Ontario Ministry Of The Environment Wastewater System (MEWS) Industrial User Guide

This document provides guidance for Industrial facilities which are required to report their effluent discharges as per the nine Effluent Monitoring and Effluent Limits Regulations through the Ministry of the Environment Wastewater System (MEWS) website.

MEWS Version 3.5.1

April 2017

We welcome your feedback

We have used our best efforts to produce a guide that will help you become familiar and comfortable with the MEWS application. Changes will be made periodically to the information contained in this guide and will be incorporated in later editions. In case of discrepancies between the MEWS guide and other guides and checklists, the official documents such as acts and regulations will prevail.

We welcome your comments about this guide, its organization or subject matter. Please send your comments directly to:

Water Wells and MISA (Municipal/Industrial Strategy for Abatement) Reporting Unit

Ministry of the Environment, Conservation and Parks

Environmental Monitoring and Reporting Branch

125 Resources Road

Toronto, Ontario M9P 3V6

Or:

Email: WastewaterReporting@ontario.ca

For user account issues and system access issues, please contact the MEWS Program Officer at WastewaterReporting@ontario.ca.

Please direct any other correspondence regarding reporting of data to the District Office of the Ministry of the Environment, Conservation and Parks, Senior Environmental Officer. A listing of ministry District Offices is viewable from the ministry website.

MEWS Industrial User Guide

© Queen’s Printer for Ontario, 2017

1. Introduction

The Ontario Ministry of the Environment Wastewater System (MEWS) is a web-based application designed for the monitoring and reporting of wastewater from companies discharging into Ontario waterways.

The Ontario Ministry of the Environment and Climate Change’s Effluent Monitoring and Effluent Limits Regulations—and other legal instruments such as Certificates of Approval and Environmental Compliance Approvals—under the Environmental Protection Act of Ontario (the EPA) and the Ontario Water Resources Act (the OWRA), require designated dischargers of wastewater who discharge directly to water bodies in Ontario to sample their wastewater discharge, analyze the wastewater discharge samples, and report data to the ministry based on the results of the analysis of the samples, as well as to ensure that the quality and quantity of wastewater discharge comply with the regulated limit.

Pre-approved users are permitted entry to the secure MEWS website and can gain access to their discharge data. Users interact with the MEWS website using Internet browsers and the World Wide Web.

The MEWS website supports the following primary business functions:

- Capturing and storing industrial wastewater discharge information for at least 4 years.

- Maintaining company and ministry contact information.

- Maintaining individual user passwords on the website.

- Calculating Industrial Summary Data.

- Generating online discharges reports.

- Submitting discharge data to the ministry at the end of a reporting period in an electronic format as required by the regulations.

This guide is prepared to help you use the MEWS website and to explain how the above functions work.

2. Before you get started

Before you can start using MEWS, you need specific hardware and software, as well as basic computer skills.

a. Computer requirements

The following are the minimum recommended software and hardware computer requirements to connect to the MEWS application:

- Internet Explorer 6.0, Firefox 2.0, or Safari 3.0 (recommended browser versions are very important as you will likely experience problems with earlier versions).

- VGA monitor with resolution set to 600 × 800 (1024 × 768 recommended) and Font Size set to Normal (96 DPI).

- Network connection to the Internet (recommended high speed internet connection; dial-up connection not recommended, but if used, recommend using only during periods when MEWS usage is likely to be low, such as early morning, weekends, and up to 15 days prior to the next quarterly submission deadline).

- Adobe Acrobat Reader (minimum version 5.0).

Hint: Allow pop-ups on your browser for MEWS. This option is found in the Tools menu of your web browser.

b. User prerequisites

To navigate effectively through the MEWS website, users should have a basic understanding of:

- Operating systems such as Microsoft Windows (NT/2000/XP/Vista/2007) or Apple Macintosh (Mac OS 10.0 or later).

- Computer and mouse operations.

- Internet browser operations (clicking on links, viewing content).

Note: Internal company policy may place constraints on your web browser. If you have difficulties accessing the MEWS website, contact your IT department.

