Odour assessment

The intent of the odour assessment test is to, as accurately as possible, determine the odour generated from the activity in the field. All odour assessment tests must be conducted at the maximum application rate approved for the site and the NASM used must be representative of the material to be applied. For example, the depth of NASM in the flux chamber must match the depth of NASM applied to the land surface.

Laboratories participating in odour assessment testing are required to have sound quality criteria for the overall performance in the odour assessment test. The testing laboratory must comply with the applicable quality criteria by means of performance testing as specified in Clause 5 of EN 13725:2003.

It is recognized that odour assessment tests conducted in a laboratory may result in a higher odour detection threshold than an odour assessment test conducted at an actual application site where there is a porous substrate underneath (i.e. soil). An odour assessment test conducted in a laboratory represents a conservative approach to classifying NASM.

The generator must submit the methodology proposed for the odour assessment test to the Director prior to doing the test. For compliance purposes, the method must be comparable to the standard methods in section 8 of this guide. An odour assessment test carried out without first discussing the methodology with the Director will not be accepted by the Director as part of a NASM plan approval.

There are two acceptable methods for collecting odour samples for evaluation by the odour evaluation panel: a Laboratory Sampling Method and an In-Field Sampling Method.

8.1. Laboratory sampling method

When an odour assessment test is done for the purpose of classifying a material, a minimum of three samples of the NASM must be collected for analysis at a laboratory. The laboratory method used must be comparable to the standard methods in section 8.3 of this guide using an EPA style flux chamber with a diameter of 40.6 cm and area coverage of 0.13 m2 with sweep gas flow rates metered at 5 L/min. NASM samples should be analyzed within 5 hours of collection but must not be analyzed later than 24 hours after collection.

8.2. In-field sampling method

If the in-field method is to be used, a minimum of 3 triplicate samples collected from a minimum of three locations that are representative of the spreading area shall be analyzed. The in-field method used must be comparable to the standard methods in section 8.3 of this guide using an EPA style flux chamber with a diameter of 40.6 cm and area coverage of 0.13 m2 with sweep gas flow rates metered at 5 L/min. Field assessments for odour must be analyzed within 3 hours of the application of the NASM to the site.

8.3. Area source – EPA style flux chamber sampling procedure

This method can be used to obtain odour samples either in the field from area sources with no induced flow, including but not limited to land application sites or in the laboratory. The flux chamber system described below can be set up in the field or in the laboratory.

Area sources are rarely homogeneous in nature. As a result, it is important that a well developed sampling strategy is employed to ensure that the samples collected provide a fair representation of the odour emission potential of the source as a whole. This may require sampling to be completed at multiple locations and/or times, for each individual source.

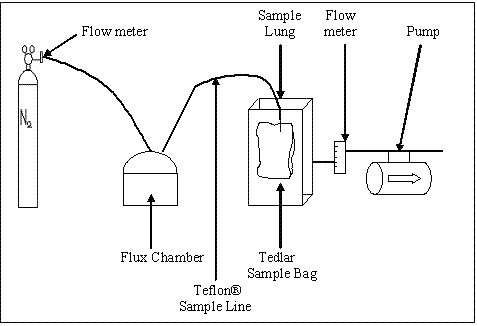

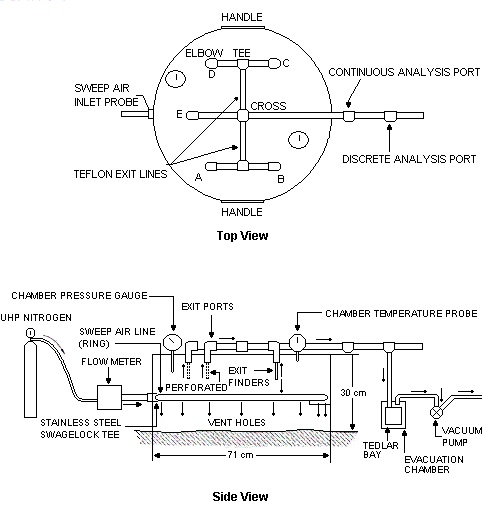

A sketch of an acceptable area source odour sample collection system is shown in Figures 8-1 and 8-3. Other odour sample collection systems and procedures may be used, provided it can be demonstrated that they are comparable to the standard methods in section 8.3 of this guide and are acceptable to the Director.

