Positive pressure air tube ventilation for calf housing

Learn about positive pressure air tube (PPAT) ventilation systems for calf barns. This technical information is for Ontario dairy and beef farmers.

ISSN 1198-712X, Published May 2025

Introduction

The trend of keeping calves indoors is increasing among dairy farmers because of challenges faced in feeding, watering and cleaning during extreme winter and summer weather conditions. Technology advancements, particularly automatic calf feeders in group housing are seeing more calves housed indoors. Indoor housing of calves also has its own challenges, especially in maintaining air quality. A properly designed ventilation system helps to maintain good air quality in the calf barn.

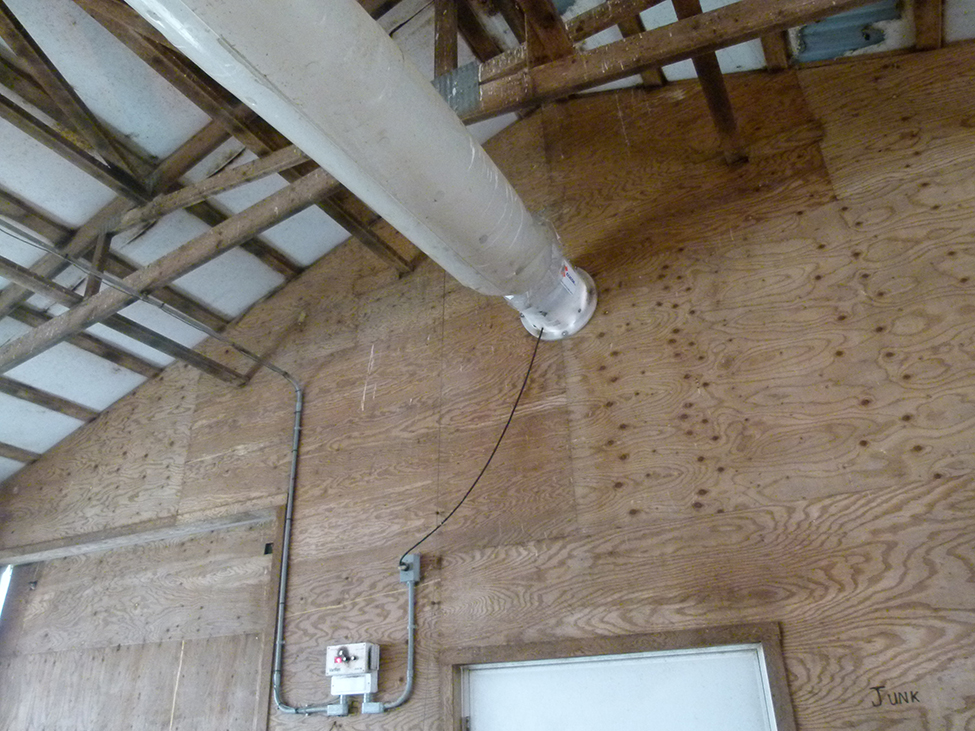

Positive pressure air tube (PPAT) ventilation systems are popular for improving the ventilation in calf barns (Figure 1). This fact sheet discusses the use of a positive pressure air tube ventilation system for calf barns.

Natural ventilation

Most producers choose natural ventilation for their calf housing areas. Natural ventilation works well for most of the year. In summer, it relies on prevailing wind conditions and in winter, it’s the thermal buoyancy created primarily by the heat produced by the animal.

However, calves do not produce enough heat to create sufficient thermal buoyancy resulting in not enough air drawn out through chimney openings during winter. This leads to a situation where there is not enough fresh air coming in through the curtains. Producers should provide a supplemental ventilation system to correct this situation.

One solution is to add fans in the chimneys to create a positive draw of air. This improves ventilation, as it provides a minimum fresh air exchange, but it does not ensure an even distribution of air throughout the room.

The other popular ventilation system for a calf barn is the PPAT system as it provides fresh air and distributes it evenly throughout the room.

