Thinning of tree fruit

Learn the importance of and different options for thinning fruit trees to increase fruit size.

Introduction

Thinning of tree fruit is a key step to annual cropping and increased fruit size. This is increasingly important to make your investment profitable in new plantings, especially trellised, high density apples and pears. In all orchards, proper thinning will: improve average fruit size, finish and colour; create more uniformity in the crop; avoid over cropping; encourage return bloom and annual bearing of apples and pears; reduce limb breakage; and reduce the probability of pest damage as some pests are more likely to damage clustered apples and pears.

Thinning can be achieved through pruning, chemical thinning and hand thinning. The first step to thinning is through pruning when many fruit buds or blossoms can be removed. At the fruitlet stage, chemical thinners can be used to remove fruitlets in apples and pears. Once June drop has occurred, which is the stage where trees will abort fruit naturally, hand thinning is done on all tree fruit.

Early thinning is important. For apples and pears, thinning near bloom or shortly afterward will increase average fruit size and maximize return bloom the next year. For peaches and plums, thinning at early fruit development or even at blossom time is the most beneficial but it is more risky since it is difficult to get a true assessment of crop load before June drop occurs. Late-summer thinning may improve fruit size and colour, and prevent limb breakage, but will not affect return bloom.

Grower experience is the best guide to thinning decisions, so it is important to document the previous thinning history including rates, conditions at time of application, and results. Other factors include: cultivars involved, fruit sizes required, strength of bloom, bee activity, weather conditions during pollination and following fruit set.

Thinning by pruning

For many fruit crops pruning can be an effective tool for crop load management. Pruning is used to maintain a balance between vegetative growth, flower production and fruit production. Fruit can be removed from fruit trees by aggressively pruning excess or poor-quality fruiting wood in late winter or early spring (apple, pear, cherry) or during bloom (peach, nectarine and plum). Pruning plays an important role in ensuring good light penetration, and removing poor quality wood that would result in smaller sized fruit.

Hand thinning

Hand thinning can be the only mechanism of thinning fruit in peaches, nectarines, plums and pears. Hand thinning is often used to supplement chemical thinning in apples and pears or blossom thinning in peaches. Hand thinning immature trees is less risky than chemical thinning. Hand thinning should start near the end of June drop (about mid-June). This will help to determine if fruit will abort naturally. Thinning at early fruit development has more benefits than late thinning.

Chemical thinning

Chemical thinning is used in apple and pear orchards to remove fruit at an early timing, at petal fall to 14 mm fruitlet size. Early thinning will have more of a positive impact on average fruit size and return bloom than hand thinning after June drop. This practice is very common in apple orchards. In pears, the use is limited in pears to one product and results have been inconsistent, therefore hand thinning is the main method to thinning. There are no chemicals registered for thinning peaches, nectarines, plums and cherries.

Peaches

Peach thinning is an essential orchard management practice but is time consuming and expensive. Thinning techniques are used before, during and after bloom to reduce peach crop load. Early ripening varieties and varieties that produce smaller fruit should be thinned first to provide the best opportunity for fruit sizing.

Thinning by pruning

Pruning in peaches generally occurs around bloom to reduce the risk of frost injury. Fruit can be removed from fruit trees by aggressively pruning excess or poor-quality fruiting wood in the dormant to pre-bloom window. Eliminating limbs in the low centre of the tree where poor light and insufficient foliage produce smaller fruit. Remove all fruiting shoots shorter than 8 inches in length, as these limbs tend to produce smaller fruit. Remove the ends of fruiting limbs longer than 12 inches.

Blossom thinning

Blossom thinning reduces labour costs, and results in larger average fruit size per tree and earlier ripening. However, blossom thinning is more risky since it is difficult to get a true assessment of crop load before June drop occurs. Several mechanical aids have been used to remove excess blossoms from peach trees. Ropes can be dragged across canopies, blossoms rubbed with a gloved hand or brush and high water pressure systems can be used. The Darwin mechanical thinner, uses nylon cords fixed to a rotating shaft mounted on a front-end loader to remove blossoms. Tractor speed, rpm of nylon cords, number of cords used, tree shape and timing can all affect the number of blossoms removed. Follow-up hand thinning is necessary to ensure good fruit size. Chemical blossom thinners are not registered for use on peaches/nectarines in Canada.

Hand thinning

Thinning in peach orchards is most commonly completed by hand. Large quantities of fruit can be removed quickly with physical aids, such as a child's plastic bat, a rubber hose mounted on a bamboo pole or broom handle, or a plastic rake manufactured for this purpose. Portable hydraulic or pneumatic limb shakers are available. Hand thinning provides better control and causes less limb damage than limb shaking and striking.

Shortly after bloom, crop load estimates can be conducted to determine the fruit thinning requirements. Look at 10 to 20 typical limbs in each block to provide a rough estimate of the thinning needed. Keep in mind that mild conditions following bloom increase cell division numbers and the potential for fruit size. High rainfall within a few weeks of harvest, will also increase final fruit size.

When thinning, consider fruit load as well as fruit spacing. Optimum fruit load depends on cultivar, tree vigour, tree age and health, and orchard management practices such as tree spacing, irrigation and pruning. Peach growers tend to space the fruit 15-20 cm apart. However, distance between fruit is less critical as long as clusters are broken up and fruit is separated. Tree crop load (kg per tree or number of fruit per tree) is a more important consideration. As an example, a yield of 18-27 tonnes/ha (8-12 tons/acre) in an orchard with a tree density of 490 trees per ha (200 trees per acre) requires about 200-300 fruit per tree, if you assume an average fruit size of 4-7 fruit per kg (2-3 fruit per lb). With current emphasis on increased fruit size for better marketability and trends towards higher tree densities, fruit loads of 175-200 fruit per tree may be more ideal, at least for cultivars that normally produce large fruit.

Start hand thinning near the end of June drop (about mid-June) when it can be determined which fruits will abort naturally. Thinning at early fruit development is more beneficial than late thinning. Always thin early ripening cultivars in order to obtain good fruit size. In some years, a follow-up hand thinning may be necessary. When thinning with a crew, consider thinning and marking several trees with coloured ribbons in advance to serve as examples. Two or three peaches can be left clustered if there is enough additional limb space to support their growth. Keep the largest fruit on a limb, even if they are clustered.

