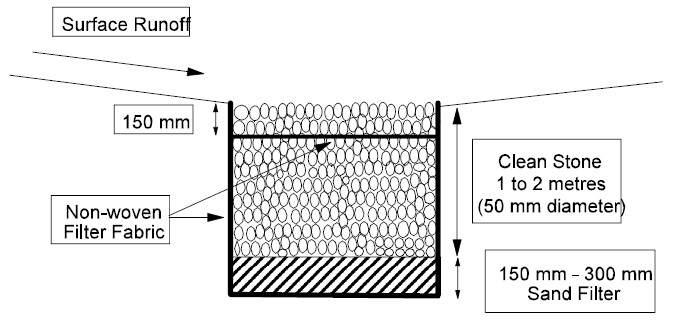

The storage media holds the stormwater until it can percolate into the surrounding native material. It is recommended that 50 mm diameter clear stone be used (Figure 4.7). While gravel is the most common medium used, precast infiltration storage media are available which are also generally acceptable.

Figure 4.7: Surface Infiltration Trench

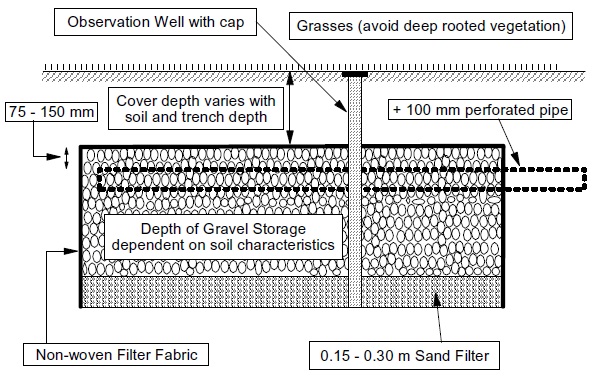

Non-woven filter fabric should be installed at the interface of the trench and the native material to ensure that the latter does not clog the trench. For subsurface trenches, the filter fabric should extend to cover the top of the trench (Figure 4.8). However, this may need to be frequently replaced depending on the volume of suspended solids transported to the trench.

Figure 4.8: Subsurface Infiltration Trench

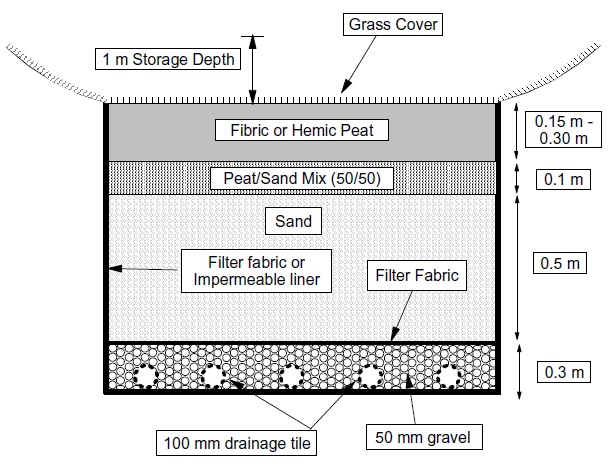

Filter layer

A filter layer is constructed underneath the storage layer to provide quality enhancement of the stormwater before it infiltrates the native soil. The most common filter medium used in infiltration trenches is sand. The sand layer should be approximately 0.3 m thick (0.15 m - 0.30 m). Grain size is specified based on the effective size (d10 – 10% of the particles are less than this size) and coefficient of uniformity (Cu – the larger the number, the less uniform the material). Sands with an effective size of 0.25 mm and Cu ≤ 3.5, or an effective size of 2.5 mm with a Cu ≤ 1.5, are recommended for filter material.

Peat may be mixed with the sand to enhance the pollutant removal characteristics of the trench. Peat has a high affinity for metals, hydrocarbons, and nutrients (Galli, 1990). Fibric or hemic peat should be utilized to achieve the desired percolation rates. Sapric or well-decomposed peat is discouraged since this type of peat has a slow percolation rate. The percolation rate of filter media should equal or exceed the percolation rate of the native soil material.

