Lighting for poultry with light-emitting diodes (LEDs)

Learn about LED lighting for poultry farms, and what to look for when purchasing LEDs for your farm. This technical information is for Ontario poultry producers.

ISSN 1198-712X, Published April 2024

Introduction

The use of light-emitting diode (LED) lighting in agricultural applications is relatively new and has shown a lot of promise to date. This fact sheet provides information on LED lighting, how to choose LEDs and what to look for when purchasing them for the farm. A cost comparison example of various lighting systems installed in the same barn is also provided.

Lighting is an important component in most poultry facilities (Figure 1) as it represents a large part of the monthly energy consumption. Traditionally, incandescent or fluorescent bulbs were used to provide the required level of light in barns. To reduce monthly lighting costs, farmers have adopted for more energy-efficient lighting technology such as LEDs. Embracing LED technology that reduces energy consumption and improves the overall business is good for both the farmer and society. There may also be production advantages to using specific spectrum lighting to improve bird performance while decreasing light energy usage. Switching to LEDs can result in an overall increase in revenue because of the lower energy costs.

Lighting terms

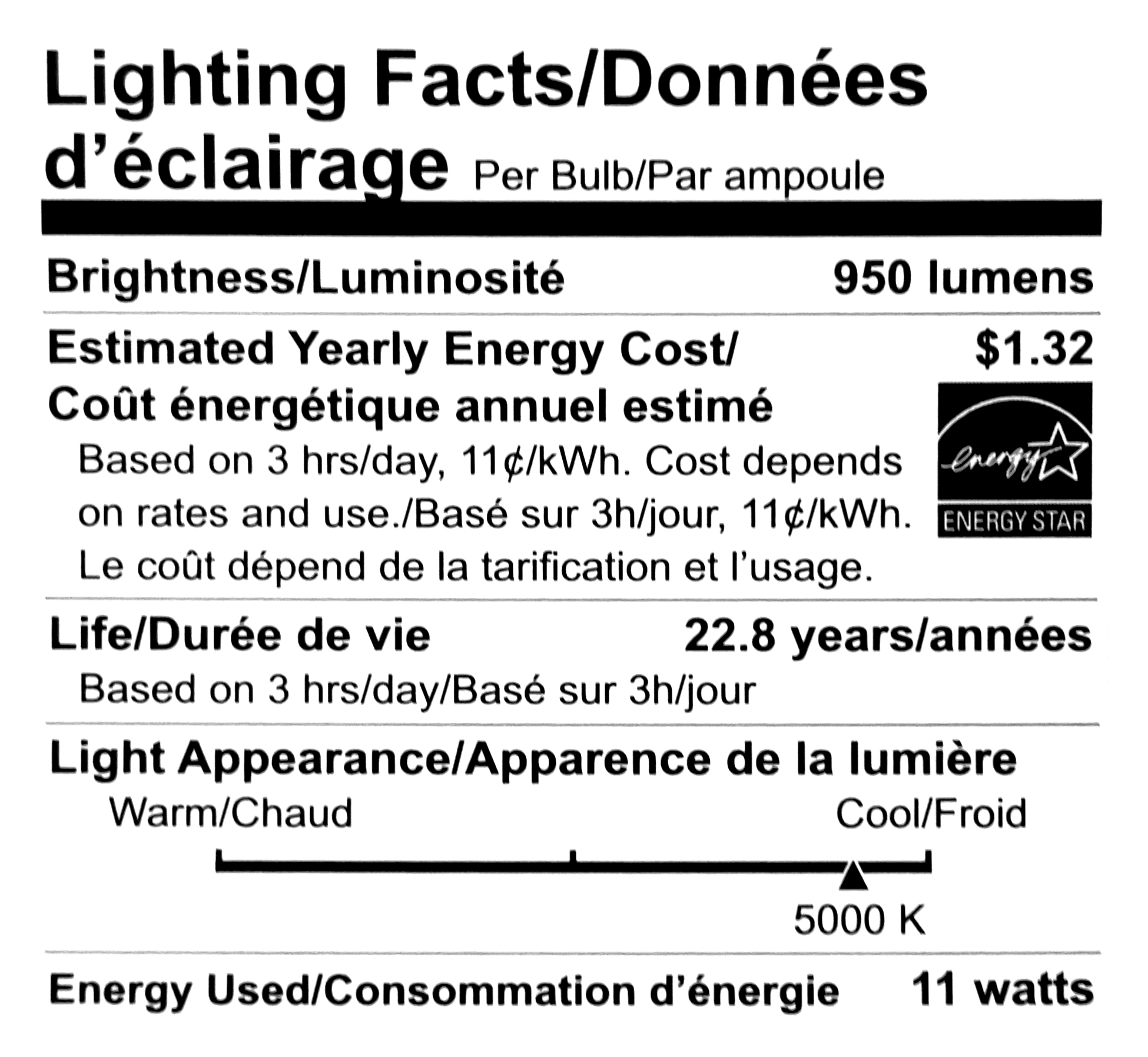

When purchasing LED lights it is important to understand the information on the label (Figure 2) in order to make the right lighting choice. The following definitions may be found on a lighting facts label:

Watt: The watt is not a measure of the brightness. It is the amount of energy required to create the light output (it is the power draw).