Follow the initial thinning with touch-up thinning a few days later to assure that fruit numbers per tree produce good-sized fruit for the cultivar and orchard condition. Ensure clusters of fruit are broken up and fruit separated. If the set is spotty on the tree, more fruit may be left on the heavy-set branches.

Cultivars vary in their thinning requirements. Earlier ripening cultivars have a high percentage of fruit with split pits. Some growers thin early cultivars twice: thinning lightly to remove some crop load, then a second time to selectively remove split-pit fruit. Harrow Diamond is the earliest-ripening commercial cultivar that has few split-pit fruits under normal conditions. This cultivar must be well-thinned to obtain suitable size.

When fruit set is heavy, there is little likelihood of over-thinning early cultivars. Hard-to-size cultivars such as Redhaven require heavier thinning than easier-to-size types like Vivid and Loring. As a rule of thumb, late-maturing cultivars with a good, uniform set are thinned to 10-13 cm between fruit. Thin each cultivar according to its individual requirements.

Irrigation is recommended to enhance fruit size, especially in long periods of dry conditions. Orchards without irrigation may, in some years, need a second thinning during July to attain marketable fruit size.

Plums

In recent years, the market demand for larger fruit has placed more importance on fruit thinning, pruning and irrigation. Japanese plums require systematic fruit thinning, otherwise, fruit size will be small and biennial cropping will ensue. European plums grown for fresh market also require thinning in the years of heavy fruit set. Inadequate fruit thinning results in production of under-sized plums and, at times, fruit ripening on overloaded trees will be delayed. Start thinning near the end of June drop in early to mid-June when it can be determined which fruit will abort naturally. Thinning at early fruit development has more benefits than late thinning. Chemical thinners do not work on plums, so hand thinning is necessary.

Fruit-size thinning is preferred to conventional-space thinning. Size thinning selectively removes small, weak, blemished or diseased fruit regardless of spacing of the fruits on the branches. The end result should be proper sizing of the fruit remaining on the tree.

Pears

The objective of thinning pears is to reduce the number of fruit per spur, and to adequately space fruit. The thinning of fruit is particularly beneficial during seasons of heavy fruit set or inadequate moisture.

The amount of thinning required depends on the age of the tree, the cultivar and the crop load. Traditionally young pear trees are defruited in the first 4 years of establishment to ensure adequate tree health and growth. In high-density pear orchards, fruit is completely removed in the first year, and approximately 3-4 fruit are left per tree in the second year. As the trees mature, an increasing number of fruit are left on the tree.

On mature trees, cultivars such as Bartlett and Bosc can set fruit in clusters of 3-5 fruit per spur. If overall crop load is heavy, reduce the number of fruit per cluster to 1 or 2. Some orchards have a tendency to be light in alternate years. In those orchards, spurs can carry more fruit when there are resting spurs on the tree. If the set on the tree is not excessive, 2-3 fruit per cluster will reach a satisfactory size without fruit thinning.

Chemical thinning

The response of pears to chemical thinners, under Ontario conditions, has been inconsistent between years. As a result, hand thinning alone is still most commonly used. However, increased labour costs and demand for larger-sized fruits have resulted in increased use of chemical thinners.

Try chemical thinning on a small scale in pear orchards until the response can be evaluated with respect to tree vigour, cultivar and fruit size. Some pear blocks can struggle to set adequate levels of fruit. It is best to assess pear set before applying chemical thinners, especially when conditions have been cool and/or wet during bloom.

As with all plant growth regulators, complete coverage is essential for good results. Chemical thinners will act only where deposited.

Use 6-BA (6-benzylaminopurine) Cilis Plus or 6-BA (6-benzyladenine) MaxCel for chemical thinning. Apply Cilis Plus or MaxCel at a rate of 50-200 ppm when fruitlets are 5-10 mm in diameter. For specific application instructions, consult the product label. See notes on MaxCel or Cilis Plus (6-BA) under Apples. Note that carbaryl (Sevin XLR) should not be used on pears as it can cause misshapen fruit. Chemical thinning should be followed up with hand thinning where needed.

The effectiveness of chemical thinners is highly dependent on weather conditions, spray coverage, timing and pollination, please see Factors influencing response to thinning agents under apples.

For more information on chemical thinning, see Steps in chemical thinning, factors influencing response to thinning and Thinning under challenging conditionsunder Apples.

Cultivar sensitivity

For pears cultivars, Cold Snap™, Bartlett and Bosc are considered to be moderate to difficult to thin, while Anjou is considerably easier to thin.

Hand thinning

Reduce the crop to 1 fruit per spur, spaced 12-15 cm apart during normal years. It is best to selectively remove smallest fruitlets when thinning.

Other tips on improving tree health and fruit size

Consider spur pruning on older trees, especially for cultivars on dwarfing rootstock. These pear trees can "runt out" if allowed to bear too heavily in years 3-6. The combination of proper fruit thinning and irrigation has the most positive results on pear fruit size.

To obtain large-sized fruit, irrigate after fruit set, during extended dry periods in midsummer and a few weeks before harvest.

Apples

The objective of thinning apples is to reduce clusters to one or two fruitlets on most cultivars, preferably the king bloom fruitlet, and to adequately space fruit to every other bearing spur. An additional benefit of thinning is reduced probability of pest damage. Some pests are more likely to damage clustered fruit. As well, a well-thinned crop is more efficient to harvest, which reduces labour costs per bin.

Fruit size benefits of thinning apples

When comparing a well-thinned apple tree to a tree that is insufficiently thinned, the following aspects become obvious:

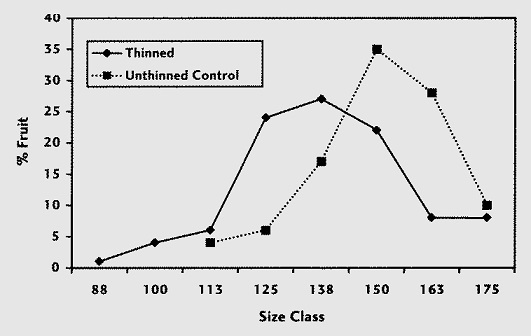

- Fruit size distribution within the canopy of both trees follows a normal distribution pattern. See Figure 1. Thinning effects on apple fruit size distribution.

