11. Maintenance & Repair

Chapter Description

This chapter provides the Wells Regulation’s maintenance requirements and recommended measures to prevent the entry of surface water and other foreign materials from entering a well and a well owner’s responsibility to meet these requirements. The chapter also provides the requirements for well owners and persons who work at the construction (or alteration) of existing wells.

To assist well owners in meeting their obligations, the chapter presents preventative maintenance programs. Common well water quality and quantity problems and well structure issues with possible rehabilitation solutions are presented for both well owners and persons who work at the construction of wells. The chapter also provides suggestions on who should assess and rectify well problems, recognizing each well and its environment are unique, and the complications involved in well rehabilitation techniques.

Regulatory Requirements - Maintenance

Relevant Sections - The Wells Regulation

- Maintenance – Section 20

- Abandonment – Section 21, sub-sections 21(3), 21(4), 21(5), 21(6), 21(7) and 21(9)

- Protection of Well Tag – Sections 14.11 and 22

The Requirements - Plainly Stated

The Wells Regulation requires the following:

Well Maintenance

The well owner must maintain the well at all times after the completion of the well’s structural stage in a way that prevents surface water and other foreign materials from entering the well.

Maintaining Casing Height Above the Ground Surface

For a well having a casing height that extends not less than 40 cm (16 inches) above the ground surface, a person must not reduce the height to less than 40 cm (16 inches) above the ground surface.

For an existing well having the top of the casing extending above the ground surface by less than 40 cm (16 inches), a person must not reduce the original casing height.

Exemption - Maintaining Casing Height for Driven Point or Jetted Point New Wells

An exemption to the minimum casing height requirement above the ground surface exists if the well is made by the use of a jetted point or driven point and it has a visible, permanent marker.

To qualify for this exemption:

- the casing must extend a sufficient height to permit the attachment of a well tag,

- the casing must be at least as high as the highest point on the ground surface within a 3 m (10ft) radius of the well’s casing after the ground surface is properly mounded with earth to direct surface drainage away from the well as measured on completion of the well’s structural stage, and

- the permanent marker must identify the location of the well and be visible at all times of the year.

Well Abandonment

The well owner must immediately abandon the well if the well is not being used or maintained for future use as a well.

The well owner must immediately abandon the well if the required measures or steps are not taken to address the following issues:

- the well produces mineralized water,

- the well produces water that is not potable,

- the well contains natural gas or other gas, or

- the well permits any movement of natural gas, contaminants or other materials between subsurface formations or between any subsurface formation and the ground surface, and the movement may impair the quality of any waters.

The well owner must immediately abandon the well if the well is constructed in contravention of the Wells Regulation requirements and the steps taken by the well owner to rectify the situation fail.

The person abandoning a well may seek the Director’s written exemption from the requirement to abandon the well in some circumstances.

Reminder: For further information see Chapter 14: Abandonment: When to Plug & Seal Wells.

Well Tags

A person must not remove a well tag from a well unless:

- the well is being altered,

- the well is being abandoned, or

- the Director has given written consent for well tag removal.

If a well tag is removed during an alteration, the well tag must be safeguarded and re-affixed after the alteration has been completed.

No person shall deface, alter, conceal or obstruct an affixed well tag.

Any damaged well tags must be returned to the Ministry and be replaced.

Reminder: See Chapter 13: Well Records, Documentation, Reporting & Tagging for further information.

Reminder: See the “Well Repair Requirements for Persons Constructing Wells” section of this chapter for information on the requirements that apply for an “alteration” (including a repair) to a well.

Reminder: The requirements listed in this chapter do not apply to the exempted activities discussed in Chapter 3: Well Contractors & Well Technicians – Licences, Responsibilities & Exemptions. However, any construction activity on a well must not cause or have the potential to cause impairment to the water in the well or the groundwater as required under Subsection 30(1) of the Ontario Water Resources Act.

Relevant Sections - Additional Regulations Or Lesgislation

Electricity Act, 1998. S.O. 1998. Chapter 15, Schedule A; Ontario Regulations 164/99: Electrical Safety Code

Occupational Health and Safety Act, R.S.O. 1990, Chapter 0.1; Ontario Regulation 632/05: Confined Spaces

Safe Water Drinking Act, 2002. S.O. 2002, Chapter 32; Ontario Regulation 169/03: Ontario Drinking Water Quality Standards.

Relevant Guidance Documents

Fleming College. 2008. Manual for Continuing Education Course: Safety (for Ontario Well Technicians).

