Dairy housing: compost-bedded pack barns

Learn how to design and build a compost-bedded pack barn for dairy cows. This technical information is for Ontario dairy farmers.

ISSN 1198-712X, Published September 2020

Introduction

Compost-bedded pack (CBP) barns (Figure 1) are a potential alternative to a tie-stall or free-stall livestock housing system. It is a loose housing option similar to a conventional bedded pack barn, except the pack is aerated everyday using cultivation. This factsheet provides general knowledge on CBP barns as a housing option for dairy cows.

CBP barns as a dairy housing option

CBP barns are getting lots of attention because of the many benefits they bring to dairy producers in terms of cow comfort, cow health and longevity. CBP barns have a bigger footprint because they are designed with a larger area per animal compared to free-stall and tie-stall barns. Producers planning a new CBP barn should be aware that there may not be much difference in terms of capital investment because of its larger footprint as compared to other livestock housings.

When planning a CBP barn, consider the following:

Advantages:

- Cows can choose their lying position and move around to express normal behaviour.

- Cows have a more comfortable lying area because of the larger space per animal and a better resting surface (dry and soft) if the pack is well managed.

- The absence of physical barriers such as stall dividers, neck rails and brisket board means a lower risk of injuries.

- The pack can be designed with an open option to convert to a 3-row free-stall barn in the future.

- The organic bedding material means less wear and tear on manure-handling equipment.

Disadvantages:

- CBP barns have a bigger footprint compared to other types of housing facilities, due to the larger space per animal provided.

- Managing the pack properly requires learning a new skill set.

- CBPs could result in udder health problems if composting fails.

- Bedding material supply and costs can be uncertain.

- Because the barn must be designed for both solid and liquid manure, there are potential additional costs for building structure and manure-handling equipment.

Facility design features

Barn orientation

Since composting generates maximum heat and moisture, design CBP barns to allow for good air movement in and around the barn. This helps to maintain a cooler micro-environment in the barn, which is necessary for cow comfort and promotes the elimination of water evaporated from the compost. Consider the following when locating a CBP barn:

- Locate the barn on higher ground for better wind movement.

- Maintain clear space around the barn to maximize natural ventilation. Any upward obstruction (e.g., trees) affects the air flow for a horizontal downwind distance of 10 times the height of the obstruction.

- Position the length of the building perpendicular to the prevailing wind.

- Orient the barn to take advantage of summer winds (north–south orientation is recommended for most areas in Ontario).

- Local wind patterns can vary from place to place. Consider the local wind pattern when selecting the barn site.

Barn layout design

Consider the following when designing a CBP barn:

Layout

Cows in CBP barns are milked either in a parlour or robotically. The cow area resembles a free‑stall barn with a pack replacing the stalls. There is drive‑through feeding, a feed manger, a feed alley next to the manger, then the pack. To maintain flexibility, consider designing the barn so the pack area can be replaced with stalls if transitioning to free-stall. A pack area equivalent to the area for a 3-row free-stall barn works well, giving each cow about 75 cm (30 in.) of manger space (Figure 2).

Base

The base to the pack area can be clay, gravel or concrete. In Ontario, there are barns with a clay base that are operating without any problems. Proper compaction of gravel and clay base is required to minimize the environmental risk due to seepage. More details on regulatory requirements for floors are found in the Ontario Nutrient Management Regulation (O. Reg. 267/03).

Pack area per animal

Design the pack to provide at least 11 m2 (120 ft2) per animal for milking cows. Smaller footage per animal requires more bedding to keep the cows clean and dry. A larger area also improves cow welfare and comfort.

Pack access

Two types of access are used between the pack and the cow-feed alley.

Continuous access allows the cows to move from the cow-feed alley to the pack at any point along the alley (Figure 3). This results in a drier transition area from the cow-feed alley to the pack. Roll-over or spring-loaded arm gates are used to separate the cows from the pack for cultivation or during clean-out. In continuous access, provide at least one walkway at each end for cow and equipment access to the pack area. For larger barns, it is recommended to have walkways located at every 36–48 m (120–160 ft).

