Alert: Inspection of crane hook block

Learn about the importance of periodic inspection of hook block assemblies used on cranes.

Hazard summary

Workers who work near cranes are at risk when the hook attached to a crane fails, and the load drops. Adequate, periodic inspections of hook blocks are necessary to ensure that these critical components are in good condition for safe hoisting operations.

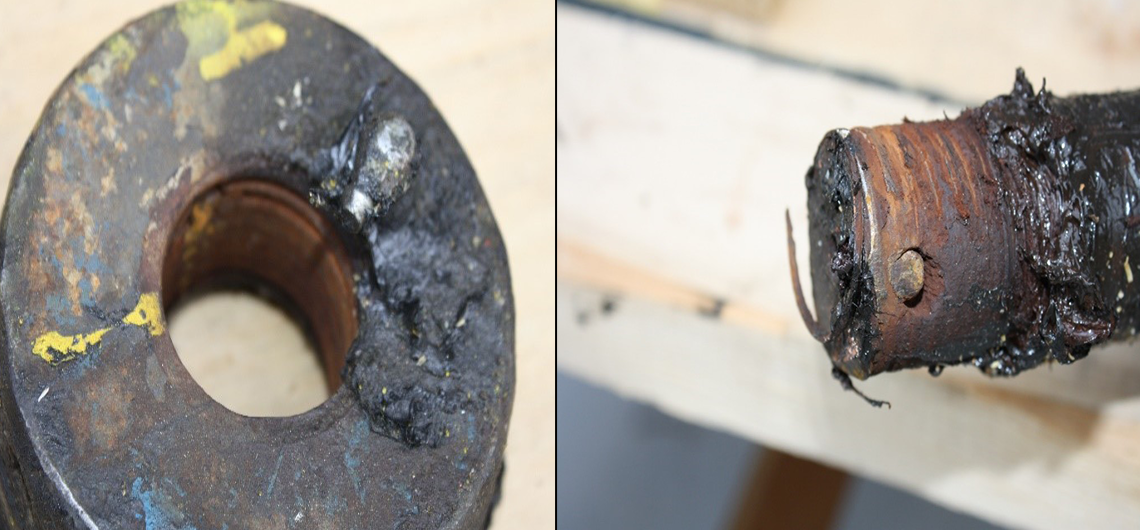

Two recent “near miss” events involving hook block assemblies occurred where the hook threads failed. It was determined that both failures were due to the degradation of the threaded portions of the hook and the nut causing a catastrophic failure of the hook block assembly. The threads on the hook and nut were found to be corroded and excessively worn. The deterioration of the threads caused the threaded hook shank to pull free from the nut and fall out of the hook block. The damage was not visible when the hook block was assembled.

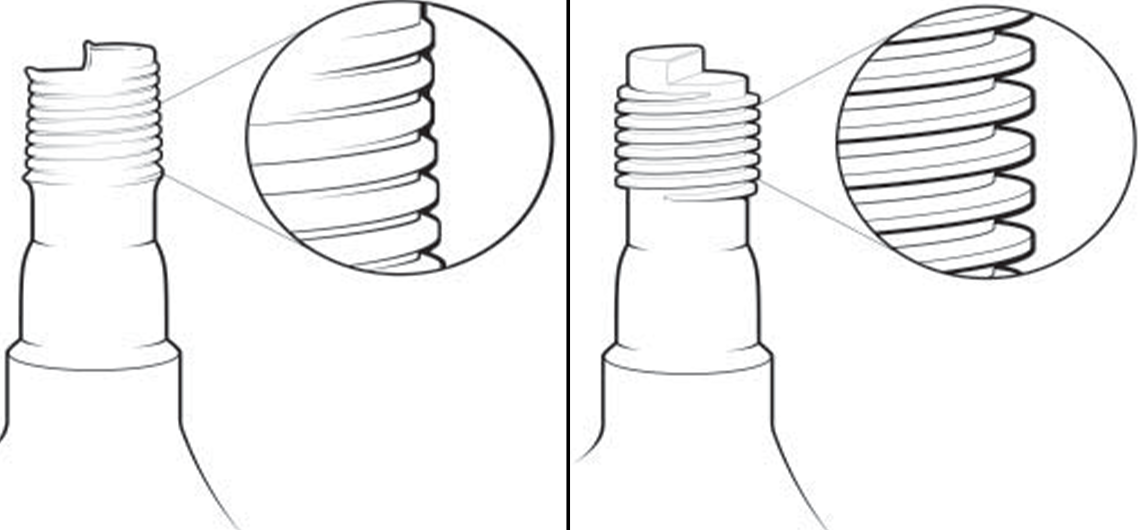

This type of wear and corrosion could be found on any crane hook with a threaded shank. Although both incidents involved a tower crane hook block, similar hook blocks may be used on other types cranes and hoisting devices. The images and photos below show the difference between corroded and undamaged threads.

