Dairy housing: ventilation options for free stall barns

Learn about building a well-ventilated barn for dairy cows. This technical information is for Ontario dairy farmers.

ISSN 1198-712X, Published February 2026

Introduction

The goal for dairy producers is to provide the best environmental conditions in the barn to maximize the animals’ well-being and productivity. Good ventilation achieves this goal by providing and distributing fresh air across the barn. This replaces stale air and regulates environmental conditions, particularly temperature and humidity, in the barn. This fact sheet discusses different options in ventilating a free-stall dairy barn.

Note: This fact sheet uses a combination of metric and imperial units that are used by ventilation designers and equipment manufacturers for sizing and designing ventilation systems.

Barn environment

The barn environment is described as either cold, modified or warm, based on the amount of insulation used in the barn. A cold-environment barn is one with no insulation under the roof steel or in the walls. A modified-environment barn has minimum insulation under the roof steel and none, or very little, in the walls. A warm-environment barn has a fully insulated attic (R30) and insulated walls (R20).

A producer must decide early in the planning process what type of barn to build — cold, moderate or warm because the type of barn construction, ventilation system and manure handling system depends on the environmental condition desired.

The key to maintaining a healthy barn environment is to allow the barn temperature to drop with falling outside temperatures. It is healthier for cows if you keep the barn fresh (well ventilated) and allow the temperature to drop, rather than closed up, with higher temperatures (above freezing), causing the humidity to rise inside.

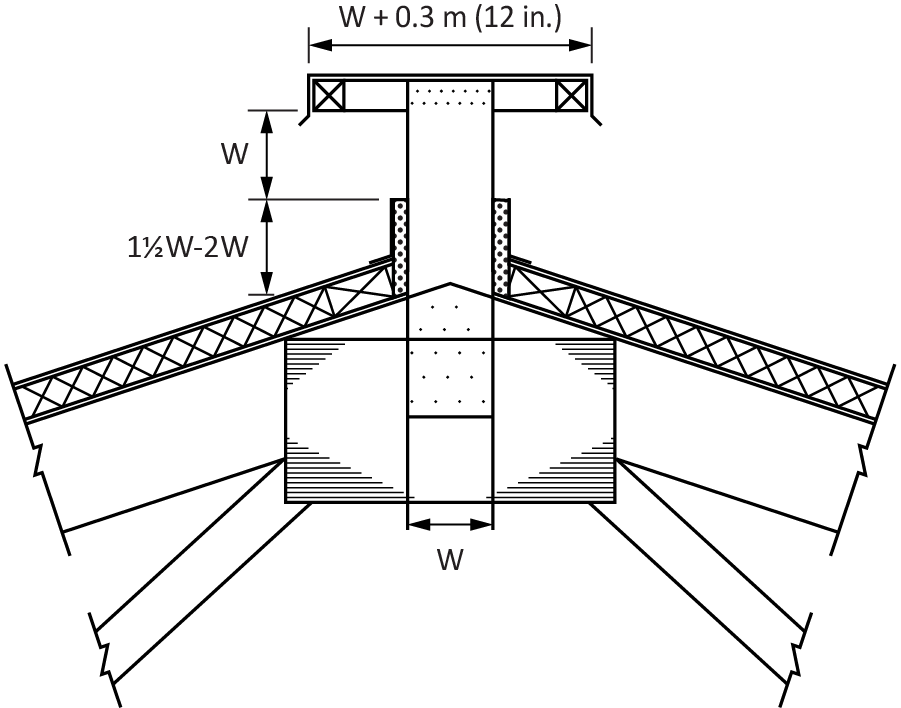

An insulated barn helps to maintain internal barn temperatures. In cold weather, insulation under the roof steel with an R value (thermal resistance) of R5 and R10 keeps the barn warm. In warm weather, insulation reduces the flow of heat into the barn and keeps it cooler. Installing an attic and increasing the amount of insulation in the ceiling (Figure 1) allows for more effective ventilation at cooler temperatures.

Ventilation

The purpose of ventilation is to provide fresh air to:

- control moisture produced by the cows through respiration, water spillage, manure and urine in cold weather

- control heat produced by cows in hot weather

- remove odours and gases produced by cows from manure, urine and breathing out CO2.

- distribute fresh air evenly throughout the barn to prevent dead spots and avoid drafts in winter and remove heat in summer

A ventilation rate that controls moisture and heat is usually enough to remove odours and gases as well. In extremely cold weather, maintain the rate at a minimum of four air changes per hour.