Lumen: The lumen (lm) is the amount of light output from a lamp (bulb). A 40-watt (W) incandescent light bulb produces about 13 lumens per watt (lm/W).

Average rated life: The average rated life for a non-LED is the time it takes for 50% of the light bulbs to fail. Failure often occurs when the bulb no longer produces light. For LEDs, usable life (called L70) is the point in time when LEDs produce 70% of initial light.

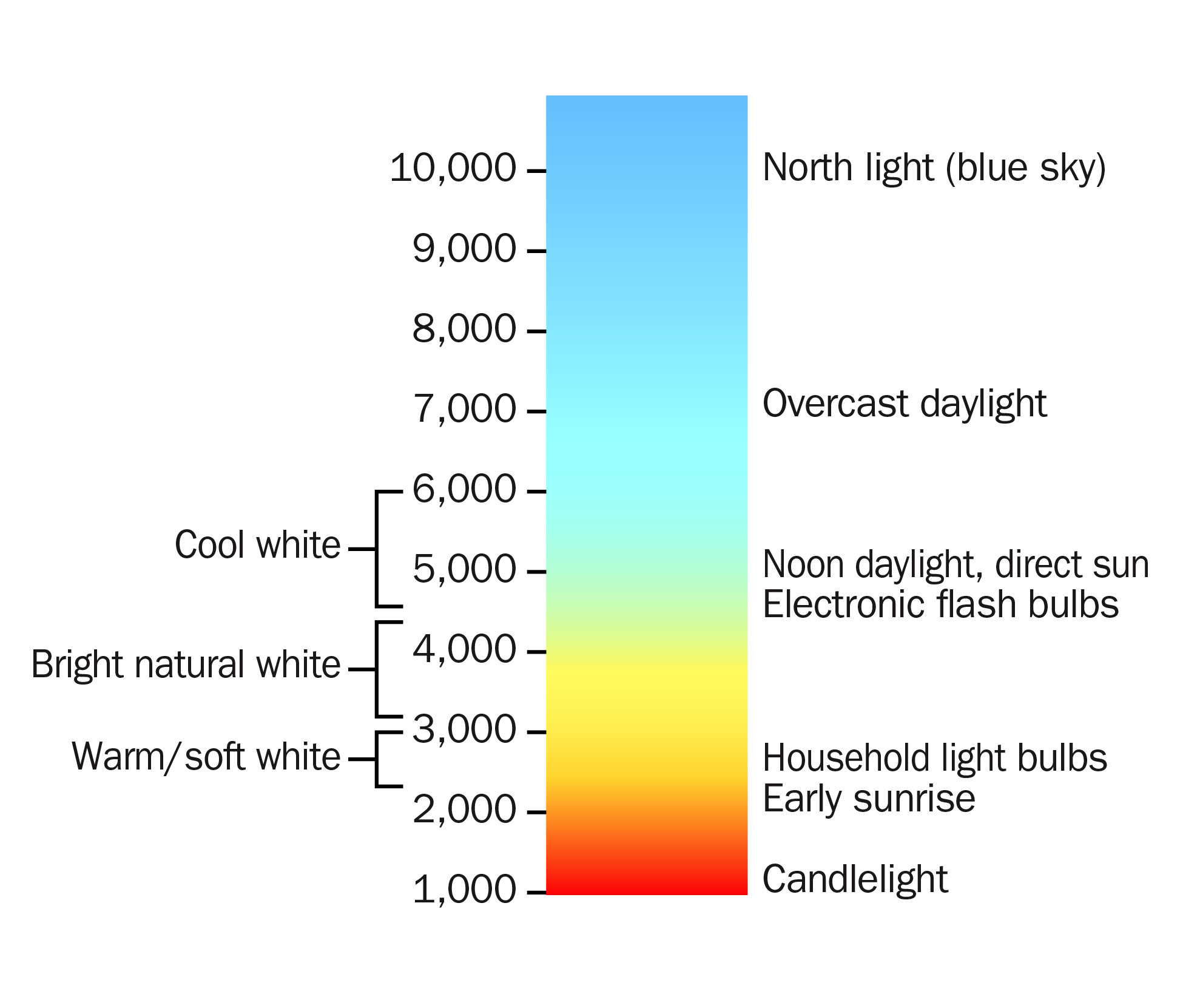

Kelvin: The Kelvin (K) in this application is not a measure of the temperature of the bulb, but rather the colour or appearance of the light that the bulb emits. Warm/soft white light (incandescent) has a range of 2,700–3,000 K, where bright natural white has a range of 3,000–4,500 K, and cool white light a range of 4,500–6,500 K.