Planting strategy

The planting requirements for an infiltration trench are more aesthetic than functional. Grass/herb mixtures are generally acceptable. Plantings with deep roots should be avoided since they can puncture the filter fabric at the top of the trench allowing native soil material to clog the gravel storage layer from above.

Distribution pipes

In an underground trench, water is conveyed into the storage layer by a series of perforated pipes. A header pipe connects to the influent storm sewer and distributes the flow into lateral perforated pipes (≥ 100 mm diameter) which traverse the entire length of the trench. The lateral pipes should be spaced a maximum of 1.2 m apart. The perforated pipes should be located approximately 75 mm - 150 mm from the top of the storage layer.

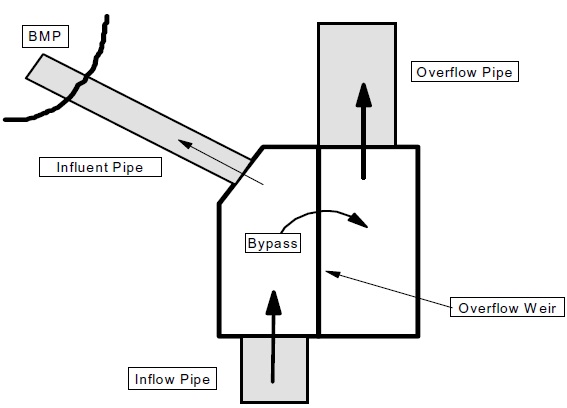

Overflow/by-pass pipe

A by-pass pipe should be incorporated into the design of an underground infiltration trench to convey high flows around the trench. This will necessitate the construction of a flow splitter upstream of the trench (see Section 4.7). The by-pass pipe may also function as the:

- normal outlet until the site is stabilized (inlet pipe to trench blocked off);

- normal outlet during trench maintenance; and

- normal outlet during winter/spring conditions.

Pre-treatment

In residential areas, where the infiltration trench takes primarily roof and pervious area runoff, the technique can be employed without pre-treatment. If the infiltration trench is being used to treat stormwater runoff from an entire site (including roads and parking lots), pre-treatment is necessary to minimize the potential for suspended sediments to clog the trench.

Sand filters, vegetated filter strips, grassed swales and/or oil/grit separators may be used. Pollution prevention through source controls should also be investigated (sanding/salting practices, public education with respect to street/driveway sediments) in areas where an infiltration trench is proposed.

Construction

Infiltration trenches will only operate as designed if they are constructed properly. There are three main rules that must be followed during the construction of an infiltration trench:

- Trenches should be installed at the end of the development construction;

- Smearing of the native material at the interface with the trench must be avoided and/or corrected by raking/roto-tilling; and

- Compaction of the trench during construction must be minimized.

Winter operation

In general, infiltration facilities are unsuitable for water quality treatment during the winter/ spring period. They are subject to reductions in capacity due to freezing or saturation of the soil. If road runoff is received, there is an increased likelihood of clogging due to high sediment loads and an increased risk of groundwater contamination from road salt.

If infiltration practices are used as an all-season water quality treatment facility, then doubling the design storage volume for surface infiltration devices to account for reduced infiltration rates is recommended. Redundant pre-treatment (more than one pre-treatment device in series) is recommended for all infiltration facilities receiving road runoff. A pre-treatment volume of about 15 mm/impervious hectare is recommended.

Technical effectiveness

Centralized infiltration trenches have a poor historical record of success (Lindsey et al., 1992; Metropolitan Washington Council of Governments, 1992). This lack of success is attributable to many factors:

- poor site selection (industrial/commercial land use, high water table depth, poor soil type);

- poor design (lack of pre-treatment, clogging by native material);

- poor construction techniques (smearing, over-compaction, trench operation during construction period); and

- large drainage area (high sediment loadings, groundwater mounding).

