Dairy housing: free-stall base material and bedding options

Learn about creating comfortable stall areas for cows. This technical information is for Ontario dairy farmers.

ISSN 1198-712X, Published July 2016

Introduction

Cow comfort starts in the stall area. To produce the highest-quality milk, start with cows that are clean, dry and comfortable (Figure 1). Design a stall area that is inviting to the cow, to encourage her to lie down and rest. It must be as unobstructed as possible to allow the cow the freedom to rise and lie down without injuring herself and it must provide a clean, dry surface for her udder.

There are two main types of free stalls: concrete based and deep bedded. For concrete-based free stalls, choose a secondary base material, then a bedding material. For deep-bedded free stalls, choose either sand or organic bedding material.

All drawings are for illustrative purposes and are not intended for use as building plans.

Concrete-based free stalls

Design

Cow size determines stall size. Over the years, average cow size has increased, so stall sizes have had to increase accordingly. It is common practice to have different-size stalls to accommodate the difference in size at various stages of lactation, for example, stalls for milking-cow size and a dry or special-needs size.

The goal is to provide a clean, dry place for the cow to place her udder. The cow should be comfortable in the use of the stall area, but the stall should position her in such a way that when she deposits her manure, it ends up in the alley and not in the stall.

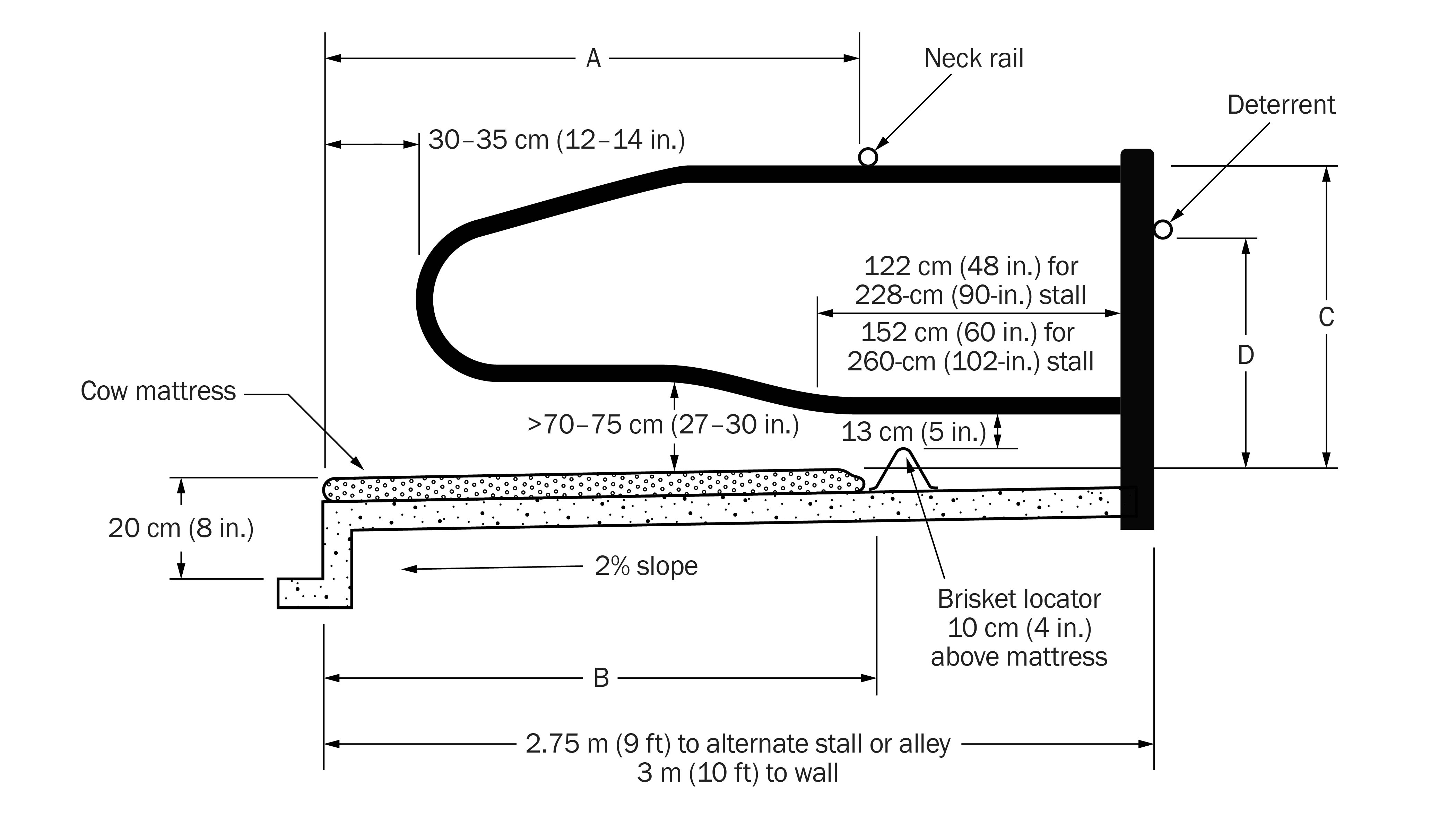

There are a number of parameters to work within when designing the stall area. All stall dimensions are taken from the rear curb of the stall. Figure 2 and Table 1 show the important stall dimensions based on size and weight.

| Holstein Cows | Curb to neck rail (A) | Curb to brisket locator (B) | Base to neck rail (C) | Base to deterrent (D) | Width | Weight | Rump | Hook bone width |

|---|---|---|---|---|---|---|---|---|

| First lactation | 173 cm (68 in.) |

178 cm (70 in.) |

122 cm (48 in.) |

85 cm for 2.75-m stall (34 in. for 9-ft stall) |

122 cm (48 in.) | 658 kg (1,450 lb) | 147 cm (58 in.) | 55-61 cm (22-24 in.) |

| Milking cows | 178 cm (70 in.) |

183 cm (72 in.) |

127 cm (50 in.) |

85 cm for 2.75-m stall (34 in. for 9-ft stall) |

132 cm (52 in.) | 748 kg (1,650 lb) | 152 cm (60 in.) | 61-66 cm (24-26 in.) |

| Dry cows | 178 cm (70 in.) |

183 cm (72 in.) |

127 cm (50 in.) |

85 cm for 2.75-m stall (34 in. for 9-ft stall) |

137 cm (54 in.) | 771 kg (1,700 lb) | 152 cm (60 in.) | 61-66 cm (24-26 in.) |

Width