3. Logging in to MEWS

This section explains how to locate MEWS on the Internet, obtain a MEWS account, log in to the system, and handle some common access problems.

a. Obtaining a MEWS user account

Contact the MEWS Program Officer to obtain a user account for the MEWS application. MEWS user accounts are provided to employees of industrial wastewater dischargers who are legally required to monitor and report on their discharges. MEWS accounts are not provided to third-party consultants for liability reasons. A discharger must have at least one Industrial Officer account, and may have more than one of each type of account—the account-holder is responsible for the proper use of the account, as detailed in the Disclaimer (see Appendix A).

b. MEWS user roles

The MEWS application is designed for two user roles: Industrial Officer and Industrial Staff. Each system user is designated as one of these user roles and is thereby limited to viewing items or performing functions associated with that specific user role. The following tables identify the MEWS views and functions accessible by each user role.

| MEWS View / Function Accessible | Industrial Officer | Industrial Staff |

|---|---|---|

| View and Delete Notification Messages | ✔ | ✔ |

| MEWS View / Function Accessible | Industrial Officer | Industrial Staff |

|---|---|---|

| Industrial Data Entry | ✔ | ✔ |

| Industrial Data Upload (XML) | ✔ | ✔ |

| Submit Industrial Data | ✔ | ✖ |

| Inactive Control Point | ✔ | ✔ |

| MEWS View / Function Accessible | Industrial Officer | Industrial Staff |

|---|---|---|

| Summary Discharges | ✔ | ✔ |

| Detail Discharges | ✔ | ✔ |

| Daily Plant Loading | ✔ | ✔ |

| Daily Pipe Loading | ✔ | ✔ |

| Limit Check | ✔ | ✔ |

| Company Profile | ✔ | ✔ |

| Outlier Statistics | ✔ | ✔ |

| Value Review | ✔ | ✔ |

| MEWS View / Function Accessible | Industrial Officer | Industrial Staff |

|---|---|---|

| Change My Password | ✔ | ✔ |

| Maintain Contact | ✔ | ✔ |

c. Connecting to MEWS

To access the MEWS application, you will need an Internet connection and familiarity with a browser application such as Internet Explorer. The following steps describe the process of connecting to MEWS.

From your Desktop:

- Start your web browser of choice.

- In the “Location/Address” box of the web browser, type the following: http://www.mewsontario.ca

- Press the Enter key.

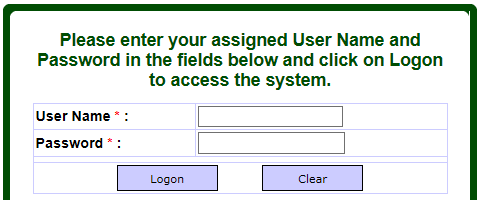

The MEWS “Log-on” page will appear as illustrated below (see Figure 1). Type in your user name and password, and then click the “Logon” button to access the system.

Figure 1

Note: To maintain the security of the account, the username and password, ensure the browser settings, such as “remember password” or “auto complete” type features, are turned off.

d. What to do if you cannot access the MEWS site

Your workstation must be properly configured to access the Internet before attempting to gain access to the MEWS website.

If you type http://www.mewsontario.ca you may receive any of the following error messages:

Cannot open the Internet site www.mewsontario.ca or A connection with the server could not be established or Unable to locate the server www.mewsontario.ca

If so, please perform one of the following actions:

- Make sure that you are connected to the Internet. Check that your internet connection is established, and you can access other websites.

- Re-type http://www.mewsontario.ca and try accessing the site again.

If you still cannot access the MEWS website after a reasonable time, contact the MEWS Program Officer.

Note: Internal company policy may place constraints on your web browser. Confirm with your IT department that access to the MEWS website is not restricted.