Key Concepts

Wells, like any equipment or structure, have a limited lifespan. They need preventative maintenance to keep supplying enough safe and reliable water for their users.

The Wells Regulation requires that the well owner must maintain the well at all times after the completion of the well’s structural stage (i.e., once it is capable of being used for the purpose for which it was constructed) in a way that prevents the entry of surface water and other foreign materials into the well.

Proper maintenance, including water quality and quantity testing, is a way of ensuring that the well is kept in good working order and may minimize the need for rehabilitation. Proper well maintenance protects the aquifer and the water supply.

Improper Maintenance

A poorly maintained or constructed well can result in the bacterial or chemical contamination of the well water, the aquifer or the natural environment. One of the most common causes of contamination is foreign materials and surface water in the immediate vicinity of a well having direct access into the well. For example, surface water and other foreign material contamination can occur if the annular seal around the outside of the casing is not watertight, if there are openings in the casing or well cover, or if casing joints are not made waterproof.

Once problems are encountered with a well, it may be possible to rehabilitate it; however, this is not always the case. Well owners should be aware that there are many instances when improper maintenance, no usage, an elevated substance identified in a water quality test or natural gas may require a well to be abandoned in accordance with the Wells Regulation.

Reminder: See Chapter 14: Abandonment: When to Plug & Seal Wells and Chapter 15: Abandonment: How to Plug & Seal Wells.

The Maintenance Program

The maintenance program is a plan or protocol that should be in place for any site with a well. The maintenance program is intended to identify issues and potential problems and rectify these as soon as possible.

Well Repair Requirements For Persons Constructing Wells

In cases where issues or problems are identified with a well, it will be necessary to rectify the issues by repairing (e.g., altering, developing) the well to ensure that it does not act as a pathway for contamination, and that it remains suitable for its purpose (e.g., drinking water supply).

There are minimum requirements and exemptions under the Wells Regulation that apply for repairing or altering wells. See the later “Well Repair Requirements for Persons Constructing Wells” section of this chapter for further information.

Safety Considerations When Maintaining Wells

There are risks associated with well construction and maintenance activities including explosive gases and electrocution. Since most well owners are not familiar with these potential hazards, licensed well technicians, knowledgeable about these hazards, should always be hired to work on the well.

Photographs Of Improper Well Maintenance

The Wells Regulation states that the well owner must maintain the well at all times after the completion of the well’s structural stage (i.e., once it is capable of being used for the purpose for which it was constructed) in a way that prevents the entry of surface water and other foreign materials into the well.

The photographs in Figures 11-1 to 11-11 provide examples of wells not being properly maintained. In these cases, it is the well owner’s legal obligation to either rectify the problem or abandon the well.

Figure 11-1: Dug Well Without Sealed Access And Improper Mounding

Figure 11-1 shows an open access lid on a dug well cover. The open lid is allowing slugs to enter the well (see Figure 11-2). The ground is not sloped away from the well to prevent ponding around the well. Even if the access lid was properly closed, surface water potentially containing pathogens and other foreign materials can still migrate through the unsealed opening (crack) between the access lid and cover and impair the well water.

Figure 11-2: Slugs Entering An Improperly Sealed Dug Well

This is the inside view of same well shown in Figure 11-1. Slugs have entered through the large opening in the well access lid and are living just below a joint between two concrete casings and just above the water level in this well. The well water is intended to be used for human consumption. The slugs are also leaving waste behind on the casing wall.

Figure 11-3: Water Seeping Through The Unsealed Joints Between Concrete Casings

Figure 11-3 shows the inside view of a well. Water is seeping through the unsealed joints between concrete well casings. The water is leaving marks on the concrete tiles as it moves. The unsealed joints are allowing surface water and other foreign materials, potentially containing potential pathogens, to enter the well and impair the quality of the well water. At the bottom of the photograph, the top of the water level is observed. There is debris and other foreign material floating on top of the water that may impair the quality of the well water.

Figure 11-4: Dug Well Casing With Small Hole

The centre of Figure 11-4 shows a 2 centimetre diameter hole that penetrates through the well casing of a dug well used for human consumption. The hole is located close to the ground surface. The ground surface is not properly sloped and can allow for ponding of surface water adjacent to the well. The hole provides a pathway for surface water and foreign materials such as insects, rodents and snakes to access the well and impair the quality of the well water.

