Offset initiative protocols for Ontario’s cap and trade program

Read Ontario’s rules and requirements to create initiatives that could be considered eligible for offset credits that can be used for compliance under the cap and trade program. The first protocol is for landfill gas.

We have developed a plan to wind down the program.

Contact us if you have any questions.

The Protocols are only available in English

Cette publication hautement spécialisée n’est disponible qu’en anglais en vertu du règlement 441/97, qui en exempte l’application de la Loi sur les services en français. Pour obtenir de l’aide en français, veuillez communiquer avec le Ministère de l’Environnement et de l’Action en matière de changement climatique au Catherine How,

© Queen’s Printer for Ontario, 2018

Introduction

The Ontario Offset Credits regulation (the Regulation) and incorporated protocols have been designed to be consistent with the Western Climate Initiative’s (WCI) Offset System Essential Elements Final Recommendations Paper, July 2010 in order to supply high quality, compliance-grade offset credits for use in Ontario’s cap and trade program.

Protocols are a central component of Ontario’s offset program and are incorporated by reference in the Regulation. These two components work together to set out the requirements that must be met in order to be eligible for the creation and issuance of Ontario offset credits. The Regulation defines the overall process, criteria and administrative requirements involved in the creation and issuance of an offset credit, while the incorporated protocols set out the eligibility criteria and requirements specific to each initiative type or class.

The Regulation requires the use of an approved protocol to quantify greenhouse gas reductions, avoidances or removals. Each protocol establishes specific eligibility criteria, baseline scenario and initiative calculation methods, monitoring, data management and reporting requirements specific to the class of offset initiatives. This document contains the protocols that have been approved for use with respect to specific classes of offset initiatives for achieving greenhouse gas reductions, avoidances or removals that are real, quantifiable, verifiable and additional.

Abbreviations and Acronyms

- atm

- Atmosphere

- CEMS

- Continuous emissions monitoring system

- CH4

- Methane

- CNG

- Compressed natural gas

- CO2

- Carbon dioxide

- GHG

- Greenhouse gas

- GJ/h

- Gigajoule per hour

- GWP

- Global Warming Potential

- K

- Kelvin

- Kg

- Kilogram

- kPa

- Kilopascal

- kWh

- Kilowatt-hour

- L

- Litres

- Mg

- Mega gram (1,000,000 grams or one tonne, or “t”)

- m3

- Cubic metres

- N2O

- Nitrous oxide

- NG

- Natural gas

- SSR

- Source, sink, and reservoir

- t

- Metric ton (or tonne)

Definitions

- Anthropogenic emissions

- means greenhouse gas emissions (GHGs) resulting from human activity that are considered to be an unnatural component of the carbon cycle (e.g., fossil fuel destruction, de-forestation, etc.).

- Baseline scenario emissions

- means GHG emissions that would have occurred within the GHG Assessment Boundary if not for the initiative.

- Initiative emissions

- means GHG emissions that occur within the GHG Assessment Boundary as a result of the initiative.

- NIR

- means the National Inventory Report: Greenhouse Gas Sources and Sinks in Canada, Part 3 published by Environment and Climate Change Canada

- O. Reg. 143/16

- means Ontario’s Quantification Reporting and Verification of Greenhouse Gas Emissions regulation as amended from time to time.

- QRV Guideline

- means Ontario’s Guideline for Quantification Reporting and Verification of Greenhouse Gas Emissions, July 2017, as amended from time to time.

Landfill Initiative Protocol

Landfill Methane Destruction

Protocol Version 2

Dated: April 12, 2018

1. Introduction

This protocol sets out the requirements that will enable a sponsor to undertake an LFG GHG reduction initiative for the purpose of registering and receiving offset credits in Ontario’s cap and trade program.

The following sections outline the definition of an LFG GHG reduction initiative, the specific eligibility criteria, baseline scenario and initiative calculation methods, monitoring, data management and reporting requirements that apply to LFG GHG reduction initiatives.

2. Definitions

- Biogenic CO2 emissions

- means CO2 emissions resulting from the destruction or aerobic decomposition of organic matter. Biogenic emissions are considered to be a natural part of the carbon cycle, as opposed to anthropogenic emissions.

- Closed landfill

- means a landfill that has ceased receiving waste on or before the day the sponsor applied for initial registration of the offset initiative or on or before the day the sponsor applied to be eligible for Ontario offset credits in respect of a subsequent crediting period (application for subsequent crediting period)

- Direct use pipeline

- means a pipeline that goes directly from a landfill gas collection system to one or more facilities that uses the gas in a boiler or other device at the facility.

- Eligible destruction device

- means a device that is set out in Table A.1 of this protocol.

- Eligible landfill

- means a landfill that meets the criteria set out in Section 4 of this protocol.

- GHG assessment boundary

- means all the GHG sources, sinks and reservoirs (SSRs) that are required to be assessed because they are identified as included in Table 5.1.

- Ineligible destruction device

- means a device that is not an eligible destruction device or is an eligible destruction device that was in use prior to a start up or testing period.

- Landfill gas (LFG)

- means the gas resulting from the decomposition of waste that has been landfilled.

- Landfill site

- means a site where waste is being landfilled or has been landfilled.

- Monitoring device

- means any device used to monitor the LFG collection system and eligible or ineligible destruction devices (e.g., flow meters, methane (CH4) analyzers, temperature sensors, thermocouples, etc.).

- Natural gas transmission pipeline

- has the same meaning as “pipeline transportation system” in O. Reg. 143/16.

- Non-beneficial destruction device

- means an ineligible device that destroys CH4 from LFG without also producing a beneficial output, such as useful thermal energy or electricity.

3. LFG GHG Reduction Initiative

3.1 Initiative Definition

- The LFG GHG reduction initiative is defined as an initiative that uses an eligible destruction device to destroy CH4 from LFG collected at an eligible landfill site.

3.2 Initiative Start Date

- The start date of an initiative is defined in s. 2 of the Regulation and is determined as follows: If reductions from the initiative are first achieved during a start-up or testing period, the start date occurs after the end of the start-up or testing period, which period cannot exceed six (6) months.

4. Eligibility

4.1 General Requirements

- A legal requirement to destroy the CH4 from LFG must not be applicable to the landfill.

- An LFG GHG reduction initiative must capture and destroy landfill gas that, in the absence of the LFG GHG reduction initiative, would have been emitted to the atmosphere.

- Where the landfill site has a geomembrane, it shall meet the requirements of Ontario Regulation 232/98 (Landfilling Sites).

4.2 Eligibility Criteria

- In order to be eligible, a LFG initiative shall use an eligible device to destroy CH4 from LFG collected at the landfill site and meet all applicable eligibility criteria in Sections 4.2.1 to 4.2.4.

4.2.1 Operational Landfill

-

An operational landfill site shall:

- receive less than 50,000 tonnes of waste annually

footnote 1 ; - have a total capacity of less than 1.5 million cubic meters; and

-

have either:

- less than 450,000 tonnes of waste in place

footnote 2 ; or -

a heat input capacity of less than 3 GJ/h from the CH4 collected from the LFG that has been calculated in accordance with the following steps:

-

calculate the quantity of CH4 emitted each hour using the following method:

- determine the quantity of CH4 generated using the Landgem software of the U.S. Environmental Protection Agency (USEPA), applying the following rules:

- determine the quantity of residual materials disposed of annually using the data available since the opening of the landfill site;

- use, for the parameters “k” and “Lo” of the software referred to in paragraph 1, the most recent parameters from the “National Inventory Report” (NIR) on GHG emissions prepared by Environment Canada;

- use a percentage of 50% as the percentage of CH4 in LFG; and

- use a value of 0.667 kg per cubic metre at standard conditions as the density of CH4.

- determine the quantity of CH4 generated using the Landgem software of the U.S. Environmental Protection Agency (USEPA), applying the following rules:

- Determine the quantity of CH4 captured each hour by multiplying the quantity of CH4 emitted each hour, obtained in A above, by 0.75; and

- Determine the heat capacity by multiplying the quantity of CH4 captured each hour, obtained in B above, by 0.0359 GJ/m3 the high heat value of the CH4 portion of the LFG as set out in the QRV Guideline

-

- less than 450,000 tonnes of waste in place

- receive less than 50,000 tonnes of waste annually

4.2.2 Closed Landfills

-

A closed landfill site shall:

- If the site opened or expanded between August 1998 and 2005 (inclusive), have had a maximum capacity of less than 3 million cubic meters;

- If the site opened or was expanded between 2006 and 2008 (inclusive), have received less than 50,000 tonnes of waste annually

footnote 3 and had a maximum capacity of less than 1.5 million cubic meters; - If the site was in operation in 2009 or a subsequent year, have received less than 50,000 tonnes of waste annually

footnote 4 and had a maximum capacity of less than 1.5 million cubic meters; and -

On the date of registration with the Ministry, in every case, have either:

- less than 450,000 tonnes of waste in place

footnote 5 , or - a heat input capacity of less than 3 GJ/h from the CH4 collected from the LFG. (see section 4.2.1 a) 3. ii. For method)

- less than 450,000 tonnes of waste in place

4.2.3 Open or Closed Landfills Outside Ontario

-

The following eligibility rule applies to an LFG initiative located at an operational or closed landfill outside of Ontario which has legal requirements with respect to the amount of waste received, landfill capacity and the amount of waste in place or heat input capacity that apply to the landfill:

- Where the legal requirement that applies to the landfill imposes a lower amount in respect of any eligibility criterion set out in 4.2.1 and 4.2.2, it is the lower amount that shall be used to determine eligibility.

4.2.4 Open or Closed Landfills–Specific Class

- Open or closed landfill sites of pulp and paper mills, sawmills or oriented strandboard manufacturing facilities do not have to meet the eligibility requirements in 4.2.1 or 4.2.2 but must meet all other eligibility criteria in this protocol.

