Technical Bulletin - Wells Regulation - Constructing New Uncased Test Holes and Dewatering Wells in Operation for no Longer than 30 days

The purpose of this technical bulletin is to summarize the information on the initial construction requirements for new uncased test holes and dewatering wells found in the Test Holes and Dewatering Wells – Requirements and Best Management Practices manual published by the Ministry of the Environment, April 2014.

April 2014

This technical bulletin is one in a series of seventeen

- may have a new test hole

footnote 2 or dewatering wellfootnote 3 constructed in the future, or - currently owns a test hole or dewatering well.

The purpose of this technical bulletin is to:

- summarize the information found in the Test Holes and Dewatering Wells – Requirements and Best Management Practices manual published by the Ministry of the Environment, April 2014 (hereon in referred to as the “Manual”) regarding the initial construction requirements for new uncased test holes and dewatering wells.

- present some construction steps that must be undertaken and materials that must be used to meet the requirements of Regulation 903 (Wells Regulation), as amended, made under the Ontario Water Resources Act.

Choosing a Construction Method

Successful completion of a test hole or dewatering well depends on the use of equipment and materials that are appropriate for the environmental conditions and geological formations encountered at a site. It is important to consider the characteristics of the drill rig or other well construction equipment including the cutting action and any flushing medium (i.e., type of drilling fluid and its circulation path).

The construction method:

- should be able to penetrate the geological formation,

- should allow the person constructing the test hole or dewatering well to get representative samples of geological formation material, to identify the boundaries of permeable zones and contaminated zones,

- must allow for the proper recording of formations, including aquifers, encountered during construction,

- must not contaminate the groundwater or the environment, and

- unless otherwise exempt, must meet the requirements of the Wells Regulation.

In many cases, the same equipment is used to construct more than one test hole or dewatering well for a project. Where there is no risk of contamination, the equipment does not have to be cleaned after each test hole or dewatering well is constructed before it can be re-used. Nonetheless, the construction method chosen must not contaminate the groundwater and the environment. To reduce the risk of contamination, however, an effective plan for decontamination of the equipment will help prevent the following:

- introduction of contaminants from one site to another site,

- contamination of clean areas,

- cross-contamination between formations, including aquifers,

- cross-contamination of individual samples,

- equipment breakdown,

- accidental exposure of personnel to contaminants, and

- non-compliance with regulatory cleanup standards.

The following standards contain procedures for equipment decontamination:

- ASTM D5088 – 02(2008) – “Standard Guide for Decontamination of Field Equipment Used at Nonradioactive Waste Sites,” (DOI:10.1520/D5088-02R08)

footnote 4 - ASTM D5608 – 01(2006) – “Standard Guide for Decontamination of Field Equipment Used at Low Level Radioactive Waste Sites,” (DOI:10.1520/D5608- 01R06)

footnote 5

Table 6-1 in Chapter 6 of the Manual: Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well provides methods, characteristics, advantages and disadvantages of various well construction systems in particular formations.

Table 6-2 in Chapter 6 of the Manual: Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well provides some appropriate types of construction equipment systems, which can be used to construct wells in particular environments and formations.

Exemption – Depth of Well

The minimum well depth requirements found in the Wells Regulation do not apply to a new uncased test hole or dewatering well.

The regulatory exemption regarding the depth of a test hole and dewatering well allows for well technicians, engineers and geoscientists to use their professional expertise to design and install test holes and dewatering wells on a case by case basis, according to the conditions at a particular site.

Exemption (30 Day Rule) - Well Casing for a New Test Hole or Dewatering Well

A person constructing a new test hole or dewatering well is not required to case the well if both of the following conditions exist,

- abandonment of the test hole or dewatering well is scheduled to take place not later than 30 days after completion of the structural stage

footnote 6 of the test hole or dewatering well, and - the person constructing the test hole or dewatering well covers the upper open end of the well securely in a manner sufficient to prevent the entry of surface water and other foreign materials whenever the test hole or dewatering well is left unattended.

For clarification, “unattended” means the person working on a well is no longer in control of or watching the specific well. For example, a person who leaves the well site is considered to have left the well unattended. Leaving the well site can include leaving the property, working on another well while not being present at the original well or not being in control of the well site.