Figure 11-5: Well With Water Ponding

Figure 11-5 shows ponded water that potentially contains pathogens located immediately beside the well. Ponded water can migrate downward through soil pores and bedrock fractures and along the side of the well casing by gravity. The ponded water can enter and impair the quality of the well water. Figure 11-5 also shows an older style non-vermin-proof well cap removed from the well and placed in the ponded water. Any pump equipment installation, repair work or other alterations would require this well cap to be replaced with a vermin-proof well cap.

Figure 11-6: Drilled Well Casing With Hole In Cap

Figure 11-6 shows a 3 cm, square hole in a well cap on top of a drilled well casing. A waterline extends out of the open hole. The open hole in the cap provides a pathway for surface water and foreign materials such as insects, rodents and snakes to access the well and impair the well water.

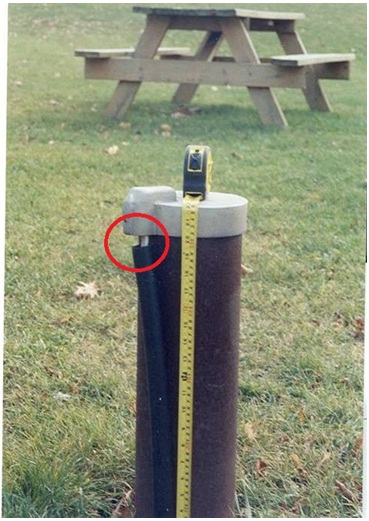

Figure 11-7: Drilled Well With Opening Between Well Cap And Conduit

Figure 11-7 shows a drilled well with a tape measure on top of a well cap. An open hole exists between the well cap and the white electrical wires and black conduit (on left side of well casing). It is likely that the top of the black conduit has slid down from the well cap over time to create the opening at the well cap. The opening (circled) provides a pathway for foreign materials such as insects, rodent and snakes to access the well and contaminate the well water.

Figure 11-8: Poorly Sited Well That Has Not Been Maintained

In this figure, there is a pond in the foreground. A black coloured goat is sitting on top of a well cover in the centre of the photograph. The well cover is not secured to the well casing and is not watertight. The well cover is bending downward likely due to the weight of animals lying and standing on the well cover. The well cover creates a safety hazard for the animals. Animal waste from the goats sitting on the well cover can also migrate through the well cover and impair the quality of the well water.

Figure 11-9: The Inside Of A Dug Well With A Tree Root Penetrating The Concrete Casing

The dug well in this figure is used for human consumption. The dug well has concrete tile as casing. Below the water level, a tree root is extending from the right side of the photograph. The tree root has penetrated the casing joint (not shown). The tree root is an indicator that the well casing is not sealed. Thus, the unsealed concrete tile joints can permit foreign materials into the well that can impair the quality of the well water.

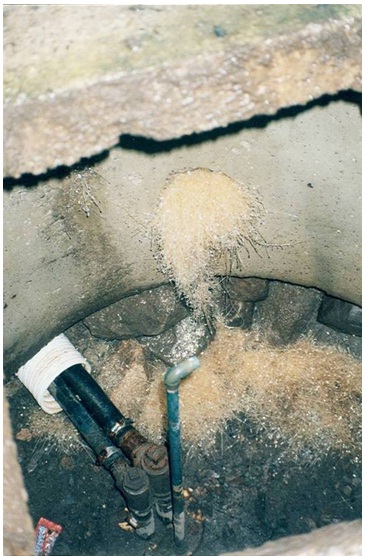

Figure 11-10: A Poorly Maintained Well Pit

Figure 11-10 was taken looking into a well pit. The concrete tile of the well pit is shown in the centre and upper portion of the photograph. The floor of the well pit consists of gravel and broken limestone bedrock. The sanitary seal of the top of the drilled well is located flush with the floor of the well pit. Two waterlines and an air vent extend out of the drilled well’s sanitary seal. There is an open hole in the well pit’s concrete tile. A white to tan coloured fungus (foreign material) has been allowed to grow in the pit from the concrete hole and onto the floor. The fungus is also an indicator that surface water can enter the pit. If surface water fills up in the well pit, it could migrate through the air vent and into the well. Fungus and other foreign materials can potentially migrate from the pit into this drilled well that is used for human consumption.

Figure 11-11: Unsealed Concrete Joints And Animal Tied To Well

The centre of Figure 11-11 shows the concrete tiles and lid of a dug well. The joint between the first and second concrete tiles is broken and not sealed. The unsealed joint creates a pathway for foreign materials to enter the well. Also a dog, tied to the top of the well cover, is shown on the right side of the photograph near a tree. There is a potential for animal waste to be discharged near or on the well. Animal waste can migrate to and impair the well water used for human consumption.

