Troubleshooting cold storage problems

Learn about some of the most common problems and solutions found in fruit and vegetable refrigerated storages. This technical information is for commercial crop producers in Ontario.

ISSN 1198-712X, Published December 2024

Introduction

There are hundreds of refrigerated storages in Ontario (Figure 1) used for short or long-term storage of fruits and vegetables (called “products” in this fact sheet). Storages are used as a marketing tool to smooth out peaks and valleys in production, allow a more continuous supply to customers, and help maintain the quality of produce. Storages come in a vast array of sizes, layouts and construction methods, all of which are critical to their proper function.

Having cold storage issues? Failure to identify issues can lead to crop spoilage while in cold storage. This fact sheet lists some of the most common problems found in refrigerated storages, with possible causes and solutions. It is always a good idea to perform regular inspections and maintenance to ensure the cold storage is structurally fit and operating properly. A cold storage contractor can assist with preparing an inspection and maintenance schedule. Some solutions can be resolved by the storage owner while others should be addressed by a qualified contractor.

Use the following tables to identity solutions and get issues corrected quickly:

Product-related problems

- Some product is freezing

- Some product is shrivelling

- Some product is sweating or has free water on it

- Product is displaying premature ripening, discolouring, loss of leaves (plants)

- Product has odours or off-flavours

- Product is rotting

Building-related problems

- Walls and/or ceiling have condensation or are mouldy

- Walls and/or ceiling are rotting

- Ceiling is dripping

- Floor is drying out even when floor is sprayed with water

- Inside air temperature fluctuates during storage period

- Inside air temperature is warmer than desired during storage period

- Inside air temperature is colder than desired during the storage period

- Inside air temperature is not uniform

- The storage air smells bad or is difficult to breathe

- Evaporator coils are icing up and create a lot of condensate

- Electrical consumption is rising

Product-related issues

Some product is freezing

| Possible cause | Possible solution |

|---|---|

| Thermostat setpoint is too low, its differential is too wide or the location of the thermostat (or its sensor) is poor. | Adjust the thermostat to a higher temperature. Decrease the temperature differential (on-off). Relocate the thermostat (or its sensor) or replace the thermostat. |

| Product is stacked too high and is directly in the airstream from the coils. | Avoid stacking product too close to the air stream from the coils. Install baffles under the coils to deflect cold air above the product. |

| Product is touching or is too close to freezing walls (in winter or if next to a freezer). | Re-insulate, especially on concrete foundations and keep product away from cold walls. |

| Evaporator coils are dirty or have one or more fans not functioning, causing the leaving air temperature to be colder. | Clean evaporator coils or repair fans. |

| One coil may not be functioning properly (with multiple coils) causing the leaving air temperature from others coils to be colder. | Have a technician check coils and valves for proper refrigerant flow, operating pressure and temperatures (superheat settings). |

| Poor air flow. | Use a smoke generator to find dead air spots. Relocate coils or increase their fan capacity. Install air tubes and/or extra circulation fans. Lay out containers to promote good air distribution. |

