Growing lavender in Ontario: an introduction for prospective growers

Learn about growing lavender in Ontario. This technical information is for Ontario lavender producers.

ISSN 1198-712X, Published July 2018

Introduction

Lavender production has a lot of potential in Ontario for agri-tourism and value-added production. To successfully incorporate lavender production into your business, many factors need to be considered such as market potential, location, soil type and interpersonal skills. This fact sheet is intended to provide an overview of considerations for a beginner lavender grower.

Marketing

Lavender has a lot of market potential in Ontario, but there is little to no established market. This means that any marketing of lavender or lavender products is entirely the grower’s responsibility. Do not assume you can grow lavender and then drop it off somewhere for an established price. The marketing of lavender takes a lot of effort.

There are currently few options for wholesale lavender production, and most lavender sales are based on attracting visitors to the farm and/or the sale of value-added lavender products on or off the farm (see Figure 1).

It is the grower’s responsibility to find a market and build the business. The market should be identified before starting large-scale production on the farm. Start small to build the market over time and ensure the business is cost-effective before spending large amounts of money. Consider what is going to set your farm or products apart.

Working with other lavender producers or agri-tourism businesses may be an opportunity for cross-promotion. Lavender production usually requires substantial interaction with the public, which demands growers with good interpersonal skills. For more information on starting an agri-tourism operation, consult the OMAFRA fact sheet Developing an Agri-Tourism Operation in Ontario.

The Ontario Lavender Association (OLA) was established in 2010 to represent the interests of Ontario lavender growers. The Association’s vision is to increase the demand for lavender in Ontario. Being a member of the OLA is a good way to work with other producers to enhance the industry and to learn strategies from existing growers.

Find more information about the association.

The business of lavender

Lavender is rarely a grower’s only source of income. Most lavender producers either have jobs off the farm, grow other crops or raise livestock. This helps reduce the risks involved, especially when first getting started.

Combining lavender with another crop/product with additional agri-tourism or value-added product potential can add to the uniqueness of an operation. It is always best to prepare a cost-of-production budget ahead of time to price products properly and ensure there is potential for profits once established.

There is no established cost of production for lavender in Ontario. Growers will have to research the cost of materials/equipment and estimate the labour requirements, and compare these with the retail prices for various lavender products. Consider starting small and developing the cost of production once you can better estimate the labour requirements on a few plants. For more information on cost of production budgeting, see the Resources section.

Location

Agri-tourism–based lavender operations may not be successful in all areas. If you are on a side road well away from any other tourism destinations or population centres, it may be more difficult to attract visitors to the farm. Sale of value-added products online or in off-farm retail locations may be a better fit in this situation.

The other main consideration for your location is the soil type. Lavender requires well-drained soil. If the soil remains saturated for an extended period, lavender will not survive. Therefore, lavender either needs sandy or sandy loam soils or a slope that allows the water to drain rapidly away from the plant. Lavender cannot be grown successfully on clay or clay loam soil without a slope or substantial raised bed. Tile drainage helps in these situations, but doesn’t solve the problem because water will sit near the surface when the soil is frozen. Also, clay soil may not provide the aeration required for the root zone during rainy periods. Even sandy soils on flat ground may not have sufficient drainage if there is a high water table or clay layer farther down the soil profile.

Growers have inquired about the addition of sand to a clay soil to increase aeration. This is not practical because of the amount of sand that would be required to make any difference, and the complete destruction of the soil structure that would occur when trying to incorporate that much sand. For example, it would take 75 extended dump trucks full of pure sand to change the top 30 cm of a hectare of land from a heavy clay to a sandy clay. Even if this was economical, it would still not be suitable for lavender production, considering that sandy clay still behaves a lot like clay, and that the lower soil layers would still be heavy clay and would restrict drainage.

It is best to conduct a soil test ahead of time to determine if the site is suitable for lavender production and what modifications may be necessary. Take a separate soil sample for each distinct area of the farm. Each soil sample should consist of 10 or more soil cores taken over the sample area to a depth of 15–20 cm and thoroughly mixed. Consult the OMAFRA fact sheet Soil Sampling and Analysis for Managing Crop Nutrients for more information.

Submit soil samples to an OMAFRA-accredited soil lab for a standard soil test (including pH, buffer pH, P, K and other nutrients) and a soil texture analysis (sand, silt, clay content). Accredited laboratories are listed on the OMAFRA website.

The lab will be able to provide some interpretation of the soil test. Additional information on interpreting soil test results is available on the OMAFRA website.