The free stall should be wide enough to allow the cow to rise and to lie down comfortably and shift her weight to the side.

Brisket locator

The purpose of the brisket locator is to keep the cow from shifting too far forward in the stall. Cows like to move a leg on top of the brisket locator, so it is best to use a curved, smooth surface rather than a board or pipe. The brisket locator should not be any more than 10 cm (4 in.) above the bed so it does not restrict forward lunging. There should also be at least 13 cm (5 in.) between the top of the brisket locator and the bottom of the stall loop, so the cow's feet can't get trapped in between.

Lunge space

The cow needs unrestricted lunge space to rise and lie down properly. The cow occupies about 245 cm (96 in.) of space, but when she lunges to rise or lie down, she needs an additional 60 cm (24 in.). It is possible for the cow to lunge to the side with certain types of stall loops, but it is better for the cow if she can lunge straight ahead.

Overall length

The overall length of the stall is the total of the lying space and the lunge space. In a single row of stalls, a stall platform should be 3 m (10 ft) long for the cow to rise and lie down comfortably. If this row of stalls faces a feed alley, the cow can lunge into the alleyway, so a 2.75-m (9-ft) platform is adequate. If the single row is against an outside wall, a small walkway can also provide the lunge space.

If the stall configuration is head-to-head, a 5.5-m (18-ft) stall platform is best. Some producers will install 5.1-m (17-ft) or even 4.9-m (16-ft) platforms, but with shorter platforms, cows become reluctant to use any stalls that are opposite cows that are already lying down.

Rear curb

The height of the rear curb plus the height of the base material (mat or mattress) should not be more than 20-25 cm (8-10 in.) Cows should not be made to step up any higher than 25 cm (10 in.). This distance provides enough height that manure removal does not spill into the stall.

Stall slope

Stalls should have a slight (2%) slope from front to back to provide some drainage of liquids from the stall. If there is too much slope, the bedding will not stay on the stall base.

Neck rail

The neck rail positions the cow in the stall when she is standing. It must be far enough forward that the cow can stand comfortably with all four feet in the stall and be high enough to not interfere with the cow rising or lying down. In new barns, it helps to position the neck rail farther forward than intended until the cow gets used to the stall. The neck rail can then be gradually moved backwards into its final position. If a cow bangs herself on the neck rail on the first attempt to use a stall, she may never adjust to it properly.

