Ventilation requirements for diesel-powered equipment in underground mines

Legal requirements and best practices to protect the health of workers from diesel emissions in underground Ontario mines.

This resource does not replace the Occupational Health and Safety Act (OHSA) and its regulations and should not be used as or considered legal advice. Health and safety inspectors apply the law based on the facts in the workplace.

Purpose

To assist workplace parties with understanding the requirements in Regulation 854 (Mines and Mining Plants) under the Occupational Health and Safety Act (OHSA) when providing ventilation where diesel powered equipment is operating underground.

Objectives

The objectives of this guide are to assist workplace parties:

- by providing information to help comply with the requirements for using diesel-powered equipment in underground mines

- by providing information about the ventilation requirements where diesel-powered equipment is operating underground

- in determining appropriate airflow rates when using diesel particulate filters or other after- treatment devices

- in how to sample emissions from diesel-powered equipment

Legal requirements

Regulation 854 (Mines and Mining Plants) sets out the requirements for the use of diesel- powered equipment in underground mines in Ontario. The regulation sets out certain measures and procedures that must be implemented to manage hazards associated with the operation of diesel-powered equipment underground and requires certain information that must be provided to workers to protect their health and safety. Other requirements in Regulation 854 relate to the safe operation of diesel-powered equipment underground either directly or indirectly.

Key legal requirements include, but are not limited to:

- Section 182 (airborne hazard management program)

- Section 183 (diesel-powered equipment used in underground mines)

- Section 183.1 (airflow where diesel-powered equipment is operated in underground mines)

- Section 183.2 (worker exposure to elemental carbon from diesel emissions in underground mines)

- Sections 183.3 and 183.4 (testing of diesel-powered equipment in underground mines)

- Section 252 (ventilation systems in mines and mining plants)

Risk assessment requirements

Regulation 854 also requires all employers to conduct risk assessments of the workplace for the purpose of identifying, assessing, and managing hazards, and potential hazards, that may expose a worker to injury or illness. The risk assessment requirements are outlined in sections 5.1, 5.2, and 5.3.

Under these provisions, an employer must develop and maintain, measures to eliminate, where practicable, or control, where elimination is impracticable, the hazards, and potential hazards, identified in the risk assessment. These measures must be developed in consultation with the joint health and safety committee (JHSC) and health and safety representative (HSR), if any.

This would include any measures the employer has put into place to mitigate the risks of operating diesel-powered equipment underground.

The results of these risk assessments should be considered in the development of measures to protect the health and safety of workers.

The Ministry of Labour, Immigration, Training and Skills Development (MLITSD) has developed a Risk Assessment and Management for Mines and Mining Plants Guideline to help workplace parties understand how to identify, assess, and control workplace hazards.

Background

Emissions produced by diesel-powered equipment are a complex mixture of:

- gases

- vapours

- aerosols

- particulate substances

Diesel emissions can be a significant source of contaminants in the underground environment. Underground workers could potentially be exposed to:

- carbon monoxide (CO)

- oxides of nitrogen (NOx) including nitrogen dioxide (NO2)

- diesel particulate matter (DPM)

- other emissions at levels higher than those encountered in other workplaces

DPM emitted by diesel engines are respirable, which reach the deepest part of the lungs, and are primarily composed of:

- soot particles

- carbon

- ash

- polycyclic aromatic hydrocarbons

- metallic abrasion particles

- sulfates

- silicates

In the short-term, workers who are exposed to diesel exhaust may experience:

- headaches

- dizziness

- eye, nose and throat irritation

Prolonged and repeated exposures to diesel exhaust may increase the risk of:

- cardiovascular disease

- cardiopulmonary disease

- respiratory disease

- lung cancer

- bladder cancer

In June 2012, the International Agency for Cancer Research (IARC) classified diesel emissions as a known human carcinogen.

Using equipment with modern diesel engines and after-treatment devices, such as diesel particulate filters (DPFs), can significantly reduce the potential exposure of workers in underground mines to hazards from diesel emissions.

General requirements for underground diesel-powered equipment

Record keeping

Subsection 183 (1) requires that all diesel-powered equipment first used in an underground mine after June 1, 1995, must meet the requirements established in CSA M424.2-22 Non-Rail-Bound Diesel- Powered Machines for use in Non-Gassy Underground Mines.

