Noise nuisance from stationary farm equipment

Learn about noise from stationary farm equipment and some best management practices to reduce possible nuisance for neighbours.

ISSN 1198-712X, Published March 2023

Introduction

Noise is unwanted sound. Although rural areas are generally quiet, farmers live in a competitive world, and modern farms sometimes have to use noisy stationary equipment (Figure 1). Some neighbours might not like the noise they produce.

Unresolved rural noise problems can result in poor neighbour relationships. Avoid problems before they start by using best management practices (BMPs) and common sense. This fact sheet provides background information on noise from stationary farm equipment and some BMPs to reduce possible nuisance for neighbours.

Agricultural noise regulations

Most farms are covered under the Farming and Food Production Protection Act, 1998 (FFPPA), which deals with nuisances such as noise, odours, dust, light, vibration, flies and smoke. The FFPPA protects farmers against nuisance complaints (such as noise) from neighbours, but only if the farmers are following normal farm practices. The FFPPA defines a normal farm practice as one that:

- is conducted in a manner consistent with proper and acceptable customs and standards, as established and followed by similar agricultural operations under similar circumstances, or

- makes use of innovative technology in a manner consistent with proper advanced farm management

It is unrealistic to expect to be able to eliminate all noise produced on farms, but when noise issues escalate between a producer and a neighbour and cannot be solved locally, the Normal Farm Practices Protection Board — a quasi-judicial board appointed by the provincial government — may get involved.

On rare occasions, stationary noise sources or processes on a farm might require an Environmental Compliance Approval, under the Ontario Environmental Protection Act, 1990. If Ministry of the Environment, Conservation and Parks staff request this kind of approval for a stationary noise source or a process, it is usually because they believe the source or process is more commercial or industrial, than agricultural.

Describing noise nuisance

Noise is difficult to describe because what sounds annoy people is so subjective. Sounds are described by their amplitude, loudness, persistence and character, similar to describing odours.

Sound

Odour

Amplitude: strength of sound measured in decibels (dB)

Concentration: strength of odour measured in odour units (OU)

Loudness: perceived changes in sound to human ears

Intensity: perceived strength compared to odour of the chemical n-butanol

Persistence: how much distance is needed to dilute a sound below detection level

Persistence: how much clean air is needed to dilute an odour below detection level

Character: tonal, beating, impulsive, intermittent

Character: minty, citrusy, fishy, earthy

Amplitude

Sound amplitude, or level, is measured in dB. Sound meters use an A-weighting setting that more accurately reflects how humans hear sound (dBA). A-weighting is commonly used for measuring environmental noise such as from stationary farm equipment. Other weightings are used to reflect very specific types of sound.

The human ear's threshold of audibility is 0 dBA; 130 dBA is considered deafening and the human threshold of pain. The Ontario Occupational Health and Safety Act, 1990, limits noise exposure to 8 hours/day for 85 dBA and 15 minutes for 100 dBA (Table 1). It takes training to measure sound (Figure 2), and acoustical consultants are hired to do sound studies.

| dBA | Activity |

|---|---|

| 0 | Threshold of hearing for humans |

| 15 | Normal threshold of hearing for humans |

| 20 | Calm human breathing; very soft whisper |

| 30 | Calm room, library, empty church, secluded woods |

| 40 | Rural ambient background sound: 7 p.m. to 7 a.m. |

| 45 | Rural ambient background sound: 7 a.m. to 7 p.m. |

| 50 | Inside an average home: refrigerator hum |

| 55 | Low volume of TV or radio |

| 60 | Normal conversation |

| 65 | Sleep disturbance |

| 70 | Busy business office |

| 80 | Curb side of a busy road |

| 90 | Barn full of finisher pigs at feeding, gas lawnmower |

| 100 | Chainsaw, circular saw, ATV, irrigation pump |

| 110 | Grain dryer fan and burner under full load |

| 120 | Threshold of discomfort, rock and roll concert |

| 130 | Threshold of pain, jet engine at 25 m away |

Loudness

Sound loudness is the perceived change between two sound levels. Human ears are good at perceiving increased or decreased changes in sound, but what does that mean objectively?

- ±1 dBA change. Most people would say this is an undetectable variation in two sound levels.

- ±3 dBA change. Most people would say this is a noticeable variation in two sound levels.

- ±6 dBA change. Most people would say this is an obvious variation in two sound levels.