Deterrent pipe or strap

Cows may occasionally try to go ahead through a stall. A deterrent pipe or strap can be installed about 85 cm (34 in.) off the stall surface to prevent this.

Loop design

Many different loop designs are available to position the cow. The goal is to provide the least amount of restriction possible, while still positioning her to keep the stall free of manure. Many loop designs will allow the cow to lunge sideways. This may be necessary in retrofit situations where the platform length is shorter than desired. In a wide loop for lunging, the top of the bottom rail should be no higher than 30 cm (12 in.) above the stall surface. The top rail becomes the neck rail, and the distance from the stall surface to the underside of the top rail should be 122-127 cm (48-50 in.).

Flexible stall dividers

There is always interest in developing new stall dividers that will be less restrictive and more comfortable for the cow to use. A number of flexible stall dividers (Figure 3) have been designed, and all will work, to a point. The more flexible they are, the more a cow may take advantage of them and lie backwards or walk behind them, which results in dirty stalls. Flexible stall dividers often require periodic adjustment to keep them in place.

Secondary bases for concrete-based free stalls

The secondary base should provide the following:

- Comfort - The base should be a cushion material. A base that is too soft may deteriorate quickly and may also trap moisture in the form of milk or manure in pockets under the cow when she lies down. A base that is too hard can be uncomfortable and slippery.

- Traction - The base must have enough give and texture to provide good traction to the cow when she rises and lies down.

- Durability - Base material that is too soft may not be durable.

- Non-abrasiveness - Base material must be durable without being abrasive to the cow's hocks and knees.

Rubber mats

A variety of rubber mats and rubber composite mats are used over concrete bases. It is a challenge to find a good product, because durable mats are often too hard and slippery, and compressible mats often stretch and don't last.

Cow mattresses

Cow mattresses filled with rubber crumbs were first introduced in 1993 and revolutionized cow comfort in the stall area. However, over time, the mattresses packed down and became hard. Most mattresses are now sold with a layer of memory foam or heavy felt. The next generation of cow mattress is a mattress core filled with a compressible gel material that is designed to stay compressible over time.

Other forms of cow mattresses combine rubber covers with compressible underlays.

Water beds

The dual chamber waterbed is another base option. A cow getting up or lying down on a water bed creates a motion in the bed that makes it difficult to keep bedding on top of the waterbed. The two chambers in these water beds reduce this motion.

Bedding for concrete-based free stalls

Some producers look for a base option that won't require bedding, but bedding does more than just provide additional comfort - it reduces friction between the cow and base and provides absorbency.

It is important to provide clean, dry bedding and to keep the base clean and dry by replacing the bedding whenever it becomes soiled. The base and bedding system should work together to keep the cow clean, dry and comfortable.

There is a wide variety of bedding options, from compost to other organic products such as sawdust, shavings and straw. Often, the bedding choice depends on price and availability. The important thing to remember with bedding is to use lots of it and replace it when it becomes soiled or wet. In addition to traditional bedding products such as straw, kiln-dried sawdust and shavings, producers are experimenting with separated manure solids (usually referred to as compost) and peat moss.

Chopped straw, kiln-dried sawdust, shavings

Chopped straw, kiln-dried sawdust and shavings continue to be the most common organic bedding types. Wood products are in high demand for composite building materials and fuel, so are becoming more difficult or costly to obtain.

Compost

Spread fresh compost liberally on the stall base two to three times per week. If the compost dries out too much before spreading, it will blow off the stalls.

Peat moss

Peat moss, where available, is another bedding alternative that is being considered by dairy producers. Finland and other Nordic countries provide good sources of information and experience with the use of peat for bedding dairy cows. There are claims that peat moss bedding prevents the growth and spread of harmful bacteria because it is acidic (pH 4). Dust may be one drawback of this bedding.