Note that sampling, using this approach, is not to be conducted on rainy days (or when rain occurs within 24 hours prior to the scheduled sampling) as the rain will interfere with the normal generation and release of the odorous emissions (odour scrubbing effect).

8.3.1. Apparatus

The following apparatus are used when collecting odour samples using either of the methods presented in sections 8.1 and 8.2 of this guide.

Sample line - made of Teflon®, or glass; the distance between the probe and the sample container shall be kept to a minimum. All fittings shall be clean and odour free and a comparable level of odour resistance of Telfon® or stainless steel composition.

Sample containers - material of construction shall be Tedlar®, Teflon® or any other materials (such as Nalophan®) which will not compromise the integrity of the sample. When such other materials are proposed, approval from the Director is required. The sample container shall be of sufficient volume to carry out a minimum of a six member odour panel evaluation.

Sample lung – rigid vessel or container, capable of maintaining a vacuum sufficient to pull the sample from the exhaust stream, within the time required.

Pump – Leak free Teflon® coated diaphragm-type pump (with adjustable flow) or equivalent, which is capable of delivering at least 1 litre/minute.

Flow meter - Two (2) flow meters with a 0 to 5 litre flow range.

Neutral gas - nitrogen (4.8 grade or higher) or air that is treated in such a way that it is as odourless as technically possible.

Flux Chamber - Enclosure with a cylindrical shaped base and a spherical top, constructed of stainless steel or plexiglass. The unit shall be equipped with odour free fittings which will allow for the introduction of neutral (sweep) gas, the extraction of a gaseous sample and the relief of sweep gas pressure (i.e. with a bleed valve). See Figure 8-1 for a diagram. The flux chamber shall be equipped with a flotation device for sampling liquid surfaces.

8.3.2. Preparation

The sample containers shall be preconditioned by heating to 70°C (158°F), and flushed continuously with neutral gas for a minimum of 24 hours. Note that materials other than Tedlar® and Telfon® may not require such preconditioning. However, guidance in this issue is required from the Director.

The flux chamber shall be clean and free of residual odour prior to each use. The flux chamber must be tested using blanks between each use to confirm that it is odour free.

The sample transfer line must be clean and free of residual odour. If any contamination is observed on the sample transfer line, the sample transfer line must be replaced. A new and/or clean odour free sample line must be used for each source being measured.

8.3.4. Sampling procedure

Assemble the odour sample collection system and place the flux chamber over the surface area to be tested. Ensure that the cylindrical walls of the flux chamber are slightly below the sampling surface thereby preventing the introduction of ambient air into the chamber.

Start the flow ofmetered neutral sweep gas into the flux chamber. The flow rate shall be metered at 0.00064 m3/s based on one square metre of coverage. Using an EPA style flux chamber with a diameter of 40.6 cm and area coverage of 0.13 m2, sweep gas flow rates shall be metered at 5 L/min.

Flux chambers covering a larger surface area will require a higher sweep gas flow rate. In such cases, the sweep gas flow rate results will need to be normalized to 0.00064 m3/s based on one square metre of coverage.

Allow a minimum of four (4) air exchanges to occur within the chamber prior to drawing a sample. Each air exchange represents passing a volume of sweep gas into the flux chamber that is equal to the chamber volume.

To condition the sample container, connect it to the sample line within the rigid vessel. Seal the vessel and start the pump. Fill the sample container and stop the pump. Empty the sample container and repeat the above procedure. The sample container is now conditioned for the collection of odour samples.