Lavender types and climate

Two main types of lavender can be grown in Ontario – Lavandula angustifolia (English lavender) and Lavandula x intermedia (lavandins or French lavender) (see Figure 2). L. angustifolia will be called “angustifolia” in this fact sheet to reduce confusion with other types and cultivars of lavender. They are mainly grown for their sweeter scent, more showy flowers and earlier blooming. They are most suitable for culinary purposes and aromatic products. Lavandin cultivars have more of a medicinal scent due to high camphor content and are mainly grown for use in personal care products and sachets. They grow much faster, with longer stems that make good flower bundles, and their scent lasts longer in stuffed products. Other species of lavender such as L. stoechas (Spanish lavender), L. dentata or L. latifolia (Spike lavender) are not hardy in Ontario.

Angustifolia lavender is hardy to Zone 5. It may be possible to grow it in colder zones with winter protection and/or consistent snow cover. Over the extremely cold winters of 2013–2014 and 2014–2015, there was substantial damage to angustifolia cultivars in Ontario, but the plants generally survived. These cultivars do best when the cold winter winds are blocked by a wind barrier such as a hedge row or snow fence. The cultivar “Folgate” has proven to be the hardiest of all cultivars trialed in Ontario.

Lavandin cultivars are generally only hardy to Zone 6 without protection. They may survive many winters and then die in colder winters. Some cultivars, such as “Provence,” “Alba” and “Tuscan Blue” are not hardy anywhere in Ontario and are not a good choice for large-scale plantings, even with winter protection. Over the winter of 2013–2014, many lavandin plants died if they did not have a good insulating snow cover. It is recommended that these plants be protected over the winter with row covers. Consult the ONspecialtycrops blog for articles summarizing the results of cultivar and row cover trials conducted in Ontario.

Growing lavender is a challenge — do not expect a perfect lavender field and high yield every year. Even when you think you have a healthy crop, any one of several pests can reduce the yield or marketability of the crop.

Sourcing plants

Lavender grown from seed is highly variable in appearance and characteristics. Lavender is normally propagated from vegetative cuttings so the new plants are identical to the parent plants. It can take several months for the new plants to be ready to plant in the field.

Many propagators require orders to be placed well in advance so the plants will be ready for spring planting. It is best to find propagators and place orders in the fall before spring planting.

Finding propagators of specific cultivars can be difficult. Consult other growers, the Ontario Lavender Association, or conduct an Internet search to identify propagators.

Lavender plants are usually purchased in 72 or 50-cell plug trays (Figure 3) or in 5–10-cm diameter pots. Larger plants are more expensive but result in more rapid establishment in the field.

Growing lavender

Lavender is a labour-intensive crop. Hand labour is generally required for planting, weed control, pruning, harvesting and product development.

Growers with several hectares or more of lavender could benefit from the purchase of small-scale harvesting and pruning equipment. It is unlikely that the purchase of large-scale equipment used in Europe will ever be justified in Ontario due to the high cost of the equipment.

Weed control is one of the biggest labour requirements. The labour required for weed control can be significantly reduced with the use of plastic mulches (Figure 4). Black solid or woven plastic mulches are often used in the row, with mowed grass between the rows (Figure 5).

Experience shows that black woven plastic mulch (ground cloth) lasts longer than thick solid black mulch (tree mulch). Machinery is available for rent or purchase to apply the mulch. Planting usually has to be done by hand. If using plastic mulch, it is best to put drip-irrigation tape under the row for both irrigation and fertilization (fertigation). Although lavender is tolerant of dry conditions, it does not grow well under dry conditions. Irrigation improves crop growth and establishment.

Lavender growers often make the assumption that lavender does not need much fertilization because it is adapted to soils very low in fertility. While lavender can survive in low-fertility soils, optimal fertility greatly improves plant growth, yield and health of the plants.

Currently there are no established Ontario recommendations for lavender. OMAFRA has created a guide to phosphorus and potassium fertilization. See the Resources section for a link to the Specialty Cropportunities resource.

The results of a nitrogen rate trial conducted in Ontario are presented on the ONspecialtycrops blog.

Harvest and postharvest

Flower and bud harvest

Lavender typically blooms from mid-June to late July in Ontario. The timing of harvest will depend on the end use of the lavender. Fresh and dried lavender bundles, including those bundles that will be stripped for buds, are best harvested right at the beginning of bloom when the first buds begin to open. This maximizes the size and colour of the buds and minimizes the number of brown and dead petals retained on the bundle.

Preliminary research conducted by OMAFRA and Apple Hill Lavender suggests that bundles that will be marketed fresh may have to be harvested up to a week after the start of bloom to ensure the stem has fully stiffened before harvest. This prevents the flowers from arching over as they wilt. Since bundle harvest removes the flowers before they reach their peak colour, farms open to the public usually have separate fields allocated for bundle harvest so agri-tourism activities can proceed as long as possible.