Some product is shrivelling

| Possible cause | Possible solution |

|---|---|

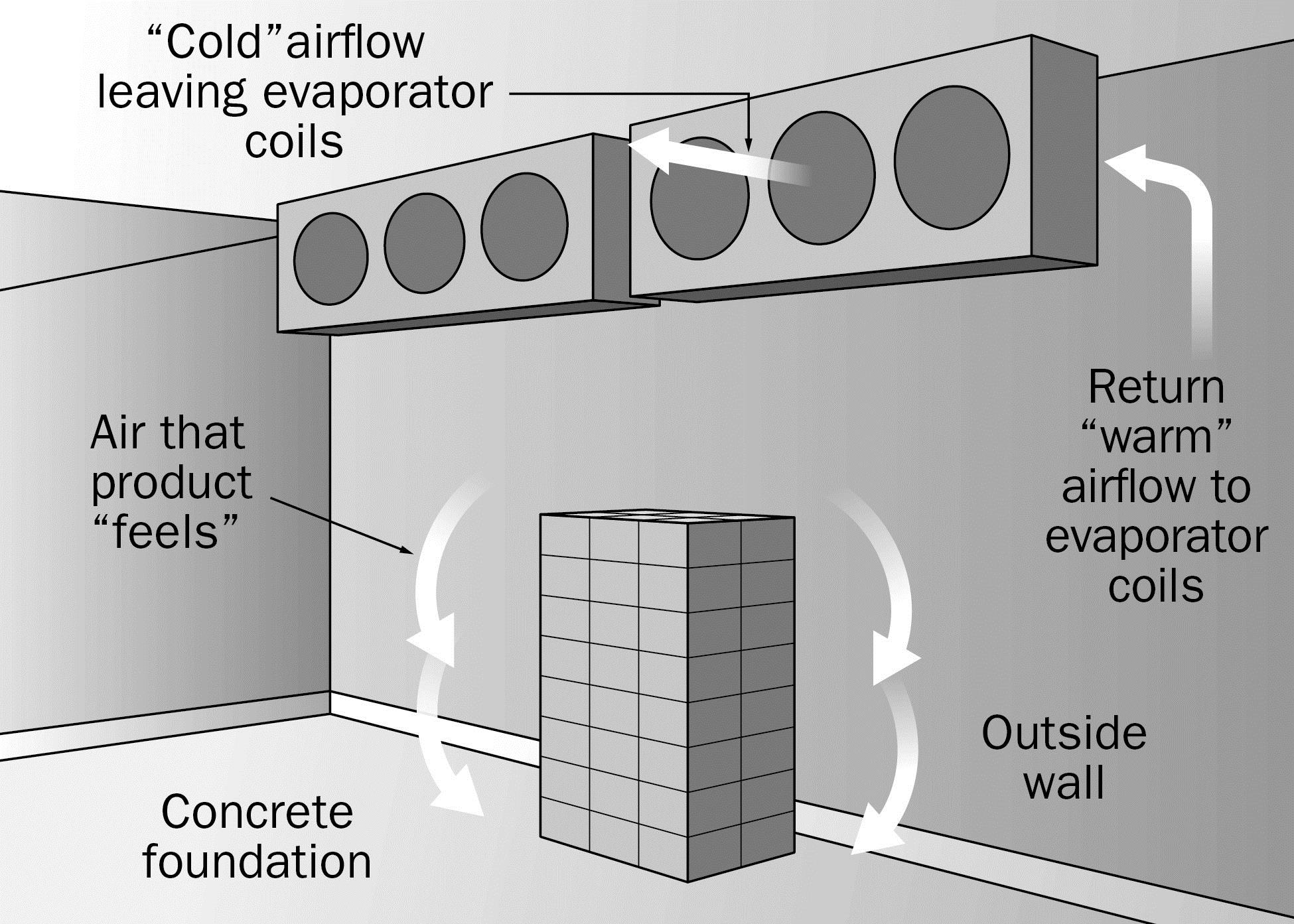

| Storage relative humidity is too low. | Clean evaporator coils (if dirty). Replace non-functional fans. Check the defrost frequency (duration and termination) as it may be adding excessive heat to the room or allowing excessive frosting between cycles. Have a contractor check the system and coils for efficient operation and proper operating temperatures. Adjust superheat settings on expansion valves. Have a contractor check system sizing (compressor vs. evaporator coil sizing and temperature difference at actual design conditions). Increase coil size or install more coils so they can operate at a lower temperature difference between “cold” air leaving the coils and air that the product “feels.” This increases air humidity. Install humidification equipment that can supply ultra-fine or atomized mist (it’s hard to put water back into desiccated product). |

| Product is warm and moist while cold air is dry and pulls moisture out. Vapour pressure differential too high. | Remove field heat more rapidly and promptly after harvest (get product into cooler as soon as possible) so there is less vapour pressure difference between the product and storage air. This promotes moisture to stay in the product and avoid desiccation. |

| Wooden containers and the storage structure itself is drawing moisture out of the air and product. | Wet the wooden containers before putting in long term storage. Tests show that wooden bins can increase 10% in weight by absorbing moisture. |

| Products such as pome fruit appear wrinkled when slightly frozen. | Refer to possible solutions under Some product is freezing. Pome fruit that has been slightly frozen does not shrivel from moisture loss and will lose wrinkles when thawed. |