About the PPAT system

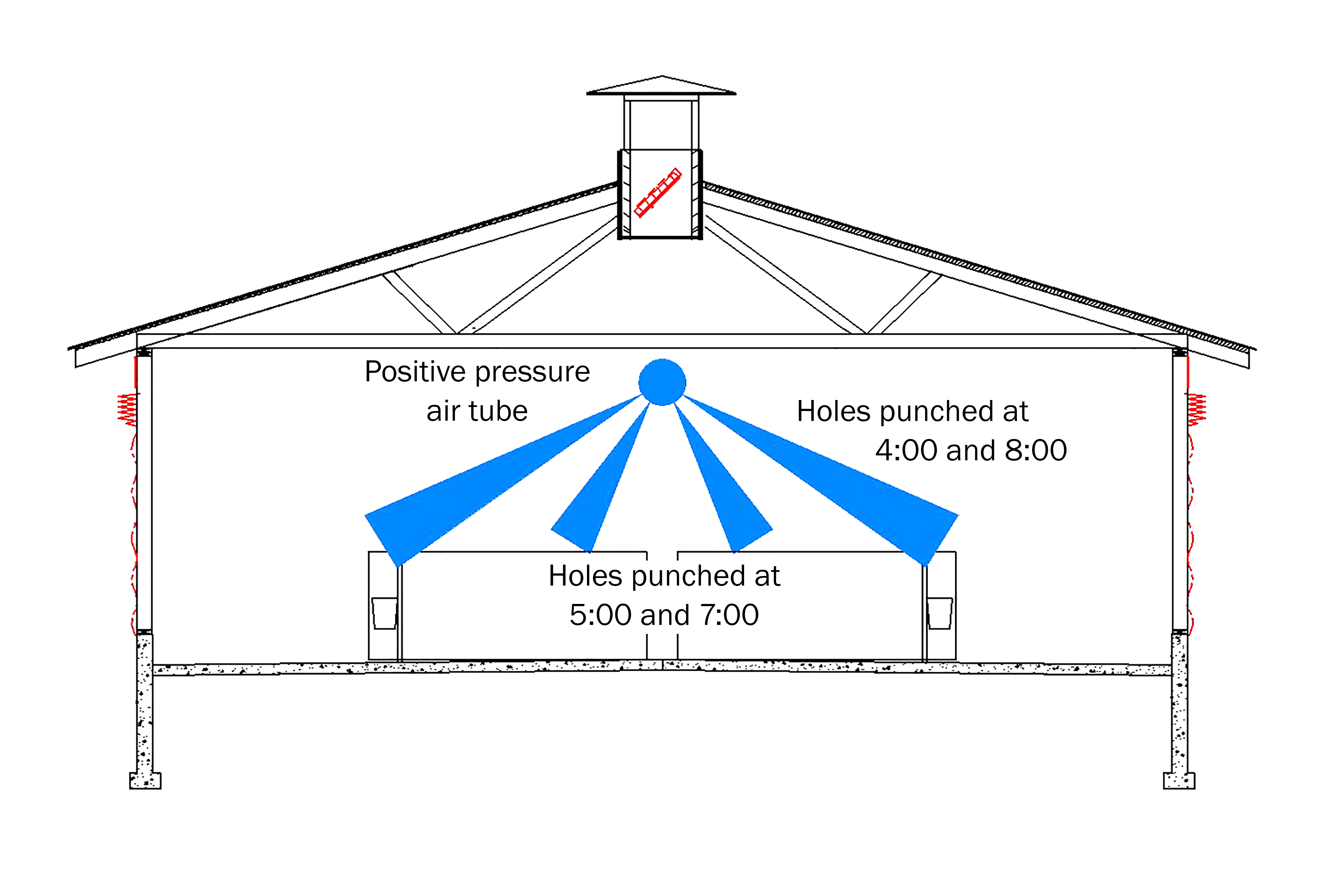

The PPAT system consists of a wall-mounted fan blowing fresh outside air into the calf room. Attached to the fan is a distribution tube with equally spaced holes in it that runs the length of the room. The fan draws fresh air in from the outside, pressurizing the tube and blowing the air out of each of the holes to distribute it evenly throughout the room. The room is pressurized by the fan, and air finds its way out of the room through the natural ventilation system, usually through the chimneys.

