We've moved this content over from an older government website. We'll align this page with the ontario.ca style guide in future updates.

Regulation

Application

What workplaces are covered by the Noise Regulation (O. Reg. 381/15)?

The Noise Regulation applies to all workplaces covered under the Occupational Health and Safety Act (OHSA).

Regulatory requirements - overview

Employer’s duty to protect workers from hazardous sound levels

Employers have a duty to take all measures reasonably necessary in the circumstances to protect workers from exposure to hazardous sound levels.

The regulation requires that every employer shall ensure that no worker is exposed to a sound level greater than a time-weighted average exposure limit of 85 dBA (decibels measured on the A-weighting network of a sound-level meter) measured over an 8-hour work day.

Employers must comply with this limit following the “hierarchy of controls”, which emphasizes the use of engineering controls and work practices to protect workers and places restrictions on the use of hearing protection devices (HPDs) by workers.

When the prescribed exposure limit would be exceeded, employers are required to put in place protective measures to proactively reduce workers’ noise exposure. These measures include:

- engineering controls to reduce noise at the source or along the path of transmission

- work practices such as equipment maintenance (to keep it quieter) or scheduling to limit a worker’s exposure time

- personal protective equipment in the form of HPDs, subject to the restrictions stated in the Regulation

Signs

Where it is practicable to do so, employers must post a clearly visible warning sign at every approach to an area in the workplace where the sound level regularly exceeds 85 dBA.

Worker training

Employers who provide workers with HPDs must provide them with adequate training and instruction on their care and use.

The training and instruction must address:

- limitations of the device(s)

- proper fit

- inspection and maintenance, and, if applicable

- cleaning and disinfection

Selection, care and use of hearing protection devices

The Regulation requires HPDs to be selected with regard to the:

- sound levels to which a worker is exposed

- attenuation or reduction in sound level provided by the HPD

- manufacturer’s information about its use and limitations

The Regulation also requires HPDs to be used and maintained in accordance with the manufacturer’s instructions.

The following sections provide guidance on the provisions of the Regulation with quotes.

General duty clause

“Every employer shall take all measures reasonably necessary in the circumstances to protect workers from exposure to hazardous sound levels.”

An Ontario employer, who is covered by the OHSA, has a legal obligation and a general duty to take all measures reasonably necessary in the circumstances to protect workers from exposure to all hazardous sound levels.

Noise exposure limits

“…every employer shall ensure that no worker is exposed to a sound level greater than an equivalent sound exposure level of 85 dBA, Lex, 8”.

This requirement is intended to protect workers from exposure to sound levels above the occupational exposure limit of 85dBA averaged over an 8 hour work shift, referred to as 85 dBA Lex, 8.

What limits apply?

The only applicable exposure limit is the 85 dBA, Lex, 8.

A worker's exposure to noise levels generally varies throughout the day. An exposure limit of 85 dBA Lex, 8 may be thought of as the time-weighted average (TWA) exposure limit for noise for an 8 hour shift.

This is similar in concept to the TWA exposure limit for a biological or chemical agent in the Regulation respecting the Control of Exposure to Biological or Chemical Agents (Regulation 833).

This does not mean that protection is required only when sound levels exceed 85 dBA. For example, a constant exposure to 84 dBA over a 12 hour period would mean that worker protection is mandated, because the Lex, 8 exposure limit for noise would be exceeded. Refer to Appendix B: Determining noise exposure and calculating Lex, 8 for information on non-standard work shifts.

What does dBA stand for?

dB stands for decibels which is the unit of measurement for sound. dBA is a measure of sound level in decibels measured on the A-weighting network of a sound level meter. The measurement of sound on the A-weighting network is commonly used to characterize noise levels in loud environments. It filters the noise frequency components to roughly imitate the hearing profile of the human ear. The decibel scale is logarithmic. Zero dBA corresponds to the threshold of hearing (auditory threshold). 130 dBA is about the threshold of pain.