Some product is sweating or has free water on it

| Possible cause | Possible solution |

|---|---|

| Warm, moist air is entering the room through door openings or air leaks in the room. | Reduce infiltration of warm air by minimizing door opening time, ensuring door seals are not damaged, installing a strip curtain (or air curtain) and preventing wind pressure and/or cooling of the adjacent area. |

| Warm, moist air from recently placed product is hitting cold product. | Keep “cold” product being stored for longer periods in a separate room from “hot” product being cooled. Install more refrigeration to reduce dramatic air temperature increases. |

| Warm, moist air is condensing on the cold product after the product has been removed from storage. | Allow product to warm up gradually; condensation is unavoidable if product is put directly into a warm, moist atmosphere or add air conditioning for the packaging area. |

| Evaporator defrost duration may be too long and/or termination may not be working, allowing room temperature to rise too high. | Check the defrost frequency, duration and termination to prevent excessive heat being added to room. |

| Defrost water from evaporator coils is dripping on produce. | Install drain pans under evaporators to collect evaporator coil defrost water and/or condensate. Route condensate drain pipes away from product to a suitable discharge location. |

| Humidification system droplets are too large or humidistat is set too high or is out of calibration. | Install humidification equipment that can supply ultra-fine or atomized mist or adjust, calibrate or replace the humidistat. |

Product is displaying premature ripening, discolouring, loss of leaves (plants)

| Possible cause | Possible solution |

|---|---|

| Ethylene gas may be present. | Remove high ethylene producing fruits in the storage area (such as apples, pears, cantaloupes, plums, peaches, apricots, muskmelons, tomatoes). Avoid using forklifts that emit ethylene in the exhaust. Thoroughly ventilate storage rooms before use. Also ventilate during use provided there is adequate refrigeration to handle the extra load from the ventilation. |

| Storage temperature may be too high. | Lower the storage temperature. Add more refrigeration, if inadequate. |

| Defrost cycles are too long and/or adding too much heat to the room. | Check defrost for correct frequency, duration and termination. |

| Product is stacked too tight, preventing it from cooling. | Leave space between rows and layers of product and stack in a manner that allows good airflow through it. |

Product has odours or off-flavours

| Possible cause | Possible solution |

|---|---|

| Products nearby that readily transfer odours and/or off-flavours. | Remove crops such as cabbage, rutabagas, celery, potatoes, onions, lettuce or garlic. |

Product is rotting

| Possible cause | Possible solution |

|---|---|

| Product is too warm and is respiring and aging rapidly. | Provide quick and uniform rapid cooling after harvest. Maintain the recommended temperature during the storage period. |

| Product damaged, overripe or of poor quality before storage. | Increase culling rates before storage. Do not expect storage to turn poor quality product into top-quality product with a long shelf life. |

Building-related issues

Walls and/or ceiling have condensation or are mouldy

| Possible cause | Possible solution |

|---|---|

| Interior surfaces are colder than the room air hitting it. Surface temperatures and moisture level are ideal for mould growth. | Install more insulation to warm up wall surfaces above the room air’s dew point (condensation). Avoid leaving doors open for extended periods of time. Provide better doors with good seals and/or tighten up the building construction to mitigate air infiltration. Provide better airflow in these areas. |

| Excessive moisture or warm moist air is entering the room. | Reduce infiltration of warm air by minimizing door opening time, installing a strip curtain (or air curtain), ensuring door seals are not damaged and preventing wind pressure and/or cooling the adjacent area. |

| Insulation in ceiling or walls is saturated. | Remove wet insulation. Allow surfaces to dry out and replace insulation with adequate spray foam insulation. |