- Other factors being equal, the average fruit size from the thinned tree is greater than that of an unthinned tree.

While adequate thinning typically reduces yield, the value of the thinned crop more than compensates for any loss in yield provided the tree is not over-thinned. In other words, where the fruit volume of thinned and unthinned trees is similar, the thinned tree has fewer apples but they are of greater size and higher value. See Table 1. Effect of Apple Fruit Size on Tray and Bin Requirement, for a comparison of fruit numbers of different size classes required to fill a standard apple bin. See Table 2. Effect of Fruit Size in Relation to Crop Load to determine how much thinning is required.

Figure 1. Thinning effects on apple fruit size distribution

This figure shows how the distribution of fruit size classes is similar on thinned and unthinned Empire trees. Note that thinning pushes the size distribution to the larger size classes. There was less than 10% difference in total yield between the two treatments.

Minimum Fruit Size | Tray size | Number of Apples per bin2 | ||

|---|---|---|---|---|

wt (g)1 | mm | inch | ||

102 | 57 | 2 1/4 | 196 | 3,920 |

114 | 60 | 2 3/8 | 175 | 3,500 |

123 | 64 | 2 1/2 | 163 | 3,260 |

133 | 67 | 2 5/8 | 150 | 3,000 |

145 | 70 | 2 3/4 | 138 | 2,760 |

160 | 73 | 2 7/8 | 125 | 2,500 |

177 | 76 | 3 | 113 | 2,260 |

200 | 79 | 3 1/8 | 100 | 2,000 |

227 | 83 | 3 1/4 | 88 | 1,760 |

250 | 85 | 3 3/8 | 80 | 1,600 |

278 | 89 | 3 1/2 | 72 | 1,440 |

313 | 92 | 3 5/8 | 64 | 1,280 |

357 | 95 | 3 3/4 | 56 | 1,120 |

417 | 98 | 3 7/8 | 48 | 960 |

1 These values are approximate as fruit of the same diameter can differ in weight.

2 20-bushel bin capacity.

272 | 500 | 1,000 | 1,500 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

mm | inch | 400 | 600 | 500 | 750 | 750 | 1,250 | 1,000 | 1,500 | ||

Minimum Size | Number of apples required per tree for given tree density, desired yield and fruit size | ||||||||||

Tree density (trees per acre) | |||||||||||

Projected yield (bu/ac) | |||||||||||

57 | 2 1/4 | 320 | 480 | 218 | 327 | 163 | 272 | 145 | 218 | ||

60 | 2 3/8 | 286 | 429 | 194 | 292 | 146 | 243 | 130 | 194 | ||

64 | 2 1/2 | 266 | 400 | 181 | 272 | 136 | 226 | 121 | 181 | ||

67 | 2 5/8 | 245 | 368 | 167 | 250 | 125 | 208 | 111 | 167 | ||

70 | 2 3/4 | 225 | 338 | 153 | 230 | 115 | 192 | 102 | 153 | ||

73 | 2 7/8 | 204 | 306 | 139 | 208 | 104 | 174 | 93 | 139 | ||

76 | 3 | 185 | 277 | 126 | 188 | 94 | 157 | 83 | 126 | ||

79 | 3 1/8 | 163 | 245 | 111 | 167 | 83 | 139 | 74 | 111 | ||

83 | 3 1/4 | 144 | 216 | 98 | 147 | 73 | 122 | 65 | 98 | ||

85 | 3 3/8 | 131 | 196 | 89 | 133 | 67 | 111 | 60 | 89 | ||

89 | 3 1/2 | 118 | 176 | 80 | 120 | 60 | 100 | 53 | 80 | ||

92 | 3 5/8 | 105 | 157 | 71 | 107 | 53 | 89 | 47 | 71 | ||

95 | 3 3/4 | 92 | 137 | 62 | 93 | 47 | 78 | 41 | 62 | ||

98 | 3 7/8 | 78 | 118 | 53 | 80 | 40 | 67 | 36 | 53 | ||

Steps in chemical thinning

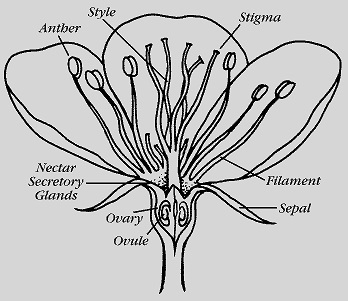

Is thinning needed? Determine if and how much thinning is required by assessing potential crop load. Look carefully at the developing fruitlets, especially the sepals (or calyx leaves). Sepals on unpollinated blooms tend to stay open or bend back. Successful pollination and fruit set result in sepal movement and closure. See Factors influencing response to thinning agents.

Which product(s) should be used? This depends on the cultivar and stage of crop development. See Chemicals available for thinning apples and Application rates for chemical thinners.

What water volume is needed? High water volumes that wet the foliage to the point of runoff are recommended for chemical thinners, because the chemicals need to contact the fruitlets and spur leaves. The average tree at a density of 720 trees per ha may require more than 2 L of spray per tree to thoroughly wet the foliage at the time of the thinning. As the tree size becomes smaller and the number of trees per ha increases, the volume of canopy that must be sprayed may become less. Calibrate the sprayer and water volumes on small groups of trees to determine just how much water is required to thoroughly wet individual trees. See Sprayers101 for articles on adjusting airblast settings.

When should thinners be applied? Thinners should be applied when fruitlets reach the optimum size for thinning and when weather conditions will allow the maximum effectiveness (warm temperatures and calm winds are best). Measure 50-60 fruitlets of each cultivar. Select the 2 largest developing fruitlets (king bloom and next) from each of 25-30 randomly selected clusters. Measure the greatest diameter of each using Vernier or digital calipers, or a thinning template and determine the average for the sample. The optimum fruitlet size for chemical thinners varies between cultivars (see Table 6. Optimum Apple Fruitlet Size for Chemical Thinning).

When should results be assessed? It will take 7-10 days to see visual effects of the thinner. Brush your hand gently across the clusters to see how many will drop. Fruitlets that will drop will stop growing, and their stems turn yellow. To decide if a second thinner is needed, the Fruitlet Growth Model can help predict which fruitlets will abscise. For more information see Fruitlet growth model.

Be sure to leave a few trees unsprayed in each bloom, and assess them to compare the natural drop to the effects of your thinners.