Subsection 183 (2) requires mines to maintain a record for each piece of diesel-powered equipment used underground. Although not required, the ministry’s “Notice of Diesel-Powered Equipment” form, can be used as a record template. At minimum, subsection 183 (3) requires the following information to be recorded for each piece of diesel-powered equipment used underground:

- make, model and serial number

- rated power, rated engine revolutions per minute (RPM), and maximum fuel injection rate,

- ventilation rate as certified in accordance with CSA M424.2

- make, model and serial number of any emission control devices used with the equipment

- capacity of both the fuel and hydraulic fluid tanks

The records may be stored electronically and must be readily available at the mine site. Any modifications made to the equipment which may alter its specifications would require the records to be updated, such as:

- engine rated power

- fuel injection rates

- emission control devices

Ventilation requirements

To comply with subsection 183 (4), employers at underground mines must keep and maintain the following underground ventilation information relating to diesel-powered equipment:

- the volume of air flowing in the underground haulage ways and workings where the equipment is operating; and

- the total ventilation requirements for the equipment when it is operating in a single continuous course of air.

A single continuous course of air is either:

- a continuous path where the same air remains between entrance and exit; or,

- a continuous path where the same air remains until a new air source enters; or,

- a path with a continuous source of air that has no addition from other sources.

Operator information

Subsection 183(5) requires that the applicable airflow rate for a piece of diesel-powered equipment must be provided directly to the operators or available in a readily accessible format. This information may be provided in various ways, such as:

- at pre-shift line up meetings or safety huddles

- through instruction from a supervisor

- on pre-operational equipment inspection cards

- by digital means, such as a phone or tablet

To assist the operator with understanding the airflow rate requirements for the equipment being operated, under subsection 183.1(4) each piece of diesel-powered equipment must have its airflow rate posted in a location on the equipment that is visible to and readable by the operator. Example locations could include a placard mounted in the operator’s cab or in a location visible from the operator’s controls.

Fuel requirements for underground diesel-powered equipment

The quality of fuel used has a direct impact on the emissions produced by diesel-powered equipment and plays a critical role in a mine’s overall emissions reduction strategy. Diesel fuel used in underground mines must meet one of the three following Canadian General Standards for diesel fuel:

- Canadian General Standards Board CAN/CGSB-3.520-2020 Diesel fuel containing low levels of biodiesel (B1-B5)

- Canadian General Standards Board CAN/CGSB-3.522-2020 Diesel fuel containing biodiesel (B6-B20)

Using fuels that meet one of these standards allows mines flexibility to incorporate biodiesel blends as part of their carbon reduction strategies. Changing between fuel types or blends may impact the amount or concentration of contaminants in diesel emissions.

The Worldwide Fuel Charter (WFC) is an international guideline published to support fuel quality standards. The WFC guideline provides recommended fuel range specifications for engines with different levels of emission control. The WFC guideline also provides explanations of the various aspects of fuel quality and their effects on vehicle emissions. Additionally, CanmetMINING, a science and technology branch of the Minerals and Metals sector of Natural Resources Canada that focuses on the development and deployment of green mining innovation technologies, recommends that underground diesel-powered equipment use fuel with a density between 820-840 kg/m3 as this range was found to offer a balance between, engine performance, fuel efficiency and emissions.

All diesel fuel used underground, regardless of which referenced fuel standard is applied, must have a minimum flash point of 52oC. As mines extend deeper their ambient temperatures will continue to rise making the use of high-flash point fuel particularly important to prevent fires and explosions.

Subsections 30(4) and 183(6) of Regulation 854 prohibit the use of gasoline or other volatile fuels to be used in underground equipment, including in their starting mechanisms.

Airflow requirements for diesel-powered equipment used underground

Determining airflow rates for diesel powered equipment

Ventilation is the primary means of controlling airborne hazards in underground mines. While ventilation dilutes contaminants and removes them from the workplace, diesel particulate filters or similar after- treatment devices — such as, Selective Catalytic Reduction (SCR) and/or Diesel Oxidation Catalysts with Particulate Filters (DOC/DPF) — can significantly reduce the level of contaminants at the source resulting in a reduction of contaminants being released into the workplace.