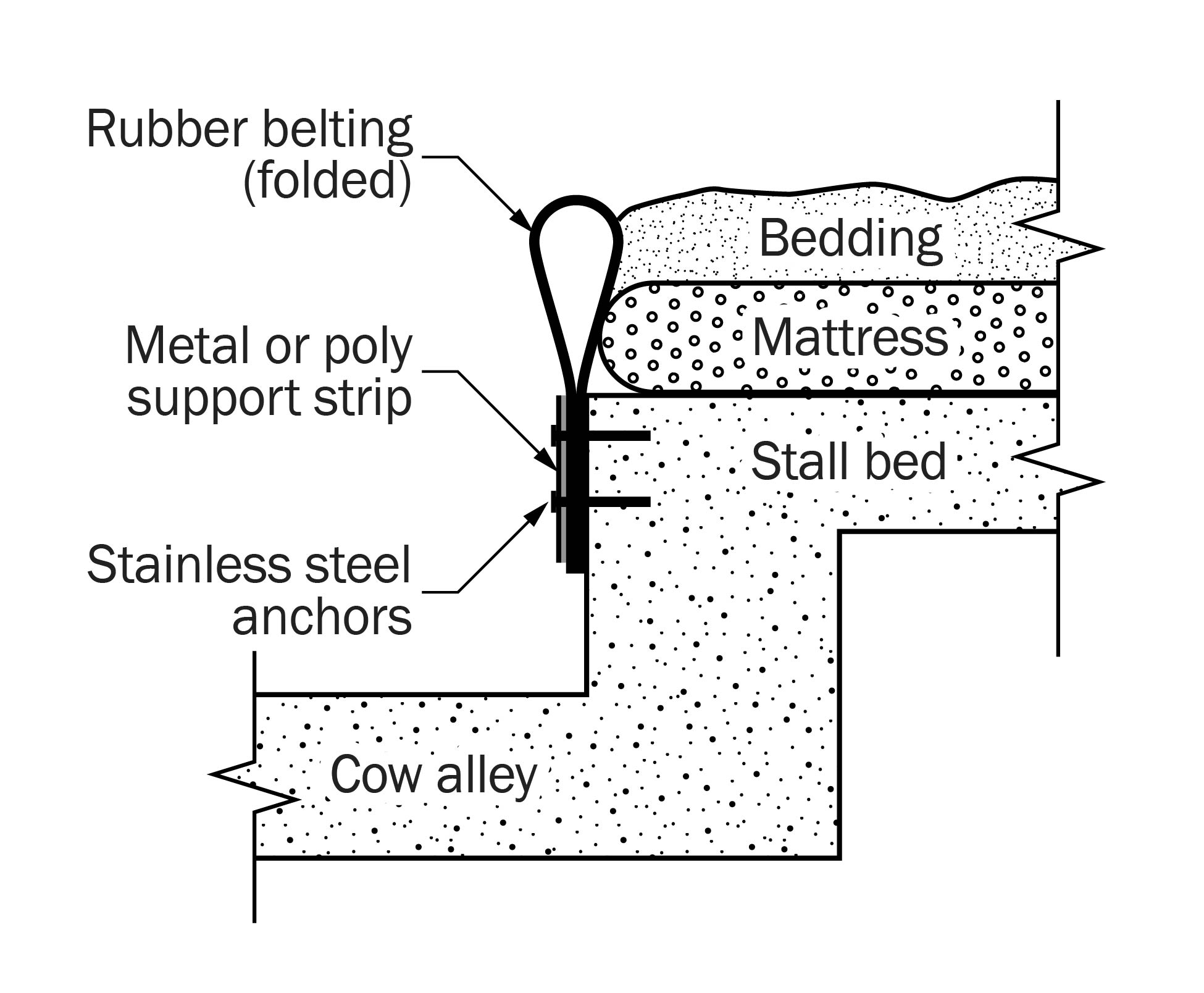

Bedding retainers

So how can we maintain a consistent layer of bedding on mattresses to achieve our cow comfort and udder health goals? Perhaps it is time to revisit bedding retainers. For many years, bedding retainers have consisted of a steel lip or pipe, fastened to the back of the stall. These often created discomfort for the cow when the bedding level wasn't maintained and the retainer became exposed. Stall maintenance was often more difficult, as some retainers trapped moisture, making it difficult to remove soiled bedding from the stall.

Another option has been promoted by Dan McFarland, an agricultural engineer from Penn State University. This bedding retainer consists of a piece of rubber belting folded and fastened to the back of the stall (Figure 4). This design is flexible and doesn't interfere with the cow when she is lying down. There is enough flex in the retainer that the bedding can be raked over the top when the stall is groomed. It is also simple and inexpensive. Bedding levels must be maintained to achieve the comfort goals, but this option allows the bedding to be retained on the stall surface where it is needed.