5. GHG Assessment Boundary

-

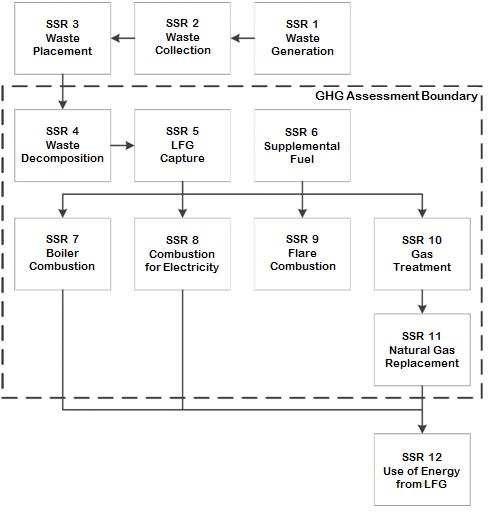

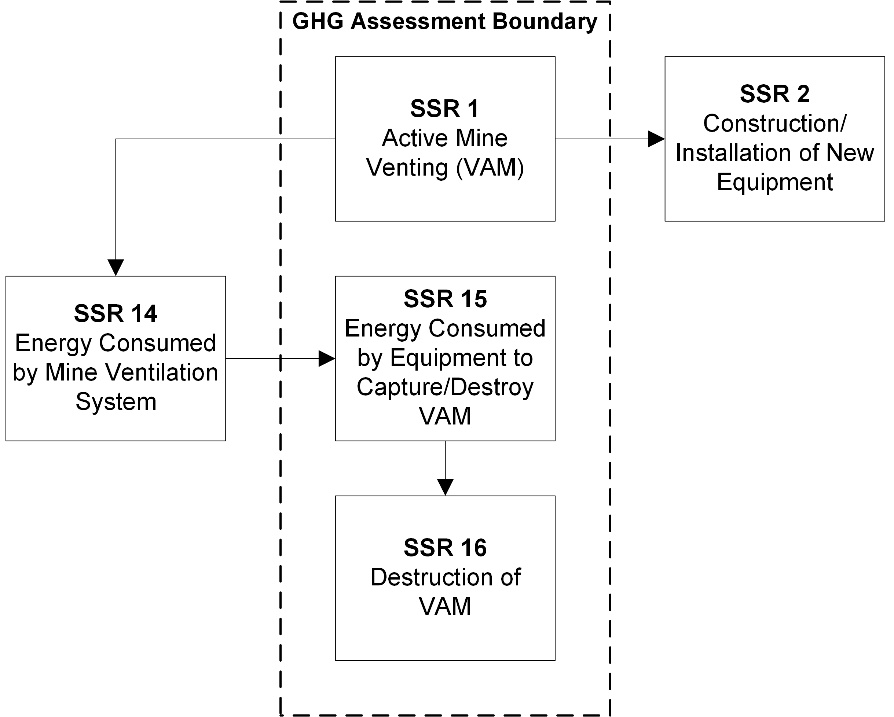

The following SSRs have been considered in determining the GHG Assessment Boundary.

- Figure 5.1 illustrates all relevant GHG SSRs associated with landfill activities and delineates the GHG Assessment Boundary.

- Table 5.1 provides greater detail on each relevant GHG SSR associated with landfill activities and includes justification for their inclusion or exclusion from the GHG Assessment Boundary.

Figure 5.1 Illustration of the GHG Assessment Boundary

| SSR | Source Description | Gas | Relevant to Baseline Scenario (B) or Initiative (I) | Included or Excluded | Justification/Explanation |

|---|---|---|---|---|---|

| 1 | Waste Generation | N/A | B, I | Excluded | GHG emissions from this source are assumed to be equal in the baseline scenario and initiative |

| 2 | Waste Collection | CO2, CH4, N2O | B, I | Excluded | GHG emissions from this source are assumed to be equal in the baseline scenario and initiative |

| 3 | Waste Placement | CO2, CH4, N2O | B, I | Excluded | GHG emissions from this source are assumed to be equal in the baseline scenario and initiative |

| 4 | Decomposition of Waste that has been landfilled | CO2 | B, I | Excluded | Biogenic CO2 emissions are excluded |

| 4 | Decomposition of Waste that has been landfilled | CH4 | B, I | Included | Primary source of GHG emissions in the baseline scenario. Calculated based on destruction in ineligible and eligible destruction devices |

| 5 | LFG Collection System | CO2 | B,I | Included | The CO2 emissions associated with the energy used for collection of LFG |

| 5 | LFG Collection System | CH4 | B,I | Excluded | Fugitive CH4 released prior to reaching the flow meter is assumed to have been released in the baseline scenario. CH4 emissions from energy are assumed to be very small |

| 5 | LFG Collection System | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 6 | Supplemental Fuel | CO2 | B,I | Included | The initiative may use supplemental fossil fuel, to enhance the heat content of the LFG which results in non-biogenic GHG emissions |

| 6 | Supplemental Fuel | CH4 | B,I | Included | Calculated based on destruction efficiency of the eligible destruction device |

| 6 | Supplemental Fuel | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 7 | LFG Destruction-Boiler | CO2 | B,I | Excluded | Biogenic CO2 emissions are excluded |

| 7 | LFG Destruction-Boiler | CH4 | B,I | Included | Calculated based on destruction efficiency of the ineligible or eligible device |

| 7 | LFG Destruction- Boiler | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 8 | LFG Destruction- Combustion engine, turbine, micro turbine | CO2 | B,I | Excluded | Biogenic CO2 emissions are excluded |

| 8 | LFG Destruction- Combustion engine, turbine, micro turbine | CH4 | B,I | Included | Calculated based on destruction efficiency of the ineligible or eligible destruction device |

| 8 | LFG Destruction- Combustion engine, turbine, micro turbine | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 9 | LFG Destruction– Flare | CO2 | B,I | Excluded | Biogenic CO2 emissions are excluded |

| 9 | LFG Destruction– Flare | CH4 | B,I | Included | Calculated based on destruction efficiency of the ineligible or eligible destruction device |

| 9 | LFG Destruction– Flare | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 10 | LFG Treatment and Upgrade | CO2 | B,I | Included | Landfill initiatives may result in GHG emissions from additional energy used to treat and/or upgrade the CH4 concentration of the LFG |

| 10 | LFG Treatment and Upgrade | CH4 | B,I | Excluded | This emission source is assumed to be very small |

| 10 | LFG Treatment and Upgrade | N2O | B,I | Excluded | This emission source is assumed to be very small |

| 11 | LFG Destruction– Natural Gas Replacement End Use (direct use boiler, NG transmission pipeline, vehicle fuel, CH4 liquefaction) | CO2 | B,I | Excluded | Biogenic emissions are excluded |

| 11 | LFG Destruction– Natural Gas Replacement End Use (direct use boiler, NG transmission pipeline, vehicle fuel, CH4 liquefaction) | CH4 | B,I | Included | Calculated based on destruction efficiency of the ineligible or eligible destruction device |

| 11 | LFG Destruction– Natural Gas Replacement End Use (direct use boiler, NG transmission pipeline, vehicle fuel, CH4 liquefaction) | N2O | B,I | Excluded | Assumed to be very small |

| 12 | Use of Energy from LFG to Displace Fossil Energy | CO2 | B,I | Excluded | This protocol does not include crediting for displacement of GHG emissions from grid-connected electricity or fossil fuels |

6. Calculation of Emission Reductions

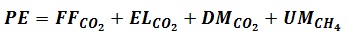

- Reductions of GHG emissions from the initiative during a reporting period shall be calculated in accordance with Equation 6.1.

-

GHG emission reductions shall not be calculated for any period during a reporting period in which:

- the device monitoring an eligible destruction device was not operating; or

- the eligible destruction device was not operating.

Equation 6.1 Calculating Initiative GHG Emission Reductions

ER = BE − PE

Where,

ER = GHG emission reductions from the initiative during the reporting period (tCO2e)

BE = Baseline scenario emissions during the reporting period, calculated using Equation 6.2 (tCO2e)

PE = Initiative emissions during the reporting period, calculated using Equation 6.11 (tCO2e)

6.1 Calculation of Baseline Scenario Emissions

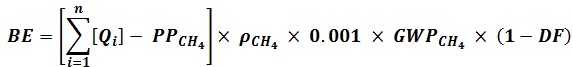

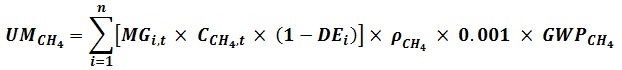

- Baseline scenario emissions of the initiative for a reporting period shall be calculated in accordance with Equation 6.2.

Equation 6.2 Calculating Baseline Scenario Emissions

BE = (CH4DestPR) × GWPCH4 × (1 − OX) × (1 − DF) − Destbase × (1 − ox)

Where,

BE = Baseline scenario emissions during the reporting period (tCO2e)

CH4DestPR = Total quantity of CH4 destroyed by all eligible destruction devices during the reporting period, calculated in accordance with Equation 6.3 (tCH4)

GWPCH4 = Global Warming Potential for CH4, as set out in O. Reg. 143/16 (tCO2e/tCH4)

OX = Factor for the oxidation of CH4 by soil bacteria, determined in accordance with Section 7.2.7

DF = Discount factor is 0 or 0.1, determined in accordance with Section 7.2.3

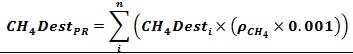

Destbase = Adjustment to account for baseline scenario CH4 destruction calculated in accordance with Equation 6.6 (tCO2e)Equation 6.3 Total Landfill CH4 Destroyed

Where,

CH4DestPR = Total quantity of CH4 destroyed by all eligible destruction devices during the reporting period (tCH4)

n = Number of eligible destruction devices

i = Eligible destruction device

CH4Desti = Net quantity of CH4 destroyed by each eligible destruction device i during the reporting period, calculated in accordance with Equation 6.4 (m3 CH4)

ρCH4 = Density of CH4 at the reference temperature, as set out in Table A.2 (kg CH4/m3CH4)

0.001 = Conversion factor, kilograms to tonnes (tCH4/kgCH4)Equation 6.4 Net Landfill CH4 Emissions Destroyed by each Eligible Destruction Device

CH4Desti = Qi × DEi

Where,

CH4Desti = Net quantity of CH4 destroyed by eligible destruction device i during the reporting period (m3CH4)

Qi = Total quantity of CH4 sent to eligible destruction device i during the reporting period, calculated in accordance with Equation 6.5 (m3CH4)

i = Eligible destruction device

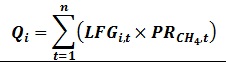

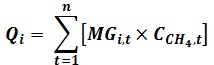

DEi = CH4 destruction efficiency of eligible destruction device i, as set out in Table A.1Equation 6.5 Total Quantity of CH4 Sent to Each Eligible Device

Where,

Qi = Total quantity of CH4 sent to eligible destruction device i during the reporting period (m3CH4)

n = Number of measurement periods

t = Measurement period as set out in Table 7.1

LFGi,t = Corrected volume of LFG sent to eligible destruction device “i” during measurement period “t”, determined in accordance with Section 7.2.2 (m3LFG)

PRCH4,t = Average ratio of CH4 to LFG in the LFG, for the measurement period “t” (m3CH4/m3LFG) - Equation 6.6 shall be used to determine the baseline adjustment amount where there was CH4 destruction before the state date of the initiative.