Luminous efficacy: The luminous efficacy is a rating of how many lumens of light are produced per watt of energy used. It is measured in lm/W.

Lux or foot candle: Brightness is a measure of the amount of light striking a surface. It is measured in units of foot candle (fc) or lux. One-foot candle is defined as 1 lm of light falling on 1 square foot. The metric equivalent of a foot candle is a lux. One-foot candle is equivalent to 10 lux. Outside on a bright sunny day in mid-summer, the light level will be around 80,000 lux or 8,000 fc.

Colour rendering indexes (CRI): The CRI is a measure of the accuracy of the colour perceived under the light of the bulb as compared to the colour perceived under natural light (sunlight). A lower CRI value indicates that some colours may appear unnatural when illuminated by the lamp. A CRI of 100 represents the maximum value. An incandescent bulb is also used to represent a CRI of 100.

A halogen bulb has a tungsten filament just like an incandescent bulb that emits light when it is heated. However, unlike an incandescent bulb, which is filled with an inert gas like argon, the inside of a halogen bulb contains a mixture of inert gas and a halogen gas. These bulbs are longer lasting and more energy efficient than incandescent bulbs.

A compact fluorescent bulb (CFL) is comprised of a glass tube that contains a phosphorus coating on the interior surface. The tube is filled with an inert gas plus a small amount of mercury, and a pair of electrodes are connected to the tube. These bulbs are more energy efficient than incandescent bulbs.

What makes LEDs different

LEDs are a type of solid-state lighting as they emit their light from a solid semi-conductor chip or diode (usually made from silicone). This allows LEDs to have some very specific qualities that make them different from other lighting technologies, since they are not producing light from a filament (as incandescent light) or an excited gas in a vacuum tube (a CFL).

Due to the lack of a filament, LEDs are able to withstand rougher handling and vibration, but dropping them is still quite hazardous to the bulb’s life.

LEDs are instant on/off lighting

LED lighting does not require any warm-up time as fluorescent and compact fluorescent lighting do. LEDs come on at full brightness with no warm-up period. Even as the temperature drops, LEDs remain instant on/off lighting.

LEDs do not radiate heat

Unlike traditional light bulbs, LEDs do not release or radiate heat, instead they conduct heat. As a result, they must be manufactured with a heat sink (these are the fins that are seen on some LEDs). The fins act to increase the surface area and disperse the heat away from the diodes and to the outside of the bulb. These heat sinks can be anything from large fins to smaller dimples, smooth sides or even fans, all of which allow the excess heat to be displaced. Figure 3 shows an example of a heat sink.

LEDs are cold-loving lighting

Unlike other lighting types, LEDs are cold loving and well suited to being out in colder areas. As the temperature drops from 24°C to –59°C, the luminous efficacy of the bulbs increases, and the light output from the bulbs can increase by 20%.

Source: National Poultry Technology Center, Auburn University.

LEDs are a type of directional lighting

Since LEDs produce light from a chip, the light radiates from one point and lenses are added to focus the light into the desired beam pattern. Lighting layout and equipment selection is critical to achieve the desired light levels and coverage at bird level. LEDs can produce light that is spot specific or in a side-to-side or end-to-end orientation.

LEDs can be produced in a variety of colours

LEDs allow bulb manufacturers to produce light in specific Kelvin range for targeted uses. The colour of light produced by the bulb can be changed by altering the number and type of individual light-emitting diodes used in the bulb.

LEDs are dimmable

Some LEDs are dimmable, and that function adds cost to the manufacturing process. Standard dimmers previously used for other lighting types often do not work with LED lighting. This results in flicker, flashes, jumps, dead travel and a change in colour temperature when trying to dim lights to low levels. Install new LED dimmers made specifically for LED lights and the lighting application. Check with the dimmer (driver) or bulb manufacturer for compatibility. LED systems can now be remotely controlled for dimming, colour turning and operation run times.