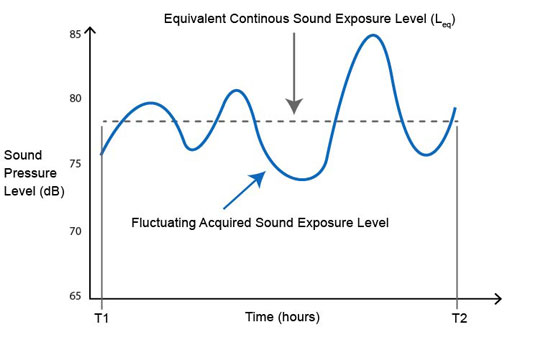

What does “equivalent sound exposure level (Leq)” mean?

An “equivalent sound exposure level”, referred to as Leq is the continuous sound pressure level of noise averaged over time which contains the same amount of energy as that generated by the actual and varying sound levels being measured. Because occupational noise is complex and worker exposure may fluctuate throughout the work shift, the sound levels need to be averaged over a sample period that is representative of the entire exposure.

T1 = start time for measurement

T2 = end time for measurement

This method of averaging noise levels is based on the “equal energy principle”, known as the 3dB rule and commonly referred to as the “exchange rate”. In this method, the allowed exposure time is halved for every 3dB increase in noise level. For example, an exposure to 85dB for 8 hours is equivalent to an exposure to 88dB for 4 hours. See “Table of Equivalent Noise Exposures” found in Appendix B.

What is Lex, 8?

“Lex, 8” is the equivalent sound exposure level of noise averaged over 8 hours, the length of a typical work shift. The mathematical equation or formula given in the noise regulation for determining Lex, 8 can be summarized as the equivalent sound exposure level over eight hours that contains the same total energy as that generated by the actual and varying sound levels to which a worker is exposed in his or her total work day. The result is expressed in decibels (dB).

What about impulse or impact noise?

Impulse or impact noise is a very short burst of loud noise which lasts for less than one second. Gun fire, or the noise produced by punch presses, are examples of such noise. By using appropriate instrumentation, impulse or impact noise is automatically included in the measurements used to determine Lex, 8 exposure level. See Appendix A: Noise measurement equipment for more information.

Is there a maximum exposure level or “ceiling limit” for noise?

The regulation does not specifically set a maximum exposure level or “ceiling” limit that cannot be exceeded for any period of time for noise.

Referring to the “Table of Equivalent Noise Exposures” in Appendix B: Determining noise exposure and calculating Lex, 8, essentially, no unprotected exposures are allowed for sound levels that exceed 115 dBA.

Noise measurement

“Any measurement of sound levels in the workplace that is done in order to determine what protective measures are appropriate shall be done without regard to any use of hearing protection devices.”

This provision requires sound level measurements to be undertaken for purpose of assessing worker noise exposures without regard to the wearing of HPDs. HPDs attenuate or reduce the sound pressure level incident upon the ear. Attenuation refers to the reduction in sound pressure level incident upon the ears when a HPD is worn. Exposures are calculated assuming that the workers are not protected by wearing HPDs.

How are noise exposures assessed?

The sound level(s) or Leq measurement(s) used to determine an Lex,8 exposure level can normally be obtained using a noise dosimeter, an integrating sound level meter, or in some circumstances, a basic sound level meter. Although section 1 of the Noise Regulation (O. Reg. 381/15) provides a formula for calculating the equivalent sound exposure level measured over 8 hours (Lex, 8), some sound level meters automatically calculate this.

Appendix A: Noise measurement equipment, Appendix B: Determining noise exposure and calculating Lex, 8, as well as CSA Standard Z107.56-13, “Measurement of Noise Exposure” provide detailed guidance on equipment selection and specifications and procedures for the measurement or calculation of Leq and Lex, 8.

Do Noise Surveys have to be done?

Compliance with Ontario’s Noise regulation does not necessarily mean that a comprehensive noise survey needs to be done in every workplace. Some employers will have previous sound level or dosimetry data that may be useful in assessing worker exposures and the likelihood of them exceeding the occupational exposure limit. Exposure data for a group of workers with the highest noise exposures may be useful to infer compliance for less exposed groups.

Even in the absence of such data, a crude assessment may be possible based on the ease or difficulty of speech communication at a normal conversation distance of about one meter. If it is necessary to speak very loudly to converse at one meter, the sound level probably exceeds 85 dBA

Other indicators that a noise exposure survey is needed include use of equipment known to produce sound levels above 80 dBA in published data, worker complaints regarding noise, or audiometric test results showing early signs of noise induced hearing loss.