Key legal requirements

Under the Occupational Health and Safety Act (OHSA) employers have general duties, including the duty to take every precaution reasonable in the circumstances to protect workers and the duty to ensure that equipment provided by the employer is maintained in good condition.

Suppliers must ensure that cranes are in good condition and comply with the OHSA and regulations.

In addition to the above general duties, workplace parties at a construction project must ensure a lifting hook block:

- is maintained in a condition that does not endanger a worker and used in accordance with the manufacturer’s operating manual

- this includes following manufacturer’s instructions for conducting periodic inspections and testing critical components of equipment

- is inspected by a competent worker for hazards and that it can handle rated capacities

- inspections must be performed before the crane is first used at the workplace and thereafter at least once a year or more frequently as recommended by the manufacturer

- is not used:

- while it is defective or hazardous

- when the weather or other conditions are such that its use is likely to endanger a worker

- while it is being repaired or serviced, unless the repair or servicing requires that it be operated

A hoisting hook must have its load rating legibly cast or stamped on it in a location where the person using it can readily see it.

A hook block must have its load rating and weight legibly cast or stamped on it in a conspicuous location.

Every replacement part for a crane must have at least the same safety factor as the part it is replacing.

For more information, please see O. Reg. 213/91 – Construction Projects, sections 93–95, 158–159, and 173–174.

In addition, there are specific requirements set out in other regulations under the OHSA that must be complied with at certain workplaces, for example:

Regulation 851 – Industrial Establishments, section 51

Regulation 854 – Mines and Mining Plants, sections 192, 195 and 201

Recommendations

Inspect the hook block assembly

Follow crane and/or hook block manufacturer’s recommendations to inspect and maintain the hook block assembly to ensure critical components are in good condition.

In general, the inspection should include the following steps:

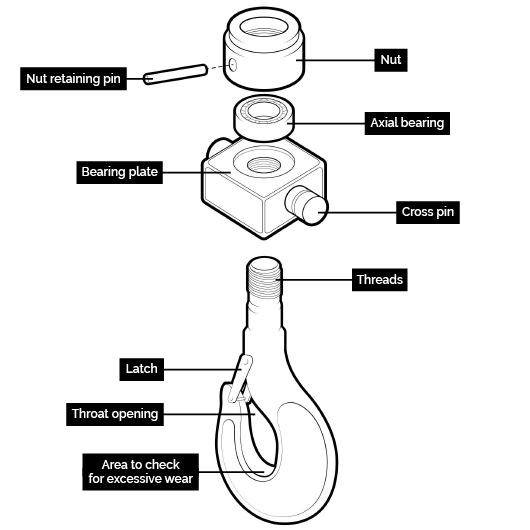

- Remove the hook from the hook block assembly and clean the threads on the hook and the nut.

- Examine the threads for cracks using magnetic particle or dye penetrant test methods. If a crack is found remove the hook from service until inspected by a competent person.

- Examine the threads for wear, damage, and corrosion. If the threads are damaged, deformed or corroded, remove the hook from service. Refer to criteria specified by the manufacturer or hook inspection and removal criteria found in applicable standards.

- Examine the hook for damage and wear as per criteria specified by the manufacturer or hook inspection and removal criteria found in applicable standards.

- Check that the nut retaining pin, set screw, or key prevents relative movement between the hook and the nut.

- Examine the hook pivot and the axial and cross pin bearings. Look for wear, and ensure the pivot and bearings provide a freely rotating support for the hook.

- Examine the block bearing plate for cracks, wear, or other damage. Damage affecting its safe use must be repaired before returning the block to service.

- Before reassembling the hook block, grease the bearings as required and coat the clean threads on the hook and nut with the manufacturer’s recommended thread sealant to provide corrosion resistance.

- When reassembling, check that the length of threads engaged between the hook and the nut is at least equal to the hook thread diameter.

- Check that the nut retaining pin, set screw, or key that prevents the nut from backing off the hook is properly in place and secure.

Review industry standards

Workplaces may also want to refer to the following industry standards to assist in compliance with the requirements under the OHSA:

CSA Z150-16 Safety code on mobile cranes:

5.3 Inspection

5.3.5 Annual inspection,

Clauses 5.3.5.1.1 and 5.3.5.3

ASME B30.10-2019 Hooks - Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

Section 10.1.10.5 Removal Criteria

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.

Footnotes

- footnote[1] Back to paragraph © WorkSafeBC (Workers’ Compensation Board), used with permission.