Why choose LED lighting

There are many benefits of choosing LED lighting for the farm:

Longest comparable lifespan

- When compared to other lighting options, LEDs generally come out on top in their average rated life, luminous efficacy rating and overall energy savings.

- The average rated life of LEDs will vary from 15,000–100,000 hours, depending on the use and type of bulb. Most commercially available bulbs will list a rated life of 25,000–50,000 hours.

- There have been some failures of LED lighting equipment in barns because of overheating due to dust accumulation, water getting inside the bulbs during pressure washing of the barn and more.

- When purchasing LED bulbs for use inside a barn, select bulbs rated for wet, dirty environments that come with a warranty.

Highest luminous efficacy rating

- LEDs tend to have a very high luminous efficacy rating when compared to other lighting types.

- LED bulbs have an average efficacy of 85 lm/W, compared to 70 lm/W for the CFL and 15 lm/W for an incandescent bulb.

- T8 and T5 fluorescent tubes have high efficacy ratings operating in the 80–105 lm/W range.

- While LED tube lamps (TLED) that are used to replace T8/T5 fluorescent tubes have a rating of 100–130 lm/W, there are currently prototype LED tube lights that produce 170 lm/W, and research is looking at improving this value even further to above 200 lm/W in the future.

High CRI

- LEDs generally have a CRI rating of 70–90. For good colour perception, choose LED lights that have a CRI rating great than 85.