Casing, Well Screen and Annular Space

A test hole or dewatering well commonly has a casing and may also have a well screen.

- casing

- means pipe, tubing or other material installed in a well to support its sides, but does not include a well screen. Casing keeps the hole open, prevents overburden materials from entering the well and accommodates pumping equipment. Casing may also be used to seal off unwanted formations.

- Well screen

- means a perforated pipe or tubing, unsealed concrete tiles or other material installed in a well to filter out particulate matter and form the water intake zone.

- Annular space

- means an open space between a casing or well screen and the side of a well, and includes space between overlapping casings within the well.

This technical bulletin deals with “uncased” test holes and dewatering wells scheduled to be abandoned not later than 30 days after completion. For the requirements that apply to cased test holes and dewatering wells see the Constructing New Test Holes & Dewatering Wells in Operation for No Longer than 180 Days” and the Constructing New Test Holes and Dewatering Wells technical bulletins and Chapter 6 of the Manual: Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well.

Covering the Well During Construction

The Wells Regulation requires that whenever a test hole or dewatering well, under construction is left unattended, including during a minor alteration or the installation of a pump, the person constructing the well must cover the upper open end of the test hole or dewatering well securely in a manner sufficient to prevent the entry of surface water and other foreign materials into the well.

Best Management Practicefootnote 7 – Covering Uncased Test Holes or Dewatering Wells

In situations where casing is not required, it is recommended that a temporary vertical tube and horizontal cover that is larger than the hole be installed into the ground and around the test hole or dewatering well to prevent hole collapse and the entry of surface water and other foreign materials. For further information see Figures 1 to 3 at the end of this technical bulletin.

A person constructing a test hole or dewatering well also must ensure a cover meets the Ontario regulation for Construction Projects (Ontario Regulation 213/91) of the Occupational Health and Safety Act requirements to prevent physical accidents at the well site for the public and workers. The person constructing the test hole or dewatering well should also take other reasonable steps to secure the site. As such, leaving the drill rods and other tools in the hole and placing a piece of plywood on top of the well is not a proper well cover.

Surface Drainage

The person constructing the well must ensure that the surface drainage is such that water will not collect or pond in the vicinity of the test hole or dewatering well.

Well Development & Disinfection

A person constructing a test hole or dewatering well is exempt from the Wells Regulation requirement to develop and disinfect the well.

Yield Test

The person constructing a test hole or dewatering well is exempt from performing a yield test on a test hole or dewatering well as long as the person measures the static water level.

Notifications (Natural Gas)

Where a test hole or dewatering well is constructed and natural gas is encountered, the person constructing the well must immediately notify the well purchaser, the owner of the land on which the well is located and the Director under the Act of the condition.

To prepare for on-site specific conditions such as hazardous gas or contamination, see the best management practices and information found in the Encountering Contamination and Water Quality Problems section in Chapter 6 of the Manual: Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well.

If a test hole or dewatering well produces natural gas, the well owner must immediately take action to ensure that the gas will not present a hazard. For further information on the appropriate action a well owner must take, see the Wells Regulation – Well Abandonment: When to Plug and Seal a Test Hole or Dewatering Well technical bulletin and Chapter 16 of the Manual: Well Abandonment: When to Plug and Seal a Test Hole or Dewatering Well.

Well Tag (Identification)

Well identification numbers link wells in the field with written records. Since October 2003, the Ministry of the Environment has issued steel well tags the size of a credit card to persons who construct wells in Ontario. Each tag has a unique number.

Before the structural stage of a new cased well is completed, the person constructing the well must obtain a well tag from the ministry and affix it permanently to the outside of the casing or to a permanent structure associated with the well.

If the well is an uncased test hole or dewatering well that is scheduled to be abandoned not later than 30 days after the completion of the well’s structural stage, then the person constructing the well is exempt from the requirement to affix a well tag on the test hole or dewatering well.

Well Record

The person constructing the well is not required to complete a well record for the construction of a test hole or dewatering well if the well is abandoned within 30 days of the completion of the well’s structural stage.