- ±10 dBA change. Most people would say this is twice as loud (or half as loud) as the original sound level. This is considered a significant change.

Persistence

Sound persistence is how easily a noise decreases with distance away from a noise source until it is not detectable. This takes long distances for some types of sounds. It is important to understand that some noises can impact a neighbour further away than one might reasonably expect. However, it is important to understand that a detectable sound is not automatically a nuisance sound.

Character

Sound character is a subjective descriptor, such as a sound's tonality (whine of a circular saw or hum of an electrical transformer), beating (wind machine blades beating against a strong wind or multiple fans running at different speeds), impulse (occurring for less than one-tenth of second, such as a door slamming or a shooting noise) or intermittence (not continuous, but remaining on longer than 1 second, such as an exhaust fan or compressor cycling on and off, with long periods of quiet in between).

Hedonic tone

Not typically used as a descriptor of sound, hedonic tone is used to describe odours: negative for unpleasant and positive for pleasant. This concept might also help describe a sound. On a scale that ranked the unpleasant sound of fingernails scratching down a blackboard as -10 and the sound of soft harp music as +10, people might subjectively describe a noise nuisance as a -7.

Attenuation of sound

Sound is a wave motion produced when a sound source causes nearby particles in a medium (usually air) to move. The movement spreads to particles further from the source. Sound moves in air at about 340 m/s (1,115 ft/s). Sound levels attenuate, or decrease in intensity, as a result of absorption of the sound wave energy and scattering out of the path of a receptor, such as a neighbour.

Ambient sound levels

Sound generated by stationary farm equipment may be considered a noise nuisance if the sound levels are higher than the ambient or surrounding background sound level. In remote rural areas, ambient sound is produced from natural sources, such as wind blowing through trees, running water, birds and insects. In urban areas, ambient sound is produced from human sources, such as road traffic creating an urban hum. Ambient sound levels in rural-urban interface areas may be 5 dBA (or more) higher than in remote rural areas.

Geometric spreading

Sound generated by stationary farm equipment reduces by the square of the distance from the equipment. When distance doubles, sound levels typically drop 6 dBA. So, 90 dBA at 5 m (16 ft) is 84 dBA at 10 m (32 ft), 78 dBA at 20 m (66 ft), and so on. Because of atmospheric and surface effects, sound levels rarely decrease exactly 6 dBA with doubling of distance.

Atmospheric effects

Sound levels are affected by atmospheric effects but are usually only noticeably different at distances beyond 100 m (328 ft) from stationary farm equipment. Sound waves move faster in warm air than cold air. If the wind direction is from the west, sound levels are increased to the east of stationary farm equipment and decreased to the west. Rain, snow or fog has little effect on sound levels.

Fog horns have a deep sound because they produce low frequency sounds that travel long distances. Bass sound waves from a music system can travel long distances and penetrate the walls of homes, whereas high-frequency waves, such as "treble" on a music system, do not travel as far and do not penetrate walls as easily. High-frequency sounds are potentially more detectable and potentially more annoying than low-frequency sounds.

Normally, air temperatures decrease with increasing height above ground. This causes sound waves to bend upward and away from receptors. However, under temperature inversions, air temperatures increase with increasing height above ground. These conditions generally occur at night when the wind is calm, the sky is dark and starlit, and daytime heat energy stored in the earth is re-directed back to the atmosphere, leaving behind cold air at the ground. This causes sound waves to bend downward off this upper layer of warm air, so sound waves can be heard at long distances. Low-frequency sound waves from a train already travel long distances, but with temperature inversions, travel even further.

Surface effects

Soft thick grass and rough vegetation can reduce sound levels by as much as 10 dBA but hard, smooth surfaces such as concrete, or even water, do not offer much reduction. Low-frequency sounds are reduced little by surfaces. Sounds produced high above ground level are less reduced by surface effects. As well, if stationary farm equipment is pointing so the sound is directed at a neighbour, it has more potential for nuisance than equipment pointing away from them.

A row of trees would only reduce sound waves if the tree screen is at least 30 m (100 ft) thick. However, trees may hide the source of the sound, which has aesthetic and psychological benefits, and might introduce other masking sounds of rustling leaves, singing birds and small animal activity.