Fruitlet growth model

Developed by Dr. Duane Greene, University of Massachusetts, this model helps to predict if fruit will abscise or persist through 'June drop' based on the assumption that the fruitlets that will persist will grow faster than the abscising fruit. Based on the growth rate of 20 of the fastest growing fruit, the fruitlets that will persist will have a growth rate greater than 50% of the growth rate of the fastest growing fruitlets. If needed, the second application should be applied before apple fruitlets exceed 10-14 mm.

Steps

- Select 5 trees per block

- Count the number of flower clusters per tree

- Mark and number 15 clusters per tree and number each fruitlet of each cluster with a permanent marker.

- Determine the % target crop load based on # of apples desired/ tree and the flower cluster count

- Measure fruitlet diameter, with calipers, 3-4 days after application and 4-5 days after the first measurement to determine the growth rate. 100-130 growing degrees days, base 4.4°C, should accumulate between the time of application and the second measurement.

Chemicals available for thinning apples

MAXCEL or CILIS PLUS

Active ingredient: 1.9% 6-benzyladenine (6-BA)

Type of thinner: A growth regulator containing a cytokinin (6-BA) that promotes cell division.

How it works: Used for both fruit thinning and improving fruit size. Fruit size potential is increased due to increased cell division shortly after flowering in the early stages of fruit growth and development.

Rate: To increase fruit size, make 2-4 applications at 10-50 ppm, beginning at petal fall and repeating every 3-10 days. Some easy-to-thin cultivars may also be thinned. To thin fruit, apply at 75-200 ppm. See Table 3. Suggested Rates of MaxCel or Cilis Plus to Use With or Without Sevin.

Application: Dilute MaxCel or Cilis Plus in 500-2,000 L of spray solution per ha. Uniform and thorough coverage is essential. Use enough water to wet the foliage just to the point of runoff. See Table 4. Tank Concentration of MaxCel or Cilis Plus.

Cultivar notes: Recommended for Empire, McIntosh, Idared, Gala and others. Not effective on all cultivars. See Table 5. Suggested Rates for Chemical Thinning of Mature Apple Trees.

Timing: For thinning, these products are most effective when fruitlets are 5-15 mm in diameter. To improve fruit size, begin applications at petal fall.

Repeat applications: Apply a maximum of 2 sprays per season for thinning, or 4 applications to improve fruit size.

Optimum conditions: Best results are obtained when temperatures greater than 20°C occur during and after application. Slow drying conditions are preferred (e.g., early morning).

Precautions: Preharvest interval is 28 days. Do not apply MaxCel or Cilis Plus in combination with NAA (naphthaleneacetic acid) either as a tank-mix or separate sprays during the same growing season. These combinations may result in pygmy fruit in Delicious and Fuji.

NAA (1-naphthaleneacetic acid)

Product name: FRUITONE-L

Active ingredient: NAA (naphthaleneacetic acid)

Type of thinner: A hormone-type thinner.

How it works: Absorbed primarily through the leaves from the solution. Mostly absorbed from original spray solution, not from re-wetting, and has a short life due to breakdown by sunlight. NAA affects auxin activity, and interferes with photosynthesis and proper fruit development. Affected fruitlets usually drop within 10-14 days. NAA can result in leaf flagging (wilting) but these leaves recover in a few days.

Rate: 1.2-9.7 ppm. See Table 5. Suggested Rates for Chemical Thinning of Mature Apple Trees.

Timing: Application window is from petal fall (3-7 mm fruit size) until early fruit set (8-10mm fruit size) or 12 days after petal fall. NAA is most effective when the king fruitlets are 5-10 mm. NAA applied too soon, in the bloom to petal fall period, can result in excessive thinning of Empire.

Application: Use larger volumes of water under slow drying conditions. NAA is considered to be rainfast after 2-3 hours.

Mixing: May be mixed with carbaryl (Sevin).

Optimum conditions: Warm, dull, slow drying conditions are preferred to maximize absorption of NAA. Morning is the preferred time when trees are damp, drying is slow and temperature is on the rise. Once the material is absorbed, the tree has the day to respond to the thinner. It is best to apply between 21°C and 24°C. This product should not be applied at temperatures below 15.6°C or above 26.7°C.

Precautions: Do not apply during the same growing season as MaxCel or Cilis Plus or pygmy fruit may result.

Carbaryl (Sevin XLR)

Product name: SEVIN XLR

Active ingredient: Carbaryl

Type of thinner: An insecticide that also causes fruit thinning after petal fall.How it works: Carbaryl is absorbed primarily through the fruit, not the foliage. The presence of carbaryl in the vascular system of the fruitlet interferes with biochemical processes. Certain important fruit growth processes cease and the fruitlet drops. This fruitlet drop usually starts 5-10 days after application.

Rate: 0.5-2 L product per 1,000 L water. See Table 5. Suggested Rates for Chemical Thinning of Mature Apple Trees. Thinning with Sevin increases as concentrations rise up to 1 kg of active carbaryl (2 L of Sevin XLR) per 1,000 L of water). There may be little or no increase in thinning with higher concentrations. Do not exceed 1.5 kg a.i./ha/ year (3.22 L of product/ha/ year) for high-density, trellised orchards or 1 kg a.i./ha/year (2.15 L of product/ ha/ year) for low- to medium-density orchards. Do not exceed 2 applications/ year and allow a minimum spray interval of 4 days.

Note: Sevin XLR does not provide additional thinning effects when rain or dews cause re-wetting (as was common with Sevin 50 W).

Note: Because carbaryl is relatively insoluble in water and quickly saturates the spray solution, exceeding this rate of 2 L product per 1,000 L water will not increase thinning. Only the carbaryl in true solution will cause thinning.

Timing: Preferred timing is 7-12 days after petal fall (7 days when warm and 12 days when cool). Can be applied up to 21 days after petal fall if conditions are less than ideal.

Application: Apply as a separate dilute spray to thoroughly cover the trees and developing fruitlets. A 3-3.5 m tall, semi-dwarf tree on M.26 may require more than 2 L of spray to thoroughly wet the foliage.

Mixing: May be tank-mixed with NAA, MaxCel or Cilis Plus.

Optimum conditions: Best applied at temperatures between 21-24°C, under slow drying conditions.