Walls and/or ceiling are rotting

| Possible cause | Possible solution |

|---|---|

| Moisture migrating into wood cladding/structure. | Before reconstruction, determine why and how to prevent moisture from migrating in again. |

| Improper installation of or missing vapour barrier. | Determine appropriate vapour barrier location, if needed. |

| Incorrect type of insulation used or inadequate insulation value installed. | Re-insulate if needed, possibly with different insulation. |

| Water leaking in from roof or other sources. | Repair roof or other source of water leak and dry out or replace wet insulation. |

Ceiling is dripping

| Possible cause | Possible solution |

|---|---|

| Poor attic ventilation allowing a buildup of hot, moist air in the attic. | Provide 1 m2 of unrestricted eave inlet vent area per 600 m2 of ceiling, with same unrestricted peak vent area, or mechanically ventilate at 1 air change/2 minutes. |

| Insufficient attic insulation causing condensation which drips through the cracks. | Remove wet insulation. Allow surfaces to dry out and replace insulation with adequate spray foam insulation |

| Improper installation of or missing vapour barrier. | Add enough insulation to prevent its temperature on the warm side from cooling to the dew point (condensation) of the warm air in the attic. Vapour barrier location depends on vapour pressure drive direction (warm side). A vapour barrier may not be advisable depending on building use. |

Floor is drying out even when floor is sprayed with water

| Possible cause | Possible solution |

|---|---|

| Storage relative humidity is too low. | Install more coils so they can operate at a lower temperature difference between “cold” air leaving the coils and air that the product “feels.” This increases air humidity. Install humidification equipment that can supply ultra-fine or atomized mist, it is hard to put water back into desiccated product. |

| Floors have cracks for water to escape. | Flood floors to see if water runs away, especially along concrete foundation. Seal if necessary. |

Inside air temperature fluctuates during storage period

| Possible cause | Possible solution |

|---|---|

| Thermostat not located properly and does not sense average room temperature. | Install thermostats in average room airflow, usually in the return airflow to evaporator coils. Relocate thermostats away from warm/cold walls, doors, lights, cold air leaving the coils or hot product. |

| Poor quality or insensitive thermostats (differential too wide). | Recalibrate thermostat including differential or replace thermostat. Use good-quality equipment rated appropriately for the environment it will be installed in since uniform temperature control is vital for maintaining product quality. |

| Defrost cycles are not set or working correctly, allowing excessive frosting between cycles or adding too much heat to room. | Check defrost for correct frequency, duration and termination. |

| Airflow not uniform throughout storage. | Use a smoke generator to determine location of dead air spots. Relocate evaporator coils or increase the capacity of their fans (if possible). Install air tubes and/or extra fans. Rearrange storage containers to allow for more uniform airflow. |

Inside air temperature is warmer than desired during storage period

| Possible cause | Possible solution |

|---|---|

| Inadequate refrigeration. | Install more refrigeration cooling capacity. |

| Insufficient insulation for summer use. | Install minimum R-20 in walls, R-24 in attic and R-12 on the foundation. Floors are seldom insulated in Ontario, but for year-round use the cost can be justified. |

| Poor attic ventilation. | Provide 1 m2 of unrestricted eave vent inlet area per 600 m2 of ceiling, with same unrestricted peak vent area, or mechanically ventilate at 1 air change/2 minutes. |

| Hot sunny days with a dark roof surface. | Paint roof chalk white and provide adequate attic ventilation, since attic temperatures can reach 60°C. |

| Airflow not uniform or of insufficient capacity in storage. | Use smoke generators to determine the location of dead air spots. Relocate evaporator coils or increase the capacity of their fans (if possible). Install air tubes and/or extra fans. Rearrange storage containers to allow more uniform airflow. |

| Poor thermostat location that senses cold temperatures. | Install thermostats in average room airflow, usually in return airflow to evaporator coils. Avoid locating thermostats on outside cold walls, near doors or near the cold air leaving evaporator coils. |