Common noise nuisance concerns

If a noise nuisance issue proceeds to the Normal Farm Practices Protection Board, the onus of proof is on the applicant (person complaining about the noise) to establish they are affected by a noise disturbance caused by a respondent (person accused of creating the noise). Noise is sometimes seen as intrusive to one's privacy, or as interfering with the normal conduct of their lives. Certain rural sounds annoy some residents more than others.

Comparison to background sound levels

If stationary farm equipment creates sound amplitude levels higher than background levels, they can be perceived as noisy and intrusive, as the noise is immediately recognizable in the presence of low ambient sound amplitude levels.

Summer versus winter

Stationary farm equipment may be perceived as noisier in the summer than in winter as people are more likely to have their windows open in summer or stay outside for longer periods.

Daytime versus nighttime

Stationary farm equipment operating at night, including late evening and early morning, may be perceived as noisier and more intrusive than similar daytime operation, as some people get annoyed when their sleep is interrupted. However, night shift workers might say the opposite if daytime sleep is interrupted.

New sounds

Stationary farm equipment operating in a neighbourhood that has never experienced that particular sound before may be perceived as noisy and intrusive. New sounds are more difficult to get used to.

Exposure time

Stationary farm equipment operating over long periods can be perceived as noisy. An irrigation pump operated 250–500 hours per year may seem noisier and more intrusive to someone's normal conduct of life than a wind machine operated 25–50 hours per year, even if the sound amplitude levels are comparable.

Impulsive versus intermittent versus continuous sound

Some say impulsive or intermittent sounds are a nuisance because of their randomness. The anticipation of the next noisy sound keeps people on edge. Others say continuous sounds are a nuisance because they never stop.

Best management practices

Good planning before installing stationary farm equipment is the best way to avoid possible future noise nuisance complaints. Where appropriate:

- Discuss with neighbours why you need to install equipment that might be noisy.

- Locate equipment as far as possible from neighbours; avoid putting it closer to their homes than to yours.

- Take into account the effects of topography, the predominant wind direction and whether neighbours will be able to see the equipment.

Wind Machines

There are at least 500 wind machines in Ontario. They work 25–50 hours per year, mostly at night when cold injury often occurs, and produce a helicopter-like sound. The OMAFRA fact sheet, Wind machines for minimizing cold injury to horticultural crops lists many BMPs. Here are three relating directly to noise nuisance:

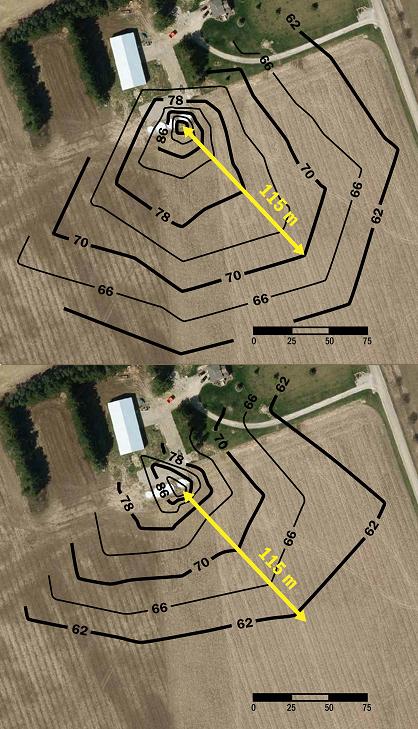

- Install wind machines at least 125 m (410 ft) from neighbours' homes (Figure 1).

- Monitor and automate start-up, operation and shut-down using real-time air temperature and wind speed sensors. Do not operate if winds are higher than 7 km/h.

- Set wind machines closest to neighbours to be turned on last and off first to minimize their duration of operation. Be careful when operating machines on remote farms, since the operator will not hear whether they are running.

Bird bangers

The OMAFRA fact sheet Using propane-fired cannons to keep birds away from vineyards lists many BMPs. Here are 3 relating directly to noise nuisance:

- Install cannons (also known as bird bangers) at least 125 m (410 ft) from neighbours' homes (Figure 3).

- Operate bird bangers during daylight hours — 30 minutes before sunrise to 30 minutes after sunset — and install light sensor override devices to ensure they cannot operate at night.

- Monitor bird bangers so they operate properly, especially those not on or near the home farm.

Irrigation pumps

Engines used for pumping water are often used 24/7 during dry periods when crops need a lot of water. Here are 3 BMPs relating directly to noise nuisance:

- Use shock-absorbing mounts and cover pumps with insulated, vented housings designed for reducing sound levels (Figure 4). This also helps avoid vandalism and theft.