Equation 6.6 Baseline Adjustment for Destruction in the Baseline Scenario

Destbase = BDdiscount × ρCH4 × 0.001 × GWPCH4

Where,

Destbase = Adjustment to account for baseline scenario CH4 destruction (tCO2e)

BDdiscount = Amount of CH4 that would have been destroyed during the reporting period, in the baseline scenario without the initiative, calculated in accordance with Subsection 6.1(c) (m3 CH4)

ρCH$ = Density of CH4 at the reference temperature, as set out in Table A.2 (kgCH4/m3CH4)

0.001 = Conversion factor, kilograms to tonnes(tCH4/kgCH4)

GWPCH4 = Global Warming Potential for CH4, as set out in O. Reg. 143/16 (tCO2e/tCH4) -

BDdiscount shall be determined using either:

- BDdiscount that is equal to the measured quantity of CH4 that is recovered through an LFG collection system installed into the corresponding cell or waste mass where the LFG flow was calculated using Equation 6.3.

footnote 6 - BDdiscount that has been calculated per Equation 6.7 and monitored per Section 7.2.6.

Equation 6.7 Calculating Baseline Adjustment for Ineligible Devices

BDdiscount = LFGB × BCH4

Where,

BDdiscount = The amount of CH4 that would have been destroyed during the reporting period, in the baseline scenario. (m3 CH4)

LFGB = Amount of LFG that would have been destroyed by an ineligible destruction device during the reporting period, calculated in accordance with Equation 6.8 (m3LFG)

BCH4 = The average ratio of CH4 to LFG, in the LFG that would have been destroyed by an ineligible destruction device during the reporting period, calculated in accordance with Equation 6.9. (m3 CH4/m3 LFG)Equation 6.8 Calculating Baseline Discount for an Ineligible Device

LFGB = 525,600 × 90%UCL (LFGflowrate)

Where,

LFGB = LFG that would have been destroyed by an ineligible destruction device during the reporting period (m3 LFG)

90%UCL (LFGflowrate) = 90% upper confidence limit of the average flow rate in the metered period, calculated in accordance with Equation 6.10 (m3/min LFG)

525,600 = Minutes in one year (min/yr)Equation 6.9 Calculating the average ratio of CH4 to LFG for in Ineligible Device

BCH4 = 90%UCL (BCH4, t)

Where,

BCH4 = The average ratio of CH4 to LFG in the LFG, that would have been destroyed by an ineligible device during the reporting period (m3 CH4/m3 LFG)

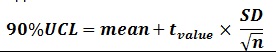

90%UCL (BCH4,t) = 90% upper confidence limit of the average CH4 concentration in the metered period, calculated in accordance with Equation 6.10 (m3 CH4/m3 LFG)Equation 6.10 Calculating 90% Upper Confidence Limit

Where,

mean = Sample mean (of BCH4,t or LFGflowrate) (m3 or %)

tvalue = 90% t-value coefficient for data set with degrees of freedom df

SD = Standard deviation of the sample (of BCH4,t or LFGflowrate) (m3 or %)

n = Sample size

df = Degrees of freedom, n-1 - BDdiscount that is equal to the measured quantity of CH4 that is recovered through an LFG collection system installed into the corresponding cell or waste mass where the LFG flow was calculated using Equation 6.3.

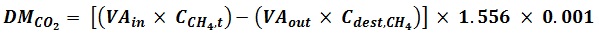

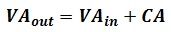

Calculation of Initiative Emissions

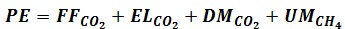

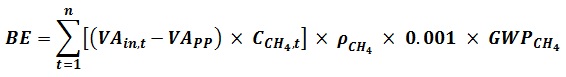

- Initiative emissions are actual GHG emissions that occur within the GHG Assessment Boundary calculated in accordance with Equation 6.11.

Equation 6.11 Calculating Initiative Emissions from GHG Assessment Boundary

PE = FFCO2 + ELCO2 + NGemissions

Where,

PE = Initiative GHG emissions during reporting period (tCO2e)

FFCO2 = Total CO2 emissions from the use of fossil fuels during the reporting period, calculated in accordance with Equation 6.12 (tCO2e)

ELCO2 = Total CO2 emissions from the use of electricity during the reporting period, calculated in accordance with Equation 6.13 (tCO2e)

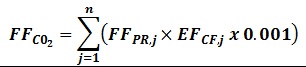

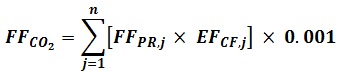

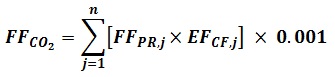

NGemissions = Total GHG emissions from the use of supplemental natural gas during the reporting period, calculated in accordance with Equation 6.14 (tCO2e)Equation 6.12 Calculating Initiative CO2 Emissions from Fossil Fuel Use

Where,

FFCO2 = Total CO2 emissions from the use of fossil fuels, other than supplemental natural gas, during the reporting period (tCO2e)

n = Number of types of fossil fuels

j = Type of fossil fuel

FFPR,j = Annual quantity of fossil fuel j consumed in the operation of equipment within the initiative boundary. (quantity of fossil fuel)

EFCF,j = CO2 emission factor for fossil fuel j, as set out in ON.20 of the QRV Guideline (kgCO2 ⁄ quantity of fossil fuel)

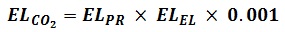

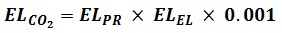

0.001 = Conversion factor, kilograms to tonnes (tCO2/kgCO2)Equation 6.13 Calculating Initiative CO2 Emissions from Electricity Use

ELCO2 = ELPR × ELEL × 0.001

Where,

ELCO2 = Total CO2 emissions from the use of electricity for the initiative during the reporting period (tCO2)

ELPR = Total electricity used for the initiative during the reporting period (MWh)

ELEL = CO2 emission factor for electricity generation from the province in which the initiative is located, as set out in the version of the NIR that is published immediately before the end of the reporting period (kg CO2/MWh)

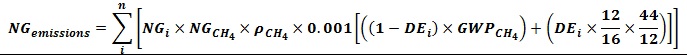

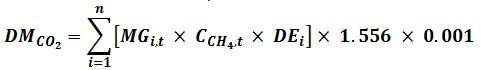

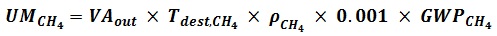

0.001 = Conversion factor, kilograms to tonnes (tCO2/kgCO2)Equation 6.14 Calculating Initiative GHG Emissions from the Use of Supplemental Natural Gas

Where,

NGemissions = Total GHG emissions from the use of supplemental natural gas during the reporting period (tCO2e)

n = Number of eligible destruction devices

i = Eligible destruction device

NGi = Total quantity of supplemental natural gas sent to eligible destruction device i during the reporting period (m3NG)

NGCH4 = Average ratio of CH4 to NG in the supplemental natural gas, as set out in the supplier’s specifications (m3CH4/m3NG)

ρCH4 = Density of CH4 at the reference temperature, as set out in Table A.2 (kgCH4/m3CH4)

0.001 = Conversion factor, kilograms to tonnes (tCH4/kgsCH4)

DEi = CH4 destruction efficiency of eligible destruction device i, as set out in Table A.1

GWPCH4 = Global Warming Potential for CH4, as set out in O. Reg. 143/16 (tCO2e/tCH4)

12/16 = Molecular mass ratio, carbon to CH4 (C/CH4)

44/12 = Molecular mass ratio, CO2 to carbon (CO2/C)

7. Data Management and Monitoring

7.1 Data Collection

- A data management system shall be implemented to collect, manage and store information related to the initiative in a way that ensures the integrity, exhaustiveness, accuracy and validity of the information.

-

The data management system for the initiative shall include procedures to:

- Monitor the performance of the initiative and the operation of all initiative-related equipment, in accordance with Sections 7.2 ,7.3 and 7.5;

- Manage information, including data in respect of the baseline scenario and the initiative;

- Provide the accredited verification body access to the landfill site, suppliers and where applicable, the owner or operator of any offsite destruction devices and any other information or persons that the accredited verification body may require to verify the initiative.

- Assess whether the initiative meets the eligibility criteria set out in the Regulation and this protocol;

- Identify and record any violations of legal requirements that apply to the initiative and that may have an impact on the amount of GHG reductions, avoidances or removals; and

- Assess and record a description of the impact of each violation identified under paragraph 5.

-

The data management system for the initiative shall include records required by the Regulation and this protocol, including the following information:

-

All baseline scenario and initiative continuous monitoring devices shall record values every 15 minutes, except as set out in paragraph (1) below, and include the average at a minimum frequency of daily.

- Initiatives with continuous CH4 analyzers may record values at frequencies other than every 15 minutes in accordance with the data acquisition system, and include the average at a minimum frequency of daily.

- The value of Destbase shall be aggregated at a frequency of at least weekly, and the selected frequency shall be applied consistently throughout the reporting period.

- All other baseline scenario monitoring devices shall record one measured value per day on the day the measurement was made.

- All other monitoring devices shall record values and average those values at the frequencies set out in Section 7.

- Documentation of the engineering design and flow characteristics of the LFG collection system.

-

7.2 Monitoring Requirements

7.2.1 General

- Procedures shall be established and followed to accurately assess whether the initiative meets the applicable eligibility criteria set out in Section 4.

- All initiative-related equipment shall be operated in a manner consistent with the manufacturer’s specifications and in accordance with the Section 7 and the performance of the initiative shall be monitored in accordance with Section 7.

- Electricity data may be measured using an on-site meter or determined using electricity purchasing records.

- Fossil fuel use may be determined using monthly fossil fuel purchasing records.

7.2.2 Flow Meters

-

The LFG collection system shall be monitored with equipment that directly meters the flow of LFG delivered to each eligible and ineligible destruction device, measured continuously.

- A single meter may be used for multiple, identical destruction devices.

- The temperature and pressure of the LFG shall be measured separately and continuously.

-

All flow data collected shall be corrected to reference pressure and reference conditions as follows:

-

The correction shall be made using:

- The volume from the flow meter when the meter corrects for temperature and pressure; or

- Equation 7.1 to calculate the corrected volume, when the condition in i is not met.

- The reference pressure shall be 1 atm (101.325 kPa),

-

The reference temperature may be chosen from Table A.2, based on any applicable reference temperature standard of the jurisdiction in which the initiative is located.

- The reference temperature shall be applied consistently for data adjustment during the reporting period.

-

- The density of CH4 at the reference temperature that is set out in Table A.2.