The reporting requirements of the Wells Regulation capture the construction, alteration and abandonment of test holes and dewatering wells that will be in place for more than 30 days. For example, the Ministry expects a well record for a new test hole that will monitor the long term groundwater impact of a waste disposal site or for a dewatering well that will be pumping contaminated groundwater to contain a spill.

Exempted Wells & Shallow Works

The Wells Regulation exempts certain types of wells, such as a pond or trench, from the Wells Regulation and from the sections on licensing of the Ontario Water Resources Act that pertain to wells

A person who constructs, maintains or abandons a shallow works that meets the conditions set out in section 1.1 of the Wells Regulation:

- is exempt from the sections on licencing of the Ontario Water Resources Act that pertain to wells,

footnote 9 and - need only meet the requirements found in section 1.1 of the Wells Regulation.

The shallow works exemption contained in section 1.1 of the Wells Regulation does not apply to a monitoring well that is constructed as part of a phase one or two environmental site assessment for a record of site condition

See the Wells Regulation – Understanding a Well, Test Hole and Dewatering Well and Wells Regulation – Shallows Works technical bulletins for further information.

Water Supply Wells

Certain licensing and construction requirements for water supply wells are different from the requirements for test holes and dewatering wells as defined by the Wells Regulation. For further information on the requirements for water supply wells see the Water Supply Wells – Requirements and Best Management Practices manual, published by the Ministry of the Environment, December 2009 and the Wells Regulation.

Additional Information Sources

The seventeen technical bulletins on test holes and dewatering wells are:

- Wells Regulation – Understanding the Meaning of Well, Test Hole and Dewatering Well

- Wells Regulation – Shallow Works Test Holes & Dewatering Wells

- Wells Regulation – Exempted Activities Performed on Wells, Including Test Holes & Dewatering Wells

- Wells Regulation – Test Hole and Dewatering Well Licensing

- Wells Regulation – Licensing (Class 5) for Individuals who Perform Tests on Wells

- Wells Regulation – Site Considerations & Initial Planning for Test Holes & Dewatering Wells

- Wells Regulation – Constructing New Uncased Test Holes & Dewatering Wells in Operation for No Longer than 30 Days

- Wells Regulation – Constructing New Test Holes & Dewatering Wells in Operation for No Longer than 180 Days

- Wells Regulation – Constructing New Test Holes & Dewatering Wells

- Wells Regulation – Constructing New Multi-level Monitoring Test Holes

- Wells Regulation – Completing the Structure of the New Test Hole or Dewatering Well

- Wells Regulation – Flowing Test Holes & Dewatering Wells

- Wells Regulation – Test Hole & Dewatering Well Maintenance

- Wells Regulation – Well Record, Reporting & Tagging for a Test Hole & Dewatering Well

- Wells Regulation – Test Hole & Dewatering Well Repairs & Alterations

- Wells Regulation – Well Abandonment - When to Plug & Seal a Test Hole or Dewatering Well

- Wells Regulation – Well Abandonment - How to Plug & Seal a Test Hole or Dewatering Well

These technical bulletins are available on Ontario.ca.

Further information on constructing an uncased test hole or dewatering well that is scheduled to be abandoned not later than 30 days after completion of the well’s structural stage can be found in Chapter 6 of the Manual: Constructing the Hole, Casing & Covering the Test Hole or Dewatering Well.

A copy of the Test Holes and Dewatering Wells – Requirements and Best Management Practices manual can be obtained on Ontario.ca.

A copy of the Ontario Water Resources Act, Regulation 903 as amended made under the Ontario Water Resources Act (Wells Regulation) and other regulations can be obtained from the e-Laws website.

The publications are also available by calling the Publications Information Centre at 1-800-565-4923 or (416) 325-4000.

For further information about wells, contact the Wells Help Desk at 1-888-396-9355 (Well) or the nearest Ministry of the Environment office listed in the blue pages of the telephone directory.

Notice: This bulletin is being provided for information purposes only and is not intended, nor should it be construed as providing legal advice in any circumstances. The applicable environmental legislation, including the following, should be consulted.