Harvest for oil distillation

Harvest for essential oil production usually occurs after peak bloom but can occur later to extend the period the flowers are in the field for agri-tourism activities. Lavender oil quality will gradually degrade after peak bloom, but marketable oil has been collected up to a month after bloom. However, some cultivars are prone to buds dropping off the stem once bloom is finished, which will greatly reduce the oil production the longer they are left in the field. Also, wet weather can lead to fungal and bacterial growth on the dead flowers and stems, and this can degrade the quality of the oil. It will be important to balance the need to extend the agri-tourism activity period and the need to collect flowers as soon as possible after bloom. Late harvest can also delay pruning of the plants, which will reduce the length of time the plants have to recover vegetative growth before the winter.

Machinery is also available to harvest the flowers for oil extraction and reduce labour costs, but can lead to lower quality oil if too many leaves are left on the stems. Machinery will miss some of the flowers on each plant, but these losses are offset by lower labour costs.

Postharvest handling

Bundles are usually tied with an elastic band after harvest so they don’t fall apart when the stems shrink after drying. Bundles that contain too many stems (for example over 2 cm diameter) may not dry fast enough and can rot before they are dry. They should be hung in a warm dry place with good air flow. However, hanging in an open structure such as a barn may lead to contamination with bird or mouse droppings and the possibility of contamination with human pathogens such as salmonella or E. coli. It is important to treat lavender as a food product, since some of the buds will end up being used in culinary products. Wait until after the bundles have dried to combine them into larger bundles intended for sale.

Using post-harvest equipment to strip buds off the stems and clean the buds reduces labour requirements. Some of this equipment can be made by hand or modified from other existing tools. Most contain two large stiff brushes (for example chimney brushes) close together turning in opposite directions. The buds are pulled off the stem as the dried bundles are inserted between the brushes. The same tool can be used to clean dead leaves off the bottom of bundles that will be sold for cut dried flowers. Seed-cleaning equipment has often been used to clean the buds after stripping to remove stem, leaf and flower debris that may be present. Sieves can also be used for this purpose.

Oil distillation

Growers also need to consider whether they are going to create their own essential oil. Many models and sizes of distillers are available on the market. Be sure the size of the distiller matches the size of the operation. A good overview of this equipment is provided in the guide “Growing and Marketing Lavender” (see Resources).

Lavender harvested for oil extraction is best distilled immediately after harvest. Research has shown that the most efficient oil extraction can be achieved by leaving about 20 cm of stem below the flowers and packing the distiller evenly. The stems keep some air space between the buds to allow steam to penetrate but not so much that channels are created for steam to bypass most of the buds.