Precautions: Do not apply MaxCel or Cilis Plus in combination with the hormone thinner, NAA (naphthaleneacetic acid), either as a tank-mix or separate sprays during the same growing season. Doing so may result in pygmy fruit. Chemical-resistant gloves are recommended when hand thinning-following an application of Sevin XLR.

Bee toxicity: When Sevin is used for fruit thinning, extensive bee kills can occur if weeds or legumes are blooming in the ground cover. To minimize bee kills, remove bees from the orchard prior to treatment. Do not spray when the wind will carry Sevin to adjacent weedy or crop areas in bloom. Advise local beekeepers of your spray activity. Sevin can be harsh on beneficial insects and mite predators. Remove bees from orchard and surrounding fields before applying Sevin as it is very toxic to bees.

Carbaryl (Sevin XLR) + NAA

This combination has been used successfully on hard-to-thin cultivars such as Paulared, Golden Delicious, Fuji and Gala strains. Use a constant rate of 1 L Sevin XLR (product) per 1,000 L of water with varying rates of NAA from 3-15 ppm. Apply 7-12 days after petal fall (7 days if warm, 12 days if cool). Since NAA only has one chance to work, use high water volumes.

Sevin XLR + MaxCel or Cilis Plus

Combination sprays of Sevin and 6-BA are required for difficult-to-thin cultivars or for situations where aggressive thinning is required to decrease crop load to improve final fruit size. Apply 7-12 days after petal fall (7 days if warm, 12 days if cool).

Calculating parts per million (ppm) : 1 ppm = 1 g active ingredient per 1,000 L of spray solution

Application rates for chemical thinners

Application rates of Chemical thinners vary depending on the product used, the desired response (size enhancement or severity of thinning) and the cultivar. For information on the suggested rates of chemical thinners refer to Table 3. Suggested Rates of MaxCel or Cilis Plus to Use with or without Sevin XLR, Table 4. Tank Concentration of MaxCel or Cilis Plus and Table 5. Suggested Rates for Chemical Thinning of Mature Apple Trees.

Desired response1 | Concentration of 6-BA (ppm)2 | Concentration of carbaryl (ppm)2 | Number of applications | MaxCel (L/1,000 L water/ha) | Cilis Plus (L/1,000 L water/ha) | Amount of Sevin XLR (L/1,000 L water/ha) |

|---|---|---|---|---|---|---|

| Enhance size only3,4 | 10-50 | - | 2 to 4 | 0.5-2.65 | 0.5-2.5 | - |

| Mild thinning and sizing | 50-75 | - | 1 to 2 | 2.65-3.95 | 2.5-3.75 | - |

| Moderate thinning and sizing | 75-100 | - | 1 to 2 | 3.95-5.3 | 3.75-5.05 | - |

50-75 | 500 | 1 to 2 | 2.65-3.95 | 2.5-3.75 | 1 | |

| Aggressive thinning and sizing | 100-150 | - | 1 to 2 | 5.3-7.95 | 5.05-7.55 | - |

75-100 | 500-1,000 | 1 to 2 | 3.95-5.3 | 3.75-5.05 | 1-2 | |

| Very aggressive thinning and sizing | 150-200 | - | 1 to 2 | 7.95-10.65 | 7.55-10.1 | - |

100-125 | 1,000 | 1 to 2 | 5.3-6.6 | 5.05-6.3 | 2 |

- = Information is not available.

1There are several factors that influence the chemical thinning outcome. Rates are generally chosen on the degree of cultivar sensitivity to chemical thinners. See Cultivar notes for further information on cultivar sensitivity to chemical thinners.

2 1 ppm is equivalent to 1 mg/L.

3 Mild thinning may occur under some conditions (weak trees, young trees, sensitive cultivars, and environmental conditions that favour the thinning response).

4 While 6-BA has the potential to increase cell division and enhance fruit size beyond the thinning (crop load) effect alone, this is not observed in all years because the response can be affected by spray concentration, coverage, cultivar, tree health, time of application, tree stress, and environmental conditions during and following spray application.

Spray volume required (litres/ha) | Rate of MaxCel - grams 6-BA/hectare | ||||||

|---|---|---|---|---|---|---|---|

10 | 26 | 50 | 76 | 100 | 200 | 446 | |

Litres of MaxCel per hectare | |||||||

0.5 | 1.4 | 2.6 | 4 | 5.3 | 10.5 | 23.5 | |

200 | 50 | 130 | 250 | 380 | 500 | 1,000 | 2,230 |

300 | 33* | 90 | 165 | 255 | 335 | 665 | 1,490 |

400 | 25* | 65 | 125 | 190 | 250 | 500 | 1,115 |

500 | 20* | 50 | 100 | 150 | 200 | 400 | 890 |

600 | 17* | 45* | 80 | 125 | 170 | 335 | 745 |

700 | 14* | 38* | 70 | 110 | 145 | 285 | 640 |

800 | 13* | 33* | 60 | 95 | 125 | 250 | 560 |

900 | 11* | 29* | 55 | 85 | 110 | 220 | 495 |

1,000 | 10* | 26* | 50 | 75 | 100 | 200 | 445 |

1,500 | 7* | 17* | 33* | 50 | 65 | 135 | 300 |

2,000 | 5* | 13* | 25* | 38* | 50 | 100 | 225 |

* (shaded area) = Concentrations of 6-BA in shaded area are not effective (for either sizing or thinning).

