Evaluating farm resources and sheep production systems

Learn how to select the optimal sheep production system by evaluating and utilizing the best available farm resources.

ISSN 1198-712X, Published August 2022

The use of imperial and metric measurement in this fact sheet reflects the way information is reported by the original source for the sheep industry.

Introduction

When a new producer enters the sheep industry, or when existing producers contemplate a change in their farming enterprise, selecting a sheep production system is one of the most important considerations. The resources that are available to the farm must be evaluated and the proper production system used, to maximize the available farm resources.

This fact sheet describes how to select the optimal sheep production system given the impact of various farm resources, including:

- land

- buildings

- labour

- machinery

- available markets

The optimal production system will be the one that best utilizes available resources, thereby improving the profitability of the operation (Figure 1).

Land

Land purchase is likely the largest start-up expense for most sheep operations. However, the extra debt load imposed on the farming business by purchasing the land may be enough to make the operation unsuccessful.

Sheep can also be raised on rented land. Renting the land and buildings may make the farming enterprise more viable, unless other enterprises or employment pay for the farm mortgage. In some cases, it may also be possible to find innovative solutions to access more land resources, such as providing vegetation control services (for example, silvopasture, solar grazing). OMAFRA has many financial planning fact sheets that may be helpful.

The productivity of the land must also be evaluated to determine the carrying capacity of pastures and the estimated yields from crop production. The available land and its expected yield will help determine the on-farm feed resources available and how much purchased feed will be needed. Consult an agronomist and a nutritionist to evaluate the capacity for feed production and the feed resources required for a new or expanding enterprise. Most new or expanding operations will also need to develop a Nutrient Management Strategy.

Buildings

The farm buildings must be evaluated to determine:

- the space available for the sheep

- the space available for feed storage and handling

- the suitability of the building for winter lambing

The amount of space an animal needs will differ by age and stage of production. Failure to provide sufficient space will often lead to health challenges and loss of productivity.

Ewes and lambs

Based on the recommendations in the Code of Practice for the Care and Handling of Sheep, each ewe requires 0.7–6.5 m2 (7–70 ft2) of floor space, depending on the stage of production and floor surface. Dry ewes need less space (0.93 m2 (10 ft2) at minimum), whereas pregnant and lactating ewes require more space (1.4–1.5 m2 (15–16 ft2) at minimum). Prolific and/or larger breeds of sheep will require more space than the minimum recommendations (1.86 m2 (20 ft2)). Dry ewes are easier to house than lactating ewes. Dry ewes can be kept in open sheds, whereas lactating ewes require more protection. When lactating ewes are housed, pen space and feeder space become extremely important.

In most cases, sheep do not need to be kept warm, but at lambing time, a warm dropping or lamb area may be needed to reduce lamb mortality from hypothermia. An insulated area may be necessary for winter lambing. All lambing areas must be warm and dry, not humid and damp. Space for hospital pens, warming facilities and to artificially rear lambs may also be beneficial at lambing time.

Rams

Rams need a minimum of 1.0 m2 (11 ft2) of space. It is important that there is a separate area available to house rams so they can be removed from the ewe flock when it is necessary to organize lambing groups.

Lambs

Space for weaned market lambs and breeding stock replacements should also be accounted for when determining the capacity of facilities. Feeder lambs can be housed in open front sheds or feedlots and require a minimum of 0.6 m2 (6.5 ft2).

Designing sheep facilities

In many cases, it is the amount of feed space in the barn that determines the number of sheep that can be kept. Pens should be long and narrow to make efficient use of barn space. If 40.6 cm (16 in.) of head space per ewe is allowed and the pen depth is 3.5–4.7 m (11.5–15 ft), then the space provided to the ewe will be appropriate. Walk-through feeders are very useful when feeding lactating ewes. See the OMAFRA fact sheets Feeding systems for sheep and Low labour feeding systems and bunk design for sheep for more information on the design of sheep feeding facilities for efficient management.