Dairy barns in Ontario are either naturally ventilated or mechanically ventilated.

Natural ventilation

Natural ventilation (Figure 2) relies on the natural forces of wind and the thermal properties of air to function effectively. This system works well for free-stall barns. The side wall openings act as air inlets and the airflow is controlled through adjusting the curtain openings based on different weather conditions.

Summer

Design the natural ventilation system to work in a cross-flow mode in summer. Orient the barn perpendicular to the summer winds so they blow across the narrowest cross-section of the barn. Locate the barn so the wind is not blocked by other buildings or other structures (such as trees) from reaching the barn. Ensure parallel buildings are at least 30 m (100 ft) apart. Any adjacent buildings will cause a downwind effect at a distance of 10 times their height.

Winter

In winter, the barn ventilates naturally because of thermal buoyancy. The barn may only be slightly warmer than outside, but as cold air enters the barn, it expands as it warms up, giving it the ability to hold moisture and gases. Heat produced from the cows causes the mixed air to rise up and exhaust out through the ventilation openings in the ridge (Figure 3). Winds blowing over the ridge of the barn will draw the air out.

Natural ventilation components

There are 3 main components to a natural ventilation system.

Sidewall inlets (openings)

Large, adjustable sidewall inlets make use of the prevailing winds to provide air exchanges. Build barns with a minimum sidewall height of 4 m (12 ft) and as high as 5 m (16 ft). Cover the inlet opening with an adjustable curtain. Depending on the sidewall height, the curtain may be a single curtain or split in two. With a split curtain, the bottom portion remains closed in the cold weather and only the top is adjusted. This allows for less wear and tear on the curtain and less strain on the controls. In warm weather, the bottom curtain is rolled up and the entire sidewall is open. Cover the wall openings with bird screen. Use a bird screen that is strong enough and fine enough to prevent birds from entering, but not so coarse that it restricts air flow (Figure 3).

Ridge exhaust

Ridge exhaust plays a critical role in winter to remove stale air. The ridge exhaust system has different forms:

Open ridge — An open ridge is suitable for cold-environment barns (Figure 4) where no control over the inside temperature is desired. Design the open ridge to provide 2.5–4 cm (1–1.5 in.) of opening for every 3 m (10 ft) of barn width. Cover the opening to reduce the entry of rain and snow and stop 2.5–3.5 m (8–12 ft) from each end of the barn to decrease down drafting.

Chimneys — Chimneys are a good option when some control over the inside environment is wanted. They reduce the amount of rain or snow entering a barn while still providing good ventilation. Most chimneys are equipped with a damper, which Is used to control the outflow of air. The damper doesn’t fit tight and has about a 2.5-cm (1-in.) gap around it, so even when closed it will allow for minimum ventilation. Dampers do not need to be adjusted daily but should be adjusted seasonally. Provide 464 cm2 (0.5 ft2) of chimney opening for every 9.3 m2 (100 ft2) of floor area. Build chimneys no more than 1.2 m x 1.2 m (4 ft x 4 ft) to prevent down drafting and never more than about 6–7.5 m (20–24 ft) apart.

Light vents — A number of light ridge options provide a controllable ridge exhaust combined with a translucent ridge cap to allow more natural light to enter the barn.

Overshot roof — This ridge vent design (Figure 5) is constructed by extending the top chord of the truss in the same direction as the prevailing wind. This is not a new concept, but the difference from previous designs is the addition of an adjustable curtain to control the outflow of air. The amount of opening should be at least 2.5–4 cm (1–1.5 in.) of ridge opening for every 3 m (10 ft) of barn width but can be more, since the amount of opening can be adjusted. The overshot roof should stop 2.5–3.5 m (8–12 ft) from each end of the barn to reduce down drafts.

Natural ventilation control systems

Control systems are necessary to provide a stable environment within the barn:

Ridge control — The ridge opening is only adjusted seasonally, so a manual adjustment system is sufficient.

Sidewall opening control — The sidewall openings require continual adjustment, using an automatic control system, to maintain a constant temperature within the barn. If the barn is more than 30 m (100 ft) in length, divide the curtain system in two so the barn can be controlled in zones.

Natural ventilation with positive pressure mechanical ventilation

A new ventilation concept, called a hybrid or all-season ventilation system has emerged in Ontario from the U.S. that combines natural ventilation with positive pressure mechanical ventilation. In this design, the dairy barn is ventilated mechanically part of the year, during extreme weather conditions (summer and winter), and naturally the rest of the year.