CanmetMINING certifies airflow rates for diesel engines used in Canadian underground mines in accordance with the CSA M424.2-22 Non-Rail-Bound Diesel-Powered Machines for use in Non-GassyUnderground Mines standard. The airflow rate is determined from engine emissions data obtained during comprehensive laboratory certification testing. These tests are for engine emissions, such as:

- carbon dioxide (CO2)

- carbon monoxide (CO)

- nitric oxide (NO)

- nitrogen dioxide (NO2)

- diesel particulate matter (DPM)

To determine the appropriate airflow rate, CanmetMINING tests diesel engines, utilizing a dynamometer to measures the:

- maximum fuel rate setting

- maximum engine intake restriction

- maximum engine backpressure

- fuel alteration system performance evaluation

- determination of untreated engine emissions

- exhaust after-treatment device performance evaluation

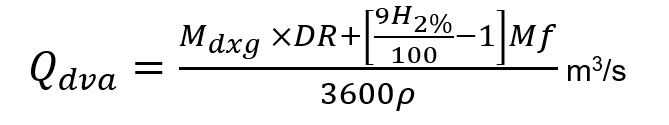

The engine operating condition that produces the greatest emission toxicity must be used when assessing the airflow rate. The airflow rate is determined based on the amount of airflow required to dilute the highest toxicity emission measured. Airflow rate for a piece of equipment is calculated as follows:

Qdva = (M-dxg X DR + [〖9H〗_(2%)/100 - 1] Mƒ)/3600ρ m3/s

Where:

- Qdva is the flow rate of dry ventilating air for the diesel machine in m3/s

- DR is the dilution ratio defined by clause 4.6.4 in CSA M424.2-22

- Mdxg is the dry exhaust rate produced by combustion of the fuel in kg/h

- M ƒ is the fuel consumption rate in kg/h

- ρ is the dry ventilation air density in kg/m3

- H2 is the percent by weight of hydrogen in the fuel

CanmetMINING will use these test results and calculations to determine the required airflow rate for each piece of diesel-powered equipment tested and will then include that rate on a certificate of homologation.

Subsection 183.1(1) requires that where diesel-powered equipment is operating in an underground mine, a mechanical ventilation system must produce a flow of air in accordance with the following rules:

- Rule 1- A piece of diesel-powered equipment that has an airflow rate certified in accordance with CSA M424.2 must have a flow of air at least equal to the airflow rate as posted on the certificate of homologation.

- Rule 2 - A piece of diesel-powered equipment that does not have an airflow rate certified in accordance with CSA M424.2 must have a flow of air at least equal to the engine power multiplied by unit airflow requirement, 0.06 m3/s per kilowatt engine power (known informally as the 100 CFM per brake horsepower rule).

- Rule 3 - If a piece of diesel-powered equipment with an airflow rate determined under rule 1 or 2 has been fitted with a diesel exhaust after-treatment device and a new airflow rate with this after- treatment device has not been certified or recertified in accordance with CSA M424.2, then the employer must determine a suitable flow of air in consultation with the JHSC or HSR, if any based on certain specified criteria (such as, applicable rates determined prior to modification, good engineering practices, results of testing after modification).

- Rule 4 - If more than one piece of diesel-powered equipment is operating in a single continuous course of air in an underground mine, then the total airflow rate must be at least equal the cumulative airflow rates as determined in Rules 1-3 for each piece of equipment.

When workplaces use Rule 3 for after-treatment devices which have not been certified or recertified in accordance with CSA M424.2, a new airflow rate for the piece of equipment will need to be determined. When determining new airflow rates, the employer must use good engineering practice and consult with the JHSC or HSR, if any. Any applicable CSA M424.2 or earlier certification rate for the engine with or without an after-treatment device, if available, would need to be considered as well. Workplaces should also consider the following:

- Select an appropriate after-treatment device that works optimally with the equipment.

- For example, a diesel oxidation catalysts (DOC) after-treatment device will reduce the amount of DPM in engine exhaust but may result in an increase of other contaminants such as nitrogen dioxide. Establish a program for selecting, cleaning, measuring performance and maintaining the after-treatment device.

- Conduct tailpipe testing before and after installing the after-treatment device in accordance with original equipment manufacture’s (OEM) requirements.

- Establish periodic benchmark tailpipe testing after the system is installed and operating, ensure that exhaust emissions are within range.

- Establish workplace air quality baselines prior to the application of the after-treatment device.

- Compare tailpipe testing results to the normal operating emission levels of the engine before the aftertreatment device was installed.

- Perform air quality test in the workplace under varying airflow rates:

- Isolate the equipment in an air stream with a known air volume and quality.

- While simulating normal operation of the equipment, test both the intake and exhaust air quality of the engine.

- Determine an airflow rate that is sufficient to provide safe workplace air quality within prescribed exposure limits.

