Alert: Low clearance of a locomotive in a construction tunnel boring machine gantry

Learn about the rules and regulations to reduce risk of injury or death when operating haulage locomotives in tunnel construction.

Hazard summary

A locomotive operator sustained fatal head injuries when their head became trapped in a gap between two overhead beams of a tunnel gantry while the haulage locomotive was in motion.

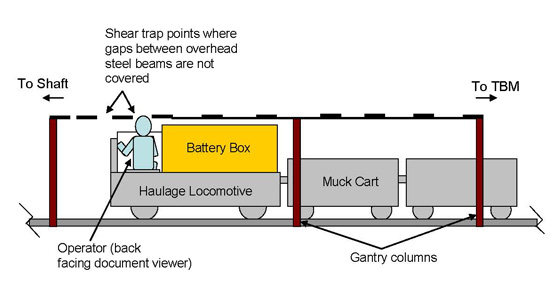

During tunnel construction, a locomotive is often used to haul excavated material from the tunnel boring machine (TBM) to a vertical shaft for disposal. There may be limited overhead clearance between the haulage locomotive and the beams of the gantry that is set up behind the TBM to support electrical and mechanical equipment in smaller tunnels – i.e., those that are less than two metres in diameter (see Figure 1, Low Clearance Tunnel Boring Machine Gantry).

Figure 1: Configuration that led to the fatality – Low Clearance TBM Gantry (worker’s head shall not be allowed to protrude beyond the highest point of the adjacent structure on the locomotive)

Locations and sectors

Tunnel construction projects where a haulage locomotive is used.

Applicable regulatory requirements and additional precautions

On a construction project where haulage locomotives are used in tunnel construction, workplace parties must comply with the requirements set out in sections 93 to 99 and 306 to 313 of Ontario Regulation 213/91 (Construction Projects) under the Occupational Health and Safety Act (OHSA).

Regulation 213/91 requires that any tunnel must have enough clear space for the passage of vehicles, such as haulage locomotives, and the movement of workers. The Regulation also requires that a constructor or employer provide a cab or screen to protect a worker who is exposed to an overhead hazard while operating a vehicle.

Additional steps to protect workers pursuant to clause 25(2)(h) of the OHSA may also be required. Constructors and employers should consider other precautions (e.g., additional barriers/guards) to protect workers from other types of hazards (e.g., contact with other moving vehicles) which workers may be exposed to when operating a haulage locomotive in a tunnel. Other types of considerations to protect workers would include:

- Conducting a hazard assessment regarding the risks and hazards for a worker operating a locomotive in areas with limited clearance.

- Providing workers with protection by a seat belt, harness or other effective means of restraint during operation of the equipment.

- Signage to warn workers of low clearance hazards, or automated devices to stop the locomotive in the event of a hazard.

Permission is granted to photocopy Ministry of Labour, Training and Skills Development alerts. Please distribute them widely and post them where people will see them.

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply and enforce these laws based on the facts they find in the workplace.