A series of fans are installed above the sidewall openings on both sides of the barn (Figure 6). These fans blow air into the barn. The spacing of the fans ensures good coverage of moving air over the entire barn area. The ventilation controller is set to turn these fans on automatically above a target temperature in summer (for example, 21°C) to maintain optimum temperature and humidity levels in the barn. The side curtains are fully closed by the automatic control systems as the fans start running, and the ridge exhaust or chimneys are fully open to allow hot air to be pushed out of the barn.

In winter when ambient temperatures fall, normally below -50°C, only a few fans are operating and run at lower speeds to introduce fresh air into the barn without dropping the barn air temperature significantly. The side wall curtains are fully closed to reduce cooling due to the low outdoor air temperature and ridge exhaust, or chimneys are partially open to allow warm moist air to escape. This helps to maintain optimum air quality in the barn even when the temperature outside drops to severe cold levels.

The primary advantage of a hybrid ventilation barn is to provide a comfortable environment for cows throughout the year, avoid heat stress in cows during the summer and avoid manure freezing in the barn during winter.

Mechanical ventilation

Mechanical ventilation uses fans to move and exchange air in the barn. Fans are used to create negative or positive pressure in the barn.

With negative pressure, a series of fans exhaust air from the barn, which creates a vacuum within the barn, allowing fresh air to enter from the inlets.

With positive pressure, air is blown into the barn and distributed uniformly across the barn through ducts.

The common layouts of mechanical ventilation are cross-ventilation and tunnel ventilation.

Cross ventilation

In cross ventilation, the direction of air flow is across the width of the barn (short axis). Barns with a cross ventilation system have fans along one sidewall exhausting air, thus creating negative pressure inside the barn. This allows fresh air to enter the barn through inlets on the opposite wall. One of the benefits of cross ventilation is that air moves parallel to the stalls, allowing better air flow in the resting area.

Design all mechanical ventilation systems, including cross ventilation, with appropriate ventilation rates based on the size and number of cows (Table 1).

| Ventilation rate | Small cow size m3/min/455 kg (CFM/1,000 lb) | Large cow size m3/min/682 kg (CFM/1,500 lb) |

|---|---|---|

| Winter minimum | 0.7 (25) | 1.1 (40) |

| Summer maximum | 11 (400) | 17 (600) |

The practical summer ventilation rate should not exceed 28 m3/min (1,000 CFM) per cow. Do not allow the air exchange rate to drop below 4 barn air changes per hour for winter and maintain between 40 to 60 barn air changes per hour in summer.

Tunnel ventilation

Tunnel ventilation is another option for increasing air flow to reduce heat stress (Figure 7). Fresh air enters the barn at one end, travels the length of the barn and is exhausted at the other end. Since the air speed depends on the cross-section of the barn, long, narrow barns are ventilated more effectively than short wide ones. In this system, large fans with diameters ranging from 120–180 cm (48–72 in.) are used to move air at an air speed of 2–3 m/s (400–600 FPM) to provide convective cooling of dairy cattle.

General recommendations for tunnel ventilation:

- air speed of 2–3 m/s (400–600 FPM)

- air exchange rate of 28 m3/min per cow (1,000 CFM/cow)

- <1 air change/min

- inlet air speed of 2.5 m/s (less than 500 FPM)

- air inlet area at least 2 ft2 per 1,000 CFM of fan capacity

To calculate the fan ventilation requirements at different air flow rates, use the formulas Q = VA or A = (Q/V), where:

- Q = quantity of air (m3/s)

- V = air speed (m/s)

- A = cross-section area of building (m2)

For example, to achieve an airspeed of 2.5 m/s in a barn having a cross-section of 110 m2:

Q = 2.5 m/s x 110 m2 (barn 3.6 m x 30.5 m)

Q = 275 m3/s = 600,000 CFM fan capacity required

Fan capacity is directly proportional to the cross‑section of the barn — the smaller the cross‑section, the fewer fans required to provide the desired air speed. Producers have increased air speed by hanging interior curtains from the ceiling to reduce the cross-section dimension. Place curtains no more than 12 m (40 ft) apart down the length of the barn.

In theory, all wall openings should be closed between the exhaust fans at one end of the barn and the end wall openings at the other. In practice, opening the side curtain slightly (about 5 cm) from the bottom provides some fresh air along outside rows of stalls.

During cold weather when these tunnel fans are not operating, it is necessary to cover them with sealed, insulated panels to minimize heat loss and prevent air leakage.