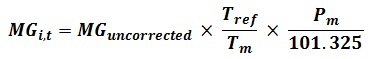

Equation 7.1 Adjusting the LFG Flow for Temperature and Pressure

LFGi,t = LFGuncorrected × (Tref ⁄ Tm) × (Pm ⁄ 101.325)

Where,

LFGi,t = Corrected volume of LFG sent to eligible destruction device i, in time interval t (m3 LFG)

LFGuncorrected = Uncorrected volume of LFG collected for the given interval (m3 LFG)

Pm = Measured pressure of the LFG for the given time interval (kPa)

Tref = Reference temperature of the LFG for the initiative (K)

Tm = Measured temperature of LFG for the given time interval (K)

101.325 = Reference pressure of the LFG for the initiative (kPa)

7.2.3 CH4 Analyzers

-

The LFG collection system shall be monitored with equipment that directly calculates the % of CH4 in the LFG and the measurements on which this calculation is based are made using:

- A continuous CH4 analyzer (This is the preferred equipment).

-

Where a continuous CH4 analyzer is not used, a non-continuous CH4 measurement may be used if:

- measurement is obtained at a frequency of at least weekly;

- the uncertainty associated with these measurements is accounted for by applying a 10% discount factor to the total quantity of CH4 collected and destroyed in Equation 6.2; and,

-

The following device is used:

- a calibrated, portable CH4 analyzer; or

- a device that collects LFG samples at least weekly into a common container which is then analyzed at least monthly by an off-site laboratory that provides an average CH4 concentration of the sample.

7.2.4 Arrangement of Devices in the LFG Collection System

- The number and arrangement of flow meters shall be sufficient to track the LFG flow to each eligible and ineligible destruction device.

- The flow meter shall be placed such that it measures the volume of LFG delivered to each eligible and ineligible destruction device prior to the introduction of any supplemental fuels.

- The CH4 analyzer shall be placed such that it measures CH4 concentration of the LFG delivered to an eligible or ineligible destruction device prior to the introduction of any supplemental fuel.

- A moisture-removing component may separate the CH4 analyzer and the flow meter where the CH4 analyzer is placed before the moisture-removing component (wet basis), and the flow meter is placed after that component (dry basis).

- A moisture-removing component shall not separate the CH4 analyzer and flow meter in any other configuration other than as described in paragraph (d) above.

7.2.5 Operational Status of Eligible Destruction Devices

- Unless the eligible destruction device is not operating and the engineering design of the LFG collection system is such that LFG is not released when the eligible destruction device is not operating and that such design elements are functioning properly and there is documented evidence to support this, the operational status of the LFG collection system and each eligible destruction device shall be monitored with measurements recorded at least hourly.

- When a single flow meter is used for multiple, identical eligible destruction devices per Subsection 7.2.2(a)1, the operational status of each destruction device shall be monitored separately unless the design of the eligible destruction device is such that LFG is not released when it is not operating and there is documented evidence to support this.

- Where LFG is delivered from the landfill site to a destruction device at another facility via a direct use pipeline, reasonable efforts shall be made to obtain data demonstrating the type of destruction device used at the other facility and the operational status of that device.

- Where LFG is delivered from the landfill site to a destruction device via injection into a natural gas transmission pipeline, reasonable efforts shall be made to obtain data demonstrating the operational status of the natural gas transmission pipeline.

-

If it is not possible to obtain the dataset out in paragraphs (c) and (d), reasonable evidence must be obtained demonstrating that there has been no significant release of LFG between when it was collected and when it was destroyed and that the appropriate destruction efficiency value, set out in Table A.1, has been applied. Evidence may include:

- A signed attestation from the owner or operator of the pipeline that no significant release of LFG occurred during the reporting period;

- Supporting documents and records such as electrical output data, engineering designs and safety features that demonstrate LFG is not released when the destruction device is not operating or that the flow of LFG off-site can be shut off in the event of an emergency or any other supporting documents.

7.2.6 Baseline Scenario Monitoring Period

-

Monitoring of all ineligible destruction devices shall be done over a period of at least 3 consecutive months prior to the start date (“baseline scenario monitoring period”).

- The baseline scenario monitoring period cannot include a period where the volume of LFG flow that is measured is decreased by activities related to the start up or testing period the initiative (e.g., pressure changes from the installation of wells, etc.).

- CH4 destruction shall be monitored at a frequency of at least weekly during the baseline scenario monitoring period, and extrapolated to one year based on the 90% upper confidence limit of the CH4 destruction values recorded during this period. (Note: Monitoring for a period longer than three months, or at a frequency greater than weekly, may lessen statistical uncertainty and reduce the required BDdiscount.)

-

LFG flow shall be monitored at a frequency of at least weekly during the baseline scenario monitoring period, and shall be normalized to maximum flow capacity (m3/min).

- For any time interval in which the LFG flow is below the measurable range for the monitoring device, the minimum flow value of the monitoring device shall be applied to that time interval.

- CH4 concentration shall be monitored at a frequency of at least weekly during the baseline scenario monitoring period.

- When using Subsection 6.1(c)(1) to determine BDdiscount, the quantity of CH4 shall be measured for a minimum period of one month during the baseline scenario monitoring period.

7.2.7 Oxidation

- For the purposes of determining the oxidation amount, the fill area of the landfill with a geomembrane shall be determined at the beginning of each reporting period.

-

Oxidation of CH4 in the landfill shall be determined in the following manner:

- For a landfill site with a geomembrane where the entire fill area has a geomembrane, use a CH4 oxidation rate of zero (0%).

- For a landfill, without a geomembrane covering any fill area, use a CH4 oxidation rate of 0.1 (10 %).

- For a landfill that has some of the fill area with a geomembrane, the CH4 oxidation rate shall be a proportionate value determined in accordance with Equation 7.2.

Equation 7.2 Calculating the Oxidation of CH4 by Soil Bacteria

OX = [(0 × areac) + (0.1 × areau)] ⁄ (areac + areau)

Where,

OX = Factor for the oxidation of CH4 by soil bacteria

areac = Area covered by a geomembrane (m2)

area u = Area uncovered by a geomembrane (m2)

0 = CH4 oxidation rate of the area covered by a geomembrane, (zero, 0%)

0.1 = CH4 oxidation rate of the area uncovered by a geomembrane, (10%)

7.3 Instrument Quality Assurance and Quality Control (QA/QC)

-

LFG flow meters and CH4 analyzers shall be:

- Located and installed for the intended use, in accordance with manufacturer specifications;

- Calibrated at the time of installation;

- Cleaned and inspected in accordance with the manufacturer’s specifications;

-

Not later than 2 months before the end of a reporting period:

- Checked for accuracy by a qualified and independent person, either using a portable instrument, such as a pitot tube, or by following the manufacturer’s specifications, and the percentage drift recorded; or

- Calibrated by the manufacturer, or by a third party certified for that purpose by the manufacturer;

and;

- Calibrated by the manufacturer, or by a third-party certified for that purpose by the manufacturer, in accordance with the manufacturer’s specified frequency or every 5 years, whichever is more frequent.

- Flow meters and CH4 analyzers that are not portable devices but are installed temporarily shall be calibrated at the time of installation.

-

The LFG flow meter and CH4 analyzer calibration accuracy must show that these monitoring devices provide a reading of volumetric flow and CH4 concentration that is within a ± 5% accuracy threshold.

- When the device shows a shift outside the ± 5% accuracy threshold, appropriate corrective action(s) shall be taken, such as cleaning or adjusting the sensor in accordance with the manufacturer’s specification.

- The device shall be rechecked for measurement accuracy in accordance with Subsection 7.3(a)4.i after the corrective action.

- If the device is still out of the ± 5% accuracy threshold, the device shall be calibrated by the manufacturer or by a third party certified for that purpose by the manufacturer.

-

For the entire period from the last time the monitoring device showed a reading within the ± 5% accuracy threshold until such time as the monitoring device shows a return to the accuracy threshold all the data from the monitoring device shall be corrected according to the following procedure:

- When the inaccuracy of the device indicates an under-reporting of flow rate or CH4 concentration, the measured values taken by the inaccurate device, without correction shall be used;

- When the inaccuracy of the device indicates an over-reporting of flow rates or CH4 concentration, the measured values of the inaccurate device shall be corrected by the percentage that the device was out of the ± 5% accuracy threshold.

-

If a portable CH4 analyzer is used to check accuracy, it shall be:

- Maintained in accordance with the manufacturer’s specifications; and

- Calibrated by the manufacturer or by a third party certified for that purpose by the manufacturer for that purpose in accordance with the manufacturer’s specified frequency or annually, whichever is more frequent.

- Equipment used for monitoring parameters other than LFG flow and CH4 concentration (e.g., standalone temperature sensors, flare thermocouples, etc.) shall be installed, maintained and calibrated in accordance with the manufacturer’s specifications.

7.4 Missing Data

-

Missing data from a monitoring device may only be replaced using the methodology in Appendix B. The methodology in Appendix B may only be used if the following two conditions are met:

- The operational status of the eligible destruction device can be demonstrated in accordance with the requirements of Section 7.2.5; and

- The operational status and proper functioning of the device monitoring the eligible destruction device can be demonstrated in accordance with the requirements of Section 7.3.

-

If the methodology in Appendix B is being used to replace missing data from a flow meter or CH4 analyzer then data may only be replaced in accordance with the following rules:

- LFG flow rate may be replaced when CH4 concentration is not missing and where a continuous CH4 analyzer was used to measure CH4 concentration and the CH4 content was consistent with normal operations; or

- CH4 concentration may be replaced when flow meter data is not missing and a flow meter demonstrates that the LFG flow rate was consistent with normal operations; or

- Where both CH4 concentration and LFG flow rate are missing, data may only be replaced for electric generators and natural gas injection and only in accordance with(c) and (d) below.

- For initiatives that destroy LFG in an eligible destruction device that also generates electricity, the missing data may be replaced for periods of up to 6 months after the applicable version of the protocol comes into effect by using Equation B.1, in Appendix B if the electrical output for the period of missing data has been monitored.

-

For initiatives that inject LFG into a natural gas transmission pipeline, the missing data for periods up to 6 months after the applicable version of the protocol came into effect may be replaced through either:

- the use of the volumetric CH4 data as reported by the flow meter at the point of pipeline injection, or,

-

by using Equation B.2 in Appendix B if the data is reported in units of energy, but only if:

- The volume of LFG is continuously monitored throughout the period of the data gap;

- Any supplemental natural gas mixed with the LFG prior to the custody transfer meter is monitored throughout the period of the data gap and subtracted from the volume in i; and

- Any other fuel sent to the pipeline, is directly monitored throughout the period of the data gap and subtracted from the volume in i.

