Best management practices when using insecticide treated seed

Learn best management practices to reduce the risk to pollinators when using insecticide treated seed.

The importance of best management practices

Insect pollinators are vital to agricultural production and the environment. Many growers, including those who grow corn and soybeans, use insecticide-treated seed to protect their crop from insect pests. Some insecticides, such as neonicotinoids, are toxic to pollinators. Planting of treated seed can result in the emission of dust-containing insecticide into the air, placing pollinators at significant risk of exposure to toxic insecticides. Factors that significantly impact the risk of exposure include the use of insecticide treated seed, type of planting equipment, planting conditions, flowering resources and bee yard locations.

The following best management practices (BMPs) are provided to reduce the risk to bees and other insect pollinators from exposure to dust from treated seed. The BMPs provide a toolbox of options that should be used in combination wherever possible.

Additional resources and information on BMPs for pollinator protection can also be found at Health Canada’s pollinator protection web page.

Practice integrated pest management when controlling pests

Practicing integrated pest management (IPM) is essential for sustainable pest control. This approach can include cultural practices to discourage pests (for example, crop rotation), correct identification of the pest problem and risk factors. As part of an IPM program, you must take certain actions before making the decision to use treated seed.

Soil pests

Evaluate fields and determine if soil pests are present at threshold levels or if fields have a high pest risk.

Find more information to support IPM practices.

Insecticide use

Use insecticide treated seed only where necessary. In Ontario, the sale and use of neonicotinoid-treated corn and soybean seed is regulated. See Neonicotinoid rules for growers to learn about the requirements for Ontario growers to use neonicotinoid-treated corn and soybean seeds. If insecticide treatment is required, use the lowest effective seed treatment rate.

Label and seed tag directions

Read and adhere to the pesticide label and seed tag directions before using treated seed. Directions for use on pesticide product labels or on treated seed labels, such as personal protective equipment (PPE) and buffer zones, must always be followed to minimize risks to human health and the environment.

Non-insecticide treated seed

Most seed companies can accommodate orders for non-insecticide treated seed, if ordered in advance. Talk to your seed dealer about timing and options.

Develop and maintain shared communication with beekeepers to help protect honey bees

Communication and cooperation among growers, custom operators and beekeepers on the timing of planting treated seed and the location of hives can help to reduce the risk of bee incidents. This communication will enable growers to know which fields have hives located close by and provide advanced notice to beekeepers of planting intentions, allowing beekeepers to ensure hives are located strategically, take actions to temporarily protect or relocate hives where feasible, and ensure clean water sources are provided. Beekeepers should inform growers of hive locations and growers should inform beekeepers of timing of planting treated seed and pesticide applications.

Recognize pollinator habitat and take special care to reduce dust exposure

Bees collect pollen and nectar from flowering crops, trees and weeds, as well as water from puddles and moist soil in or beside fields. Pollinators can be exposed to dust contaminated with insecticide from treated seed when it is carried in the air or deposited on food and water sources.

During planting season, weeds, such as dandelions and flowering trees, including maples, willows, hawthorns and apples, are important pollinator foraging resources. Dust emitted through planter exhaust may be transported under all weather conditions. Pollinator exposure may be increased under very dry and/or windy conditions which favour dust transport. Avoid planting treated seed under these conditions if flowering resources, standing water or bee yards are located downwind and follow best practices to reduce dust exposure. Control flowering weeds in the field before planting so that pollinators are not attracted to in-field forage.

Avoid generating dust when handling and loading treated seed

Handle bags with care during transport, loading and unloading to reduce abrasion, dust generation and spillage. Do not load or clean planting equipment near bee colonies and avoid places where bees may be foraging such as flowering crops, trees or weeds. When turning on the planter, avoid engaging the system where emitted dust may contact honey bee colonies or foraging pollinators.

Use appropriate seed flow lubricant

Starting in 2014, the Fluency Agent by Bayer Crop Science is the only seed flow lubricant permitted with corn or soybean seed treated with insecticides clothianidin, thiamethoxam, or imidacloprid (for example, Poncho, Cruiser, Gaucho, Stress Shield). Research has found that the Fluency Agent significantly reduces the quantity of neonicotinoid in the exhausted dust.

Carefully follow the use directions on the fluency agent label. Do not use more than the recommended ⅛ cup of Fluency Agent per unit seed (for example per 80,000 kernel seed corn unit or 140,000 seed soybean unit). Thorough mixing of the Fluency Agent with the seed is required for proper performance. This can be accomplished in the seed hopper or by adding the Fluency Agent to the seed auger when loading bulk seed.