Pruning lavender

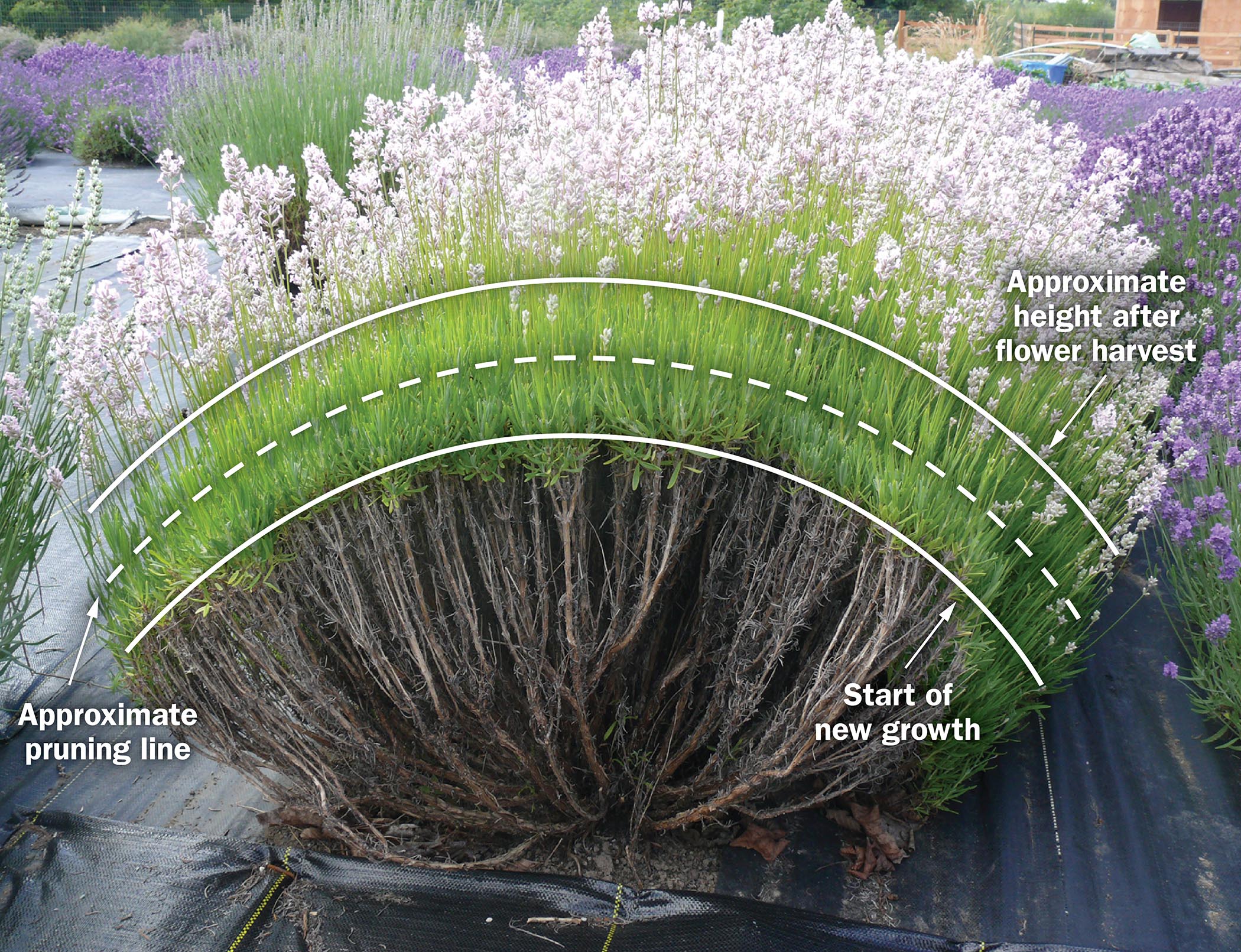

Pruning lavender is very important for ensuring a healthy plant that does not collapse under the weight of the flowers during bloom. Experience shows that pruning is best done after flower harvest in Ontario. If there is significant regrowth, a second, lighter pruning can be done in late summer. Fall pruning, which is recommended in warmer regions, can lead to more winter kill in Ontario. Spring pruning should only be done to remove winter-killed tissues, since flowering potential can be impacted if healthy material is removed prior to flowering.

Once plants are harvested, prune plants in a rounded shape by removing approximately a third of that year’s growth (green tissue) not including the flower stem (Figure 6). A heavier pruning to 50% of the green tissue can be done if plants have become overgrown and loose. Cutting back into the woody growth can harm or even kill the plant, especially older plants.

Newly planted plants, especially angustifolias, will tend to send out a few flowers throughout the growing season. These should be pruned out in the first year to encourage more rounded growth of the plant. Some angustifolia cultivars (such as “Buena Vista”) will have a smaller second bloom in the fall every year. These flowers can be harvested for bundles but are often frozen off before they reach full bloom. There is no need to prune these out.

Conclusion

Lavender production in Ontario has many challenges but can also provide an opportunity for additional income. It is important for potential growers to know the potential challenges involved in lavender production before placing an order for plants. Lavender may not be a viable option for growers in the wrong location or with the wrong soil type. As with most specialty crops, starting small can help growers learn production techniques and identify markets. Connecting with other growers and joining the Ontario Lavender Association is the best way to learn about the crop and determine if this is the right crop for your operation.

Resources

The following resources provide a good starting point for understanding the production and post-harvest requirements of lavender.

- ONspecialtycrops blog

Lavender information is found under Herbs. - Specialty Cropportunities

This resource provides a good overview of specialty crop production and marketing and includes crop profiles of over 100 specialty crops, including lavender.

It also contains information on phosphorus and potassium fertility of specialty crops, including lavender you can access by:- going to ontario.ca/crops

- clicking on Specialty Cropportunities, “Herbs,” then “Lavender”

- clicking on the link provided in the “Fertility” section of the Lavender crop profile

- Direct farm marketing business resource guide

This guide provides an overview of best practices for direct farm marketing, along with case studies, infosheets and template forms for record keeping.

Topics covered include:- marketing research

- social media

- costing and pricing

- selecting the right marketing channel

- assessing performance

- managing expectations

- OMAFRA food safety and traceability information

- Getting started in agritourism, Cornell Cooperative Extension

- Growing and Marketing Lavender, Curtis Beus, Washington State University

This guide provides a good overview of all aspects of lavender production. Note: Not all production practices will work in Ontario’s climate. For example, fall pruning is not advised in Ontario. Mid to late-summer is best in Ontario. Also, Ontario has pests, such as four-lined plant bug, that are not an issue in Washington. - Guide to cost of production budgeting OMAFRA fact sheet

- Managing risk on farms open to the public OMAFRA fact sheet

- OMAFRA Publication 858 programs and services for Ontario farmers

- Starting a farm in Ontario - business information bundle for new farmers

Provides an overview of business planning and resources for new growers.

This fact sheet was authored by Sean Westerveld, ginseng and herbs specialist, Simcoe, OMAFRA.