General Maintenance For Well Owners

Proper maintenance by the well owner requires ongoing observation of the state of the well, the pumping and other equipment associated with the well and the surrounding area. The owner of the land is responsible for the maintenance of every well located on the owner’s property. A well maintenance checklist and some solutions are found in Table 11-1.

Download Table 11-1: Well Maintenance Checklist Items

Reminder: Where existing well pits are in use, they should be regularly inspected and must be properly maintained just like a well. Well pits are prone to collect surface water and other foreign materials. Any surface water or foreign materials that collect in a well pit can potentially access the well through the top of the well. If surface water or other foreign materials are entering a well pit, the well including the well pit must either be properly plugged and sealed or upgraded to prevent the surface water and foreign materials from entering the well.

Reminder: Well owners should review the safety considerations at the end of this chapter when conducting assessments of their wells.

Testing The Water

Groundwater quality in Ontario is generally quite good. However, as part of protecting a drinking water supply, it is important to know the well’s water quality and to monitor its changes.

Bacterial Testing

Routine water quality testing is an important aspect of well maintenance for a well owner. A well owner should submit a water sample at least three times each year, or more frequently if a problem is suspected, to:

- the Public Health Unit,

- an Ontario Public Health laboratory (in a bottle supplied by the Ontario Agency for Health Protection and Promotion), or

- a private licensed laboratory for indicator bacteria (total coliform and E. coli) testing.

The bacterial quality of water cannot always be determined from a single sample. To establish bacterial drinking water quality, the well owner should submit 3 samples at least one week apart. Even if the well shows acceptable total coliform and E. coli results, it is recommended that samples be taken and analyzed at least three times a year. One of these samples should be taken in the early spring.

Reminder: See “Sampling and Analyzing Well Water” section, Table 8-9 in Chapter 8: Well Disinfection for information on groups involved in bacterial sampling and testing.

Repeated detection of bacteria in the well water samples means that there is a source of bacteria affecting the well water (e.g., surface water, septic system, manure storage, animal exercise yards or fields where manure is spread). In cases of repeated detection of indicator organisms or other contamination, measures should be taken to identify the source and then prevent it from accessing the well. This may include hiring a licensed well technician working for a licensed well contractor, Professional Geoscientist or Professional Engineer to conduct the assessment. If the assessment concludes remediation of the well is required, it is recommended that the well owner retain a licensed well technician. The well technician that is retained, must hold the correct class of licence and work for a licensed well contractor to conduct the recommended rehabilitation of the well. A water treatment specialist may also be consulted to remove the contaminant from the drinking water, however, the problem will not be resolved if water treatment is pursued without identifying and addressing the source of contamination. If water quality interference is suspected, it is important to contact the local Ministry of the Environment and Climate Change district

Reminder: For issues with water that is not potable see Chapter 14: Abandonment: When to Plug & Seal Wells.

Additional Parameter Testing

Water should be tested regularly for additional parameters (e.g., chemical). A well owner should:

- test the water in the well for nitrate annually and other metals and minerals at least every two years. Some common chemical parameters include sodium, chloride, conductivity, colour, turbidity, calcium, magnesium, manganese, hardness, alkalinity, pH, ammonia, nitrite, nitrate, phosphorus, fluoride, uranium, lead, antimony, arsenic, copper, iron, zinc and sulphate.

- test for some common gases such as hydrogen sulphide, methane and radon.

If there is a reason to suspect that there may be a local problem such as nearby spills (e.g., gasoline station leak), landfills, industrial and mining activities, accidents, or land use changes, a well owner should test the water in the well for pesticides, volatile organic compounds (solvents), petroleum hydrocarbon parameters (benzene, toluene, ethylbenzene, xylenes and petroleum hydrocarbon fractions F1 to F4), heavy metals, and radionuclides.

If there is no cause for concern, a general screening of these additional organic chemicals and metals at least every five years will help verify current water quality.

If problems with well water quality are reported by neighbours, or there are changes in taste or visual quality of the water, test the well water for the above bacterial and chemical parameters.

Local public utilities regularly test well water quality of municipal and other communal well supplies. If nearby municipal or communal supplies uncover elevated parameters in the municipal well water, test the well water for the problem parameter.