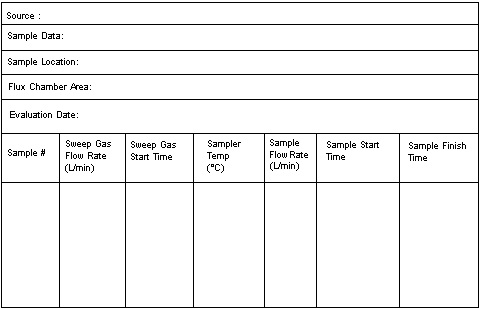

Reconnect the conditioned sample container to the sample line within the rigid vessel, seal the vessel and begin sampling by starting the pump. The sample flow rate is required to be such that the sample container is filled over a 10 minute sampling period. The sweep gas volumetric flow rate must exceed that of the sample flow rate. Record all data according to Figure 8-2.

A minimum of three separate samples shall be collected from each source but, as indicated previously, area sources are rarely homogeneous in nature. The number of separate samples may be higher than three depending on the number of selected locations that will provide a fair representation of the odour emission potential of the source as a whole.

Note that when using the flux chamber approach for collecting odour samples, the odour concentration is calculated based on the sweep gas rate; meaning that the rate of odourant released from the source, may not be equivalent to the rate of the flux chamber sweep gas.

The flux chamber sweep gas rate, and its normalization, is used for convenience; as the rate of odourant release is very complicated to calculate. The rate of odourant release from a surface area will depend (among other parameters) on the temperature of the surface, the porosity of the surface, ambient relative humidity, the substance chemical and physical composition releasing the odourant, the surface tension between the odourant and the surface area, and the sweeping effect of the wind on the surface area.

8.3.5. Sample recovery

After completion of the 10 minute sample collection, the sample container is immediately sealed, labeled and shielded from direct sunlight. To protect from photo-chemical degradation samples shall be placed in a dark or opaque container for storage and transport.

Samples shall be transported to an accredited odour analysis laboratory to be analyzed within 24 hours of sample collection.

Note: Do not use stickers, tapes or other adhesive/solvent based products to label Tedlar® or Teflon® sample bags as there is the potential for odours to migrate into the sample container.

8.4. Sample evaluation/odour detection threshold determination

8.4.1. Dilution apparatus

The dilution apparatus is the equipment used to mix neutral gas with the sample of odourous gas at set ratios prior to evaluation by the odour evaluation panel. The EN 13725:2003 sets out the requirements for the general properties of materials in Clause 6.1 and the dilution apparatus in Clause 6.5.

8.4.1. Odour evaluation panel

The selection of the odour evaluation panel is critical for an objective and unbiased evaluation of the subject NASM. The panel must have a minimum of 6 members. Panel member selection criteria must be based on the criteria established in EN 13725:2003 Clause 6.7.

8.4.2. Odour evaluation and calculation of odour concentration

The EN13725:2003 recommends two Modes of Presentation (Binary and Forced Choice) for the evaluation of odour by the panel. Either method can be used in the evaluation of the odour from a NASM that is to be applied to agricultural land under O. Reg. 267/03. The criteria for each mode of presentation are in Clause 8 of EN 13725:2003.

The odour detection threshold is calculated as the geometric mean of the individual panelist responses. The odour concentration (ou/m3) is equal to this numeric value.

Pre-dilution of samples may be required in situations where the odour concentration is so high that it exceeds the dilution capability of the olfactometer, or in the case that a wet source results in the formation of condensation in the sample bag. In the case that field dilution (pre-dilution) is employed, the DT is the product of the pre-dilution ratio and the geometric mean of the individual odour panelist responses.

Example calculations for determining odour concentration and odour detection threshold are in Appendix F of EN 13725:2003.

Once the odour detection threshold of the subject NASM has been determined it can be assigned an odour category based on the limits established for OC1, OC2 and OC3.

Figure 8-1. Sketch of an acceptable sampling train for odour sampling (flux chamber approach).

Figure 8-2. Flux chamber odour sample data sheet.

Figure 8-3. Flux chamber odour sampling configuration.