7.5 Monitoring Parameters

- Table 7.1 sets out the monitoring parameters required to be used in the calculation of baseline scenario and initiative emissions

| Eq. # | Parameter | Description in Equation | Units | Calculated (c), Measured (m), Reference (r), Operating Records (o) | Measurement Frequency | References |

|---|---|---|---|---|---|---|

| N/A | Operating status of destruction device | Unit determined per destruction device | m | Hourly | ||

| Equation 6.2 | CH4DestPR | Total quantity of CH4 destroyed by all eligible destruction devices during the reporting period | tCH4 | c | Once per reporting period | Calculated in accordance with Equation 6.3 |

| Equation 6.2, Equation 6.6, Equation 6.14 | GWPCH4 | Global Warming Potential for CH4 | tCO2e/tCH4 | r | Once per reporting period | As set out in O. Reg. 143/16 |

| Equation 6.2 | OX | Factor for the oxidation of CH4 by soil bacteria | N/A | r | Once per reporting period | Determined in accordance with Section 7.2.7 |

| Equation 6.2 | DF | Discount factor is 0 or 0.1 | N/A | r | Once per reporting period | Determined in accordance with Section 7.2.3 |

| Equation 6.2 | Destbase | Adjustment to account for baseline CH4 destruction | tCO2e | c | At least weekly | Calculated in accordance with Equation 6.6 |

| Equation 6.3, Equation 6.14 | n | Number of eligible destruction devices | N/A | r | ||

| Equation 6.3, Equation 6.4, Equation 6.14 | i | Eligible destruction device | N/A | r | ||

| Equation 6.3 | CH4Desti | Net quantity of CH4 destroyed by each eligible destruction device i during the reporting period | m3 CH4 | c | Calculated in accordance with Equation 6.4 | |

| Equation 6.3, Equation 6.6, Equation 6.14 | ρCH4 | Density of CH4 at the reference temperature | kgCH4/m3CH4 | r | Once per reporting period | As set out in Table A.2 |

| Equation 6.4, Equation 6.5 | Qi | Total quantity of CH4 sent to eligible destruction device i during the reporting period | m3 CH4 | c | Daily (if CH4 is monitored continuously); Weekly (if CH4 is monitored weekly) | Calculated in accordance with Equation 6.5 |

| Equation 6.4, Equation 6.14, Equation B.1, Equation B.2 | DEi | CH4 destruction efficiency of eligible destruction device i | N/A | r/m | Once per reporting period | As set out in Table A.1 |

| Equation 6.5 | n | Number of measurement periods | N/A | r | ||

| Equation 6.5, Equation B.2 | t | Measurement period | m | Continuously, daily, or weekly | ||

| Equation 6.5 | LFGi,t | Corrected volume of LFG sent to eligible destruction device i during measurement period t | m3 LFG | m/c | Continuously | Measured for cases where the meter internally corrects to standard conditions, otherwise calculated in accordance with Equation 7.1 |

| Equation 6.5 | PRCH4,t | Average ratio of CH4 to LFG in the LFG, for measurement period t | m3CH4/m3LFG | m | Continuously or weekly | |

| Equation 6.6, Equation 6.7 | BDdiscount | Amount of CH4 that would have been destroyed during the reporting period, in the baseline without the initiative | m3 CH4 | c | Once per reporting period | Calculated in accordance with Subsection 6.1 (c) |

| Equation 6.7 | LFGB | LFG that would have been destroyed by an ineligible destruction device during the reporting period | m3 LFG | c | Once per reporting period | Calculated in accordance with Equation 6.8 |

| Equation 6.7 | BCH4 | The average ratio of CH4 to LFG in the LFG that would have been destroyed by an ineligible devices during the reporting period | m3CH4/m3LFG | m | Continuously or weekly | Calculated in accordance with Equation 6.9 |

| Equation 6.8 | 90%UCL(LFGflowrate) | 90% upper confidence limit of the average flow rate in the metered period | m3/minLFG | c | Once per reporting period | Calculated in accordance with Equation 6.10 |

| Equation 6.9 | 90%UCL(BCH4,t) | 90% upper confidence limit of the average CH4 concentration in the metered period | m3/min LFG | c | Once per reporting period | Calculated in accordance with Equation 6.10 |

| Equation 6.10 | tvalue | The 90% t-value coefficient for data set with degrees of freedom | N/A | c | Once per reporting period | |

| Equation 6.10 | SD | Standard deviation of the sample | m3 or % | c | Once per reporting period | |

| Equation 6.10 | n | Sample size | N/A | r | Once per reporting period | |

| Equation 6.10 | df | Degrees of freedom, n−1 | N/A | c | Once per reporting period | |

| Equation 6.11 | FFCO2 | Total CO2 emissions from the use of fossil fuels during the reporting period | tCO2e | c | Once per reporting period | Calculated in accordance with Equation 6.12 |

| Equation 6.11 | ELCO2 | Total CO2 emissions from the use of electricity during the reporting period | tCO2e | c | Once per reporting period | Calculated in accordance with Equation 6.13 |

| Equation 6.11 | NGemissions | Total GHG emissions from the use of supplemental natural gas during the reporting period | tCO2e | c | Once per reporting period | Calculated in accordance with Equation 6.14 |

| Equation 6.12 | n | Number of types of fossil fuel | N/A | o | Once per reporting period | |

| Equation 6.12 | j | Type of fossil fuel | N/A | o | Once per reporting period | |

| Equation 6.12 | FFPR,j | Annual quantity of fossil fuel j consumed in the operation of equipment within the GHG assessment boundary | kg (solid) m3 at standard conditions (gas) L (liquid) |

o | Once per reporting period | |

| Equation 6.12 | EFCF,j | CO2 emission factor for fossil fuel j | kg CO2/ quantity of fossil fuel | r | Once per reporting period | As set out in ON.20 of the QRV Guideline |

| Equation 6.13 | ELPR | Total electricity used during the reporting period | MWh | r | ||

| Equation 6.13 | ELEL | CO2 emission factor for electricity generation from the province in which the initiative is located | kgCO2/MWh | r | Once per reporting period | As set out in the NIR |

| Equation 6.14 | NGi | Total quantity of supplemental natural gas sent to eligible destruction device i during the reporting period | m3 NG | m/r | Continuously | |

| Equation 6.14, Equation B.1, Equation B.2 | NGCH4 | Average ratio of CH4 to NG in the supplemental natural gas | m3CH4/m3NG | m/r | Once per reporting period | |

| Equation 7.1 | LFGuncorrected | Uncorrected volume of LFG collected for the given interval | m3 LFG | m | Continuously | |

| Equation 7.1 | ρm | Measured pressure of the LFG for the given time interval | kPa | m | Continuously | |

| Equation 7.1 | Tref | Reference temperature of the LFG for the initiative | K | m | Once per reporting period | |

| Equation 7.1 | Tm | Measured temperature of LFG for the given time interval | K | m | Continuously | |

| Equation B.1 | EOi | Total electric output of device i during the period of missing data | kWh | m | Per data gap | |

| Equation B.1 | HRi | Heat rate of destruction device i | GJ/kWh | r | N/A | |

| Equation B.1, Equation B.2 | HHVCH4 | Higher heating value of the CH4 portion of LFG, 0.0359 | GJ/m3 | r | N/A | |

| Equation B.1, Equation B.2 | NGi | Total quantity of supplemental natural gas sent to device i during the period of the missing data | m3 NG | m/r | Continuously | |

| Equation B.2 | FEt | Fuel energy delivered during measurement period t | GJ | m | Per data gap |

8. Reversals

8.1 Reversals Listed for the Purposes of s. 20(1) paragraph 1

- There are no reversals listed in this protocol for the purpose of s. 20(1) paragraph 1.

8.2 Errors, Omissions or Misstatements

-

In the event that an error, omission or misstatement is discovered after Ontario offset credits have been created and issued for a reporting period, the Sponsor shall determine the total amount of the reversal by:

- Using this protocol to re-calculate the corrected value of the GHG emission reductions from the initiative during the reporting period for each initiative report affected by the reversal.

- Calculating the total reversal of GHG emission reductions from the initiative using Equation 8.1.

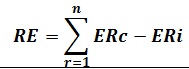

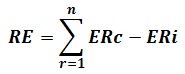

Equation 8.1 Calculating GHG Emission Reductions Reversed

Where

RE = GHG emission reductions reversed (tCO2e)

n = Total number of initiative reports affected by the reversal

r = Initiative reports affected by the reversal

ERc = Corrected GHG emission reductions from the initiative during the reporting period calculated in accordance with Subsection 8.2(a)(1) (tCO2e)

ERi = Initially reported GHG emission reductions from the initiative during the reporting period (tCO2e)

9. Reporting

- The following information shall be set out in an initiative report or a reversal report in addition to the information required by the Regulation.

9.1 Initiative Report

9.1.1 Eligibility Criteria Information

- The total waste capacity of the landfill

- Amount of waste in place

- For an operational landfill, the amount of waste accepted annually, in tonnes

- For a closed landfill, the amount of waste that was accepted annually in tonnes

- If a geomembrane has been used at the site, a description of whether the geomembrane, meets the requirements of Ontario Regulation 232/98 (Landfilling Sites).

9.1.2 Monitoring Information

- A description of the baseline scenario and how it was monitored in accordance with Section 7.2.6.

- Identify all eligible and ineligible destruction devices within the initiative GHG Assessment Boundary as set out in Section 5.

-

A description of how the initiative was monitored, including the following:

- A statement of whether the monitoring performed meets the requirements set out in Section 7.

- A statement of whether all gas flow meters and CH4 analyzers adhered to the instrument QA/QC requirements set out in Section 7.3.

- Where applicable, an identification of any deviations from the requirements set out in Section 7 and a description of whether these deviations should be considered material.

- Calibration certificates or verification reports on the calibration accuracy, from either the manufacturer or a qualified third-party certified by the manufacturer for each piece of monitoring equipment.

- Where applicable, identification of instances where any piece of equipment failed a calibration and a description of how the data from that equipment was corrected in accordance with Section 7.3, including any calculations used.

- Where applicable, identification of instances where the data substitution methodology set out in Section 7.4 was applied, and a description as to how the data was substituted including any calculations used.

- Identification of the measurement frequency used for each monitoring parameter, where multiple frequencies may be used in accordance with Section 7.5.

9.1.3 Quantification Information

- All calculations set out in Section 6, including any supporting calculations set out in Section 7, that were used.

- The reference temperature and density used.

- Identification of any source test data, if used in place of the default destruction efficiencies, as set out in Appendix A.

9.2 Reversal Report

9.2.1 General

- Information about the circumstances and causes of the reversal including the number of reporting periods affected.

- For each initiative report that was affected by the reversal, all information that has changed as a result of the reversal and a description of those changes.