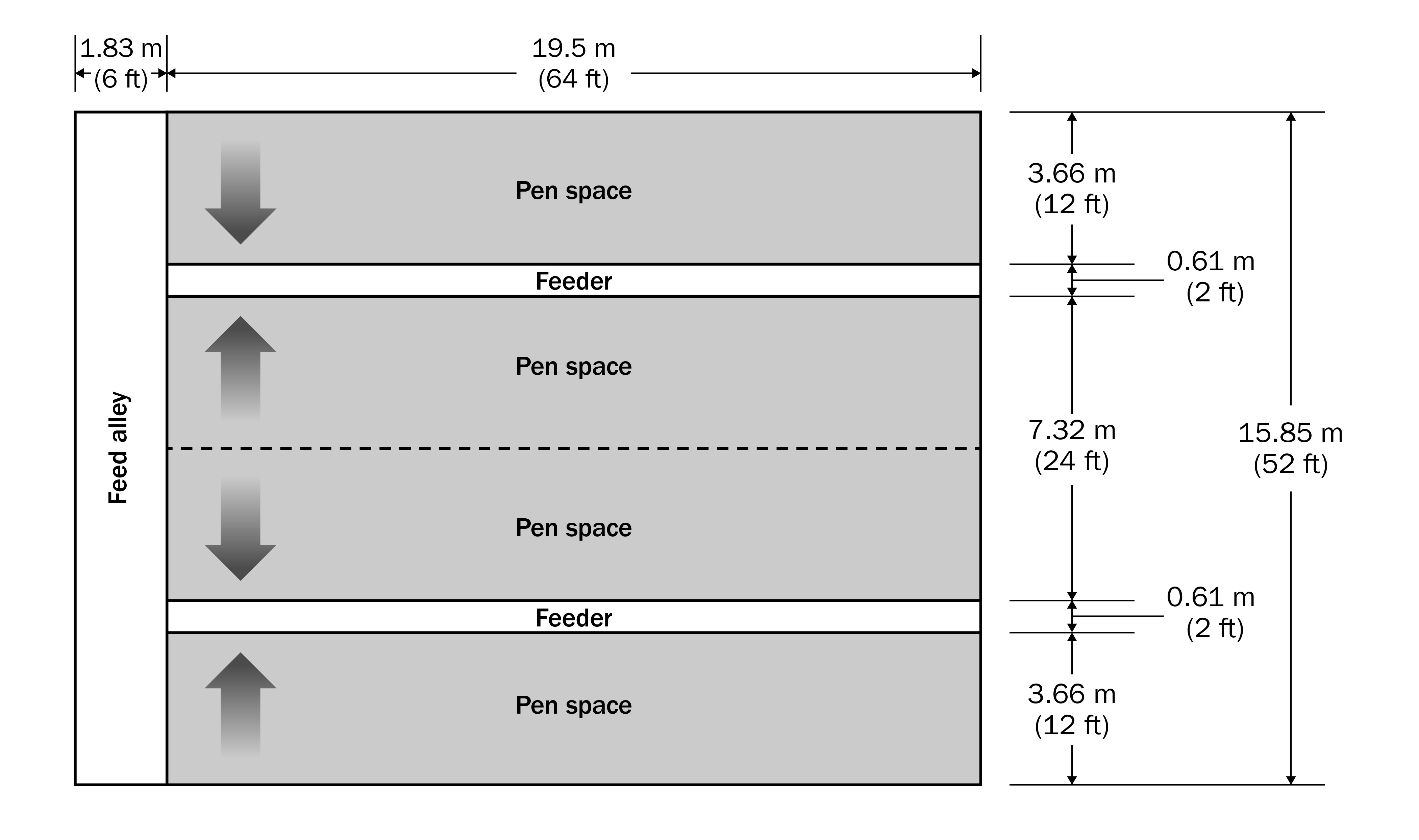

Figure 2 shows an example floor plan for a 19.5-m (64-ft) barn with recommended floor and bunk space for lactating ewes. In this figure, there are 4 areas where the ewes can eat so the barn will accommodate a ewe for every 10.2 cm (4 in.) of barn length. Therefore, a facility with this design would have the capacity to feed 192 ewes.

The calculated barn capacity assumes that the ewes will eat at the same time. Table 1 shows how floor space and feeder space needs can change at different stages of production. Dry ewes fed ad libitum hay only require 15.2 cm (6 in.) of head space, and floor space becomes the limiting factor with the result that 76 ewes can be put in a pen. Late pregnancy or lactating ewes fed twice a day require 40.6 cm (16 in.) of head space, and in this case, floor space and feed space both result in a pen capacity of 48 ewes. But if those same ewes are prolific, floor space becomes a limiting factor resulting in a pen capacity of 38 ewes.

Space for feed storage must also be adequate. A ewe lambing in the winter will consume approximately 340 kg (750 lb) of hay and 54.5 kg (120 lb) of mixed grain during the winter. Round bales of hay could be stored outdoors to reduce building storage costs. Handling facilities are essential for sheep operations, and adequate space must be available for the handling equipment.