For some workplaces such as construction projects, mines, farming operations and fire services, there are resources available that provide noise measurement information for various pieces of equipment that can assist workplace parties in undertaking their initial noise assessment. Examples are provided in Appendix D: Noise in construction, mining, farming and firefighting operations.

In addition, equipment manufacturers often provide noise emission data such as sound pressure levels under standard conditions and the sound power of equipment. A number of international standards are available for labelling machines and equipment with their noise emission levels. In Canada, the CSA Standard Z107.58-15- 02 “Noise Emission Declarations for Machinery” provides manufacturers with a means to determine and to create noise emission declarations for the machinery they produce. This information helps workplaces purchase quieter machinery and plan noise control programs.

Employers may contact their Health and Safety Association, Occupational Health Clinics for Ontario Workers (OHCOW) or consultants specializing in noise assessments to assist them with assessing noise exposures in their workplace, if they do not possess the instrumentation, resources, or knowledge to do so. OHCOW has published a Noise Calculator spreadsheet (XLS) on their website to assist workplace parties in determining noise exposures.

Protective measures

“The protective measures shall include the provision and use of engineering controls, work practices and, subject to subsection (5), hearing protection devices.”

(Note: Restrictions on wearing of hearing protection devices are described in the section on “hierarchy of controls".)

Similar to an occupational exposure limit for a biological or chemical agent, when a worker is exposed to a daily noise dose exceeding the limit of 85 dBA Lex, 8, the employer must take measures to reduce the exposure to noise. The measures include a hierarchy of controls and the list in decreasing order of effectiveness includes:

- elimination (including substitution) of the noise source

- engineering controls

- administrative controls, including work practices, and finally

- the wearing of HPDs

Engineering controls include measures to reduce noise at the source or along the path of transmission. Limiting a worker’s exposure time to noise (e.g. task rotation) is an example of an administrative control.

The above regulatory provision requires the employer to consider all types of controls to protect workers against noise, but does not necessarily expect an employer to use all types for every situation. There may also be circumstances where HPDs are provided and worn in conjunction with other control measures to minimize noise exposure.

Hierarchy of controls

“Except in the circumstances set out in subsection (6) [see phrase below] the employer shall protect workers from exposure to a sound level greater than the limit described in subsection (4) [i.e. 85dBA, Lex, 8] without requiring them to use and wear hearing protection devices.”

“Workers shall wear and use hearing protection devices appropriate in the circumstances to protect them from exposure to a sound level greater than the limit described in subsection (4) [i.e. 85dBA, Lex, 8] if engineering controls are required by subsections (1) and (2), and,

- are not in existence or are not obtainable

- are not reasonable or not practical to adopt, install or provide because of the duration or frequency of the exposures or because of the nature of the process, operation or work

- are rendered ineffective because of temporary breakdown of such controls; or

- are ineffective to prevent, control or limit exposure because of an emergency.”

These provisions reinforce the concept of the hierarchy of controls. They emphasize that the preferred and most effective way to control noise exposure is through the use of engineering controls and sets out the conditions under which hearing protection devices (HPDs) may be used for worker protection.

In keeping with good industrial hygiene practice, the wearing of HPDs to protect workers from hazardous sound levels should be considered as a last resort. Engineering and administrative controls are preferable because HPDs are often less protective than their ratings due to: testing methodology; improper selection; use and fit; poor maintenance; and, discomfort with prolonged use.

In practice, a number of noise exposures in dynamic workplaces such as construction projects, may qualify for the use of HPDs in circumstances where engineering controls are not reasonable or practical because of the duration or frequency of the exposures or because of the nature of the process, operation or work. To demonstrate compliance with the Regulation, employers should document what other control measures were considered and why those measures were not adopted.

The intent of the phrase “wear and use hearing protection appropriate in the circumstances” will be described in a more detailed manner in the section “Hearing protection devices – selection, use and maintenance” below.