Figure 3. CBP barn with continuous access to the feed alley. Limited access design allows cows to move between the cow-feed alley and the pack area through limited gated openings in a 1.2-m (4-ft) high wall that runs around the pack area. Pack areas near access points are relatively wetter due to cow traffic, so extra bedding may be required to keep these areas dry. Locate access points every 18–24 m (60–80 ft) and at each end (Figure 4).

Figure 4. CBP barn with limited access to cow-feed alley.

Many barns in Ontario are designed with continuous access. Continuous access has an advantage over limited access design in terms of cow movement and pack management.

The Code of Practice for the Care and Handling of Dairy Cattle, 2009 (Code), requires producers to ensure daily access to feed and water of adequate quality and quantity to fulfil the nutritional and physiological needs of cattle. Barns are designed with feed areas inside the barn or outside the barn under a separate roof. A feeding area inside the barn is preferred to encourage more feed intake. Provide a minimum of 76 cm (30 in.) of feed bunk space per cow. Provide at least two waterers at two different locations per pen. Waterers should be accessible only from the alley side to keep the pack dry. They should be protected by a wall or piping to avoid access from areas other than the cow-feed alley (Figure 5).

Concrete alleys

Typically, CBP barns are designed with two types of concrete alleys: a cow-feed alley and a feed alley.

- Cow-feed alleys: The cow-feed alley is the alley between the pack and the feed manger. Even though some barns are 3.6 m (12 ft) wide, the recommended minimum width for a cow-feed alley is 4.3 m (14 ft). Wide alleys allow extra space for better cow movement and provide room to incorporate future developments in manure handling that may be available due to technological advancement.

- Feed alley: The drive-through feed alley must be wide enough to accommodate the drive-through feed equipment. It should be at least 6 m (20 ft) wide to prevent equipment from driving on feed and should be 6.7 m (22 ft) if the TMR mixer is parked in the drive-through. The drive-through doors should be big enough for the equipment to pass through comfortably and avoid damage. Protect the doors on the outside with bollards (i.e., vertical pipe filled with concrete). Robotic or automated feeding systems are becoming more popular and may lead to improved labour efficiency and better feed management practices. Using an automated feeding system such as belt feeders or rail feeders normally reduces the alley width to 2.4–3 m (8–10 ft), depending upon the type of system in place.

Ventilation

Good ventilation is critical in compost-bedded pack barns because of the tremendous amount of heat and moisture generated from the pack during composting. Ventilation improves air movement in the barn, which is essential to maintain pack temperature and humidity levels in the barn. Most CBP barns have adopted a natural ventilation system designed similar to that used in free-stall barns. However, natural ventilation alone may not be able to keep the barn cool during hot weather. Supplemental ventilation (e.g., fans) will be required in such conditions. Good air movement is also necessary to reduce heat stress in livestock.

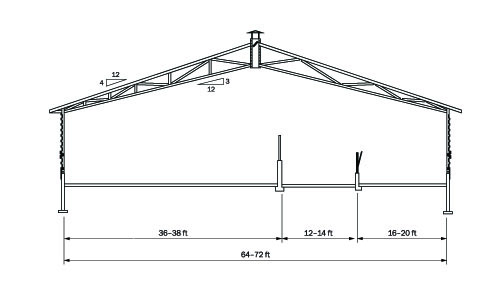

Sidewall openings in CBP barns should be slightly larger than in free-stall barns — at least 4.5 m (14 ft). For barns wider than 12 m (40 ft), the recommended opening height is 5 m (16 ft). Ridge exhaust is critical for ventilating a barn during winter. The University of Kentucky, College of Agriculture, recommends a minimum 1.2 cm (3 in.) of opening for every 3 m (10 ft) of building roof width for continuous ridge ventilation. For barns less than 12 m (40 ft) wide, the minimum opening is 30 cm (12 in.).