Deep-bedded free stall

Design

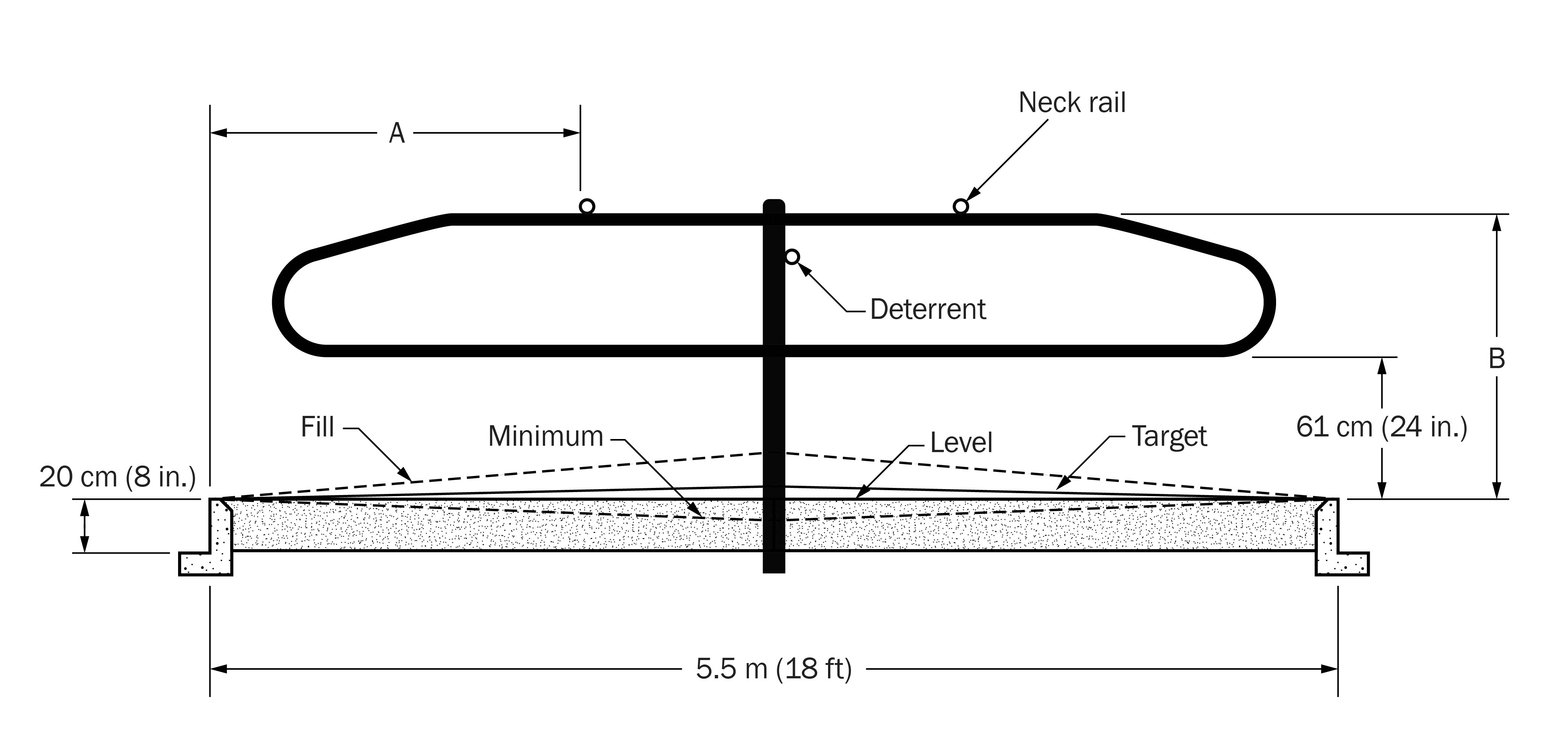

The sizing principles are the same for deep-bedded free stalls, but determining the dimensions becomes more of a challenge because the stall surface is continually changing (Figure 5 and Table 2).

Sand bedding levels

- Target = 5-8 cm (2-3 in.) above level

- Minimum = 7.5 cm (3 in.) below level

- Fill = 15 cm (6 in.) above level

| Holstein Cows | Curb to neck rail (A) | Curb to brisket locator (B) | Minimum width |

|---|---|---|---|

| First lactation | 173 cm (68 in.) | 117 cm (46 in.) | 117 cm (46 in.) |

| Milking cows | 178 cm (70 in.) | 122 cm (48 in.) | 122 cm (48 in.) |

| Dry cows | 178 cm (70 in.) | 122 cm (48 in.) | 127 cm (50 in.) |

Width

Cows get superior traction with sand, so it is possible to make sand stalls slightly narrower without reducing cow comfort.