Water samples should be submitted to a laboratory licensed under the Safe Drinking Water Act to analyze the well samples for the chemical and radiological parameters. To obtain accurate results, a well owner needs to follow the sampling and preserving procedures provided by the laboratory or retain the services of a Professional Geoscientist or Professional Engineer to conduct the sampling.

If necessary, a well owner should use a Professional Geoscientist or Professional Engineer to interpret the test results.

Table 8-9 of Chapter 8: Well Disinfection provides the various roles of different groups involved in bacterial testing and interpretation. Some of these same groups can also provide assistance with chemical testing and interpretation.

The Technical Support Document for the Ontario Drinking Water Quality Standards, Objectives and Guidelines June 2003, revised June 2006, PIBS 4449e01 (found on the Ontario website) can also assist in the interpretation of the well water quality.

The Public Health Ontario’s website also has information on water quality testing for well owners.

Assessing The Interior Of The Well With Video Technology Equipement

The lack of light and significant depth in many drilled and bored wells may result in unknown problems with the well’s structure, pumping equipment, water quantity or water quality because they are hidden from view. To assist in the visual interpretation of the well, video cameras and other equipment can be installed into the interior of a well and linked to video terminals at the surface.

Down-hole video equipment can help assess:

- the well’s interior structure including the casing, casing joints and well screen,

- the pump and associated pumping equipment,

- water levels, water producing zones and depth,

- turbidity, colour and sediment problems, and

- biofilm and mineral encrustation problems.

Best Management Practice – Use Down-hole Video Equipment in Assessment of Well Problem

As part of a well assessment for a well problem, well owners, or their consultants, should consider retaining the services of businesses that have down-hole video equipment and who employ persons who have proper experience in installing the equipment and interpreting the video. In some cases, pumping equipment needs to be installed in the well with the video camera to lower the well’s water level to inspect the well.

The video should be recorded by the person conducting the inspection and the video should be kept by the well owner for future reference and repairs.

Persons and businesses conducting this work must meet the licensing requirements in Chapter 3: Well Contractors & Well Technicians – Licences, Responsibilities & Exemptions to determine if they are required to be licensed for this activity.

Well Repair Requirements For Persons Constructing Wells

Requirements For Repairs And Alterations On Existing Wells

Unless exempt, if a person performs a repair on an existing well and during the course of the repair, the person performs any type of well construction activity, then the person must:

- meet the requirements for existing wells found in the Wells Regulation, and

- hold a valid well technician licence of the correct class and hold, or work for someone that holds, a valid well contractor licence.

- Construct

- when used with respect to a well, means bore, dig, drill or otherwise make, extend or alter. “Construct” also includes installing equipment in or connected to a well (see Chapter 2: Definitions & Clarifications, Table 2-1).

Requirements for the construction of new wells are found in sections 12 (location of wells), 12.4 (well depth), 13 (casing), 14, 14.1 to 14.5 (annular space), 14.8 (development) and 14.11 (tags) of the Wells Regulation. Except for well tagging (see Chapter 13: Well Records, Documentation, Reporting & Tagging), these requirements will typically not apply to persons repairing or altering existing wells. For example, new well construction requirements do not apply when a person constructing a well:

- Conducts a minor alteration on an existing well (see “Minor Alteration” in Chapter 2: Definitions & Clarifications, Table 2-1 and “Routine Repair” in Chapter 2: Definitions & Clarifications, Table 2-2)

- Replaces a pump or associated pumping equipment such as a pitless adapter or pitless unit into an existing well

- Extends a well casing above the ground surface

- Installs a new length of casing (commonly called a casing sleeve or liner) inside the well

- Removes a portion or section of well casing from the well.

Reminder: A well is considered to be a “new well” at the time when the initial hole (well) is constructed. See the definition of “new well” in Chapter 2: Definitions & Clarifications, Table 2-2.

Reminder: Equipment used in the re-development of an existing well, such as hydraulic fracturing, and other equipment installed in an existing well for rehabilitation purposes is not considered to be a routine repair. As such, this activity is an “alteration” to a well that is not a “minor alteration”. This includes situations where the equipment is installed permanently or temporarily into a well.

Reminder: If an existing well is being altered (other than a minor alteration or pump and equipment installation) some regulatory requirements do apply. For example, the person constructing the well must complete a well record for the alteration (see Chapter 15: Well Records, Documentation, Reporting & Tagging).