There are many reasons why an infiltration trench can fail. One of the main problems with centralized infiltration trenches is that water from a large area is expected to infiltrate into a relatively small area. This does not reflect the natural hydrologic cycle and generally leads to problems (groundwater mounding, clogging, compaction).

Water quality enhancement can be achieved using infiltration trenches. However, care must be taken to avoid degradation of groundwater quality. Trenches are ineffective quantity control facilities unless substantial storage is provided and the soil conditions are optimum.

4.5.9 Grassed swales

Grassed swales have historically been associated with rural drainage and have been constructed primarily for stormwater conveyance. Stormwater management objectives have changed and grassed swales are now being promoted to filter and detain stormwater runoff. Swale drainage can be a useful technique in areas of low grade, as long as the distance that the flow is to be conveyed is not too long.

The majority of swale systems in Ontario have been designed as "dry" swales. The guidance provided below is for such systems. An alternate design, the "wet" swale, can also be useful in areas where there is sufficient space, especially where soils are not highly permeable, or where there are low lying areas with a high water table.

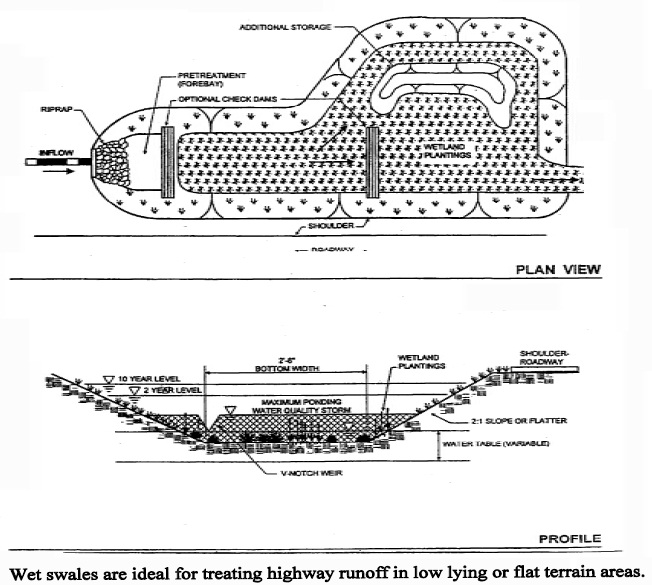

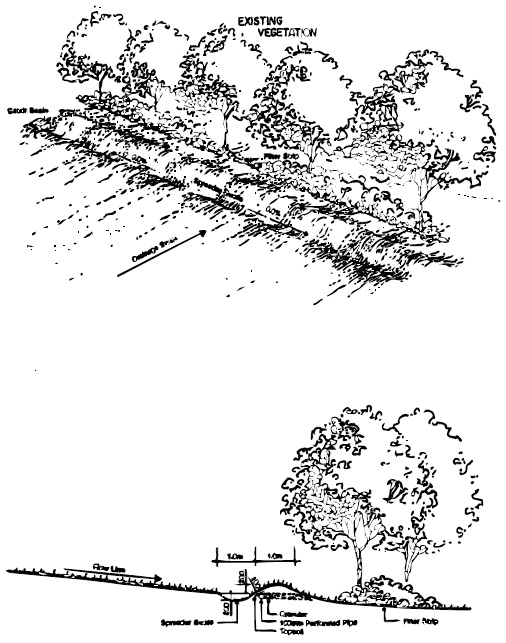

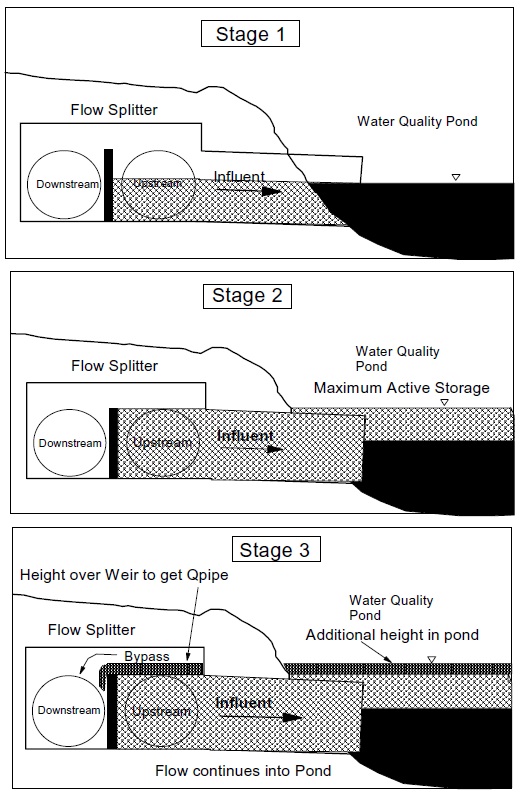