Different types of fans are used to supplement natural ventilation. The most common fans are either panel/basket fans or high-volume low-speed (HVLS) fans (Figure 6).

Position fans to cover the entire resting area (i.e., pack area) to avoid cows congregating at certain spots. It is important that cows cover the entire pack so that manure is distributed evenly.

For more information on ventilation systems, see the OMAFRA fact sheet Dairy housing — ventilation options for free-stall barns.

Pack management

Proper composting in CBP barns depends on a balanced supply of oxygen, carbon and nitrogen under optimum moisture condition. Oxygen is supplied by working or turning the pack (aeration), and carbon and nitrogen (nutrients) are added through bedding materials. Good pack management involves proper selection of bedding material, a continuous supply of oxygen and regular monitoring of the pack temperature and moisture levels. Studies show that bedding materials with high carbon content and a low moisture level yield better results in the composting process. Hence, selecting the right bedding material is critical in CBP barns.

Bedding materials

The success of composting in CBP barns depends on the quality and quantity of bedding materials used. Bedding materials that are rich in carbon, provide a large ratio of surface area to volume, are easy to till and absorb, and hold liquids result in better composted manure. Wood-based materials (e.g., sawdust, wood shavings and woodchips) are rich in carbon and are commonly used bedding materials for manure composting. Carbon is an essential source of energy, and nitrogen is a crucial component (containing proteins, acids and different enzymes) required for bacteria cell growth and function.

A good ratio of carbon to nitrogen (C:N) is essential for proper composting (based on the results from various research projects). It is one of the reasons wood-based materials, particularly dry sawdust (hard or soft wood) is the most commonly used bedding material in CBP barns. The high C:N ratio and fine particle size contributes to better composting. Table 1 shows the C:N ratio of some of the most commonly used bedding materials in CBP barns. Avoid using bedding materials that have a high moisture content.

In Ontario, most dairy producers use sawdust supplied from different sources. Some producers add chopped dry wallpaper to the sawdust to increase the absorbency and aid in the composting process. Others use straw, wood chips and shavings as well. Additional materials, such as soybean straw, corn cobs and corn stalks have also been tried, but sawdust has shown better results in maintaining optimum temperature and moisture and keeping the pack dry.

| Material | C:N ratio (weight to weight) | Moisture content % (wet weight) |

|---|---|---|

| sawdust | 200–750 | 19–65 |

| corn cobs | 56–123 | 9–18 |

| corn stalks | 60–73 | 12 |

| dairy manure (typical) | 13 | 83 |

| straw — general | 48–150 | 4–27 |

| straw — oat | 48–98 | n/a |

| straw — wheat | 100–150 | n/a |

| wood chips/ shavings (hardwood) | 451–819 | n/a |

| wood chips/ shavings (softwood) | 212–1,313 | n/a |

Source: Part 637 Environmental Engineering National Engineering Handbook, USDA

The properties of bedding materials may vary depending upon the source of the material. It is a good practice to analyze the material when starting a new source or considering switching between sources, as differences in the C:N ratio and moisture content can have costly effects on compost performance. No matter what material is used, the bedding materials must be low in moisture content (preferably not exceeding 18%) and finely chopped to provide enough surface area for bacteria to multiply.

Composting basics in CBP barns

Composting is a biological process during which microbial breakdown of organic matter takes place. A huge amount of heat and moisture is generated during the process. In CBP barns, since the pack is the resting area for cows, it is important to maintain a comfortable temperature and dry pack for them to lay down on.