Reminder: If an existing well without a well tag is being altered (other than a minor alteration) some tagging requirements apply (see Chapter 15: Well Records, Documentation, Reporting & Tagging). If an existing well with a broken, defaced, illegible, or otherwise unusable well tag is being altered (including a minor alteration) some tagging requirements apply (see Chapter 15: Well Records, Documentation, Reporting & Tagging).

Reminder: If an assessment determines that a repair or upgrade (alteration) of the well is required, it is recommended that the well owner retain a licensed well technician. The well technician that is retained must hold the correct class of licence and work for a licensed well contractor to conduct the recommended repair or upgrade of the well.

Some registered professionals (e.g., P. Eng, P. Geo, C.E.T.) working for licensed well contractors are exempt from the well technician licensing requirements for certain specified well construction activities (see Chapter 3: Well Contractors & Well Technicians – Licenses, Responsibilities & Exemptions).

Although the Ontario Water Resources Act allows a residential well owner to repair or upgrade (alter) his/her own well without a licence, if remuneration takes place (i.e., any form of compensation), or if the land owner is a business corporation, partnership, sole proprietor or a government agency, the land owner must retain a licensed well contractor and employ licensed well technicians of the correct class to alter or repair the well.

Reminder: To determine which prescribed well technician licence class applies to the type of work being performed on an existing well see Chapter 3: Well Contractors & Well Technicians – Licences, Responsibilities & Exemptions.

Alterations Not Considered Minor Alterations

Unless exempt, the person performing an alteration to a well must meet, as a minimum, the maintaining field notes (section 12.1), covering the well (section 12.2), surface drainage (section 12.3), flowing well (section 14.7), well yield (sections 14.9 and 14.10), well tagging (section 14.11), venting (section 15.1), equipment connections (section 15.2), caps and covers (section 15.2), clean equipment (section 15.3), natural gas and mineralized water reporting (section 16), providing the well purchaser with information (section 16.1), well record (section 16.3) and casing height maintenance [subsection 20(2)] requirements found in the Wells Regulation.

Minor Alterations

There are some requirements in the Wells Regulation that will apply also to a “minor alteration” such as removing a well cap. Unless exempt, the person performing a “minor alteration” to a well must meet, as a minimum, the maintaining field notes (section 12.1), covering the well (section 12.2), surface drainage (section 12.3), flowing well (section 14.7), well tagging for broken or defaced well tags (section 14.11), venting (section 15.1), equipment connections (section 15.2), caps and covers (section 15.2), clean equipment (section 15.3), natural gas and mineralized water reporting (section 16), and casing height maintenance [subsection 20(2)] requirements found in the Wells Regulation.

Reminder: If a person performs a “minor alteration” on a well, unless exempt, the licensing requirements apply (see Chapter 3: Well Contractors & Well Technicians – Licenses, Responsibilities & Exemptions).

Extension Of Well Casing For A Well In A Well Pit

If an alteration involves the extension of a well casing above the ground surface for a well in a well pit, the well owner will need to decide if the well pit is to be maintained or abandoned. The person constructing the well and the well owner should also consider following the “Best Management Practice – Well Casing Extensions” for determining the appropriate height for the well casing above the ground surface.

If the well pit is to be maintained, then the person constructing (altering) the well must ensure surface drainage is such that water will not collect or pond in the vicinity of the well, including in the well pit. If the well pit cannot be maintained such that surface water and other foreign materials are prevented from entering the well, then the well pit must be abandoned.

If the well pit is to be abandoned, the person abandoning the well (often the well owner) must ensure the well pit is abandoned, with necessary modifications, as if it were a well. See Chapter 15: Abandonment: How to Plug & Seal a Well for further information.

Best Management Practice – Consider Abandoning Well Pits at the Time of Well Casing Extension

Where a well pit is present, a well owner should consider abandoning the well pit if the well casing is extended above the ground surface. If abandoned, the well pit must be abandoned in accordance with the Wells Regulation requirements that are presented in Chapter 15: Abandonment: How to Plug & Seal a Well. Properly abandoning the well pit will reduce well maintenance issues and reduce the risk of surface water and foreign materials entering the well.

Reminder: To determine which prescribed well technician licence class applies to the types of work being performed on an existing well see Chapter 3: Well Contractors & Well Technicians – Licenses, Responsibilities & Exemptions.

Installing Used Equipment During Well Repair

The Wells Regulation allows for the installation of used pumps, pumping equipment, vents, cover, caps, pitless adapters, pitless units and other equipment in wells.