- Ontario Water Resources Act, R.S.O. 1990, c. O. 40

- R.R.O. 1990, Regulation 903 (Wells) as amended made under the Ontario Water Resources Act, R.S.O. 1990, c. O. 40

- Ontario Regulation 153/04 as amended made under the Environmental Protection Act, R.S.O. 1990, c. E. 19

Legislation and regulations change from time to time so it is essential that the most current versions be used.

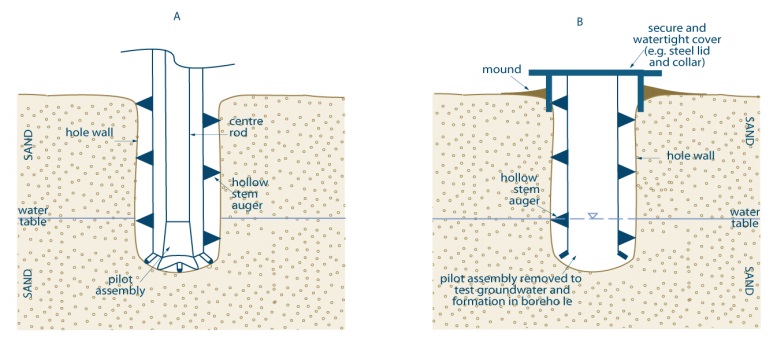

Figure 1: Examples of Uncased Test Holes or Dewatering Wells Constructed by Augering (Scheduled to be Abandoned Not Later than 30 Days After Completion of Structural Stage)

This figure is not to scale, is for illustrative purposes for this technical bulletin only, and does not necessarily represent full compliance with the requirements found in the Wells Regulation.

The example on the left (A) shows a well including its hole wall being constructed into the ground with a hollow stem auger. The auger has a pilot assembly and centre rod within the auger flight. The well has been constructed through sand overburden below the water table.

The example on the right (B) shows construction of a well stopped. The hollow stem auger has been left in the hole. The auger’s pilot assembly was removed to test groundwater and the formation in the borehole. The well has been constructed through sand overburden below the water table. A secure watertight cover (e.g., steel lid and collar) has been placed at the ground surface over the auger flights and borehole wall. The ground surface beside the cover and collar has been mounded to prevent the ponding of water in the vicinity of the well.

There are two notes below the diagram.

Note 1 states the hole is constructed and held open using hollow-stem auger flights.

Note 2 states the well cover must be placed securely on the well and placed in a manner to prevent the entry of surface water and other foreign materials whenever the test hole or dewatering well is left unattended. The well cover could consist of a water tight steel cover and lid as shown in B.

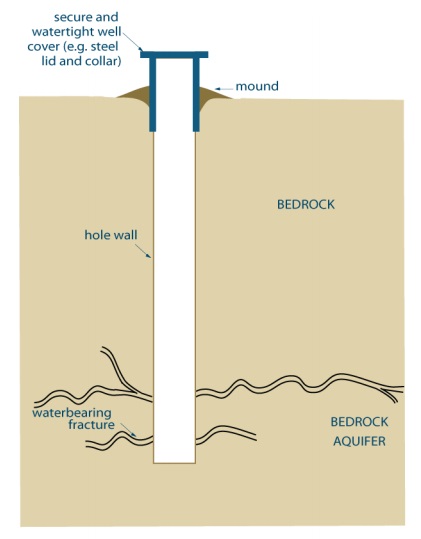

Figure 2: Example of Uncased Well Constructed By Diamond Drilling (Scheduled to be Abandoned Not Later than 30 Days After Completion of Structural Stage)

This figure is not to scale, is for illustrative purposes for this technical bulletin only, and does not necessarily represent full compliance with the requirements found in the Wells Regulation.

The example shows construction of a diamond drilled well including its borehole wall through bedrock to a water bearing fracture (bedrock aquifer). A secure watertight cover (e.g., steel lid and collar) has been placed at the ground surface over the open hole. The ground surface beside the cover and collar has been mounded to prevent the ponding of water in the vicinity of the well.

There are two notes below the diagram.

Note 1 states the hole is constructed diamond drilling equipment and the bedrock is strong enough to hold the hole open. As this well is uncased, an annular space does not exist.