Wet swales combine elements of dry swale systems and wetland systems. Wet swales are typically wider than dry swales (e.g., 4 m - 6 m) and the check dams are used to create shallow impoundments in which wetland vegetation is planted or allowed to colonize. Because of their width, wet swales are not generally implemented along the front of residential properties, but rather are included where overland flow routes use linear open space areas. Combined systems of dry and wet ponds may be used. Wet swales have been implemented in several highway projects, but monitoring results are limited. A schematic of a wet swale is provided in Figure 4.9.

Figure 4.9: Schematic of a Wet Swale

Source: Maryland Stormwater Manual, Volume 1, 1998.

Design guidance

Swale cross-section

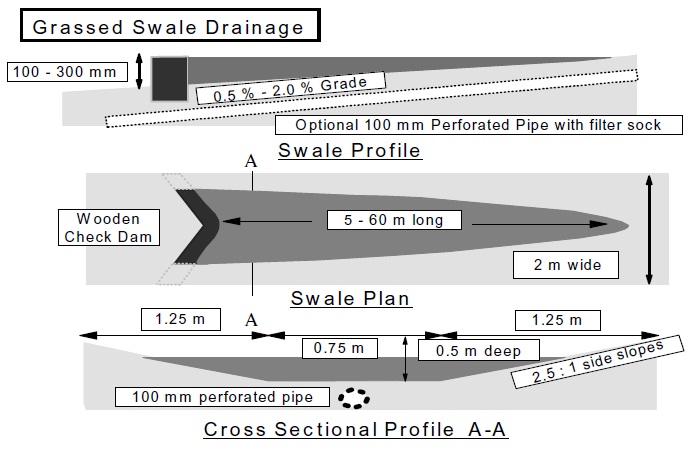

Grassed swales can be effective SWMPs for pollutant removal if designed properly. The water quality benefits associated with grassed swales depend on the contact area between the water and the swale and the swale slope. Deep narrow swales are less effective for pollutant removal compared to shallow wide swales. Given typical urban swale dimensions (0.75 m bottom width, 2.5:1 side slopes and 0.5 m depth), the contributing drainage area is generally limited to ≤ 2 ha (to maintain flow ≤ 0.15 m³/s and velocity ≤ 0.5 m/s). Table 4.5 indicates drainage area restrictions for various degrees of imperviousness, based on the assumptions given regarding channel cross-section, slope and cover. The swales evaluated in Table 4.5 are indicative of swales servicing an urban subdivision and not a transportation corridor.

| % Imperviousness | Maximum Drainage Area (ha) |

|---|---|

| 35 | 2.0 |

| 75 | 1.5 |

| 90 | 1.0 |

* Based on the following assumptions: trapezoidal channel, grassed lined (n = 0.035), slope of drainage area = 2%, 2.5:1 side slopes, 0.75 m bottom width, 0.5% channel slope, max. allowable Q = 0.15 m³/s, max. allowable V = 0.5 m/s.