The Wells Regulation - All new or used equipment installed in, or connected to, a well must be clean and must not impair the quality of the well water or aquifer. Well owners must maintain installed equipment to ensure it does not impair the quality of the well water.

Best Management Practice – Ensuring Equipment is New and Chlorinated

In addition to the requirement that equipment be clean and free of contamination, anyone working on an existing well should:

- install new parts, devices and materials in drinking water wells that are certified to meet the National Sanitation Foundation (NSF) International Standard 61 “Drinking Water System Components - Health Effects”. Verify the components are certified by searching NSF/ANSI Standard 61

footnote 1 Approved Drinking Water System Components database and by looking for the NSF logo on the equipment, - install parts, devices and materials that are suitable for the particular type of environment and well,

- clean and sanitize the parts, devices, materials and well construction equipment with chlorinated water as recommended in the “Sanitary Practices” section in Chapter 8: Well Disinfection, and

- ensure parts are installed to the manufacturers' specifications,

Casing Height When Preforming Work On Or Near A Well

The Wells Regulation - Persons, including well owners, should be aware of the following Wells Regulation requirements when performing any routine well maintenance, repair or alteration, or when performing other work such as landscaping around a well:

- Where a casing height extends ≥40 cm (16 inches) above the ground surface, the top of the casing must not be reduced to a height of < 40 cm (16 inches) above the ground surface.

- Where the well is an existing well and the casing height extends < 40 cm (16 inches) above the ground surface, the top of the casing must not be reduced to a height of less than the original casing height.

Reminder: The casing heights above do not apply to wells constructed by the use of a driven point or jetted point wells as long as they meet the minimum requirements of the Wells Regulation. For further information see the section titled: “Casing Height and Mounding,” of Chapter 7: Completing the Well’s Structure.

Reminder: To determine which prescribed well technician licence class applies to raising the well casing height on an existing well see Chapter 3: Well Contractors & Well Technicians – Licenses, Responsibilities & Exemptions.

Best Management Practice – Well Casing Extensions

A person extending a well casing above the ground surface in an existing well should:

- consider the methods, materials and installation techniques outlined in the Best Management Practice titled “Ensuring Equipment is New and Chlorinated” on page 24 of this chapter,

- meet or exceed the new well requirements for the height of the well casing and annular space in the Wells Regulation,

- extend the top of the casing above the known height of any anticipated flood level, and

- consider the final grade of the ground surface around the well to direct surface water runoff away from the well.

Safeguarding The Well Tag

The Wells Regulation - It is not permitted to deface, alter, conceal or obstruct a well tag.

The Wells Regulation - It is not permitted to remove a well tag that is affixed to a well unless the:

- person has the written consent from the Director;

- well tag on the well that is being altered is broken, defaced, illegible or otherwise unusable; or

- well is being altered or abandoned (plugged and sealed).

The Wells Regulation - It is not permitted to use a well tag issued by the Ministry except in accordance with the Wells Regulation.

The Wells Regulation - During alterations to a cased well with a well tag, the well tag must be safeguarded and, if removed, it must be re-affixed permanently to the outside of the casing or to a permanent structure associated with the well, upon completion of the alteration.

Reminder: Any damaged well tags must be returned to the Ministry and be replaced. See Chapter 13: Well Records, Documentation, Reporting & Tagging for further information.

Well Problems And Rehabilitation

Any damaged well tags must be returned to the Ministry and be replaced. See Chapter 13: Well Records, Documentation, Reporting & Tagging for further information.

Reminder: Table 11-2, below, contains only some examples of common causes of well problems and rehabilitation techniques and may not apply to all wells. As each well and environment is different, a Professional Engineer or a Professional Geoscientist should assess the well and well water to identify the source of the problem and provide recommendations on a case by case basis. In some cases, a licensed well technician with the correct class of licence working for a licensed well contractor can conduct the assessment of the well. If the assessment concludes remediation of the well is required, it is recommended that the well owner retain a licensed well technician. The well technician that is retained must hold the correct class of licence and work for a licensed well contractor to conduct the recommended rehabilitation of the well. It is important to retain properly licensed persons where electrical or plumbing work is necessary. Where water treatment is deemed necessary or is advised, it is recommended that a professional water treatment expert install any water treatment devices on the building’s plumbing. It is important that water treatment devices are maintained in accordance with manufacturers’ specifications to ensure effective operation.