The airflow rate determined under Rule 3 may be lower than the airflow rate determined under Rule 1 or 2 based on the emission test results after installing the after-treatment device. A record of the suitable flow of air determined under Rule 3 together with all testing results, calculations, and any other relevant information used to determine the new airflow rate must be kept readily available at the mine.

CSA M424.2 airflow rate certifications can apply to multiple combinations of the same engine specifications, and after-treatment devices used across multiple platforms. It is therefore possible to broadly retrofit fleets of equipment when equipped with the same configurations and certifications. Employers are encouraged to evaluate their equipment needs and airflow rates on a fleet basis.

Under section 183.4, employers must ensure that undiluted exhaust from diesel-powered equipment contains less than 600 parts per million by volume of CO and less than 60 parts per million by volume of NO2. Exhaust testing must be performed both routinely such as once per month, or more frequently if required by the OEM and after any repairs are made to the engine or exhaust system.

Testing undiluted exhaust

Tailpipe emission testing is critical to ensure engine and after-treatment devices are operating as designed. Employers must develop and implement safe measures and procedures for testing undiluted exhaust from diesel-powered equipment. These measures and procedures must be developed in consultation with the JHSC or HSR, if any. Each piece of diesel-powered equipment must be tested under consistent conditions and testing should be carried out, as far as is practical, under a full load (subsection 183.4 (3) of Reg. 854). If a test is carried out on equipment that is not under full load, the employer should be able to provide clear evidence demonstrating why it was not practical to do so.

Maintenance programs developed to evaluate engines and related systems against previous results have been successful in reducing emissions. Studies on engine maintenance and emissions have shown that:

- Exhaust emissions can be used to determine if an engine may need maintenance.

- Emission testing may indicate that repairs are needed or there are leaks in the exhaust systems, fuel systems, or cooling systems.

- Untreated exhaust should be measured before any after-treatment devices are used, to form a baseline.

- Emission levels can be checked against historical readings and the data collected may indicate engine maintenance is needed.

- A properly maintained emission-based maintenance program may improve fuel consumption as well as extend the life of the engine.

Sampling equipment

- The sampling equipment should be in good working order and designed for undiluted diesel emissions testing.

- All testing equipment should be used following manufacturer’s recommendations.

- The gas monitor should be calibrated using manufacturer’s recommendations.

- The monitor should also perform an initial self-check procedure before use.

- Use the same make/model of sampling equipment to ensure consistent results.

- Use sampling equipment which prevents condensation in the sampling line when sampling for NO2 as water can affect the sensor readings.

- Emission levels often spike during the first 30 seconds of engine loading. Emission samples should be collected after this period.

Tailpipe testing area risk assessment

Workplaces should conduct a risk assessment on the area where equipment is being tested. Evaluate and mitigate hazards including, but not limited to:

- the noise of the equipment being tested

- heat exposure from the equipment

- the ventilation requirements in the area

- the tasks other workers in the area are performing

- preventing the tested piece of equipment from inadvertent movement

- access and ergonomic requirements for the workers conducting the tests including ensuring workers have safe access to all sampling locations and have proper illumination

- that workers have the required personal protective equipment, including noise and respiratory protection

Considerations during tailpipe testing

To ensure tailpipe test consistency, tests must be conducted:

-

- at normal engine operating temperature

- at stabilized CO/CO2 levels

- while the engine is under full load as far as is practical

Here are some recommended steps for testing:

- The engine should be at operating temperature during testing.

- All mobile equipment brakes should be tested and functioning properly.

- The equipment being tested should be assessed to determine if it can safely perform a load test.

Selection of test procedures based on equipment

An automatic transmission with hydraulic systems should be tested using a torque converter stall or hydraulic stall (for example load haul dump and haulage trucks). Here are the recommended steps for testing:

- Place the drive unit in forward at the highest gear.

- Place the hydraulic system under a consistent stall condition (the testing measures and procedures should specify what hydraulic function is to be used to perform the test).

- Operate the engine at full throttle.

A standard transmission with a hydraulic system (for example many articulated units, such as scissor lifts and forklifts, etc.) should be tested by:

- Operating the engine at high idle (maximum revolutions per minute or RPM)

- Placing the hydraulic system under a consistent stall condition (the testing measures and procedures should specify what hydraulic function is to be used to perform the test). It is important to ensure the hydraulic system is capable of safely withstanding a stall condition.