Grassed swales are most effective for stormwater treatment when depth of flow is minimized, bottom width is maximized (≥ 0.75 m) and channel slope is minimized (e.g., ≤ 1%). Grassed swales with a slope up to 4% can be used for water quality purposes, but effectiveness diminishes as velocity increases. Grass should be allowed to grow higher than 75 mm to enhance the filtration of suspended solids.

Flow velocity

As a general guideline, grassed swales designed for water quality enhancement should be designed to convey the peak flow from a 4 hour 25 mm Chicago storm with a velocity ≤ 0.5 m/s. This guideline results in a requirement for wide, flat swales for larger drainage areas.

All grass swales must be evaluated under major system and minor system events to ensure that the swale can convey these storms effectively.

Ditch and culvert servicing

Ditch and culvert servicing is viable for lots which will accommodate swale lengths ≥ the culvert length underneath the driveway (not just the driveway pavement width). The swale length should also be ≥ 5 m for aesthetic and maintenance purposes. This is generally achievable for small lots (9 m) with single driveways or larger lots (15 m) with double driveways.

Winter operation

Swale systems which receive road runoff may have their infiltration capacity diminished over time, as salt effects on soil structure and clogging occur. Swale systems need to be maintained periodically (removal of accumulated sand and addition of mulch to the soil structure) in order to maintain their ability to infiltrate.

Relatively few design modifications are warranted for swales in cold climates, primarily due to their inherent simplicity. The following design modifications will tend to enhance their performance:

- Culverts should have a minimum diameter of 450 mm and a slope of 1% or greater; and

- For swale systems with an underdrain system, the underdrain should have a minimum diameter of 200 mm and should be bedded in gravel.

Performance enhancements

In order to promote infiltration of stormwater and the settling of pollutants, permanent check dams can be constructed at intervals along the swale system. These enhancements are best utilized on large swales where the cumulative flow depth and rate is not conducive to water quality enhancement (V ≥ 0.5 m/s or Q ≥ 0.15 m³/s during the 25 mm 4 hour storm). The distance between check dams can be calculated based on the depth of water at the check dam and the swale channel slope. For example, if a swale has a 1% slope and a check dam height of 0.3 m, the distance between check dams should be 30 metres (or less). Figure 4.10 illustrates an enhanced grassed swale design.

Figure 4.10: Enhanced Grass Swale

The dam should be constructed out of durable material (wood) which blends into the surrounding landscape. A rock check dam can be used if the swale is located in a remote area which is not subject to vandalism. The dam should be configured in a "V" shape to help minimize scour and erosion of the downstream swale banks ("V" points upstream). The dam should be securely embedded in the swale banks and some rip-rap should be placed downstream of the dam to prevent scour and erosion. The velocity of the design conveyance storm should be kept to approximately 1 m/s whereby smaller stone sizes can be utilized (75 mm diameter).

In areas where the swales are separated by driveway culverts, the culverts can be raised such that the driveway embankment (up to the invert of the driveway culvert) acts as the check dam. This design is more aesthetically appealing and negates the need for rip-rap erosion protection. The driveway culvert should be underdrained, however, to ensure that a permanent pool of water is not created in the swale.

A low flow opening can be created in the check dam to ensure a drawdown time ≤ 24 hours. However, recognizing the potential for clogging of the low flow opening, it is recommended that swales with check dams be underdrained in soils with poor infiltration potential (e.g., clays).

Standard 100 mm perforated pipe (or larger) should be used in combination with a filter sock in any type of underdrain system. Stone storage can be provided around perforated pipes that are installed under swales as a secondary storage medium to promote exfiltration. The appropriate depth of soil cover for the stone storage should be based on the surrounding soil conditions and the potential for frost heave. Figure 4.4 indicates the recommended soil cover based on the native soil type and trench depth.

All grass swales must be evaluated under major system and minor system events neglecting the storage/conveyance below the overflow of any check dam to ensure that the swale can convey these storms effectively.