Note 2 states the well cover must be placed securely on the well and placed in a manner to prevent the entry of surface water and other foreign materials whenever the test hole or dewatering well is left unattended. The well cover could consist of a water tight steel cover and lid as shown.

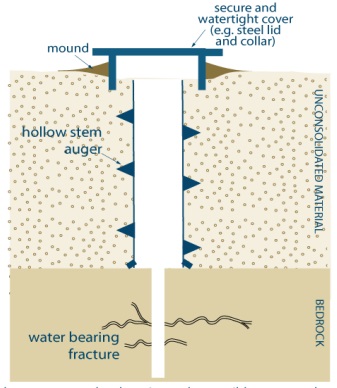

Figure 3: Example of Well Construction With Use of Hollow-Stem Auger in Conjunction with Drilling (Scheduled to be Abandoned Not Later than 30 Days After Completion of Structural Stage)

This figure is not to scale, is for illustrative purposes for this technical bulletin only, and does not necessarily represent full compliance with the requirements found in the Wells Regulation.

The example shows construction of a well using a hollow stem auger through an unconsolidated material to the top of the bedrock. The auger’s pilot assembly was removed in the borehole. The remainder of the well has been constructed using some drilling equipment through bedrock to a water bearing fracture. A secure watertight cover (e.g., steel lid and collar) has been placed at the ground surface over the open hole. The ground surface beside the cover and collar has been mounded to prevent the ponding of water in the vicinity of the well.

There are two notes below the diagram.

Note 1 states this figure shows an example where it may be possible to auger through the overburden, but not the entire desired depth of the well. In this example, a hollow stem auger has created a hole through the overburden. A drilling system has been used to complete the remainder of the hole in the bedrock.

Note 2 states the well cover must be placed securely on the well and placed in a manner to prevent the entry of surface water and other foreign materials whenever the test hole or dewatering well is left unattended. The well cover could consist of a water tight steel cover and lid as shown.

PIBS 9617e

Footnotes

- footnote[1] Back to paragraph A list of the seventeen technical bulletins is shown in the Additional Information Sources section near the end of this technical bulletin.

- footnote[2] Back to paragraph A “test hole” means a well that, (a) is made to test or to obtain information in respect of ground water or an aquifer, and (b) is not used or intended for use as a source of water for agriculture or human consumption, subsection 1(1) of the Wells Regulation, e-laws.

- footnote[3] Back to paragraph A “dewatering well” means a well that is not used or intended for use as a source of water for agriculture or human consumption and that is made, (a) to lower or control the level of ground water in the area of the well, or (b) to remove materials that may be in the ground water, subsection 1(1) of the Wells Regulation, e-laws.<

- footnote[4] Back to paragraph (DOI:10.1520/D5088-02R08) ASTM International, West Conshohocken, PA.

- footnote[5] Back to paragraph (DOI:10.1520/D5608-01R06) ASTM International, West Conshohocken, PA.

- footnote[6] Back to paragraph A well’s structural stage is complete on the day on which the well is capable of being used for the purpose for which it was constructed but for, (a) compliance with section 15; (b) the installation of a pump; or (c) any alterations necessary to accommodate pumping, monitoring, sampling, testing or water treatment equipment, subsection 1(1) of the Wells Regulation, e-laws.

- footnote[7] Back to paragraph Best management practices are recommended actions or steps that exceed the minimum regulatory requirements to better protect the groundwater and the natural environment but are not enforceable.

- footnote[8] Back to paragraph Sections 36 to 50 of the Ontario Water Resources Act, R.S.O. 1990, c. O. 40.

- footnote[9] Back to paragraph Sections 36 to 50 of the Ontario Water Resources Act, R.S.O. 1990, c. O. 40.

- footnote[10] Back to paragraph Ontario Regulation 153/04 as amended made under the Environmental Protection Act, R.S.O. 1990, c. E. 19.

- footnote[11] Back to paragraph Figure based on: ASTM D5784 - 95(2006) – “Standard Guide for Use of Hollow-Stem Augers for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices.” (DOI: 10.1520/D5784-95R06). ASTM International, West Conshohocken, PA.