Barn capacity = barn length/space per ewe

64 ft (768 in.) of barn length × 4 pens/16 in. feeder space per ewe = 192 ewes

19.5 m (1,950 cm) of barn length × 4 pens/40.6 cm feeder space per ewe = 192 ewes

| Stage of production | Feeder space | Floor space |

|---|---|---|

| Dry ewes eating at same time (40.6 cm (16 in.) head space and 0.93 m2 (10 ft2) floor space per ewe) | 1,950 cm/40.6 cm (768 in./16 in.) = 48 ewes | 71.37 m2/0.93 m2 (768 ft2/10 ft2) = 76 ewes |

| Dry ewes with feed at libitum (15.2 cm (6 in.) head space and 0.93 m2 (10 ft2) floor space per ewe) | 1,950 cm/15.2 cm (768 in./6 in.) = 128 ewes | 71.37 m2/0.93 m2 (768 ft2/10 ft2) = 76 ewes |

| Late pregnancy or lactating ewes eating at the same time (40.6 cm (16 in.) head space and 1.48 m2 (16 ft2) floor space per ewe) | 1,950 cm/40.6 cm (768 in./16 in.) = 48 ewes | 71.37 m2/1.48 m2 (768 ft2/16 ft2) = 48 ewes |

| Prolific late pregnancy or lactating ewes eating at the same time (40.6 cm (16 in.) head space and 1.86 m2 (20 ft2) floor space per ewe) | 1,950 cm/40.6 cm (768 in./16 in.) = 48 ewes | 71.37 m2/1.86 m2 (768 ft2/20 ft2) = 38 ewes |

Labour

Labour is essential and an important input in a sheep enterprise. The amount of labour required will depend on the individual farm set-up and the degree of mechanization. Caring for the sheep is the most important job, and observation time is critical. Sheep show few signs of sickness, so subtle changes in behaviour may indicate a more serious issue. It is important to allocate time and labour resources to observe and handle sheep to assess their condition and changing needs.

When evaluating labour requirements, consider the distribution of the labour required throughout the year. Lambing time requires considerably more labour. Plan the farm’s labour requirements so that lambing times do not compete for labour when another farm enterprise, such as cropping, has a high need for labour.

Machinery

Machinery can be a large capital cost. It is important to be realistic about how much capital cost the sheep operation can support. Many Ontario sheep operations are only large enough to support a limited amount of equipment. Using OMAFRA’s Budgeting farm machinery costs fact sheet and worksheet will help you determine whether your operation can support the equipment being considered.

Choose equipment carefully and balance the cost against usage, labour, convenience, return on investment and possibilities of renting, borrowing or using custom operators. Handling equipment is crucial to success and must be available on farm. More information on handling facilities is available in the OMAFRA fact sheet Using sheep behaviour to your advantage when designing handling facilities.

Markets

Live auction

Sheep producers in Ontario are fortunate to have several markets available. Most market lambs are sold by live auction at the 16 markets available in Ontario. Sheep producers can sell lambs from 40–120 lb at auction, categorized into the following six weight classes:

- under 50 lb

- 50–64 lb

- 65–79 lb

- 80–94 lb

- 95–109 lb

- 110 lb or more

Auction prices fluctuate throughout the year and producers often plan their production cycle to take advantage of typical peaks in sale prices. Auction prices are quoted on a price per hundred weight ($/cwt) basis (1 cwt = 100 lb). To determine the price per pound, divide the price per hundred weight by 100. To calculate the average gross revenue per lamb for a group of market lambs, first determine the price per pound and then multiply this by the average weight of animals in the group. For example, if the auction price for a group of 80–94-lb lambs was $225/cwt — equivalent to $2.25/lb ($225/100 lb = $2.25/lb) — and the average weight of lambs in this group was 85 lb, the average gross revenue per lamb is equal to $191.25 ($2.25/lb × 85 lb per lamb = $191.25).

Directly to processors

Although the auction system accounts for most lamb sales in Ontario (80–85%), some lambs are marketed directly to processors. Direct to processor marketing allows producers to negotiate a premium market price and may offer more predictability in revenue than marketing lambs on the free market, however, it can also be time-consuming to find buyers and market product.

Lambs marketed directly to processors may be sold on either a liveweight basis, where animals are weighed prior to slaughter to determine the price paid to the producer, or on a dressed-carcass weight basis after slaughter. It is important to understand the specifics of the pricing formula that will be applied to determine the profitability of marketing directly to a processor.

Farm-gate sales

Farm-gate sales directly to consumers offer another marketing opportunity for Ontario lambs. This option may achieve the highest sale prices, however, marketing product and maintaining customer relationships will require significant time. Additionally, it can be more challenging to produce lambs that meet each individual customer’s needs. It is important to note that all meat sold through farm-gate sales must be slaughtered and inspected in a licensed abattoir. See Ontario’s Meat Inspection System for more information.

Market proximity

Proximity to markets and the cost of shipping lambs are other aspects to consider when evaluating marketing options. A constant supply of high-quality lambs available from the production sector could expand the market for Ontario lamb.