Proper composting takes place when there is an appropriate balance between oxygen, temperature, moisture and the amount of organic matter. Table 2 shows the recommended range that producers should target, to ensure proper composting.

| Parameters | Operating range |

|---|---|

| C:N ratio | 25:1–30:1 |

| temperature | 43°C–55°C (measured at 15 cm (5 in.) deep) |

| moisture content | 40%–60% |

A 2020 study of temperatures in Ontario CBP barns found ranges of 33°C–52°C. The pack’s temperature provides a good indication of level of microbial activity. Lower temperatures indicate that composting is slow, often because of inadequate oxygen, too high moisture content or high heat loss during the winter.

When moisture levels are too low, the microbes don’t have enough water, and the pack temperature will be too cool. This will slow down the composting process. If the moisture level is too high, the pack becomes anaerobic. This will also slow down the composting process, resulting in less heat generation (low pack temperature).

Starting the pack

Starting a new pack can be challenging. Consider starting a new pack only when the weather is expected to be warm (temperatures above 10°C) for the next 4–6 weeks. Steps for starting a new pack include:

- Apply between 30–45 cm (12–18 in.) of bedding material. The ideal depth is 45 cm (18 in.) or more so that the stirring equipment will not touch the barn floor.

- Sawdust, low in moisture content (less than 18%), is the preferred bedding material to start the pack. If using other material such as straw or wood shavings, make sure it is dry and finely chopped.

- Start stirring the pack twice a day after 24 hr of cows being on the pack.

- Start monitoring the pack temperature 15–30 cm (6–12 in.) below the surface using a long thermometer. The temperature should start rising after 24 hr. In Ontario, pack temperature ranges between 33°C–52°C in packs that are composting well. Monitor the temperature until the temperature starts falling.

- Add a first round of 10–15 cm (4–6 in.) of fresh bedding when the temperature starts falling, before the pack becomes too moist for cows to lie down on or before the manure starts sticking to the cows, whichever happens first. Decreasing temperature is an indicator of more carbon (bedding) required. Typical bedding change frequency in Ontario is once every week or twice every 3 weeks during cold weather conditions.

Monitoring the pack

Monitor a new pack frequently for temperature and moisture until you are sure the pack is composting well.

- Monitor the pack temperature and moisture level regularly.

- Conduct a visual assessment of the pack more frequently to check on temperature and wetness of the pack.

- Measure pack temperature using a long needle thermometer or cooking thermometer.

- Pack moisture content can also be measured by laboratory analysis of a compost sample.

- Do a simple moisture check by squeezing a handful of bedding (compost). If water can be squeezed out or water droplets drip or appear on the surface of the squeezed bedding, the pack is too wet. This is a sign that fresh bedding material should be added.

- If a ball of compost can’t be formed, the pack is too dry. A perfect bedding will be fluffy and dry.

Cleaning the pack

Compost pack barns are usually cleaned every year. Choose warmer days to clean the pack. Leave 15–20 cm (6–8 in.) of compost in the barn to accelerate the process of composting the fresh lot. The compost left in the barn should preferably be the top cultivated layer of the pack that is fluffy and dry.

Aerating the pack

Composting in-barn is an aerobic process. A constant supply of oxygen (aeration) is required to maintain a good population of bacteria, which is key to keeping the composting process going. A healthy population of bacteria is necessary to maintain an optimum temperature in the pack.

Aeration is done by stirring the pack. The frequency and depth of stirring makes a difference in how much oxygen is supplied to micro-organisms, which in turn impacts the pack temperature. Stir the pack twice a day, using a cultivator, rototiller and/or chisel plow (Figure 7), to maintain a continuous supply of oxygen.

A 2013 study carried out in the U.S. (Black, et al.) showed that increasing stirring frequency increased pack temperature from 30C (with one-time stirring) to 40°C (with two-times stirring every day). In the same study, pack temperature increased as stirring depth was increased from 15–40 cm. In Ontario, it is recommended to maintain the stirring depth between 22–30 cm and not exceed 40 cm.

In a parlour barn, stir the pack when the cows are being milked. In a robotic milking barn, stir the pack when fresh feed is added. Cows get used to the cultivation practice, and most will move out of the way when they hear the tractor.