Inside air temperature is colder than desired during the storage period

| Possible cause | Possible solution |

|---|---|

| Thermostat poorly located and senses warmer temperatures. | Install thermostats in average room airflow, usually in return airflow to evaporator coils. Avoid locating thermostats on outside warm walls or near doors or lights. |

| Insufficient insulation for winter use. | Install minimum R-20 in walls, R-24 in attic and R-12 on foundation. Floors are seldom insulated in Ontario, but for year-round use, the cost can be justified. |

Inside air temperature is not uniform

| Possible cause | Possible solution |

|---|---|

| Airflow is not uniform or is insufficient for product capacity in storage. | Use smoke generators to determine the location of dead air spots. Relocate evaporator coils or increase the capacity of their fans (if possible). Install air tubes and/or extra fans. Rearrange storage containers to allow more uniform airflow. |

| Short-circuiting of air directly back to the evaporator coils because of poor storage container arrangement. | Avoid alleys/openings that allow air to by-pass product or storage containers. Air will always take the easiest path and air must be forced to travel a meandering path to maximize cooling potential. Use a smoke generator to inspect for short-circuiting. |

The storage air smells bad or is difficult to breathe

| Possible cause | Possible solution |

|---|---|

| Gases such as carbon dioxide or ethylene may be present in excessive quantities as a result of decay or respiration. | Look for and dispose of decaying product. Install a small exhaust fan that provides ventilation of 1 or 2 air changes/day. Some newer storages (not built as controlled atmosphere storages) are very tight so there is no natural air-change ventilation. |

Evaporator coils are icing up and create a lot of condensate

| Possible cause | Possible solution |

|---|---|

| Coils running at too low a temperature. | Clean coils and ensure that all fans are blowing in the correct direction. Increase coil temperature. This may require larger capacity evaporator coils. |

| Defrost system not running properly. | Repair defrost system or install a more effective one, since the relative humidity should be high for most crops. |

| Storage relative humidity is high. | Some crops such as onions, garlic or squash require lower humidities. |

Electrical consumption is rising

| Possible cause | Possible solution |

|---|---|

| Insulation is wet or missing. | Correct moisture problem and re-insulate with an insulation that is more suitable for cold storages. |

| Higher volume of product being cooled than before. | Install more refrigeration as crop production rises. Properly size the system to reduce costs. |

| Product is entering storage hotter than in previous seasons. | Earlier varieties and variable weather may mean harvested product is warmer, requiring more refrigeration capacity than before. |

| Building less tight or doors open more often. | Ensure the building construction is tight since they do become less tight over time. Install flaps over access doors. |

| Dirty evaporator coils or condenser coils (on outdoor units). | Clean evaporator and condenser coils. |

| Malfunctioning refrigeration equipment. | Get equipment serviced by a qualified refrigeration contractor familiar with the needs of farm produce. |

Summary

Keeping the cold storage structure and cooling system in optimum condition will help with ensuring high quality product and meet processor and retail demand over longer periods. Some issues can be resolved using storage techniques. However, some will need to be addressed by a qualified contractor.

Author credits

OMAFRA fact sheet 14-039 Forced-Air Cooling Systems for Fresh Ontario Fruits and Vegetables

This fact sheet was updated by Kevin Baines, P. Eng., specialty greenhouse and horticultural crops, Ministry of Agriculture, Food and Agribusiness (OMAFA). It was originally written by John Warbick P. Eng., Horticultural Crops, OMAFA and reviewed by Hugh W. Fraser, OTB Farm Solutions and Dennis Bering, Penn Refrigeration, St. Catharines.