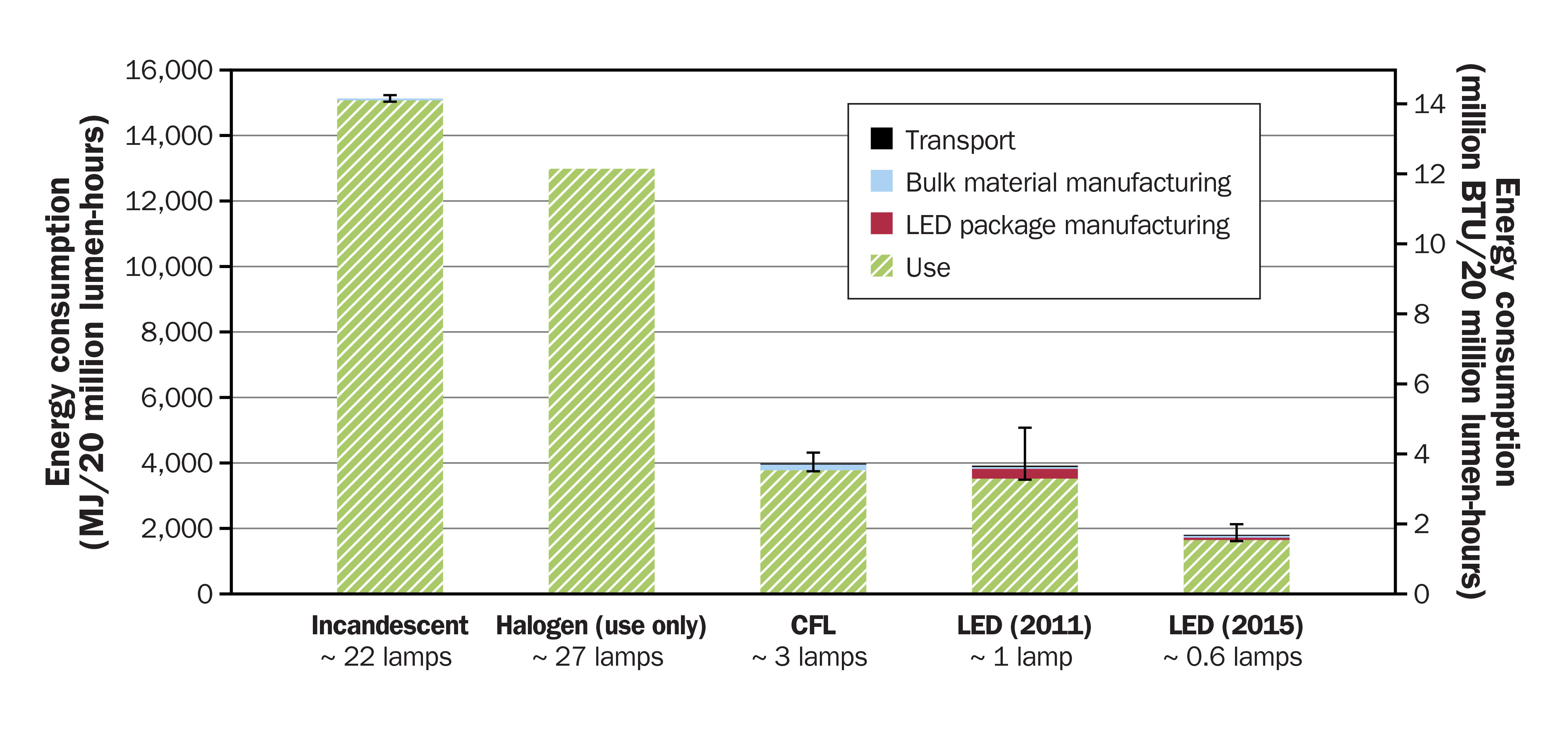

Overall energy savings

- LEDs tend to require the least amount of energy to produce the required amount of lumens due to their high efficacy (Figure 4). As a result, a 60W incandescent bulb can be replaced with a 10W LED. This energy saving in combination with the long life of LEDs will save money on both energy usage costs and bulb (lamp) replacement costs.

Source: U.S. Department of Energy Solid-State Lighting Program, 2015.

How LEDs compare to other lighting technologies

Table 1 shows a side-by-side comparison of LEDs to other common lighting technologies. The table is useful in maximizing the light received from each individual bulb while reducing the amount of light bulbs to be purchased.

| Light type | Incandescent lighting | CFL | LED bulbs |

|---|---|---|---|

| Luminous efficacy (lm/W) (range) | 10–17 lm/W | 65–75 lm/W | Cool white 60–96 lm/W Warm white 27–86 lm/W |

| Power used | 60W | 13W | 10–8.5W |

| Lifetime (hours) | 750–2,500 | 10,000 | 25,000–50,000 |

| Initial cost | $0.50 | $3.00 | $12.50 |

| Energy cost/year | $8.02 | $1.74 | $1.34 |

| Lumens (mean) | 800 | 800 | 800 |

| Colour temperature (K) | 2,700–2,800 | 2,700–6,500 | 2,700–7,000+ |

| Bulb life (years) at 3 hours/day | 1 | 10 | 15-25+ |

| CRI | 98–100 | 7–88 | 70–92 |

Choosing the correct LED light bulb

Lighting is very important in poultry facilities, as there are different lighting requirements depending on the type of poultry production and the growth stage of the flock. As a result, lighting can account for up to 50% of the annual electrical consumption. When choosing LED lighting for a poultry facility, consider the following:

- Determine the lighting requirements of the facility.

- Determine the minimum amount of light required at the working surface and purchase the correct LED bulb with the required lumen value. Table 2 provides suggested lighting levels for poultry.

| Type of poultry | Age (weeks) | Minimum light level (lux) | Photoperiod (hours/day) |

|---|---|---|---|

| Chicken broilers | 0–0.5 | 30–50 | 24 |

| Chicken broilers | 0.5–1.5 | 30–50 | 23 |

| Chicken broilers | 1.5–market | 5 | 18–20 |

| Chicken breeders | 0–3 | 30–50 | 14 |

| Chicken breeders | 4–20 | 30–50 | 8 |

| Chicken breeders | 20–64 | 30–50 | 15 |

| Chicken layers | 0–6 | 10–30 | 16 |

| Chicken layers | 6–18 | 5–10 | 8 |

| Chicken layers | 18–80 | 5–10 | 15 |

| Turkey grow outs | 0–2 | 30–50 | 24 |

| Turkey grow outs | 3–5 | 30–50 | 20 |

| Turkey grow outs | 6–9 | 30–50 | 18 |

| Turkey grow outs | 10–market | 30–50 | 16 |

| Turkey breeder hens | 0–5 | 20 | 24 |

| Turkey breeder hens | 5–8 | 20 | 8 |

| Turkey breeder hens | 8–22 | 20 | 8 |

| Turkey breeder hens | 22–30 | 20 | 8 |

| Turkey breeder hens | 30+ | 20 | 13–15 |

| Turkey breeder toms | 0–5 | 20 | 24 |

| Turkey breeder toms | 5–30 | 20 | 13–15 |

| Turkey breeder toms | 30+ | 0 | 13–15 |

Source: American Society of Agricultural and Biological Engineers (ASABE) Table 9 – Lighting guide for poultry production from Standard ASAE EP344.4 JAN2014 Lighting Systems for Agricultural Facilities.

Figures 5 and 6 show a comparison of the same LED bulb spaced at 3.6 metres (12 feet) and at 7.3 metres (24 feet) apart. Note that in Figure 6, the barn is much darker, and the lighting is not as uniform across the barn (there are shadow areas on the floor between bulbs). If a producer is trying to achieve uniform 30–50 lux at bird level, this may be difficult with the second layout and result in production problems.

Source: University of Georgia.

Source: University of Georgia.