Technical effectiveness

The effectiveness of swale systems is highly dependent on their design and maintenance. It is therefore recommended that they be used as part of a multi-component approach (i.e., one measure in a series of stormwater quality measures). They may be used for pre-treatment or polishing.

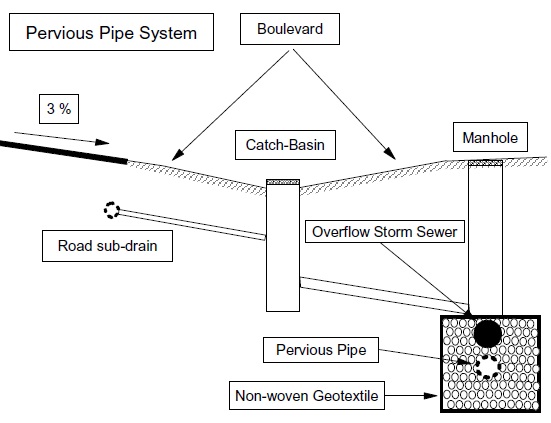

4.5.10 Pervious pipe systems

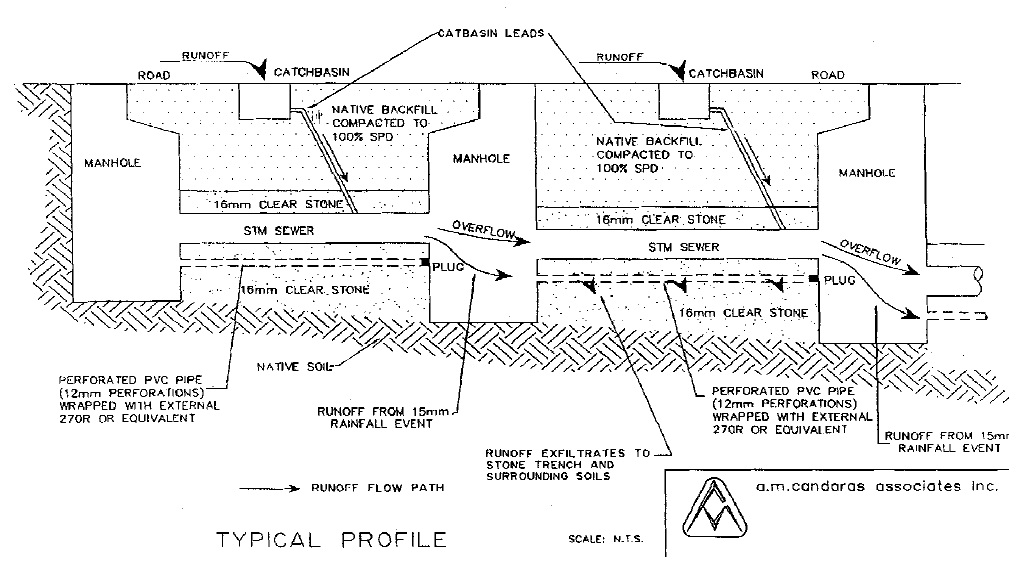

A few municipalities in Ontario (e.g., City of Nepean, City of Etobicoke) have implemented pervious pipe systems (Figure 4.11). These systems have experienced some problems in the past and are still experimental in nature.

Figure 4.11: Pervious Pipe System

Pervious pipe systems are perforated along their length allowing exfiltration of water through the pipe wall as it is conveyed downstream. The pipe itself is similar to that used for tile drainage on agricultural lands and is available with either a smooth-walled or corrugated interior.

Design guidance

Soils

Pervious pipes can be used where soils have a percolation rate ≥ 15 mm/h.

Water table depth

If a pervious pipe system is implemented in an area where the seasonally high water table is higher than the obvert of the pipe, the pipe will drain the groundwater table. In this scenario, depending on the native soil characteristics and whether the trench or pipe is wrapped in geotextile fabric, soil can be transported into the pipe system undermining the pipe foundation and leading to structural failure. Pervious pipe systems should not be implemented in areas where the seasonal high groundwater level is within 1 metre of the bottom of the storm sewer backfill to ensure this does not happen.