Engineering controls and noise reduction

Engineering controls are the preferred method for addressing noise exposure on a long- term basis. Engineering controls are based on the following principles:

- controlling at the source

- controlling along the path of transmission

Engineering controls at the source include:

- modification, retrofitting of equipment (e.g. installing a noise-reduction attachment or noise damping materials)

- replacement of worn parts that may be a source of noise

- relocation of equipment

Some examples of these types of engineering controls that can control noise at the source are:

- installing mufflers on air exhausts

- purchasing quiet air jet nozzles

- applying mechanical damping treatment to metal panels in impact situations

- using vibration isolators on vibrating equipment

- redesigning noisy saw blades or press dies

Engineering controls along the path of transmission involve stopping the noise before it reaches a worker. Engineering controls along the path can include:

- absorbing noise by installing enclosures

- screens and shields

- minimizing the noise reflected from surfaces using sound-absorbing materials

- enclosing a work station in a noisy area

Administrative controls/work practices and noise reduction

Addressing workplace noise through administrative controls, including work practices, may be useful in controlling noise exposures. An example includes reducing a worker’s exposure time to noise by reorganizing tasks or rotating work assignments to limit the worker’s total shift exposure to an acceptable level. These controls may be particularly useful on construction projects where the risk of exposure to noise by the workers of one contractor to noise generated by the work of another contractor could potentially be avoided through the project planning and the staging of work.

Professional judgment is required when designing a job or worker rotation schedule to reduce worker noise exposures using this method. Other controls include the implementation of a good preventive maintenance program to prevent equipment from becoming a significant source of noise and the setting of maximum noise specifications for the purchase of new equipment. CSA Standard Z107.58-02 (R2014), “Noise Emission Declarations for Machinery”, provides harmonized information on noise emissions from machinery and equipment using internationally recognized standards and procedures.

Employers may contact the Health and Safety Associations, OHCOW, or consultants specializing in the design and fabrication of noise controls for assistance. Acoustical consultants can often provide effective solutions for specific noise sources or for reducing noise exposures generally.

There are also various resources available that discuss control measures. See “General references and endnotes” section at end of guideline for more information.

Warning signs

“Where practicable, a clearly visible warning sign shall be posted at every approach to an area in the workplace where the sound level measured as described, regularly exceeds 85 dBA.”

The purpose of the signage requirement is to warn workers that they are entering an area, that is, or may become, loud enough to cause damage to their hearing if unprotected.

The intent of this provision is for the employer to post a sign at every approach to an area where continuous or intermittent noise levels regularly exceed 85 dBA. This would include intermittent noise from power tools, or equipment normally used in the area, but would exclude one-time or rare noisy, activities.

The regulation provides for an exception to the signage requirement where it is not practicable to do so. This provision recognizes that it may not be reasonable to place warning signs at every approach to noisy areas in all workplaces, such as underground mines and some construction projects, due to their unique design and the dynamic nature of the work.

In such cases, greater emphasis may be placed on the provisions of subsection 2 (1) of the Regulation for the employer to ensure that workers are aware of the noise hazards in the workplace and the appropriate measures and procedures in place for their protection.

What must the sign indicate?

It is ultimately left to each workplace to decide on what kind of warning signs should be provided, but it is recommended that the signs advise workers that there is a potential for hearing loss in that area, if unprotected, and what measures are to be taken to control this potential exposure.

The content of the signs may include:

- identification of actual sound level in dBA

- warning of hazardous sound levels

- requirement for mandatory hearing protection to be worn in the area

- the allowable exposure duration for the area, without hearing protection

- icons indicating that hearing protection is to be worn

Training and instruction

“An employer who provides a worker with a hearing protection device shall also provide adequate training and instruction to the worker in the care and use of the device, including its limitations, proper fitting, inspection and maintenance and, if applicable, the cleaning and disinfection of the device”.

This section stresses the importance of ensuring that workers know how to properly use and maintain any HPDs they may be required to wear to ensure that they are properly protected from noise exposures. The training and instruction to a worker on the care and use of HPDs must include, but is not limited to, the following:

- Limitations – Not all HPDs are suitable for use in all work environments (e.g. extreme temperatures) and may not be compatible for use with other personal protective equipment (e.g. wearing of ear muffs combined with safety glasses).

- Proper Fit – Obtaining a proper fit of the HPDs is critical to ensuring effective protection.

- Inspection and maintenance – Regular inspection (e.g. before each use) of the HPDs and maintaining them in good condition is essential.