- In the case of an error, omission or misstatement reversal, a description of the corrective actions taken to address the circumstances and causes of the reversal.

- Supporting documentation for each of the items in paragraphs (a) through (c) above.

9.2.2 Quantification Information

- All calculations set out in Section 8, including supporting calculations set out in Section 6 and Section 7, that were used to determine the amount of the reversal.

- Supporting documentation related to the calculations.

10. Record Keeping

-

The following records and documents shall be kept in addition to the records that are required to be kept under the Regulation:

- The information and data required under the monitoring requirements in Section 7, including all GHG calculations and related data inputs.

- Information on each eligible and if applicable ineligible flow meter, CH4 analyzer and destruction device used, including type, model number, serial number and manufacturer’s maintenance and calibration procedures.

-

Maintenance documents and records relating to collection, destruction and monitoring systems including:

- For each LFG flow meter and CH4 analyzers, records and documents relating to all instrument QA/QC activities.

- For a portable analyzer, time and place where measurements are taken and, for each measurement, the CH4 concentration in the LFG.

-

The calibration date, time and results for CH4 analyzers and flow meters, and the corrective measures applied if a piece of equipment failed to meet the requirements of this protocol:

- Flow meter calibrations shall be documented to show that the meter was calibrated to a range of flow rates corresponding to the flow rates expected at the landfill site.

- CH4 analyzer calibrations shall be documented to show that the calibration was carried out to a range of temperature and pressure conditions corresponding to the range of conditions measured at the landfill site.

- Records showing the quantity of waste disposed of at the landfill.

- All documentation related to any violations of legal requirements that apply to the initiative or that may have an impact on the amount of GHG reductions, avoidances or removals.

Appendix A: Parameters for Quantification

A.1 CH4 Destruction Efficiency

The appropriate CH4 destruction efficiency shall be selected from Table A.1 below.

| Eligible Destruction Device | Efficiency |

|---|---|

| Open Flare | 0.96 |

| Enclosed Flare | 0.995 |

| Internal Combustion Engine | 0.936 |

| Boiler | 0.98 |

| Microturbine or Large Gas Turbine | 0.995 |

| Boiler Following Upgrade and Injection into a Pipeline | 0.96 |

| CH4 Liquefaction Unit | 0.95 |

| Injection into Natural Gas Transmission Pipeline | 0.98 |

| Direct Use Pipeline (End Use Other than Boiler) | Per the appropriate end use device |

A.2 CH4 Density

- The appropriate CH4 density at the reference temperature shall be selected from Table A.2 below.

| Reference Pressure (kPa) | Reference Pressure (atm) | Reference Temperature (°C) | Reference Temperature (K) | Density of CH4(kg/m3) |

|---|---|---|---|---|

| 101.325 | 1 | 0 | 273.15 | 0.717 |

| 101.325 | 1 | 5 | 278.15 | 0.704 |

| 101.325 | 1 | 10 | 283.15 | 0.692 |

| 101.325 | 1 | 15 | 288.15 | 0.680 |

| 101.325 | 1 | 20 | 293.15 | 0.668 |

| 101.325 | 1 | 25 | 298.15 | 0.657 |

Appendix B: Missing Data Methods

B.1 Substitution Methods

- The appropriate substitution method to replace data shall be selected from Table B.1 below.

| Missing Data Period | Substitution Method |

|---|---|

| Less than 6 hours | Use the average of the 4 hours immediately before and following the missing data period |

| 6 to less than 24 hours | Use the 90% upper or lower confidence limit of the 72 hours prior to and after the missing data period, whichever results in greater conservativeness |

| 1 to 7 days | Use the 95% upper or lower confidence limit of the 72 hours prior to and after the missing data period, whichever results in greater conservativeness |

| More than 7 days | No data may be replaced and no reduction may be credited, except for initiatives that destroy LFG in a device that generates electricity or via pipeline injection, as set out in Subsections 7.4(c) and (d) respectively. |

B.2 Calculations

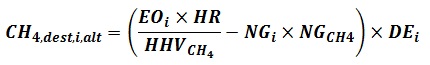

Equation B.1 Calculating Estimated Volume of CH4 Destroyed in Electricity Generators

CH4,dest,i,alt = {[(EOi × HRi) ⁄ HHVCH4] − NGi × NGCH4} × DEi

Where,

CH4,dest,i,alt = Net quantity of CH4 destroyed by electricity generating device i during the period of missing data (m3CH4)

EOi = Total electrical output of device i during the period of missing data (kWh)

HRi = Heat rate of destruction device i, as determined through the most recent source testing event. If no source test data are available, the highest heat rate specified by the manufacturer shall be used (GJ/kWh)

HHVCH4 = Higher heating value of the CH4 portion of the LFG, 0.0359 (GJ/m3CH4)

NGi = Total quantity of supplemental natural gas sent to device i during the period of the missing data (m3NG)

NGCH4 = Average ratio of CH4 to NG in the supplemental natural gas, as set out in the supplier’s specifications (m3CH4/m3NG)

DEi = CH4 destruction efficiency of device i, as set out in Table A.1 (%)

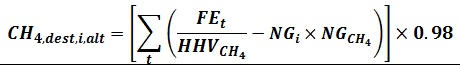

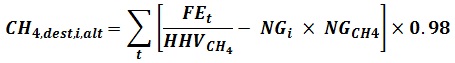

Equation B.2 Calculating Estimated Volume of CH4 Destroyed by Pipeline Injection

Where,

CH4,dest,i,alt = Total quantity of CH4 destroyed by pipeline injection device i during the period of missing data (m3CH4)

t = Measurement period

FEt = Fuel energy delivered during measurement period t, as reported in gas delivery data. (GJ)

HHVCH4 = Higher heating value of the CH4 portion of the LFG, 0.0359 (GJ/m3CH4)

NGi = Total quantity of supplemental natural gas sent to device i during the period of missing data (m3NG)

NGCH4 = Average ratio of CH4 to NG in the supplemental natural gas, according to the supplier’s specifications (m3CH4/m3NG)

0.98 = CH4 destruction efficiency of pipeline injection, as set out in Table A.1 (%)

Ozone Depleting Substances Initiative Protocol

Destruction of Ozone Depleting Substances Used as Foam Blowing Agents and Refrigerants

Protocol Version 1

Dated April 12, 2018

Abbreviations and Acronyms

- AHRI

- Air-Conditioning, Heating and Refrigeration Institute

- CFC

- Chlorofluorocarbons

- HCFC

- Hydrochlorofluorocarbons

- HFC

- Hydrofluorocarbons

1. Introduction

This protocol sets out the requirements that will enable a sponsor to undertake an ozone depleting substances (ODS) greenhouse gas (GHG) reduction initiative for the purpose of registering and receiving offset credits in Ontario’s cap and trade program.

The following sections outline the definition of an ODS GHG reduction initiative, the specific eligibility criteria, baseline scenario and initiative calculation methods, monitoring, data management and reporting requirements that apply to ODS GHG reduction initiatives.

2. Definitions

2.1 Terms

- Accredited Laboratory

- means a laboratory that is:

- Independent of the Sponsor and of the Qualified Destruction Facility; and

- Accredited for analysis of ODS by the Air-Conditioning, Heating and Refrigeration Institute in accordance with AHRI Standard 700 with Addendum 1 (2017 Standard for Specifications for Refrigerants) of that organization as amended from time.

- Aggregation

- means grouping together multiple containers of eligible ODS.

- Certificate of Destruction

- means a document that complies with the requirements set out in Section 7.7.2 of this Protocol provided by the Qualified Destruction Facility certifying the date, quantity, and type of eligible ODS destroyed at the Qualified Destruction Facility.

- Commercial refrigeration equipment

- means the refrigeration appliances, equipment or systems used in the retail food, cold storage warehouse or any other sector that requires cold storage.

- Container

- means an air and water-tight unit for storing or transporting eligible ODS contained in foam or used as or intended for use as a refrigerant without leakage or escape of ODS.

- Destruction

- means destruction that complies with the requirements in Section 7 of this Protocol of eligible ODS contained in foam or used or intended for use as a refrigerant by a Qualified Destruction Facility.

- Emission rate

- means the rate at which eligible ODS contained in foam or used or intended for use as a refrigerant is emitted and includes emissions from leaks during operation and servicing events.

- GHG assessment boundary

- means all the GHG sources, sinks and reservoirs (SSRs) that are required to be assessed because they are identified as included in Table 5.1 of this Protocol.

- Ozone Depleting Substances (ODS)

- means substances known to deplete the stratospheric ozone layer.

- Eligible ODS

- means an ozone depleting substance set out in Section 4.3 of this Protocol.

- Point of Origin

- means the locations as determined in accordance with Section 7.3 of this Protocol.

- Pure ODS

- means eligible ODS with a chemical composition of a minimum of 90% of a single chemical by mass, excluding moisture and high boiling residue and contained in a single container.

- Qualified Destruction Facility (QDF)

- means a facility that destroys, transforms or converts eligible ODS contained in foam or used as or intended for use as a refrigerant and complies with the requirements in Section 7.7 of this Protocol.

- Recharge

- means replenishment of refrigerants into an appliance, piece of equipment or system that is below full capacity.

- Reclaimed ODS

- means recovered eligible ODS that has been reprocessed and upgraded through processes such as filtering, drying, distillation or chemical treatment in order to restore the eligible ODS to a specified standard of performance.

- Recovery

- means the removal of eligible ODS from refrigeration, freezer or air-conditioning appliances, equipment and systems and deposited into a container intended for destruction.

- Substitute refrigerant

- means refrigerants that replace recovered eligible ODS.

- Substitute refrigerant emissions

- means greenhouse gas emissions from the use of substitute refrigerants.

2.2 References

- A reference to equipment in this Protocol includes containment vessels.

- A reference to eligible ODS used as a refrigerant in this Protocol includes eligible ODS intended for use as a refrigerant.

3. ODS GHG Reduction Initiative

3.1 Initiative Definition

- The ODS GHG reduction initiative (‘ODS Initiative’) is defined as an initiative that has activities specified in paragraphs 1. or 2. that are associated with the destruction of eligible ODS as set out in Section 4.4 of this Protocol .

- Activities for Eligible ODS Contained in Foam: Activities for ODS Initiatives for eligible ODS contained in foam include the collection, recovery, extraction, concentration, storage, transportation, mixing (where applicable), sampling, analysis, and destruction of the eligible ODS (‘ODS Foam Initiative’).

- Activities for Eligible ODS Used as or Intended for use as a Refrigerant: Activities for ODS Initiatives for eligible ODS used as or intended for use as a refrigerant include the collection, recovery, handling, transportation, mixing (where applicable), sampling, analysis, and destruction of the eligible ODS (‘ODS Refrigerant Initiative’).