Select the type of LED lamp to purchase

There are many different types of LED bulbs, and it is important to find the bulb that is best suited for use in a poultry facility. Verify with the manufacturer if the bulb has been tested or used in a poultry facility. Avoid LEDs with large fins or fans or any small place that may catch and hold dirt since dust and dirt will build up in these small areas and require frequent cleaning. Figures 7 and 8 show examples of dirty bulbs in a barn environment.

Smooth-sided LEDs are more ideal for a poultry facility as they are easier to clean (Figure 9).

If the facility previously used T8 or T5 fluorescent tubes, consider tube LEDs, which are available for T8 as Plug-and-Play, meaning the existing ballasts do not have to be changed (Figure 10).

The best result has been accomplished with the installation of new fixtures and dedicated LED drivers. The bulbs in Figures 7–10 were all tested in poultry facilities.

Source: National Poultry Technology Center, Auburn University.

Source: National Poultry Technology Center, Auburn University.

Source: National Poultry Technology Center, Auburn University.

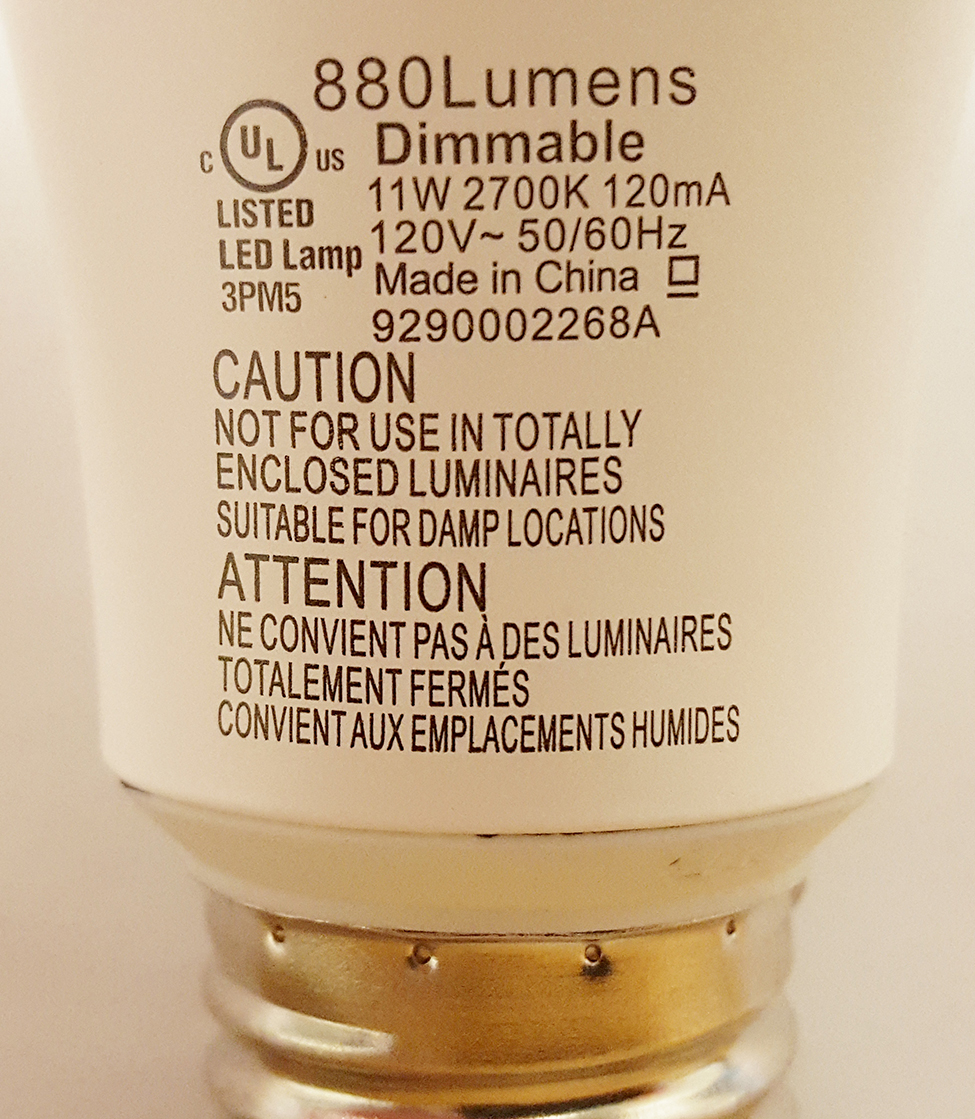

Confirm that the bulb is certified or tested

All bulbs and fixtures selected for use in barns must show a certification logo from either the Underwriters Laboratories Inc. (UL), Canadian Standards Association (CSA) or any other recognized certification mark approved by the Electrical Safety Authority (ESA). Certification means the bulbs and fixtures meet the safety standards and can be safely used in the tested normal environments.