- Install extra sound-reducing mufflers on internal combustion engines, or switch to electric pumps, where practical and possible.

- Install pumps out of sight of neighbours or behind obstructions that shield the source from neighbours.

Grain dryers

There are many types of grain dryers used to dry corn, beans, wheat and other grains to ideal moisture levels for long-term storage. The fan and burner create sound levels from 85–112 dBA, 1 m (3 ft) in front of the dryer fan (Clarke, 1998). Many dryers operate 24 hours per day during harvest. These 7 BMPs relate directly to noise nuisance:

- Use centrifugal fans instead of axial flow fans, and use fans with the lowest possible sound levels.

- Orient in-bin dryer fans or overhead batch bin dryer fans away from neighbours.

- Account for sound waves travelling further from dryers with the fan/burner mounted high above ground.

- Place dryers in areas that use existing structures to shield or mask the sound for neighbours.

- Minimize night-time operation, where possible.

- Install silencers where practical. A common example is a car muffler. Silencers are custom-designed and tuned to the distinct frequency character of a noise. Reactive silencers are sometimes available from the original manufacturers of grain-drying equipment.

- Minimize sounds often associated with grain drying: chatter from grains moving in augers, pneumatic transfer pipes, drying and cooling aeration fans.

Sound absorbent and barrier materials

All materials absorb, form barriers and transmit sound waves. The best way to reduce transmission of sound waves is to combine absorbent materials with barrier materials and install them in tight-fitting enclosures around stationary sound sources. The sound blanket panels hanging in front of the grain dryer in Figure 5 are a sandwich of absorbent materials on the outer surfaces, with a heavy flexible plastic-type barrier inside. However, because the stationary sound source is not enclosed and sound waves can escape, this is considered a partial enclosure. Think of how a door or window only slightly cracked open still allows lots of sound from outside to enter the home. Partial enclosures should at least interrupt the line of sight path between the noise source and a receptor, and they should absorb as much of the sound reflected from the source as possible.

Absorbent materials

Sound waves vibrate materials turning the energy into tiny amounts of heat due to friction. Fibrous materials absorb more sound than dense ones. Low-frequency sound waves are more difficult to physically absorb since they have a longer wavelength, while high-frequency (shorter wavelength) waves are more easily absorbed. This partly explains why bass music sound waves easily travel through insulated walls, and treble music sound waves don't.

Commercially available absorbent materials include mineral and glass wools, felts and foams. Absorbent materials reduce reverberant and reflected sound, but not transmission of sound, and should only be used when they are installed right beside stationary farm equipment. Be careful of a fire hazard around hot grain dryers or hot engines if using absorbent materials that might be flammable.

Even though the sound blanket panels in Figure 5 did not enclose the stationary sound source, they still helped reduce sound amplitude levels at a distance. Measurements were taken (by the author) in a grid across a field facing the grain dryer both with and without sound panels in place. The resulting sound level contour map is shown in Figure 6.

Barrier materials

Barrier materials are different from absorbent materials. Barriers are dense materials such as wood, metal, concrete, thick plastic or any dense material – the denser, the better. True barriers have a minimum surface density of 20 kg/m2 (4 lb/ft2) perpendicular to the direction of sound wave movement. Place barriers as close as possible to stationary farm equipment. Be aware of the potential fire hazard around hot grain dryers or hot engines if using flammable barrier materials.

The sound blanket panels shown in Figure 5 are not considered true sound barriers since their surface density is less than 20 kg/m2 as per the calculation below:

Mass (kg) ÷ Area perpendicular to sound waves (m2) = Surface density

36 kg ÷ (1.2 m × 2.4 m) = 12.5 kg/m2

Absorbent and barrier materials on the farm

Some farm materials can be used as sound-absorbent materials and/or barriers for cost-effective short-term solutions until long-term solutions can be found or afforded (Figure 7).

In Figure 7a, concrete blocks form a 1.2-m (4-ft) wall to store wood chips. These blocks are 0.6 m × 0.6 m × 1.2 m (2 ft × 2 ft × 4 ft), widely available, portable and inexpensive. They are a good sound barrier (1,440 kg/m2 surface density; material density: 2,400 kg/m3) and could form a partial enclosure around noisy stationary farm equipment along with an absorbent material such as loose soil, wood chips or compost. Absorbent materials must be placed on the side the sound is coming from. This could be a short-term noise solution for a grain bin aeration system or a generator.