Brisket locator

Most deep-bedded stalls don't have brisket locators, because of the changing bedding levels. Some producers have developed creative ways to install brisket locators, for example, fastening them to a board and staking the board down. Others have put 15-cm (6-in.) square or round posts in the stalls that float with the sand. Over time they can become buried. Another option is to pour a rounded concrete brisket locator.

Rear curb

The rear curb contains the bedding. It should be no more than 20-25 cm (8-10 in.) high. The corner should be angled off on the inside to reduce the exposed concrete surface, but it shouldn't come to a pronounced point that would put pressure on the hoof.

Loop design

Narrow loop designs are often used in deep-bedded stalls. The narrow loop controls cow position and forces forward lunging. The narrow loop also allows for the use of tractor-mounted grooming equipment.

Bedding for deep-bedded free stalls

Sand

Sand is the best bedding option for the cow because it is comfortable, provides excellent traction, is inorganic, so does not aid in bacterial growth, does not produce hock abrasions, is relatively inexpensive and is easy to obtain in most areas.

However, sand, when it is moved out of the stall and becomes mixed with manure, can become a manure-handling nightmare. If you decide to work with sand, be aware of the costs as well as the benefits and be committed to making it work. Many producers choose sand for the cow's sake without thinking of the impact of the sand on manure handling.

Deep-bedded sand

The more regularly the stalls can be filled or groomed, the easier it is to maintain recommended stall dimensions and the better the cows will use the stalls. If the stalls get too empty before refilling and the platform distance is reduced by the width of the rear curb, the cows will move forward because the height to the neck rail increases, and the cows end up lying in a hole. In addition, cows may injure themselves on the exposed rear curb.

Conversely, if the stalls are filled with too much sand or compost, the height to the neck rail decreases, and the cows are shoved back in the stalls. It is best to fill the stalls often, with small amounts, and groom them regularly so the dimensions to the neck rail stay as close as possible to that recommended.

Deep-bedded compost

Separated manure solids are usually referred to as compost. They are produced in three ways: one process separates the solids from the manure after anaerobic digestion, another separates the solids and then treats them through an accelerated composting process using a drum composter, and the third separates the solids without any treatment process.

Recommendations for deep-bedded stalls with compost (Figure 6) are similar to those for sand, but the moisture content of the compost and maintenance of the compost stalls is more critical. For deep-bedded compost, it is best to let the compost dry before filling the stalls. Remove soiled or wet compost immediately and replace it with dry compost, as you would with any other bedding. Groom compost-bedded stalls to keep them uniformly level and dry.

Deep-bedded mixture

Some producers are experimenting with a deep-bedding mixture composed of straw, limestone and water. Both wheat straw and soybean straw have been used successfully. The limestone is food-grade quality with a particle size of 90% <0.09 mm. One popular mixture consists of 3 kg of straw, 3 kg of limestone and 2 kg of water mixed for 30 minutes in a TMR mixer.

Producers are considering this mixture as an alternative to sand, as it binds together very well, stays in the stall and keeps the hooves drier and the udder softer.

Sand-mattress combination

An alternative for producers that want to reduce their sand use is to use a cow mattress filled with rubber crumbs as the base, covered by 2.5-5 cm (1-2 in.) of sand. The sand does not pack down, and the stall dimensions stay more consistent.

Summary

There are a number of options for free-stall design, base and bedding. Sand is best for the cows but presents a number of challenges with manure handling. Whatever option is selected for base and bedding materials, it is important to regularly maintain the stalls, so that the bedding remains at a consistent depth and is replaced whenever it becomes soiled or wet.

Resources

Anderson, N.G. 2014. Cow Behaviour to Judge Free-Stall and Tie-Stall Barns. Ontario Ministry of Agriculture, Food and Rural Affairs. Infosheet. Guelph, ON..

Anderson, N.G. 2014. Free Stall Dimension. Ontario Ministry of Agriculture, Food and Rural Affairs. Infosheet. Guelph, ON..

Bickert, W.G., et al. 2000. Dairy Freestall Housing and Equipment, 7th edition.

Lang, B., H.K. House, N.G. Anderson and J. Rodenburg. 2012. Free Stall Housing Manual. Ontario Ministry of Agriculture, Food and Rural Affairs. Guelph, ON.

This Factsheet was written by Harold K. House, P.Eng., Engineer, Dairy and Beef Housing and Equipment, OMAFRA, Clinton (retired).