Other voluntary lighting certifications include Design Lights Consortium (DLC) and the Energy Star Rating. DLC promotes quality, performance and energy efficiency in lighting. The Energy Star rating is given to products that meet the strict criteria of efficiency, quality and lifetime. Lamps that have been Energy Star– or DLC–approved contain a 5-year warranty. If they have not been approved, they may only have a 3-year warranty. DLC Premium is a higher-performance classification for luminaires and retrofit kits. Most power LEDs are also Reduction of Hazardous Substances (RoHS)–compliant. Figure 11 shows where to find this information on a light bulb.

Confirm the bulb is wet rated

Poultry facilities are generally cleaned and washed down between flocks for biosecurity reasons. When purchasing LED lights, it is important for the bulb to be both waterproof and strong enough to withstand pressure washing. Most LED bulbs will state that they are suitable for damp locations. If purchasing T8 Plug-and-Play LED tubes, it is essential to also purchase the appropriate lamp enclosure to keep moisture away from the tubes.

To determine the suitability of an enclosure, check the IP rating of the enclosure where the value is stated as IP(#),(#). The first number defines the intrusion protection of the fixture from no protection (0), protection from tools or wires (3) to dust tight (6). The second number is the moisture protection where no protection is 0, protection from low power water jets is 5 and protection from prolonged emersion of water is 8. For use in poultry facilities, the ideal or required enclosure rating is IP66 or better (dust tight, protection against strong water jets).

Determine if the lamp is dimmable

In poultry facilities, it is important to be able to dim the lights to control the light level in the barn during different growth stages and to ensure a smooth transition from dark to light and back to dark in order to keep the birds calm. Remember that dimming controls used with other lighting may not work properly with LED lights and may need to be replaced with LED drivers.

Ensure the bulb is the correct colour

LEDs, like other lighting types, are available in a variety of different colours or Kelvin as shown in Figure 12. The colours can range greatly, as shown in the Kelvin scale in Figure 13, from orange (2,000K) to blue (10,000K). University of Guelph researcher, Dr. Bédécarrats has been researching bird performance using different spectrum (coloured) light in the barn. Red/orange light is supposed to increase reproductive efficiency while blue/green light is supposed to be better for growth. One company has produced a bulb specifically for layers that emits light with a red/orange hue and another bulb specifically for broilers that emits light with a blue/green hue. The increased exposure of the birds to light in these specific Kelvin ranges has shown some positive results in the initial trials. The research projects are ongoing.

Modular design

To extend the life of the lighting system, buy fixtures that are modular in design to allow for future replacement and upgrades to LED light modules and drivers.

Surge/low/high voltage protection

Severe thunderstorms and voltage fluctuations can cause LED fixtures to fail. Ensure that drivers and LED lights have surge and voltage fluctuation protection.

Will the retrofit save money and energy?

Before taking on any project, calculate the projected energy savings to ensure the retrofit will save money and energy. Contact a local electrical utility to see if they have rebates and incentives available on the lighting technology. This will help decrease the cost of the project. Table 3 shows a cost comparison for retrofitting a barn from 60W incandescent bulbs to 10W LED or to 13W CFL bulbs. Table 4 shows a cost comparison for retrofitting a barn with 60W incandescent bulbs to 18W tube LEDs or T8 35W fluorescent lighting. The comparison is based on the following assumptions:

- lights run for an average of 18 hours/day for a 42-day lighting cycle with 7 days of full wattage and 35 days at half wattage

- 6.5 cycles/year

- average annual usage: approximately 5000 hours

- the cost of electricity with delivery charge is 17 cents/kWh

- estimated equipment costs use 2017 prices

| Incandescent 60W (dimmed to 30W) | LED 10W (dimmed to 5W) | CFL 13W (dimmed to 7.5W) | |

|---|---|---|---|

| Average rated life (hours) | 1,000 | 30,000 | 15,000 |

| Number of bulbs | 54 | 54 | 54 |

| Typical cost per bulb | $1 | $18 | $10 |

| Total cost of bulbs | $54 | $970 | $540 |

| Annual cost of electricity | $1,600 | $260 | $380 |

| Bulb replacement rate (times) | 35 | 2 | 3 |

| Total bulbs cost | $1,890 | $1,944 | $1,620 |

| Total electricity cost | $11,200 | $1,820 | $2,660 |

| Total cost, end of year 7 | $13,090 | $3,764 | $4,280 |

| Savings | N/A | $9,326 | $8,810 |

Note: Total cost, end of year 7 includes the initial cost of installation and the cost of replacing the bulbs after they reach the end of life (no labour cost included). The total cost of bulbs is included 35 times for incandescent, 2 times for LED and 3 times for CFL lighting. Cost has been rounded off. No labour cost was included.