Spray volume required (litres/ha) | Rate of Cilis Plus - grams 6-BA/hectare | ||||||

|---|---|---|---|---|---|---|---|

10 | 26 | 50 | 76 | 100 | 200 | 446 | |

litres of Cilis Plus per hectare | |||||||

0.5 | 1.3 | 2.5 | 3.8 | 5 | 10 | 22.3 | |

200 | 50 | 130 | 250 | 380 | 500 | 1,000 | 2,230 |

300 | 33* | 90 | 165 | 255 | 335 | 665 | 1,490 |

400 | 25* | 65 | 125 | 190 | 250 | 500 | 1,115 |

500 | 20* | 50 | 100 | 150 | 200 | 400 | 890 |

600 | 17* | 45* | 80 | 125 | 170 | 335 | 745 |

700 | 14* | 38* | 70 | 110 | 145 | 285 | 640 |

800 | 13* | 33* | 60 | 95 | 125 | 250 | 560 |

900 | 11* | 29* | 55 | 85 | 110 | 220 | 495 |

1,000 | 10* | 26* | 50 | 75 | 100 | 200 | 445 |

1,500 | 7* | 17* | 33* | 50 | 65 | 135 | 300 |

2,000 | 5* | 13* | 25* | 38* | 50 | 100 | 225 |

* (shaded area) = Concentrations of 6-BA in shaded area are not effective (for either sizing or thinning).

| Cultivar | Sevin XLR (L/1,000 L water)2 | Fruitone (NAA) (ppm)3 | Sevin XLR (L/1,000L water) + Fruitone (NAA) (ppm)2,3 | MaxCel or Cilis Plus (g BA/ha)4 | Sevin XLR (L/1,000 L water)2,3 + MaxCel or Cilis Plus (g BA/ha)4 |

|---|---|---|---|---|---|

| Ambrosia | 1-1.5 | - | - | 50 | - |

| Aurora Garden Gala™ | 1-1.5 | - | - | 75 | 1+50 |

| Braeburn | - | 1.2-7.3 | - | - | - |

| Cameo | 1 | 2.4-9.7 | - | - | - |

| Cortland | - | 1.2-7.3 | 1-2+2.5-5 | - | - |

| Creston | 0.5-1 | - | - | - | - |

| Crispin/Mutsu | 0.5-1.5 | 2.4-9.7 | - | - | - |

| Empire | 1-1.5 | 2.4-9.7 | 1+2.5-4 | 50-100 | 1+50 |

| Enterprise | 1-1.5 | - | - | - | - |

| Fuji | - | - | 1-1.5+10-12 | 100-150 | 1-2+50-75 |

| Gala | - | 2.4-9.7 | 1+5-10 | 75-100 | 1-2+50 |

| Gingergold | 1-1.5 | 2.4-9.7 | 1+2.5-5 | 75 | 1+50 |

| Golden Delicious, Wealthy | 1-2 | 3.6-9.7 | 1+5-10 | 75-100 | 1-2+50 |

| Golden Supreme | 1 | 2.4-9.7 | - | - | - |

| Goldrush | - | - | 1+10 | - | - |

| Honeycrisp | 1-1.5 | 2.4-9.7 | 1+2.5 | - | - |

| Idared | - | 1.2-7.3 | - | 50-75 | - |

| Jerseymac | 1-1.5 | 2.4-9.7 | - | - | - |

| Jonagold | 1-1.5 | 3.6-9.7 | - | 50-75 | - |

| Jonamac | - | 3.6-9.7 | - | - | - |

| Lodi | - | 3.6-9.7 | 1+10-15 | - | - |

| Macoun | - | 3.6-9.7 | - | - | - |

| McIntosh, Early | - | 3.6-9.7 | 1+5-105 | 50-75 | - |

| McIntosh, Non-spur | 1-2 | 1.2-7.3 | - | 50 | - |

| Mcintosh, Spur-type | - | 1.2-7.3 | 1-2+2.5-5 | 50-75 | 1+50 |

| Northern Spy | 0.5-1.5 | 1.2-7.3 | - | - | - |

| Paulared | 1-1.5 | 3.6-9.7 | 1+10-15 | 75 | 1+50 |

| Red Delicious | 0.5-1.5 | 1.2-7.3 | - | - | - |

| Red Delicious, Spur-type | - | 1.2-7.3 | 1-2+5-10 | - | - |

| Shizuka | 1-1.5 | - | - | - | - |

| Silken | 1-1.5 | - | - | - | - |

| Spartan, Russets | 1-2 | 2.4-9.7 | 1+10-15 | - | - |

- = Treatment information not available.

1These rates are suggested for trees with a settled cropping history. Chemically thinning a first crop tree or immature trees is considered very risky.

2Sevin XLR is 43% active ingredient and contains 466 g or approximately 0.5 kg of carbaryl per litre. 1 L of Sevin XLR is roughly equivalent to 1 kg of Sevin 50 W. For actual amount of NAA, refer to the label.

3Sufficient water volumes must be used to thoroughly wet trees. See Steps in chemical thinning.

4Based on a dilute spray of 1000 L/ha. Rates need to be increased when higher water volumes are required for adequate spray coverage. Consult Table 4. Suggested rates of MaxCel or Cilis Plus to Use With or Without Sevin, to determine the amount of product/1000 L of water and the actual ppm of benzyladenine (BA) being applied. Concentration of BA should be no less than 50 ppm to be effective.

5At petal fall.

Factors influencing response to thinning agents

Length of wetting period and temperature for material absorption: Higher temperatures allow plants to absorb thinning materials more quickly. Optimum temperatures for absorption are in the 20-25°C range. At these temperatures, drying time is usually much faster than early morning or evening when temperatures are 10-15°C cooler. Under cooler conditions, absorption is slower and stretches over a longer period or until the canopy dries.

The total amount of thinning chemical absorbed by the tree canopy appears to be more or less equal regardless of drying time (i.e., warm temperatures and fast drying, or cool temperatures and slower drying). Time of day for application of thinners is not a critical factor. Research on selected cultivars suggests minimal differences in success based on timing of sprays during day or night. However, early morning or evening sprays will reduce the likelihood of off-target drift since winds tend to be calmer.

Cultivar sensitivity (mature trees):

Easy-to-thin or easy-to-over-thin cultivars include Ambrosia, non-spur Red Delicious, Idared, Mutsu/Crispin, Jonagold strains, Jerseymac, Honeycrisp, Gingergold, Silken, Creston, Cameo and Golden Supreme.

Moderately difficult-to-thin cultivars include Empire, McIntosh, Northern Spy and Cortland.

Harder-to-thin apple cultivars include Golden Delicious, Paulared, Gala strains, Fuji, Goldrush, Spartan, Wealthy, spur-type McIntosh and spur-type Red Delicious.

Weather conditions

Weather conditions encourage absorption of chemical thinners, which may increase the thinning response. These weather conditions include:

- cool, wet weather and low light conditions before or after application

- prolonged period of high humidity without rain, either before or after application

- high temperatures after cool periods; frost or near-freezing temperatures before or shortly after application

- prolonged period of dry weather before or after application

- excessively warm conditions following fruit set.