An automatic/power shift or standard transmission with no hydraulic system (for example pickup trucks, personnel carriers, small utility vehicles, tractors, etc.) should be tested by:

- Operating the engine at the maximum RPM recommended by the manufacturer.

- Having a method to verify the RPM such as a tachometer.

Stationary units (for example welders, compressors, and pumps, etc.) should be tested by operating the unit under full load as far as is practical. Other test protocols may need to be established for special vehicles or circumstances (example hydro-static drive).

Stopping the test

If for any reason there is a concern of risk to the operator or the person sampling, the test should be stopped. If the operator notices that temperature levels (engine or torque converter) are getting too high, the test should be interrupted to allow the engine systems to return to normal operating temperatures.

Results of the test

The results of all testing must be recorded and kept readily available. Engines which fail to meet prescribed limits would need to be:

- removed from service

- inspected to determine the cause of the failure

- repaired where required

- re-tested to ensure compliance

- returned to service

Sampling for diesel particulate matter in mines

Where diesel-powered equipment is operating, section 183.3 requires employers to test:

- the volume of airflow in underground haulageways and workings

- the concentrations of carbon monoxide (CO), nitrogen dioxide (NO2) and elemental carbon in the atmosphere of the workplace

The time-weighted average exposure of a worker to elemental carbon shall not be more than 0.12 milligrams per m3 of air . The time-weighted average airborne concentration of a biological or chemical agent to which a worker may be exposed is usually calculated based on an eight-hour workday or forty- hour work week. An Occupational Exposure Limit (OEL) Adjustment Tool is available to help those workplaces to calculate OEL for irregular or extended work shifts.

Section 183.3 requires that employers at underground mines conduct at least weekly testing of the volume of air flowing in underground haulageways and workings where diesel-powered equipment is operating.

Additionally, a worker may request under section 183.3, that the employer test the personal exposure of workers to carbon monoxide (CO), nitrogen dioxide (NO2), or elemental carbon. The results of the tests must be:

- recorded and maintained

- readily available

- shared with the JHSC or HSR, if any, on request

If the tests indicate a worker has been exposed to CO, NO2 or elemental carbon in excess of the limit or any other hazardous contaminants as set out in section 4 of Regulation 833 (Control of Exposure to Biological or Chemical Agents), subsection 183.3 (4) of Reg. 854 requires that the employer investigate the cause and take remedial action, if possible, to prevent recurrence. The employer must notify the affected worker(s) and the JHSC or the HSR, if any, of the exceedance. The employer is required to re- test and confirm that the concentrations do not exceed the applicable limits.

The most accurate way to measure DPM is to measure the elemental carbon portion of the engine emissions in the ambient atmosphere. Elemental carbon is used as a surrogate for measuring DPM levels because it can be accurately determined at low concentrations and diesel engines are likely the only source of submicron elemental carbon in underground mines.

The US-based National Institute of Occupational Safety and Health (NIOSH) recommends measuring elemental carbon using the 5040 thermal optical analysis method as it is both accurate and validated. In mines which may have other contributing sources of elemental carbon, such as a mine that has a high graphite content or sampling an area where workers are performing carbon arc gouging, method 5040 using a cyclone or impactor plate as part of the sampling equipment may be necessary to mitigate interference caused by elemental carbon containing dusts.

Additional considerations for determining underground airflow rates

In addition to the requirements set out in Regulation 854 (Mines and Mining Plants), Regulation 833 (Control of Exposure to Biological or Chemical Agents) requires that every employer shall take all measures reasonably necessary in the circumstances to protect workers from exposure to a hazardous biological or chemical agent because of the storage, handling, processing or use of such agent in the workplace.

There may be situations where airflow rates based solely on diesel-powered equipment may not be sufficient for managing other airborne hazards in the workplace, such as silica, blasting contaminants, or heat. The management of airborne hazards is required as part of a comprehensive airborne hazard management program including diesel exhaust under section 182 of Reg. 854.

Consultation with the committee or representative

Where the OHSA or its regulations require that an action be taken in consultation with another party, including but not limited to the JHSC or HSR, the Ministry expects that the employer will engage in a meaningful interaction (including dialogue, discussion and providing all relevant information) with the JHSC or HSR.

There should be a genuine opportunity for the JHSC or HSR to provide input, and that input should be received and considered in good faith. This includes taking into account any feedback and responses from the JHSC or HSR before taking action (such as, implementing a plan, program, etc.) and responding to any recommendation arising out of the consultation.

Consultation is not simply informing the JHSC or the HSR that the employer intends to take action.