Depth to bedrock

The depth to bedrock should be greater than or equal to 1 metre below the bottom of the perforated pipe storage media to ensure adequate drainage/hydraulic potential.

Storage volume

A minimum storage volume equal to the runoff from a 4 hour 5 mm storm over the contributing drainage area should be accommodated in the pervious pipe bedding/storage medium without overflowing. The maximum target storage volume should be equal to the runoff from a 4 hour 15 mm storm over the contributing drainage area since 80% of all daily rainfall depths are less than this amount.

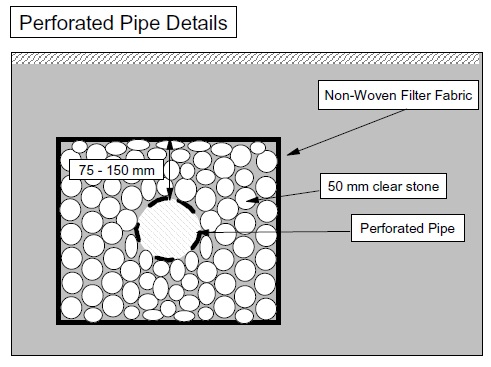

Storage configuration

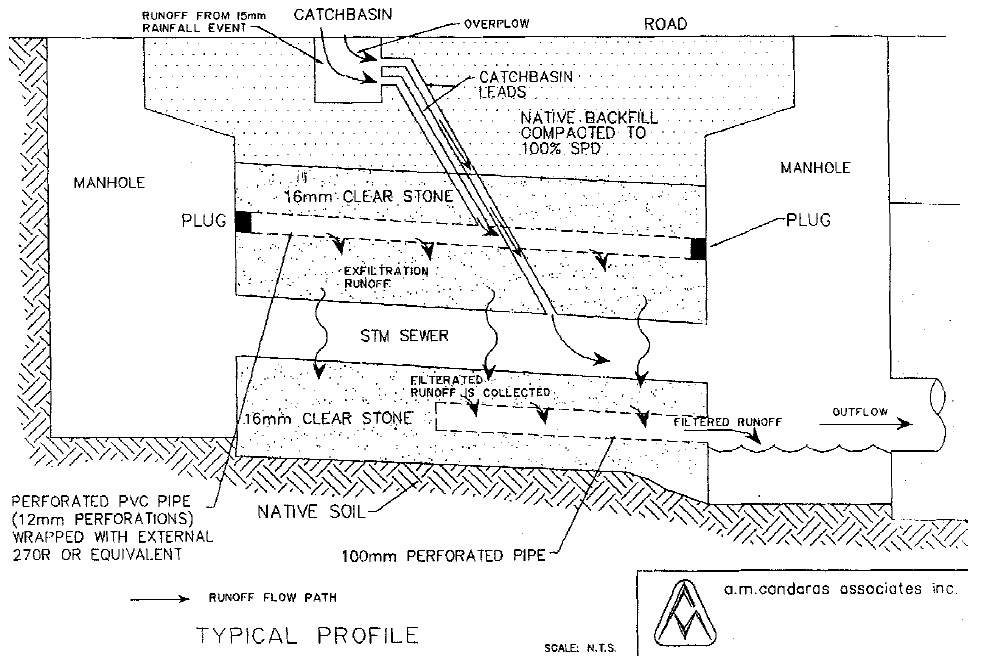

The exfiltration storage bedding layer should be 75 mm - 150 mm deep above the pervious pipe. A shallow bedding above the pipe is used since the storage above the pipe obvert is not utilized. The depth of bedding below the pipe obvert is dependent on the storm to be exfiltrated and the native soil material. Maximum depths which permit the bedding to drain in 24 hours can be calculated using Equation 4.2. Details of a pervious pipe end section are shown in Figure 4.12.