Note: Estimated costs are subject to change and are approximated to demonstrate potential savings. Consult a designer to check lighting needs for the project and to confirm project costs.

For the incandescent lighting system in Table 3, only the cost of the bulbs was considered at $1/bulb, with annual energy cost of $1,600. If the incandescent lighting were replaced with LED 10W bulbs, only the cost of the bulbs is used as they can be screwed into existing sockets (cost $970 to purchase and $260 to operate annually). The 13W CFL system would cost $540 to install, but cost more, at $380 annually, to operate.

Over a 7-year period, the LED system saves $9,326 and a compact fluorescent system saves $8,810.

| Incandescent 60W (dimmed to 30W) | TLED 17W (dimmed to 9W) | T8 32W (dimmed to 16W) | |

|---|---|---|---|

| Average rated life (hours) | 1,000 | 36,000 | 40,000 |

| Number of bulbs/fixtures in barn | 54 | 27 | 27 |

| Typical cost per bulb | $1 | $200 | $174 |

| Annual cost of electricity | $1,600 | $500 | $800 |

| Bulb/fixture replacement rate (times) | 35 | 1 (original) | 1 (original) |

| Total bulb/fixture cost | $1,890 | $5,400 | $4,700 |

| Total electricity cost | $11,200 | $3,500 | $5,600 |

| Total cost, end of year 7 | $13,090 | $8,900 | $10,300 |

| Savings | N/A | $4,190 | $2,790 |

Note: Incandescent is only the cost of the bulb. Four-foot TLED tubes and T8 includes the cost for the entire water tight fixture and the 2 tubes per fixture. Cost has been rounded off. No labour cost was included.

If the incandescent lighting were replaced with four-foot TLED tubes, at $200 per fixture (2 tubes/fixture), total cost would be $5,400, with an annual energy cost of $500. As a result, by year 7, there would be a savings of $4,190. In comparison, T8 would cost $4,700 for the fixture with 2 tubes and an annual energy cost of $800. As a result, the savings over 7 years would be $2,790.

Lighting design program

The company supplying the barn lighting system should run a lighting program to ensure light levels meet the need and provide a copy of the report to the producer. Any lighting design should use the ability of LED systems to be remotely controlled for dimming, colour turning and operation run times. One way to get longer life and full light output from an LED system is to install a higher lumen output system and dim it down to required lighting levels. As the LED light output decreases, turn off the dimmers and let the bulbs maintain full light output.

Key points to consider when selecting LED lights for barn lighting:

- Use a lighting design program.

- Ensure surge protection (low/high voltage protection).

- Choose fixtures that are CSA- and UL-approved.

- Choose an Energy Star or DLC product.

- Look for CRI >85.

- Select sealing standards for a dust/waterproof fixture (equal or great than IP66 and IP68 for drivers).

- Choose a modular design for LED and drivers.

- Select LED drivers for dimming lights.

- Purchase LEDs with a warranty of at least 5 years.

- Purchase LED drivers with a warranty.

- Ensure light fixtures (luminaire) have a 10-year warranty.

- Use TLED Retro kits (existing ballasts) with an electronic instant start ballast.

- Check with the local electrical utility for energy-saving incentives.

Conclusion

Lighting is a major expense for poultry farms, as it adds up to 50% of the annual energy consumption. LEDs can reduce the energy usage as they consume 76–83% less energy than comparable incandescent or halogen bulbs. Remember, higher wattage does not necessarily mean greater brightness, as a 10W LED has a lumen output comparable to a 60W incandescent (consult the lumen value for brightness). Since LEDs are a relatively new and developing technology, it is important to research prior to purchasing LED bulbs. Make sure the bulbs contain a safety rating from either UL, CSA or have a recognized certification mark. The initial cost of LEDs may be high but with a short payback time due to energy savings and possible rebates and incentives offered by some local utilities, the long-term savings are significant. Switching to LEDs can result in overall increased revenue because of the lower energy costs.

Author credits

This fact sheet was written by Steve Clarke, P. Eng., energy and crop systems (retired), Ministry of Agriculture, Food and Agribusiness (OMAFA) and Dan Ward, P. Eng., poultry and other livestock housing and equipment, OMAFA.