A decrease in thinning response can result from sunny and warm daytime temperatures accompanied by relatively cool night temperatures before and after thinning treatments have been applied. This results in a high net accumulation of carbohydrate reserves in the tree.

Pollination and bee activity

Pollination and bee activities are closely tied with weather conditions. Pollination conditions and bee populations can make fruit either more or less difficult to thin. Fruit set under good pollination conditions, which results in increased seed count, is harder to thin. Fruit set on king blossoms is more difficult to thin than fruit set on side blossoms. Single fruit are more difficult to thin than clustered fruit. Even a light or spotty set with clustered fruit should be thinned, in order to break up the clusters.

Tree age and vigour

Tree age and vigour are factors to consider when determining the rate of the thinner. Young trees are more easily thinned than mature trees that have cropped well for 2-3 years, so hand thinning young trees of high value cultivars is recommended. Even low rates of thinners that work on mature trees can easily over-thin young trees. Mature trees with winter-injured buds, or trees that are low in vigour, are more easily thinned. Trees bearing a heavy crop with good bloom one year may be more easily thinned the next year. The heavier the bloom, the more stress on the tree and the easier to thin. Producing flowers and pollen requires nitrogen and adds stress to the tree. Stress from the previous season makes a tree easier to thin (e.g., excessively dry, excessively wet, nutritional deficiencies, insect or disease injuries).

Density of foliage

Pruning and the density of foliage impact ease of thinning and spray coverage. Poorly pruned dense trees are thinned more easily than well-pruned open trees with stronger fruit buds. Partially shaded spurs on low branches of well-pruned trees thin more easily than upper spurs. Late thinning sprays require increased water volumes for adequate coverage of the rapidly developing tree canopy.

Spray coverage

As with all plant growth regulators, complete coverage is essential for good results. Chemical thinners will act only where deposited.

Timing of application

Application timings vary with the chemical used. See Chemicals available for thinning apples. Petal fall is an important stage for making thinning decisions. Petal fall is when 80% of the petals have fallen but before calyx lobes are closed.

Apply chemical thinners based on the average fruitlet diameter. See Steps in chemical thinning. Apply thinners when the king bloom fruitlets reach the stated diameter to cause the smaller and weaker fruitlets to drop off. This relationship works best when the king bloom fruitlet is larger than the side bloom fruitlets and when the size and stage of development of all fruit to be thinned is fairly uniform. See Table 6. Optimum Apple Fruitlet Size for Chemical Thinning, to determine the best timing for each cultivar.

Cultivar | Diameter of largest fruitlets in cluster* |

|---|---|

| McIntosh | 8-12 mm |

| Red Delicious | 6.5-8 mm |

| Northern Spy | 10-11 mm |

| Empire, Idared, Jonagold, Gala, Golden Delicious, Fuji | 8-12 mm |

* Due to variability in fruit size, a sample of king fruitlets in 25-30 randomly selected clusters should be measured using a thinning template or Vernier calipers to determine the average.

Thinning under challenging conditions

Thinning after a badly frosted bloom

Carefully evaluate damage to the bloom. Petals, stamens, pistils and ovaries can exhibit a significant difference in their response to freezing temperatures. See Figure 2. Anatomy of an apple bloom, for further details. Although flower petals are browned off by frost, the process of fruit set can still take place from pollination that occurred 1-2 days before the frost event.

Frost around bloom usually produces a variety of frost damage symptoms: bands of russeting around the fruitlet, called frost rings; russeting that runs lengthways from stem to calyx; reduced seed count and misshapen fruit (blocky or ridged)

A light amount of frost damage should not prevent the use of thinning treatments that worked in the past for any given cultivar. However, use extreme caution when thinning after a significant frost. Leaves damaged by frost absorb more of the thinner and fruitlets with reduced seed count abscise more easily. Consider the application of lower rates of thinner for many varieties under these circumstances, or on a badly damaged block, do not apply a thinner but rely on hand thinning if necessary.

Depending on the severity of the damage, growers may thin areas of the orchard that escaped the worst of the frost damage. Differences in elevation and airflow in the orchard can lead to great variations in frost damage. Trees on lower ground can be exposed to air 2-3?C colder than trees on higher ground in the same frost event.

When deciding to apply thinners, the grower may plan to spray some of the block because of what appears to be a fairly normal set on trees on higher ground. Nozzles can be shut off in areas of the block that show significant potential losses in crop load from frost. Likewise, nozzles that direct thinning sprays into the lower canopy can be shut off.

Figure 2. Anatomy of an apple bloom

Thinning when the king bloom is lost to frost

Chemical thinners usually work best when the king fruitlet is larger, stronger and more dominant than side bloom fruitlets. The king will normally hold on when weaker, smaller fruitlets drop in response to treatments.

If the king bloom or king fruitlet is lost to frost, size and strength differences among remaining fruitlets can be minimal, which makes them equally weak and vulnerable to thinners. The best approach in this case may be to wait until size differences appear in the cluster, provided the largest fruitlet does not exceed the size range for fruitlet thinning. Size differences may become more apparent several days after full bloom. A few hours' difference in pollination timing can show up in size differences of side bloom fruitlets as the postbloom period progresses.

Thinning when weather conditions are poor

Weather conditions are often not suitable for the application of thinners even though the fruitlet diameter is at the optimum size. Sometimes cold, wet, windy or rainy weather can persist for many days. It is better to wait for warmer temperatures, more sunlight and less wind, even though fruitlet diameter is increasing. Applying thinners when king fruitlets are slightly larger than the optimum size for thinning will give a better response under warmer conditions than thinners applied at the optimum size for thinning in persistent cold, wet and rainy conditions. Wait for warmer temperatures above 18°C during the day of application or for 24 hours after spraying.

Thinning an unevenly set crop

In most cases, apply thinners even when the crop is unevenly set. Single fruitlets are much tougher to remove from the canopy. These fruitlets can be present at the same time as multiple-set clusters in the same tree or block. In comparison, fruitlets found in clusters of 3-5 are easier to thin because of competition within the group. Ultimately, only 5-10% of the bloom in any cultivar is required to produce a commercial crop of fruit. Therefore, in situations of uneven set on unstressed trees and in the absence of frost injury, follow the recommended thinning treatments.