A 2018 study by OMAFRA in a limited number of CBP barns in Ontario showed use of a manure spreader as a popular way of bedding the pack, typically taking 5 minutes to load and 10 minutes to add to the pack. The length of time spent rototilling or cultivating the pack was consistently around 10 minutes for the majority of the packs. Methods to keep the cows off the pack during cultivating and bedding also varied. Some used gates, and others had staff move the cows into the feed alley or lock them into head gates.

Manure management

Two types of manure are produced in CBP barns. Liquid manure is produced in the feed alley and can be handled by tractor, skid steer scrapers or by an automatic alley scraper. Partially composted solid manure stays in the barn until cleaned out. Some producers will clean out the pack twice a year; others, with limited-access designs, may only do it once. Never clean out the pack completely; leave some material to start the composting process when new material is added. The best time to clean the pack is early fall. This will allow enough time for the new pack to maintain heat and begin composting before the cold weather sets in.

Solid manure from the pack can be directly land applied. Liquid manure is stored in permanent manure storage tanks and land applied as needed. Management of manure in livestock housing facilities is regulated under Nutrient Management Regulation (O. Reg. 267/03). The OMAFRA fact sheet Constructing a permanent concrete or steel liquid nutrient storage facility for agricultural source materials provides more information on constructing a manure storage tank.

Fertilizer value of composted manure

The increased interest in compost bedding packs has led to the need for information on the fertilizer value of the compost pack. A good practice is to analyze the compost samples for their fertilizer value and record them in manure management plans.

Manure characteristics from different barns vary depending on barn size, ventilation and pack size (herd size), as well as the pack elements such as moisture content, temperature and nutrient content. A 2006 study collected samples from eight CBP barns to study manure characteristics. Herd sizes in the study ranged from 38 to more than 200 milking cows. All the farms used wood chips or sawdust for bedding, with sources varying from ground particle board to fine hardwood sawdust. The packs were aerated twice daily. Moisture content varied between 61% (surface) and 64% (compacted layer).

Two additional U.S. studies involved compost sample analysis from CBP barns. Table 3 summarizes characteristics of the compost collected by these studies and the preferred conditions for composting.

- SL

- surface layer top 3–8 in.

- CL

- compacted layer >8 in.

| Parameters | Barberg | Janni | Russelle | Preferred |

|---|---|---|---|---|

| barns in study | 12 | 6 | 8 | n/a |

| moisture (wet basis) | 52.7% in SL 56.7% in CL | n/a | 61% in SL 64% in CL | 50%–60% |

| total nitrogen | n/a | 0.99% | 1.09% | n/a |

| phosphorus (P205) | n/a | 0.36% | 0.28% | n/a |

| potassium (K20) | n/a | 0.70% | 0.74% | n/a |

| pH | 8.5 | 8.45 | 7.5 | 6.5–8.0 |

| carbon:nitrogen ratio (C:N) | 19.5 | 15.5 | 11.2–20.9 | 25:1–30:1 |

| temperature (°C) | 42.5°C | n/a | n/a | 54°C–60°C |

| density | n/a | n/a | 55.3 lb/ft3 | n/a |

| bedding use1 | n/a | 19.0 lb/cow/day | n/a | n/a |

1 Information for one barn only.

Russelle measured total nitrogen concentration of 1.09% and noted it did not change with depth or location in the pack. Phosphate concentration averaged 0.28%, and again did not change with depth or sampling location. The potash concentration averaged 0.74% and did not change with sampling location but was higher in the surface layer than in the compacted layer. All the studies got similar results.

Russelle measured carbon-to-nitrogen ratios of 11.2–20.9, similar to Janni’s at 12.2–20.2. Russelle recorded a pH of 7.5 compared to 8.5 recorded by both Barberg and Janni. Barberg was the only one to record an average temperature 42.5°C.