Figure 4.12: Pervious Pipe Details

The width of storage can be determined based on the rate of exfiltration from the pipe, the proposed length of pervious pipe, and the desired volume of runoff for infiltration. Section 4.8 provides methods for estimating the rate of exfiltration based on the number and size of pipe perforations.

Pipe slope

Pervious pipe systems should be implemented with reasonably flat slopes (0.5%) to promote exfiltration.

Pervious pipe bedding/storage media

Granular A material, or preferably clear stone (50 mm), should be used for the pipe bedding. Granular B is generally discouraged for use as pervious pipe bedding because it contains too many fines which may infiltrate the pipe system.

Pervious pipe systems should be constructed with anti-seepage collars to ensure that exfiltrated water does not travel along the pervious pipe bedding to the outlet. The spacing of anti-seepage collars should be based on the permeability of the native soil material and the pipe slope.

Pervious pipe

Smooth-walled (interior) pervious pipe is recommended for stormwater exfiltration since corrugated pipe has a higher potential for clogging. Furthermore, the maintenance of corrugated pipe via traditional sewer flushing is relatively ineffective since material becomes trapped in the corrugations. A minimum diameter of 200 mm should be used for the pervious pipe to facilitate maintenance.

Geotextiles

Although a filter sock can be used to prevent fines from entering the pipe system from the native material, the sock may prevent fines in stormwater from exfiltrating to the native material. As such, the use of a filter sock may cause clogging at the pipe/sock interface and decrease the longevity of the pervious pipe system.

Non-woven filter fabric installed at the interface between the pipe bedding (exfiltration storage) and the native soil can prevent native material from clogging the voids in the exfiltration storage media.

Pre-treatment

Pervious pipe systems are intended to convey road drainage which has high levels of suspended sediment. Pre-treatment of road drainage is necessary before it reaches the pervious pipe system to enhance the longevity of the system and reduce the potential for groundwater contamination. Pre-treatment of pervious pipe systems can best be achieved by the incorporation of grassed boulevards as pre-treatment areas (Figure 4.11). Stormwater is conveyed from the road to a low boulevard. The boulevard is graded towards catchbasins which are connected to the pervious pipe system. The catchbasins are raised such that water must reach a certain depth in the boulevard before it can overflow into the pervious pipe system. This will provide a sense of an urban cross- section while maintaining the benefits of traditional grass surfaced conveyance systems.

Technical effectiveness

Pervious pipe systems have been implemented in a number of municipalities. In areas where they have been implemented and monitored, numerous systems clogged after several years. The Regional Municipality of Ottawa-Carleton, however, has reported success with pervious pipe systems. Pervious pipe systems can be an effective alternative in retrofit situations (e.g., replacement of existing storm sewers), especially in areas where the catchment has stabilized.

The primary reason for system failure is clogging which can be attributed to several factors:

- Poor Design(storage media, lack of filter cloth, lack of pre-treatment);

- Poor construction practices;

- Inadequate stabilization of development before implementation of pervious pipe(construction timing); and

- Poor site physical conditions (soils, water table.)

One of the problems of implementing pervious pipe systems is construction timing. Ideally, for new development the pervious pipe system would be constructed after the houses have been built and the sod has been laid. However, the road sub-grade needs to be drained and requires the pipe system to be constructed with the road network. The pervious pipe system functions as the storm sewer and therefore must be constructed in its entirety. Although the catchbasins can be blocked to try and prevent sediment laden water from clogging the pervious pipe system, there is a great potential for clogging and compaction of the system during the construction phase of development.

Pre-treatment of road drainage before it reaches the pervious pipe system will enhance the longevity of the system and reduce the potential for groundwater contamination.

Etobicoke exfiltration system

The former City of Etobicoke (now City of Toronto) implemented a double pipe system (regular storm sewer over a perforated pipe) in a retrofit situation on a local road which is not subject to heavy salting or sanding. This system, while relatively expensive if applied in a "new development" situation, provides a means for implementing water quality controls on a retrofit basis in areas of existing development which are undergoing storm sewer rehabilitation or upgrading.