The amount of cooling is directly related to air speed achieved down the length of the barn. As the ambient temperature rises, the amount of cooling is increased by operating more fans in a staged manner. The first stage is set with a minimum number of fans (normally 2 fans). The following stages are designed with an increased number of operating fans as the temperature and humidity rises. All fans are running at full speed during the final stage.

Tunnel ventilation can also be supplemented with secondary fans such as basket, cyclone or low‑speed, high-volume fans to improve air movement (Figure 8).

Mechanical ventilation components

Fans

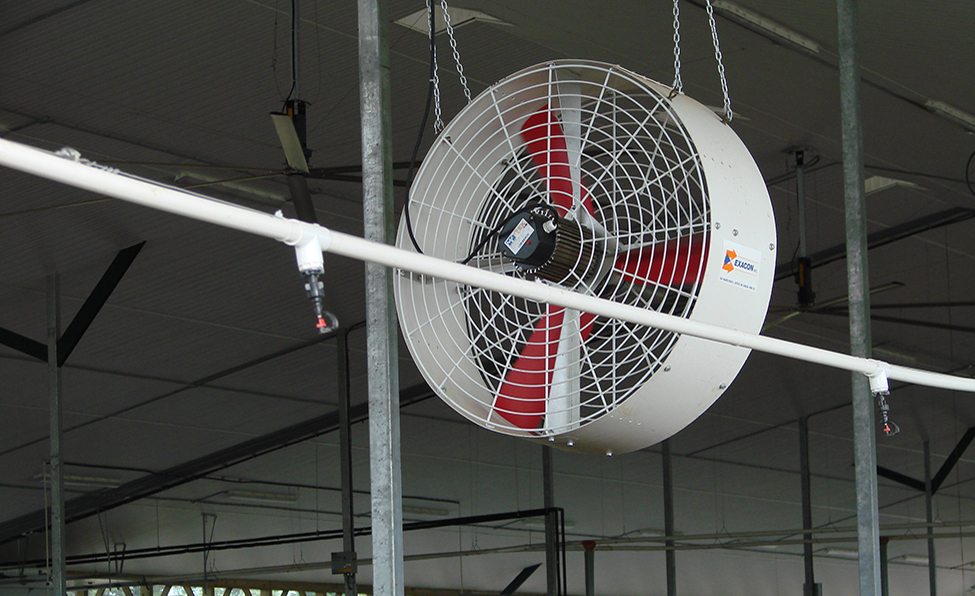

Fans provide the power to move and exchange the air (Figure 9). The air-moving capacity is based on their size and efficiency. Select a range of fan sizes to provide the required air flow rate from the winter minimum to the summer maximum. Fans used in dairy barns can be single speed or variable frequency drive (VFD) fans. VFD fans are capable of operating at more than one speed. Use smaller fans to provide the winter minimum ventilation rate, combined with larger fans to provide the range to the summer maximum.

Fan controllers

A centralized unit is used to control the number of fans running and the individual fan speed for the different temperature and humidity conditions. As the temperature rises, more fans are activated. Ventilation designers often use the “doubling rule” when setting up the controller so that each successive fan stage exhausts no more than double the capacity of all the operating fans in the preceding fan stage.

Set the controller for different temperature thresholds, ranging from 20°C (start point) to 27°C (maximum). All fans should be running at maximum speed at the maximum threshold.

Inlets

These are the openings where fresh air enters the barn. There are a variety of inlet types and styles that can be used to provide fresh air. Generally, have a maximum opening size of 2 ft2/1,000 CFM fan capacity. Adjust inlet openings to provide enough air speed (4–5 m/s (800–1,000 ft/min)) to mix the air throughout the room.

Extreme weather and ventilation

Dairy cows are susceptible to extreme heat causing heat stress. Heat stress leads to decreased milk production and impacts animal health and welfare. Design dairy barn ventilation systems to help cows cope with these high temperatures during summer.

Cooling options

In general, there are two cooling strategies for dairy cows:

- One strategy is to increase the rate of heat transfer between the cow and her environment. This means increasing the convective heat transfer rate by increasing the air speed over the cow.

- The other option is to modify the environment to reduce the heat stress placed on the cow. This means lowering the air temperature using evaporative cooling by wetting the cow or the air around the cow. The phase conversion from liquid water to water vapour pulls heat energy from the air and lowers the temperature.