| Problem | Potential Cause | Possible Action/Rehabilitation |

|---|---|---|

| Foreign substances in the well (e.g., insects) |

|

|

| Pumping equipment failure |

|

|

| Pumping equipment failure |

|

|

| Pumping equipment failure |

|

|

| Pumping equipment failure |

|

|

| Pumping equipment failure |

|

|

| Drop in the groundwater level or no water (after verifying pump is in working order) |

|

|

| Drop in the groundwater level or no water (after verifying pump is in working order) |

|

|

| Drop in the groundwater level or no water (after verifying pump is in working order) |

|

|

| Reducing flow rates over time |

|

|

| Reducing flow rates over time |

|

|

| Reducing flow rates over time |

|

|

| Bacteria identified in well

Reminder: If the well is producing total coliforms or E. coli with the raw well water, see Chapter 14: Abandonment: When to Plug & Seal Wells and do not drink raw well water |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Bacteria identified in well |

|

|

| Slimy red, black or grey coloured material in water, well or on pumping equipment |

|

|

| Red or black staining on plumbing fixtures and laundry |

|

|

| Scaling on tubs and sinks |

|

|

| Blackish water or blackish flakes associated with well water |

|

|

| Salty taste associated with well water |

|

|

| Salty taste associated with well water |

|

|

| Salty taste associated with well water |

|

|

| Salty taste associated with well water |

|

|

| Laxative effect after drinking water and bad tastes (where bacteria are not present) |

|

|

| Rotten egg odour or corrosion |

|

|

Presence of poisonous or explosive gas as observed by the following:

|

Hydrogen Sulphide

Methane

Other Gases

|

|

| Radon gas has been identified |

|

|

| Gasoline or fuel oil odour, or rainbow film on water |

|

|

| Sampling analysis shows raw well water producing fluoride |

|

|

| Sampling analysis shows raw well water producing elevated uranium, arsenic or other metals exceeding the Ontario Drinking Water Quality Standards |

|

|

| Sampling analysis shows water producing elevated lead |

|

|

| Flood water entering the well |

|

|

Best Management Practice – Well Rehabilitation Literature

In addition to Table 11-2 the following books provide further information on the rehabilitation of wells including biofilm and mineralization problems:

Schnieders, John H. 2003. Cleaning, Disinfection and Decontamination of Water Wells. Johnson Screens Inc., St. Paul, MN, ISBN 0-9726750-0

Mansuy, Neil. 1998. The Sustainable Well Series - Water Well Rehabilitation: A Practical Guide to Understanding Well Problems and Solutions. Layne Geosciences Inc. /CRC Press. ISBN10: 1566703875, ISBN13: 9781566703871

Safety Considerations When Maintaining Wells

There are many serious dangers associated with wells that must be considered when maintaining and rehabilitating well. Important precautionary actions to take include:

- making sure that the power supply to the pump has been shut off to minimize the risk of shock or electrocution when inspecting a well,

- safeguarding the well site any time the well cap or cover is removed to minimize hazards, and

- following all applicable safety plans for the site.

Reminder: A person must not enter any confined space (e.g., non-ventilated areas including well pits, pump house, and others defined in the O. Reg. 632/05 under the Occupational Health and Safety Act) unless properly trained and equipped. Confined spaces present asphyxiation hazards and some wells produce naturally occurring gases that may be poisonous and/or explosive.

When maintaining wells, well owners should be made aware of the many serious risks associated with wells including explosive gases and electrocution. Since most well owners are not familiar with these potential hazards, licensed well technicians, knowledgeable with respect to these hazards, and working for licensed well contractors should always be hired to work on the well. See Chapter 3: Well Contractors & Well Technicians – Licenses, Responsibilities & Exemptions for further information on licensed well contractors and well technicians.

It is important that anyone working on a well:

- obtain and follow the guidelines set out in the Material Safety Data Sheet (MSDS) for any chemical product used in the rehabilitation. The MSDS will include the following:

- properties of the material,

- hazards associated with the material,

- personal protective equipment (PPE) required when using the material,

- contact information, and

- first aid and medical attention information.

- make sure that all rehabilitation products are approved for the intended use and will not impair the quality of the groundwater.

- check product labels to verify product contents, proper use and storage

Reminder: Safety practices and requirements (e.g., Workplace Hazardous Materials Information System training), as regulated and advocated by the Ministry of Labour, must be followed.

Footnotes

- footnote[1] Back to paragraph NSF International Standard/American National Standard 61, 2008. “Water Treatment and Distribution Systems - Health Effects, 27th Edition.” NSF International, Ann Arbor, MI 2008. NSF website.