- Activities listed above in paragraphs a)1. and a)2. that occur prior to the collection of eligible ODS at the Point of Origin are not part of the ODS Initiative.

- A single ODS Initiative may combine collection, recovery and destruction of eligible ODS contained in foam or used or intended for use as a refrigerant.

- All eligible ODS included in an ODS Initiative must be destroyed at a Qualified Destruction Facility.

3.2 Initiative Start Date

- The ODS Initiative start date is the date on which the destruction of eligible ODS commences as documented on a Certificate of Destruction.

4. Eligibility

4.1 General Requirements

- A legal requirement to destroy eligible ODS contained in foam or used as a refrigerant must not be applicable.

- An ODS Initiative must destroy eligible ODS that, in the absence of the ODS Initiative, would have been emitted to the atmosphere.

4.2 Duration of Initiative

- The duration for the ODS Initiative is:

- One year from the start date of the ODS Initiative; or

- Up to a maximum of 5 years from the start date of the ODS Initiative if all of the following conditions are met in each year following the first reporting period for the ODS Initiative:

- The extraction and destruction locations for the eligible ODS is the same as in the first reporting period of the ODS Initiative;

- The methods of destruction of eligible ODS are the same as in the first reporting period of the ODS Initiative;

- The types of appliances, equipment and systems from which eligible ODS are recovered are the same as in the first reporting period of the ODS Initiative;

- At least one destruction event for eligible ODS included in the ODS Initiative occurs; and

- An initiative report is prepared and verified in accordance with Sections 21 – 24 of the Regulation.

4.3 Eligible ODS

- The following ODS are eligible for the purposes of this Protocol:

- ODS Contained in Foam: The following ODS blowing agents contained in foam removed from refrigeration, freezer or air-conditioning equipment, systems or appliances at industrial, commercial, institutional or residential locations:

- CFC-11;

- CFC-12;

- HCFC-22; and

- HCFC-141b.

- ODS Used as a Refrigerant: The following ODS used as a refrigerant and removed from or intended for use in refrigeration, freezer or air-conditioning equipment, systems or appliances at industrial, commercial, institutional or residential locations:

- CFC-11;

- CFC-12;

- CFC-13;

- CFC-113;

- CFC-114; and

- CFC-115.

- ODS Contained in Foam: The following ODS blowing agents contained in foam removed from refrigeration, freezer or air-conditioning equipment, systems or appliances at industrial, commercial, institutional or residential locations:

- ODS that were used as or produced for use as solvents, medical aerosols or other applications are not eligible under this Protocol.

- Where an eligible ODS used as a refrigerant is removed from a refrigeration, freezer or air conditioning appliance, equipment or system that also contains eligible ODS contained in foam, and the destruction of the eligible ODS used as a refrigerant commences after October 22, 2016, the eligible ODS contained in foam must also be extracted and destroyed.

5. GHG Assessment Boundary

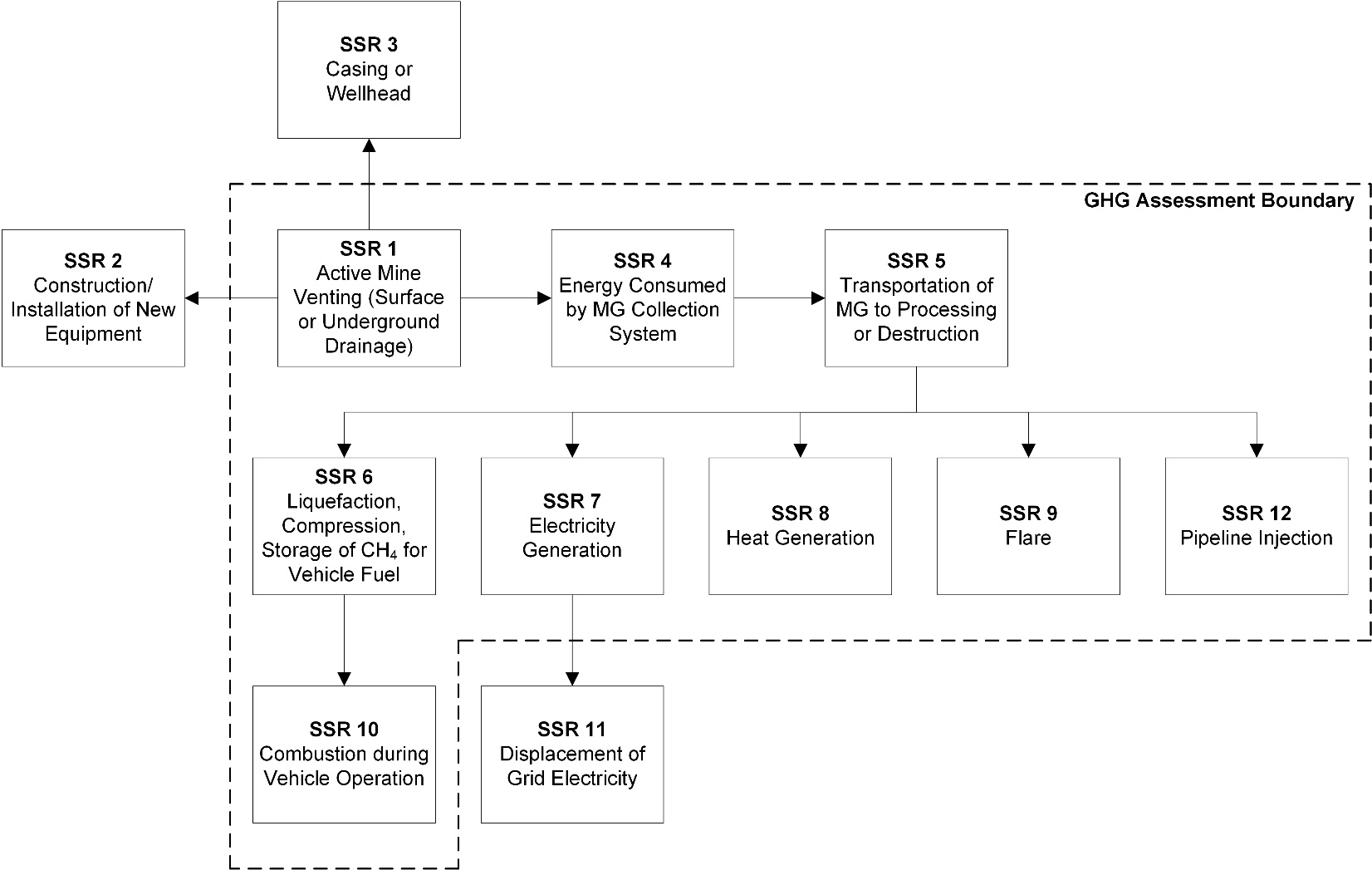

- The following SSRs have been considered in determining the GHG Assessment Boundary;