The use of graphite to lubricate the planting mechanism (for example finger pick-up units for corn or mechanical metering units for soybeans) is acceptable under the regulations. However, graphite may not be used in pneumatic planters when the seed has been treated with a neonicotinoid insecticide.

Manage planting equipment to decrease dust drift

Research indicates that use of vacuum (negative pressure) planters poses a significant risk of pollinator exposure from drift of insecticide containing dust exhausted from these planters. Limited information is available on the extent of exposure though other planter types. All growers should take care to reduce/control insecticide containing dust exhausted from planters.

Follow the directions provided by planting equipment manufacturers and keep up to date on new use practices. Clean and maintain planting equipment regularly, including the fan housing and hoppers of air-assisted planters. For example, vacuum any dust remaining in the fan housing and hopper. Use deflector equipment, where appropriate, to direct exhaust to the ground level and thus reduce dust drift.

Deflector equipment

Some planter manufacturers may not support warranty or performance claims when a deflector has been installed. However, producers are encouraged to view corn planter deflectors as they would selecting the proper nozzle on a sprayer to reduce drift and reduce pesticide movement off the field. Similarly, it should be noted that seeding in proximity, especially upwind, to areas where pollinators may gather such as bee yards should be avoided regardless of the usage of alternate seed lubricants or deflectors.

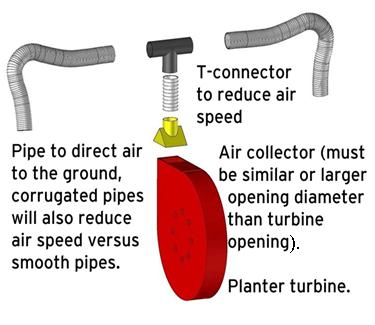

Growers should consult their local equipment dealers for options. Growers can also explore possibilities on their own to develop a dust deflector system for their planter based on important design considerations. An adaptor or fitting will be required that fits on the vacuum fan housing that collects the discharged air and funnels it into a round opening so that tubing can then be attached (see Figures 1 and 2). It is critical that the fitting and initial tubes are large enough as to not produce any back pressure that may lead to planter malfunction. The fitting and exhaust tubes must be at least equal in area to the original fan exhaust. Larger is better. An initial vent tube which is 15 cm (6 in.) in diameter would provide roughly 177 cm2 (28 in.2) of opening and may be adequate for some but not all fans.

At some point in the system, it is very important to expand the total size of the venting to slow the air speed. The goal is to have the air velocity significantly reduced as it is directed at the ground. This may occur immediately as the air exits the fan housing with the appropriate manifold (Figure 2) or slightly after the fan by splitting the air stream with a “T” or “Y” connector into two exhaust tubes (Figure 1). In some cases, it may be easier to run only a single tube until a spot on the planter is reached where it could be more conveniently split into two. In other designs, the single tube may deliver the air to an expansion box (Figures 3 and 4), which has a much larger area than the tube, before the air is discharged towards the ground.

The discharge area is directed towards the ground and should be positioned as close to the ground as possible without the exhausted air creating soil dust. It is recommended that this release point should be encircled with strips of carpet, rubber or bristles to help diffuse the exhaust air (see Figures 3 and 4) and to allow the system to run closer to the ground without the fear of damage from obstacles in the field. Position the hose outlet or expansion box with sufficient clearance from other planter components to facilitate the flow of crop residues.

To ensure that the modification has been done properly, you should run the planter outside, with seed in the metering discs and at the proper RPM without the deflector and then once you attach the deflector run it again at the same RPM. You should be able to achieve suitable vacuum readings, with or without the deflector, with reasonable adjustment to the fan speed.

Ensure proper clean-up and disposal

Spilled or exposed seeds and dust must be incorporated into the soil or cleaned-up from the soil surface. Keep treated seed and dust away from surface water. Do not leave empty seed bags or left-over treated seed in fields or the environment. Participate in collection programs for seed bags where available.

Growers can return their empty seed bags to select retail locations. Contact your local dealer for details on disposal of these empty seed bags or contact Cleanfarms at

Report suspected pollinator pesticide poisonings

For suspected pollinator poisonings related to planting of treated seed or pesticides, contact the appropriate federal authority. Find contact information for the appropriate authorities on Health Canada’s pollinator protection web page or by calling Health Canada’s Pest Management Regulatory Agency at