- Cleaning and disinfection – This applies to non-disposable HPDs. Ideally HPDs are assigned to individual workers for their personal use and are not shared. Where not individually assigned, cleaning and disinfecting must be performed before the next use. Cleaning is the physical removal of inorganic and organic foreign materials (e.g. dirt, microorganisms). Disinfection is the inactivation of disease-producing microorganisms. In general, HPDs must be cleaned thoroughly before effective disinfection can take place.

The training and instruction must be “adequate”, which means sufficient to protect the health and safety of workers. Workers should be able to apply the training and instruction in their daily work when using HPDs. To demonstrate compliance with the training requirement, an employer should keep training records.

Hearing protection devices – selection, use and maintenance

“A hearing protection device shall be selected having regard to,

- sound levels to which a worker is exposed

- the attenuation provided by the device

- the manufacturer’s information about the use and limitations of the device

“A hearing protection device shall be used and maintained in accordance with the manufacturer’s instructions”.

For situations where employers rely on hearing protection devices (HPDs) to protect workers against excessive noise exposures, the employer must ensure that the HPDs are appropriate and effective for the intended use. The selection of HPDs requires an understanding of the physical characteristics of the noise exposure at the workplace, the functional capabilities of HPDs, the performance limitations of the various types of HPDs and an understanding of the limitations of the selected HPDs under the conditions of use.

HPDs are commonly grouped into two main types: ear plugs and earmuffs. There are also other specialized types of HPDs. The CSA Standard Z94.2-14, “Hearing Protection Devices – Performance, selection, care, and use” can be reviewed for more detail on the types of HPDs.

HPD selection is even more critical in extreme noise environments. Sound levels in excess of 105 dBA may be considered extreme noise environments. Where it is not reasonable or practical to reduce the sound levels below 105 dBA and minimize worker exposure, special HPDs or dual protection from ear plugs and ear muffs may be necessary as the use of a single HPD will likely not be sufficient to reduce noise levels below the 85dBA Lex, 8.

Attenuation

Attenuation is the anticipated level of protection, at both ears, that would be provided by a properly functioning hearing protection device (HPD) or a combination of HPDs (e.g. ear plugs, ear muffs) worn by properly fitted and trained users. Either laboratory or real-world attenuation data may be used to estimate the protected noise exposures that wearers of HPDs receive.

Information on the attenuation is provided by the manufacturers of HPDs. CSA Standard, Z1007 Hearing Loss Prevention Program Management requires HPDs to be selected based one of the following methods:

- Single Number methods

- Noise Reduction Rating (NRR) method

- Subject Fit 84th percentile (SNR (SF84))method

- CSA Class Method

- Octave-band (OB) Computation method

- Field attenuation estimation system (FAES)

Section 7.1 of CSA Standard Z94.2-14, “Hearing Protection Devices- Performance, section, care and use” requires that both the NRR or SNR (SF84) and CSA Class of the HPD be included on the packaging information that comes with the HPD. In Ontario, the NRR and CSA Class are usually provided by the manufacturers for the HPDs.

For more information on these methods see Appendix C.

De-rating of HPDs

Typically the attenuation data from laboratories is much higher than real-world data based on actual use. The principal reasons for this include: poor fit, lack of proper training and supervision. To address the discrepancy between laboratory and real-world results, there are different computational procedures for using the laboratory hearing protection device (HPD) attenuation values to estimate protected exposure.

It is important that this information as well as other limitations be considered when selecting the appropriate HPD.

The NRR method and its limitations

When selecting hearing protection devices (HPDs), it is often incorrectly assumed that the Noise Reduction Rating (NRR) on the package accurately predicts the dBA reduction that the device will provide. This is untrue for two reasons.

First, the NRR is designed for use with C-weighted sound measurements. This means that if only A-weighted noise measurement data is available there must be an adjustment to account for the difference between A-weighting and C-weighting.

Second, the data used to determine the NRR for a device is normally obtained under laboratory conditions, so devices must be “de-rated” to account for the significantly reduced protection provided under “real world” conditions.

Employers who use the NRR method to select hearing protection devices need to consider both of these factors when discussing the purchase of appropriate HPDs for their specific workplace noise environment.

See Appendix C for further discussion of HPD selection and de-rating schemes.

Footnotes

- footnote[1] Back to paragraph J. Malchaire, Strategy for prevention and control of the risks due to noise, in Occ. Environ Med 2000; 57:361-369.