Collected data compared to preferred conditions for proper composting suggested pack material was not composting in the traditional sense. However, the researchers concluded heat and biological activity of the pack was enough to control environmental mastitis organisms, fly larvae and other potential problems.

Janni also found that producers were estimating 25%–30% of the manure was deposited on the scrape alleys. In Ontario, estimated number is 50% based on producer experiences. Although the amount of bedding used varied widely, one producer was using 8.6 kg (19 lb) per cow per day.

In 2018, OMAFRA collected compost samples from several CBP barns in Ontario. Table 4 provides a summary of the results from samples analyzed.

Producers are encouraged to take samples from their barn and use the information for developing nutrient management plans. The results are helpful in assessing whether the composting process is going well.

| Samples | C:N Ratio | Organic matter (%) | pH (Sat) | Potassium (total) (%) | Organic Carbon (total) (%) | Nitrogen (total) (%) | Solids (total) (%) | Sodium (%) | Moisture (%) | Phosphorus (total) (%) | Bulk density (kg/m3) | Ash (total) (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 11:1 | 90.93 | 9.31 | 1.32 | 50.52 | 3.9 | 47.15 | 0.61 | 52.85 | 0.31 | 420 | 9.07 |

| 2 | 28:1 | 83.7 | 9.11 | 1.9 | 46.5 | 1.5 | 36.07 | 0.52 | 63.93 | 0.38 | 558 | 16.3 |

| 3 | 42:1 | 93.83 | 9.08 | 1.13 | 52.13 | 1.2 | 42.44 | 0.28 | 57.56 | 0.17 | 432 | 6.17 |

| 4 | 26:1 | 89.44 | 9.16 | 1.47 | 49.69 | 1.7 | 42.32 | 0.5 | 57.68 | 0.26 | 477 | 10.56 |

| 5 | 18:1 | 84.24 | 9.21 | 2.31 | 46.8 | 2.3 | 44.89 | 0.94 | 55.11 | 0.6 | 538 | 15.76 |

| 6 | 12:1 | 86.08 | 9.13 | 1.48 | 47.82 | 3.8 | 41.08 | 0.61 | 58.92 | 0.39 | 503 | 13.92 |

| 7 | 20:1 | 76.12 | 9.38 | 2.08 | 42.29 | 1.9 | 52.37 | 0.43 | 47.63 | 0.4 | 428 | 23.88 |

| 8 | 21:1 | 78.65 | 9.07 | 2 | 49.69 | 1.9 | 40.67 | 0.5 | 59.33 | 0.52 | 508 | 21.35 |

| 9 | 22:1 | 87.51 | 9.15 | 2.48 | 48.62 | 2 | 33.91 | 0.31 | 66.09 | 0.47 | 589 | 12.49 |

| 10 | 21:1 | 86.24 | 9.06 | 2.54 | 47.91 | 2.2 | 34.41 | 0.32 | 65.59 | 0.46 | 595 | 13.76 |

| 11 | 20:1 | 85.01 | 9.18 | 2.43 | 47.23 | 2.1 | 39.4 | 0.55 | 60.6 | 0.53 | 513 | 14.99 |

| 12 | 21:1 | 85.83 | 9.14 | 1.24 | 47.68 | 2.1 | 46.59 | 0.6 | 53.41 | 0.49 | 524 | 14.17 |

| 13 | 18:1 | 87.3 | 9.15 | 1.85 | 48.5 | 2.4 | 42.3 | 0.45 | 57.7 | 0.56 | 455 | 12.7 |

| 14 | 19:1 | 85.5 | 8.9 | 1.8 | 47.5 | 2.3 | 31.16 | 0.31 | 68.84 | 0.32 | 483 | 14.5 |

| 15 | 21:1 | 86.97 | 8.6 | 1.81 | 48.31 | 2.1 | 41.13 | 0.31 | 58.87 | 0.36 | 475 | 13.03 |

| 16 | 13:1 | 86.84 | 9.25 | 1.48 | 48.24 | 3.2 | 44.41 | 0.32 | 55.59 | 0.3 | 619 | 13.16 |

| 17 | 13:1 | 82.18 | 9.25 | 1.71 | 45.65 | 3 | 47.25 | 0.34 | 52.75 | 0.43 | 533 | 17.82 |

| 18 | 12:1 | 87.93 | 9.38 | 1.78 | 48.85 | 3.5 | 36.64 | 0.71 | 63.36 | 0.41 | 565 | 12.07 |