How a PPAT is different from traditional systems

The air tube system for ventilating calf barns has been in use for over 30 years. The PPAT system developed by Dr. Ken Nordlund

PPAT design

The fresh air fan is sized to provide the minimum fresh air requirement for the calves, which is 25.5 cubic meters per hour (15 cubic feet per minute (CFM)) per calf. Another consideration for determining the minimum ventilation rate is the room volume. Four air changes per hour are required to keep the air fresh in a room during winter. Choose the fan on the basis of which is the larger air flow: 25.5 cubic meters per hour per calf or 4 air changes per hour. In an ideal world, a single speed fan would be used, where the fan capacity would match the minimum calculated ventilation rate. In practice, it may be necessary to select a variable speed fan with a controller. Set the speed to provide the calculated fan capacity and leave it at that setting.

Select tubes to best fit the size and layout of the room. Use a single tube if the room is less than 9 m (30 ft) wide, and 2 tubes if the room is between 9 m and 18 m (30 ft and 60 ft). The goal is to ventilate the entire room space evenly. The location of the pens will also dictate how many and where to mount the tubes to provide uniform ventilation. Mount tubes to direct the fresh air at the fronts of individual or group pens.

Size the air tube to match the fan capacity. To ensure equal air distribution, the tube must inflate evenly, end to end, with the holes positioned correctly in the fully inflated position. Size the tube for an air speed of about 1,000-1,200 FPM. This usually requires the tube diameter to be larger than the fan diameter (Figure 2).

The most common tube material is a lightweight plastic, but more permanent tubes can be made from PVC water pipe or drainage tile. It is also possible to obtain heavier-duty plastic tubes from ventilation suppliers. Shallow, wide rectangular boxes constructed of plywood have also been used in rooms with extremely low ceilings.

The hole size determines how far the air will travel. The larger the diameter of the hole, the further the air will travel. A 2.5-cm (1-in.) diameter hole will jet the air about 3 m (10 ft), while a 5-cm (2-in.) diameter hole will jet the air about 6.1 m (20 ft). The air speed at the hole should be about 1,000 FPM. Calculate hole spacing to match the fan capacity to provide uniform air distribution along the length of the tube.

Match the hole location to the shape of the room and the pen layout (Figure 3). The goal is to distribute the air evenly across the width of the room. If this is not possible, direct it towards the front of the pens.

The hole location will vary, depending on the mounting height of the tube. Hole location is usually described as positions on a clock face. If the tube is mounted 2.4-3 m (8-10 ft) above the floor, holes punched at 4 o'clock and 8 o'clock will provide a good distribution. If the mounting height is over 3 m (10 ft), punching holes at 5 o'clock and 7 o'clock is better. It may also be necessary to add a row of holes at 6 o'clock in a wide room.

Ventilating calf barns with PPAT systems

Most calf barns are designed to ventilate naturally, and natural ventilation works well for all but the coldest months of the year. When the temperature becomes too cold to provide a good air pattern naturally, the sidewall curtains can be closed completely and the PPAT system used to provide the minimum amount of fresh air.

PPAT systems can be left running year-round to provide air circulation. In hot weather, they do not supply sufficient ventilation, but on humid days when there is no wind, they continue to circulate air.

Straw and solid partitions

In cold, naturally ventilated calf barns, calves also benefit from lots of long straw bedding, which allows the calf to "burrow" or "nest" in the bedding to get out of any drafts.

Calves also like to lie along solid walls. In cold weather, a cold outside wall will draw the heat from the calf, making it more susceptible to drafts. It is best to provide a walkway around group calf pens to keep them away from an outside wall. Design individual pens to be away from outside walls. Use solid panels in group pens to provide a lying space where a calf can get out of a draft. Large straw bales can be used to provide the same protection.

Summary

PPAT systems can improve calf barn ventilation during cold weather when natural ventilation systems do not do well distributing the small amounts of fresh air required.

Author credits

This fact sheet was updated by Rajan Niraula, P. Eng., engineering specialist livestock structures and equipment - dairy and beef, Ministry of Agriculture, Food and Agribusiness (OMAFA). It was originally written by Harold K. House, P. Eng., engineer, dairy and beef housing and equipment, OMAFA.

Footnotes

- footnote[1] Back to paragraph Lago, A., S.M. McGuirk, T.B. Bennett, N.B. Cook, and K.V. Nordlund. 2006. Calf Respiratory Disease and Pen Microenvironments in Naturally Ventilated Calf Barns in Winter. J. Dairy Sci. 89:4,014-4,025.