Circulation fans

Circulation fans are used in dairy barns to improve the air movement in the barn. There are two types:

Basket fans

Basket fans are usually selected for cooling dairy cows. Choose fans based on their capacity and the air velocity they produce:

- at least 14 m3/min (500 CFM/cow) and up to 28 m3/min (1,000 CFM/cow) per cow

- air velocities in the range of 1–2.5 m/s (220–500 FPM)

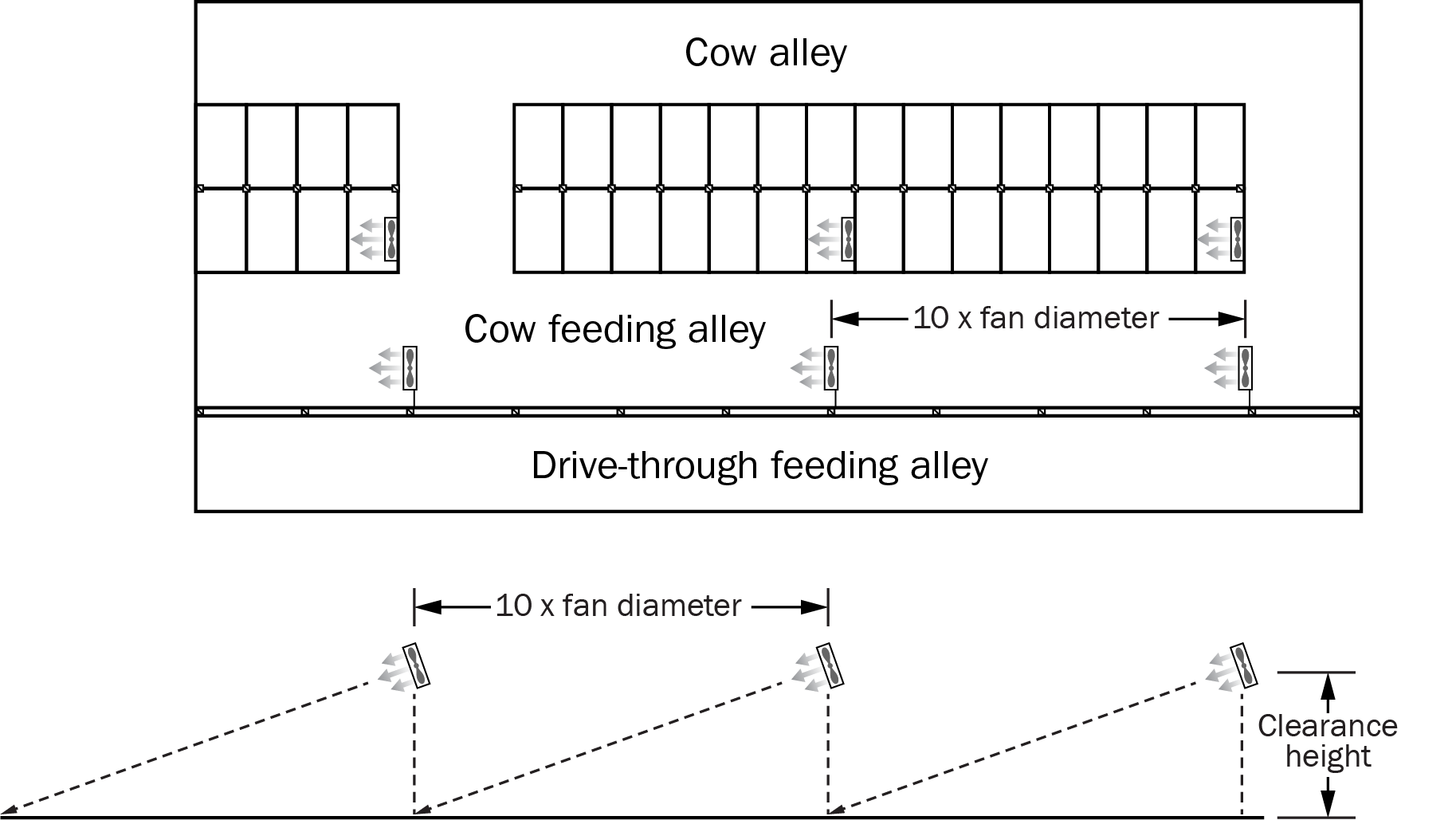

Typically, these fans are 60–120 cm (24–48 in.) in diameter and provide low volumes of air but at a high speed (LVHS). Fans normally maintain adequate airflow to a distance of 10 times the fan diameter.

Mount the fans high enough to provide clearance for any equipment used in the alleys and with about 2.5 m (8 ft) clearance above the free stalls to keep the cows from damaging them (Figure 10). Place fans so they blow air in the direction of the prevailing winds, spaced at a distance of 10 times their diameter.