Challenges

Composting requires nutrients, moisture and heat. Mastitis organisms also require nutrients, moisture and heat, so careful management is required to make sure the right organisms are growing and not harmful ones.

The 2018 study by OMAFRA noted a number of challenges experienced by producers. The most common challenge was keeping the pack dry in cool, wet and winter days. The amount of water evaporated from the pack may be less in winter compared to summer because of falling temperatures. Maintaining optimum pack temperature (above 40°C) is key in keeping the pack dry. Adding increased amounts of bedding material in winter will help keep the bed dry. Good air movement and humidity maintained below 80% is also important to maintaining a dry pack.

Another challenge is ensuring a steady supply of good sawdust for bedding. Wood products are also sought after for fuel, and this competition is making it more difficult to obtain good-quality sawdust in some areas. It may be worthwhile to store some bedding materials on site where there is no steady supply of bedding materials.

Some barns may also experience heavy fogging (steaming), especially during winter. Some fogging during aeration is normal in CBP barns (Figure 8). Good air exchange (every 10–15 minutes in winter) will help clear fog from the barn more quickly. Ridge ventilation supplemented by fans is an effective way of handling fogging issues during winter. Some producers reverse the direction of the blades to accelerate air movement through the ridge.

Summary

Compost bedding pack barns are a management alternative for dairy producers. Pack barns provide very comfortable conditions for the cow as she is free to lie down and rise as if she were on pasture. The operational success of these barns depends on the choice of bedding material and the management practices in place. Maintaining aerobic conditions in the pack is critical for udder health. A continuous supply of oxygen combined with a balanced supply of carbon and nitrogen will help maintain aerobic conditions. It is only possible to maintain a favourable pack temperature and moisture content when the pack is in an aerobic condition. Good pack temperature and moisture content are the indicators of successful composting taking place. Producers’ experience and studies by researchers have shown dry sawdust as the most effective bedding material for good composting to take place.

Resources

Bewley, J.M., J.L. Taraba. Compost-Bedded Pack Barns in Kentucky.

Black, R.A., J.L. Tarabe, G.B. Day, F.A. Damasceno, J.M. Bewley. 2013. Compost-bedded pack dairy barn management, performance and producer satisfaction.

The Dairy Practices Council. Guidelines for Managing Compost-Bedded Pack Barns, The Dairy Practices Council, USA.

The original factsheet was written by Harold K. House, P.Eng., OMAFRA (retired), and revised by Rajan Niraula, P.Eng., Engineering Specialist, Livestock Structure & Equipment — Dairy and Beef, OMAFRA, Clinton.

Footnotes

- footnote[i] Back to paragraph Barberg, A.J., M.I. Endres and K.A. Janni. 2007. Compost dairy barns in Minnesota: A descriptive study. Appl. Eng. Agric. 23:231–238.

- footnote[ii] Back to paragraph Janni, K.A., M.I. Endres, J.K. Reneau and W.W. Schoper. 2007. Compost dairy barn layout and management recommendations. Appl. Eng. Agric. 23:97–102.

- footnote[iii] Back to paragraph Russelle, M., K. Blanchet and L. Everett. 2007. Characteristics and Fertilizer Value of Compost Dairy Barn Manure. Proc. of the National Compost Dairy Barn Conference. June 21 & 22, 2007. Burnsville, MN.