In Figure 7b, a berm of soil with a solid-faced wooden fence on top creates a sound absorbent material and sound barrier because of its very thick base. The slope of the soil berm also helps reflect sound waves from a railway running along the facing (left) side of the fence over the homes on the back (right) side. Soil berms are common along busy highways and can reduce sound levels by 5–10 dBA for nearby neighbours.

In Figure 7c, waste plastic hay wrap is compacted by a hay baler to reduce waste disposal transportation costs. A wall two bales wide could act as a partial enclosure and sound barrier (150 kg/m2 surface density; material density: 160 kg/m3) if bales are stacked tightly like building blocks and placed with corners to enclose a sound source. The rough plastic might also act as a sound absorbent material. Baling plastic wrap can be hazardous, as the wrap is often in very long pieces. Do not hand-feed plastic wrap into the baler because of the danger of entanglement. Also be aware of a fire hazard around any heat sources if using dense bales made of plastic wrap materials.

In Figure 7d, big square bales of hay, about 1 m × 1 m × 1.8 m (3 ft × 3 ft × 6 ft) create an effective sound absorbent material, sound barrier and partial enclosure for a grain bin aeration system. Bales were stacked 3 high, 2 bales thick (325 kg/m2 surface density; material density: 180 kg/m3). Again, be careful about fire hazards using hay bales.

Reducing sound at the receptor

The best ways to reduce noise nuisance for neighbours are to first reduce sound at the source, then reduce sound through absorbent materials, barriers and enclosures. The third, but least preferred method is to try to reduce the sound when it finally reaches a receptor, or neighbour. To quote an old phrase, this is like "closing the barn door after the horse has bolted." Reducing sound at the receptor is difficult, often ineffective, and implies that it is up to a receptor to change his or her household activities. Usually, whatever a receptor does is just a short-term solution, until more sustainable solutions are found.

If you are the receptor, talk directly to farmers about noise nuisance. Most farmers would rather speak directly to the person affected, rather than through a third party. Even though the temptation is to call grape growers in the middle of the night the first time they operate their wind machine, wait until the next day or two when both parties have more time (and have slept more) to discuss things.

See if there are areas of the house where sound levels are reduced. Usually this is in the basement with its heavy concrete walls, or the opposite side of the house to the sound source. Carpeted rooms help absorb sound, and smaller rooms don't allow sound waves to amplify as they do in large rooms with hard floors.

Just as deodorants can mask odours, white noise can mask sounds. White noise consists of all audible frequencies with equal intensity. Only special equipment creates perfect white noise, but many sounds in nature are like white noise, such as the sound of moving water, wind or even ventilation fans. People who travel will turn on a fan in their hotel room to mask road traffic or people talking.

Conclusion

Noise nuisance issues can be difficult to solve. A good discussion between farmers and their neighbour is the best solution for lasting neighbourhood relationships. Sometimes neighbours are more accepting of noise from stationary farm equipment when they fully understand how that noise is created and if they believe the equipment is being operated under normal farm practice.

Farmers often have few options to protect their crops (wind machines and bird bangers), feed their crops (irrigation pumps) or condition their crops (grain dryers). As one grape grower in Niagara told his neighbours, "If I had a fire in my shed, you'd be the first to come to help me save my livelihood. So when my wind machines run, you are also helping me save my livelihood by tolerating the noise a few nights of the year."

References

Clarke, S., M. Toombs, S. Rambie and R. Richardson. 1998. Quantifying Grain Dryer Noise to Prevent Hearing Loss and Nuisance Complaints. Canadian Society for Engineering in Agricultural, Food and Biological Systems. Paper No. 98-404. Vancouver, BC.

This fact sheet was updated by Dan Ward, P. Eng., poultry and other livestock housing and equipment, OMAFRA. It was originally written by Hugh Fraser, P. Eng., horticultural crop protection and post harvest, OMAFRA, and reviewed by Jake DeBruyn, P. Eng., new technology integration, OMAFRA, Amadou Thiam, P. Eng., air quality, OMAFRA, and Vince Gambino, P. Eng., Aercoustics Engineering, consulting engineer in vibration, acoustics, noise control, Toronto, Ontario.