Production systems

Once the land, buildings, labour, machinery and available markets have been evaluated, the production system that most efficiently utilizes these farm resources can be determined. In general, production systems can be divided into annual lambing systems, with one lambing each year, or accelerated systems, where breeding groups are planned to lamb several times a year.

Table 2 describes some of the advantages and disadvantages of the different systems. The production system best suited to the farm resources available will usually be the most efficient.

| Production system | Advantages | Disadvantages |

|---|---|---|

| Annual spring lambing (April to May) | lower lamb mortality lower labour requirements lower housing costs lower feed costs lambs need very little, if any, extra feed to be finished on grass highest period of nutritional demand for the ewe is satisfied by the pasture | higher parasite burden market prices may be lower higher risk of predation lambing may occur during periods where labour requirements for other enterprises on the farm are high higher susceptibility to adverse weather conditions (for example, hypothermia from cold weather during lambing, reduced carrying capacity during droughts) |

| Annual winter lambing (January to February) | lower parasite burden higher revenue potential lambs grow faster in cooler temperatures lower risk of predation of newborn lambs | higher lamb mortality higher feed costs for lactating ewes market lambs raised on stored feed more health problems greater management and labour required less ewes can be handled per person higher housing costs |

| Accelerated lambing | year-round supply of lambs more market price stability because of increased number of marketing dates lambs can be marketed during seasonal peaks lower lamb mortality (for example, 2 warm season lambings and 1 cold season lambing per year) more lamb marketed per ewe less lambing barn space needed | management is more intensive insulated lambing areas needed for winter lambing higher feed cost/ewe/year potentially more health problems (for example, udder issues) |

When selecting a production system and budgeting for the sheep enterprise, it’s critical to weigh the opportunities for revenue from the market lamb crop relative to the costs of production. Keep in mind that auction prices fluctuate both within the year and over time. Table 3 compares three scenarios for target markets using average Ontario auction prices from 2017 to 2020. The three scenarios compared were:

- marketing light lambs (50–64 lb) in March and April for the Easter market

- marketing moderate to heavy lambs (80–94 lb) in July and August for the Eid-al-Adha market

- marketing heavy lambs (95–109 lb) in the Fall

Although a higher price per hundred weight is observed for lighter lambs around Easter, the gross revenues per lamb are similar between the three scenarios. Thus, it may be more important to consider the relative costs of producing lambs for each of the target markets when determining the profitability of each option. The OMAFRA lamb finishing and ewe flock cost of production tools can assist with budgeting.

| Market period | March to April | July to August | September to October |

|---|---|---|---|

| Target markets | Light lambs (50–64 lb) for Easter | Moderate to heavy (80–94 lb) lambs for Eid-al-Adha | Heavy (95–109 lb) lambs |

| Price per hundred weight ($/cwt) | $363.55 | $260.99 | $226.41 |

| Average weight for target class | 58.2 lb | 87.0 lb | 101.4 lb |

| Gross revenue per lamb | $211.59 | $227.06 | $229.58 |

| Production considerations | Winter lambing Higher lamb mortality higher feed costs | Winter/early spring lambing Higher feed costs | Spring lambing Lower lamb mortality lower feed costs |

Breeding stock

Once the farm resources have been evaluated and the production system that best uses those farm resources is chosen, the next step is to determine what breeding stock is available that matches the production system selected.

All dam lines should exhibit good fertility, prolificacy, longevity, mothering ability and milk production. They should also be of a medium size, be easy to feed and give birth to lambs with good livability. When lambing on grass, a dam line that exhibits hardiness may be desired and when lambing every 7.2–8 months, ewes that breed out of season and exhibit early sexual maturity would be optimal.

Selecting the proper breeds to fit the production system is extremely important. See the OMAFRA factsheet Choosing breeds for producing profitable market lambs for more information.

Conclusion

Selecting the right production system is an important decision for commercial sheep producers. The best management decisions can be made if the resources are evaluated first and the production system is selected to fit the farm and the resources, instead of the farm and the resources being adapted to fit a production system or a breed of sheep.

This fact sheet was written by Erin Massender, small ruminant specialist, and Delma Kennedy, sheep specialist, OMAFRA.

Footnotes

- footnote[1] Back to paragraph Linear feeder space for a 19.5 m (64 ft) pen is equivalent to 1,950 cm (768 in.).

- footnote[2] Back to paragraph Floor space area for a 19.5 m × 3.66 m (64 ft × 12 ft) pen is equal to 71.37 m2 (768 ft2).

- footnote[3] Back to paragraph The Eid-al-Adha holiday shifts about 11 days earlier each year so peak sale prices will also be expected to move earlier.

- footnote[4] Back to paragraph Calculated using weighted average prices reported in the Ontario Sheep Farmers’ monthly market summaries for the months in each market period from 2017 to 2020.