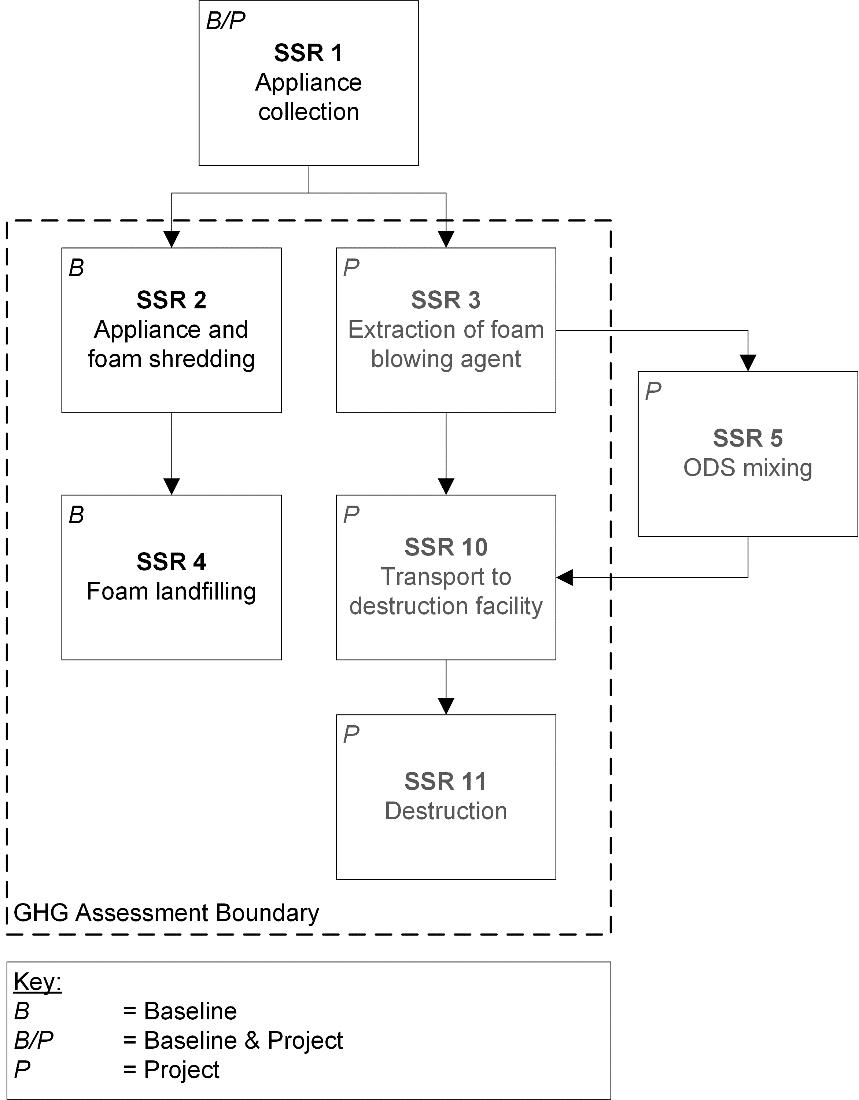

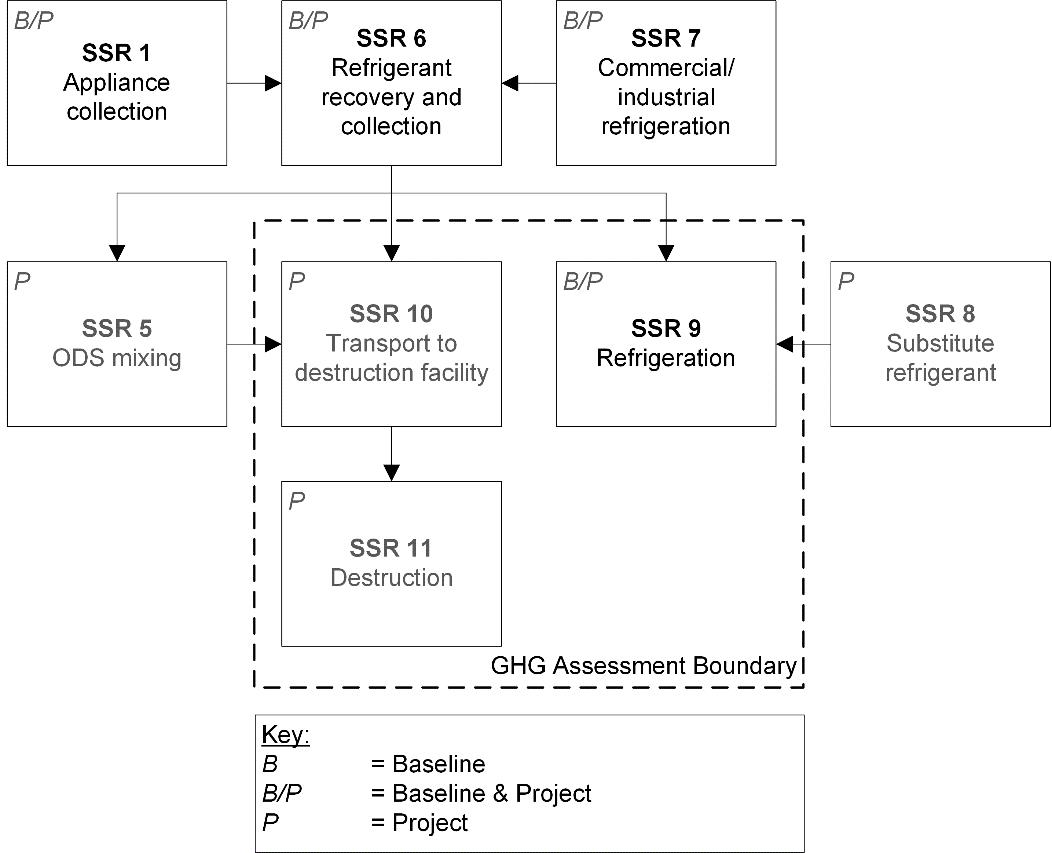

- Figure 5.1 and Figure 5.2 illustrate all relevant SSRs associated with the ODS Initiative and delineates the GHG Assessment Boundary.

- Table 5.1 provides greater detail on each relevant SSR associated with the ODS Initiative and identifies the inclusion or exclusion of the relevant SSR from the GHG Assessment Boundary.

Figure 5.1. GHG Assessment Boundary for eligible ODS Contained in Foam

Figure 5.2. GHG Assessment Boundary for eligible ODS Used as a Refrigerant

| SSR # | SSR | Source Description | Type of Emission | Relevant to Baseline Scenario (B) and/or Initiative (I) | Included or Excluded |

|---|---|---|---|---|---|

| 1 | Appliance, Equipment and System Collection | Emissions from the collection and transportation to the Point of Origin of appliances, equipment and systems | CO2 | B, I | Excluded |

| 1 | Appliance, Equipment and System Collection | Emissions from the collection and transportation to the Point of Origin of appliances, equipment and systems | CH4 | B, I | Excluded |

| 1 | Appliance, Equipment and System Collection | Emissions from the collection and transportation to the Point of Origin of appliances, equipment and systems | N2O | B, I | Excluded |

| 2 | Appliance, Equipment and System Shredding | Emissions of eligible ODS from the shredding of appliances, equipment and systems for materials recovery | ODS | B | Included |

| 3 | Extraction of ODS contained in foam | Emissions of eligible ODS from the removal of foam ODS blowing agent from appliances, equipment and systems | ODS | I | Included |

| 4 | Disposal of foam at a landfill site | Emissions of eligible ODS from the disposal of foam at a landfill site | ODS | B | Included |

| 4 | Disposal of foam at a landfill site | Emissions of ODS degradation products from foam disposed of at a landfill site | HFC, HCFC | B | Excluded |

| 4 | Disposal of foam at a landfill site | Fossil fuel emissions from the transportation of shredded foam to a landfill site and from disposal at a landfill site | CO2 | B | Excluded |

| 4 | Disposal of foam at a landfill site | Fossil fuel emissions from the transportation of shredded foam to a landfill site and from disposal at a landfill site | CH4 | B | Excluded |

| 4 | Disposal of foam at a landfill site | Fossil fuel emissions from the transportation of shredded foam to a landfill site and from disposal at a landfill site | N2O | B | Excluded |

| 5 | ODS mixing | Fossil fuel emissions from eligible ODS mixing activities at mixing facility | CO2 | I | Excluded |

| 5 | ODS mixing | Fossil fuel emissions from eligible ODS mixing activities at mixing facility | CH4 | I | Excluded |

| 5 | ODS mixing | Fossil fuel emissions from eligible ODS mixing activities at mixing facility | N2O | I | Excluded |

| 6 | Refrigerant recovery and collection | Emissions of eligible ODS from the removal of refrigerant from appliances, equipment and systems | ODS | B, I | Excluded |

| 7 | Industrial and commercial refrigeration | Emissions of eligible ODS from appliances, equipment and systems leakage and maintenance | ODS | B, I | Excluded |

| 7 | Industrial and commercial refrigeration | Fossil fuel emissions attributable to the operation of refrigeration and air conditioning appliances, equipment and systems | CO2 | B, I | Excluded |

| 7 | Industrial and commercial refrigeration | Fossil fuel emissions attributable to the operation of refrigeration and air conditioning appliances, equipment and systems | CH4 | B, I | Excluded |

| 7 | Industrial and commercial refrigeration | Fossil fuel emissions attributable to the operation of refrigeration and air conditioning appliances, equipment and systems | N2O | B, I | Excluded |

| 8 | Production of substitute refrigerants | Emissions of substitute refrigerants during the production of substitute refrigerants | CO2e | I | Excluded |

| 8 | Production of substitute refrigerants | Fossil fuel emissions during the production of substitute refrigerants | CO2 | I | Excluded |

| 8 | Production of substitute refrigerants | Fossil fuel emissions during the production of substitute refrigerants | CH4 | I | Excluded |

| 8 | Production of substitute refrigerants | Fossil fuel emissions during the production of substitute refrigerants | N2O | I | Excluded |

| 9 | Refrigerants | Emissions of eligible ODS from leakage and maintenance during the continuous operation of appliances, equipment and systems | ODS | B | Included |

| 9 | Refrigerants | Emissions of substitute refrigerants from leakage and maintenance during the continuous operation of appliances, equipment and systems | CO2e | I | Included |

| 9 | Refrigerants | Indirect emissions from the use of electricity | CO2 | B, I | Excluded |

| 9 | Refrigerants | Indirect emissions from the use of electricity | CH4 | B, I | Excluded |

| 9 | Refrigerants | Indirect emissions from the use of electricity | N2O | B, I | Excluded |

| 10 | Transportation to the Qualified Destruction Facility | Emissions of fossil fuels from the transportation of eligible ODS from the Point of Origin to the Qualified Destruction Facility | CO2 | I | Included |

| 11 | Destruction of Eligible ODS | Emissions of eligible ODS from incomplete destruction at the Qualified Destruction Facility | ODS | I | Included |

| 11 | Destruction of Eligible ODS | Emissions from the oxidation of carbon contained in the destroyed eligible ODS | CO2e | I | Included |

| 11 | Destruction of Eligible ODS | Fossil fuel emissions from the destruction of eligible ODS in a destruction facility | CO2 | I | Included |

| 11 | Destruction of Eligible ODS | Fossil fuel emissions from the destruction of eligible ODS in a destruction facility | CH4 | I | Excluded |

| 11 | Destruction of Eligible ODS | Fossil fuel emissions from the destruction of eligible ODS in a destruction facility | N2O | I | Excluded |

| 11 | Destruction of Eligible ODS | Indirect emissions from the use of electricity | CO2 | I | Included |

| 11 | Destruction of Eligible ODS | Indirect emissions from the use of electricity | CH4 | I | Excluded |

| 11 | Destruction of Eligible ODS | Indirect emissions from the use of electricity | N2O | I | Excluded |

6. Calculation of Emission Reductions

-

Reductions of GHG emissions from the ODS Initiative for the reporting period shall be calculated in accordance with Equation 6.1.

Equaltion 6.1. Calculating Total ODS Initiative GHG Emission Reductions

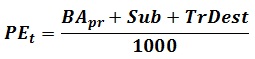

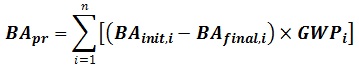

ERt = BEt − PEt

Where,

ERt = Total GHG emission reductions from the ODS Initiative for the reporting period (tCO2e)

BEt = Total baseline scenario emissions for the reporting period, calculated using Equation 6.2 (tCO2e)

PEt = Total ODS Initiative emissions for the reporting period, calculated using Equation 6.6 (tCO2e)

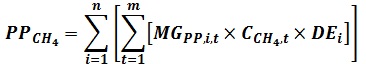

6.1 Calculation of Baseline Scenario Emissions

- The total baseline scenario emissions shall be calculated using Equation 6.2.

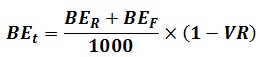

Equation 6.2. Total Baseline Scenario Emissions

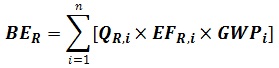

Where,

BEt = Total baseline scenario emissions for the reporting period (tCO2e)

BER = Baseline scenario emissions from the destruction of eligible ODS used as a refrigerant for the reporting period, calculated using Equation 6.4 (kgCO2e)

BEF = Baseline scenario emissions from the destruction of eligible ODS contained in foam for the reporting period, calculated using Equation 6.3 (kgCO2e)

1000 = Conversion from kilograms to tonnes (kgCO2e/tCO2e)

VR = Deduction for vapour composition risk determined in accordance with Subsection 6.1.1 (%)

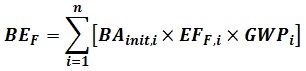

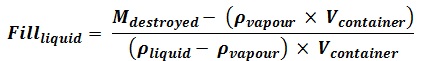

Equation 6.3. Baseline Scenario Emissions for Eligible ODS Contained in Foam

Where,

BEF = Baseline scenario emissions from to the destruction of eligible ODS contained in foam for the reporting period (kg CO2e)

n = Total number of Types of eligible ODS

i = Type of eligible ODS

BAinit,i = Initial quantity of eligible ODS blowing agent of type i contained in foam prior to processing, determined in accordance with Appendix C (kg ODS)

EFF,i = GHG emission rate for eligible ODS of type i contained in foam, as set out in table B.1 (%)