Tilt fans downwards to aim their airflow at a point directly below the next fan in line. In holding areas or when blowing across the width of the barn, install fans 2.5–3.5 m (8–12 ft) apart and use 45–60-cm (18–24-in.) fans.

In summary:

- Place fans over the alley next to the feed manger and over the rows of free stalls in a four-row barn.

- In a six-row barn, it may be necessary to place a row of fans over the outside row of free stalls.

- Space fans according to their diameter.

- Start fan operation when the barn temperature reaches 21°C.

- All fans should be running when the barn temperature reaches 27°C.

HVLS fans

High-volume, low-speed (HVLS) ceiling fans are an alternative to the panel fan for hot-weather ventilation (Figure 11). These 6–7.5-m (20–24-ft) diameter fans are installed on the ceiling at a spacing of 15–18 m (50–60 ft) apart, along the length of a free-stall barn. Fans run at approximately 50 rpm and will move from 150,000 CFM up to almost 400,000 CFM of air. Air speeds are highest directly under the fan and decrease with increasing distance away from the fan.

Guidelines for installing HVLS fans:

- In four-row barns, space 6–7.5-m (20–24-ft) diameter fans 15–18 m (50–60 ft) apart.

- In six-row barns, HVLS fans do not provide good coverage to the outside row of free stalls unless two rows of fans are used.

- A 7.3-m (24-ft) diameter fan should have at least 76 cm (30 in.) clearance at the blade tips.

- Mount fans at least 0.3 m (1 ft) higher than the highest overhead door for safety.

- Install variable frequency drive (VFD) controllers to reduce radio interference:

- Make sure controllers are grounded properly.

- Use the correct type of shielded cable.

- Locate controllers within 3 m (10 ft) of the fan.

Some additional observations:

- Producers notice fewer birds in the barns when the HVLS fans are running.

- Fans can be operated at very low speeds during the winter to keep the air mixed.

Sprinkler systems

Using sprinkler systems with fans can provide additional cooling (Figure 12). A sprinkler system uses simple, readily available and easily maintained components. The sprinklers create droplets that wet the cow’s hair coat to the skin. Fans force air over the cow’s body, causing evaporative cooling to take place on the skin and hair coat. Heat from the cow’s body causes the moisture to evaporate. The droplet size should be large enough to wet the skin surface and must be applied intermittently to allow time for the moisture to evaporate from the skin.

A sprinkler system should:

- use a timer to run sprinklers for 1–3 min, every 15–30 min

- provide enough water to soak the skin but not wet the udders

- turn sprinklers on and off regularly to allow for evaporation

- use low-pressure nozzles (20–40 psi)

- use solid-cone coarse droplet spray nozzles with flow rates of 0.75–1.8 L/min (0.2–0.5 U.S. gal/min)

- use 180° nozzles (half circle) along feed bunk

- use 360° nozzles (full circle) over holding area

- start the system at temperatures over 25°C–27°C

Variable-rate control systems are popular. They increase the sprinkler frequency as the temperature rises as follows:

- 21°C–27°C every 15 min

- 27°C–32°C every 10 min

- >32°C every 5 min

Fans should run continuously when the sprinklers are on. If water is being blown on the feed or on the stalls, the droplet size is too small, or the fans need repositioning.

Misting systems

Misting systems are also effective for cooling cows. They cool the air around the cows without wetting the cows or the surroundings directly. The amount of cooling achieved depends on the air temperature, relative humidity and the amount of moisture evaporated. Misting systems use high-pressure nozzles (200 psi) to inject small water droplets directly into the air stream. The nozzles are usually installed in a ring in front of the fan, but they can also be used with tunnel ventilation systems by injecting water close to the air inlets. The conversion from liquid water to vapour requires energy and will extract heat energy from the air stream, thus lowering the air temperature downstream of misters.

Summary

There are different ventilation options for free stall barns. In Ontario, the majority of free stall barns are naturally ventilated barns with supplementary cooling systems using fans to improve air movement.

Fans blowing over the cows can increase their convective cooling rate significantly. Use sprinkler or misting systems to increase the evaporative cooling rate when additional cooling is needed.

Author credits

This fact sheet was updated by Rajan Niraula, P.Eng., livestock structure and equipment — dairy and beef, OMAFA, and reviewed by Dan Ward, P.Eng., poultry and other livestock housing, OMAFA. It was originally written by Harold K. House, P.Eng., dairy and beef housing and equipment, OMAFA.