Cultivar notes

Ambrosia

This spur-type upright-growing cultivar has been successfully thinned in Ontario with moderate rates of Sevin XLR. A well-thinned crop of Ambrosia produces good fruit size and colour development. The picking window for Ambrosia is narrow if the crop is to be held in long-term storage. Consult OMAFRA fact sheet, Commercial Production of Ambrosia™ Apples in Ontario.

Aurora Golden Gala™

Aurora Golden Gala™ can be extremely productive and therefore requires early and heavy thinning for acceptable fruit size. The cultivar appears to thin relatively well with moderate rates of carbaryl. It requires a follow-up hand thinning to space fruitlets 15-20 cm apart. Match crop load to trunk diameter. Many young Aurora trees have been cropped too heavily, resulting in small fruit, delayed maturity, poor colour, poor taste and generally poor quality fruit. This cultivar responds well to Surround Crop Protectant particle film to increase fruit size and improve shape and fruit finish.

Cameo

Trees can normally handle heavy crop loads in a vigorous canopy. This cultivar has been shown to thin adequately with Sevin XLR (1 L per 1,000 L water) on established trees.

Creston

Creston has been shown to over-thin easily with low to moderate rates of Sevin XLR. It is a productive large-size cultivar that requires 2 pickings.

Empire

Before the application of NAA, make sure the king bloom fruitlet is set through a check of sepal posture. Petal fall of king bloom can take place as early as 3-4 days past peak pollination. If NAA is used too early (full bloom to petal fall), the overall fruit size of unthinned apples may be reduced compared to treatment at a stage when the king fruitlet is 8-10 mm in diameter.

Fortune

Fortune is a large-sized, highly coloured, dual-purpose apple that requires thinning to avoid biennial bearing. Fortune requires a strong treatment of NAA in combination with Sevin XLR. Experienced growers have reported success with 10 ppm NAA plus 1 L of Sevin XLR per 1,000 L of water.

Fuji

Fuji must be thinned aggressively for best results. This cultivar exhibits strong biennial characteristics and unthinned Fuji normally returns very little bloom the next year. Mature trees usually thin adequately with combinations of Sevin and NAA, but follow-up hand thinning of king fruitlets is usually necessary. Excessive crop may prevent the fruit from maturing to premium quality.

Gala

Gala is relatively difficult to thin successfully, and requires aggressive thinning on mature trees. NAA and Sevin at the rates listed for Golden Delicious have given good results, if applied when king fruitlets are 8-9 mm. Combination sprays of MaxCel or Cilis Plus and Sevin have also been very effective. Clusters must be thinned to 1 fruitlet or king bloom by mid to late June to achieve best fruit size. A follow-up hand thinning within 30 days of full bloom is normally required to further reduce crop load.

Late thinning sprays may increase the production of mummified fruitlets, which are colonized by the fungus that causes black rot. Earlier applications produce fewer mummies which reduce black rot inoculum and maturing fruit is less likely to be infected.

Gingergold

This cultivar appears to be more sensitive to thinners than McIntosh, Northern Spy and Empire. It can be over-thinned with high rates of NAA or strong combinations of NAA and Sevin XLR or MaxCel and Sevin XLR.

Goldrush

Goldrush requires a combination of NAA and Sevin XLR (10 ppm NAA + 1 L Sevin XLR per 1,000 L water). This cultivar is much tougher to thin adequately, but a well-thinned crop will mature more easily.

Honeycrisp

This cultivar seems to be more sensitive to thinning treatments than Empire. Thin Honeycrisp cautiously as it can easily become oversized and is very prone to bitter pit. Where large fruit is a problem, it may be best to leave 2 fruitlets per cluster, or space the fruit closer together. Use of growth regulators (such as 6-BA), which enhance fruit size, may not be warranted for this large-fruited cultivar. Use no more than 2.5 ppm NAA with 1 L of Sevin XLR per 1,000 L of water as a starting point on established trees. Many growers report good fruit size distribution when the largest fruitlets are removed by hand thinning following the spray thinning treatment. Honeycrisp is highly biennial in nature and may not return an adequate crop year after year.

For a discussion on crop load and trunk circumference with respect to thinning, see OMAFRA fact sheet, Commercial Production of Honeycrisp Apples™ in Ontario.

Jonagold

This cultivar thins relatively easily and has good size potential when clusters are thinned to singles. Most producers get adequate thinning with moderate rates of Sevin. Over-cropping Jonagold may result in very poor return bloom and fruit may not mature to a premium quality.

Silken

Silken thins with 1-1.5 L of Sevin XLR per 1,000 L of water, depending on tree age. This cultivar bruises easily. Evenly spaced fruit in the canopy is important for ease of harvest.

Defruiting immature apple trees

In some cases, it is desirable to defruit immature apple trees to encourage proper tree development. A diluted spray of NAA at 15 ppm combined with Sevin XLR at 1.5-2 L per 1,000 L of water 5 days after petal fall, gives acceptable results. Also, successful results have been achieved with Ethrel at a concentration between 400-750 mg per L (ppm) when fruit are between 10 and 30 mm in diameter, typically mid-June. Well-established, supported trees under minimal stress can carry some crop load in the second year following planting.

Hand Thinning

Hand thinning is often used supplementary to chemical thinners in apples to help with crop load management. Hand thinning will help to:

- increase fruit size and manage fruit development

- single the fruitlets, improve fruit colour, balance the number of fruiting spurs with resting spurs

- enhance return bloom (if done early before fruit bud initiation)

- improve pest control because spray coverage is more uniform on unclustered fruit

- improve efficiency in harvest and handling of crop

- allow the tree to continue to develop canopy

- help to prevent runted trees

Conclusion

Thinning plays an important role in the production of high quality fruit. Proper thinning will:

- improve average fruit size, finish and colour improve fruit distribution

- avoid over cropping

- encourage return bloom (apples and pears), reduce limb breakage

- reduce the probability of pest damage.

Read the product label and follow all safety precautions.

Reviewed and edited by Kathryn Carter, tender fruit and grape specialist, OMAFRA and Erika DeBrouwer, tree fruit specialist, OMAFRA. Originally written by Kathryn Carter and Amanda Green (formerly of OMAFRA). Thanks to Dr. John Cline, University of Guelph, Simcoe and Leslie Huffman and Margaret Appleby (formerly of OMAFRA).