4. Getting started

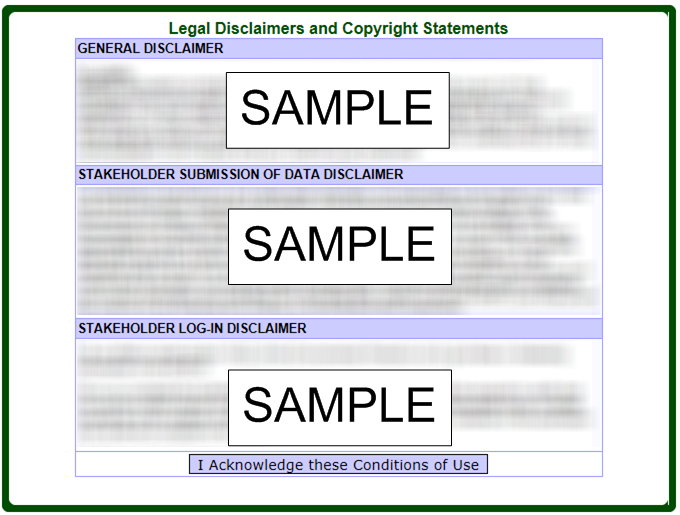

a. Accept the legal disclaimer

A legal disclaimer will be displayed the first time you log in to the MEWS system (see Figure 2 and Appendix A). It explains that MEWS is a public service provided by the Ministry of the Environment and Climate Change. The Government of Ontario assumes no responsibility and you should verify the information from other sources prior to making decisions or acting upon it. This notification is displayed once. To proceed, read the content and click the “I Acknowledge these Conditions of Use” button.

Figure 2

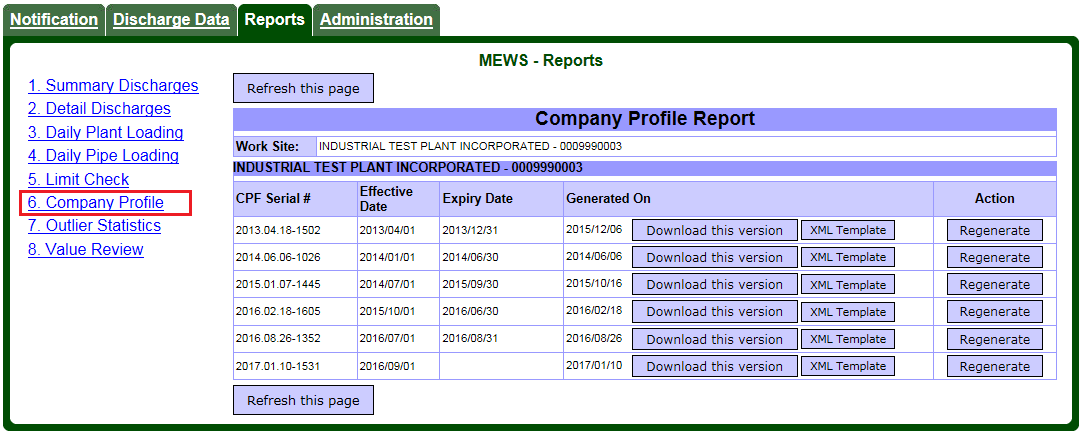

b. Check your company profile

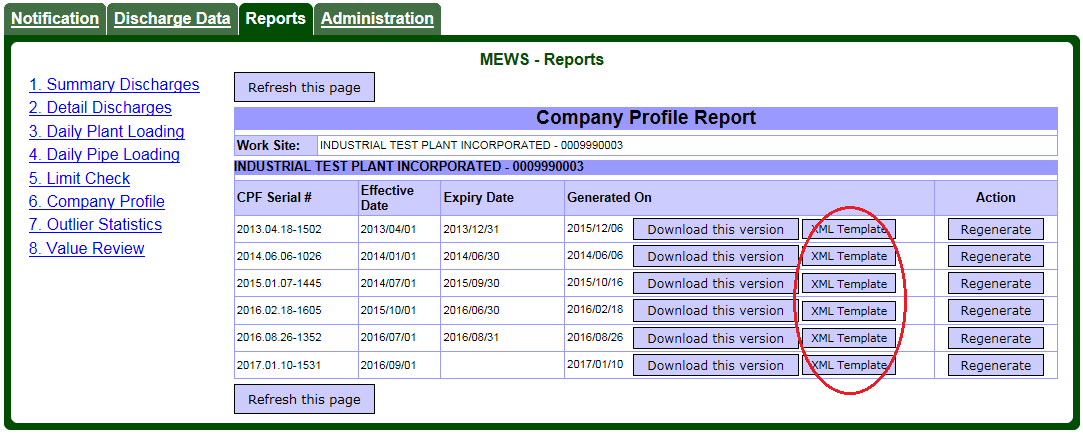

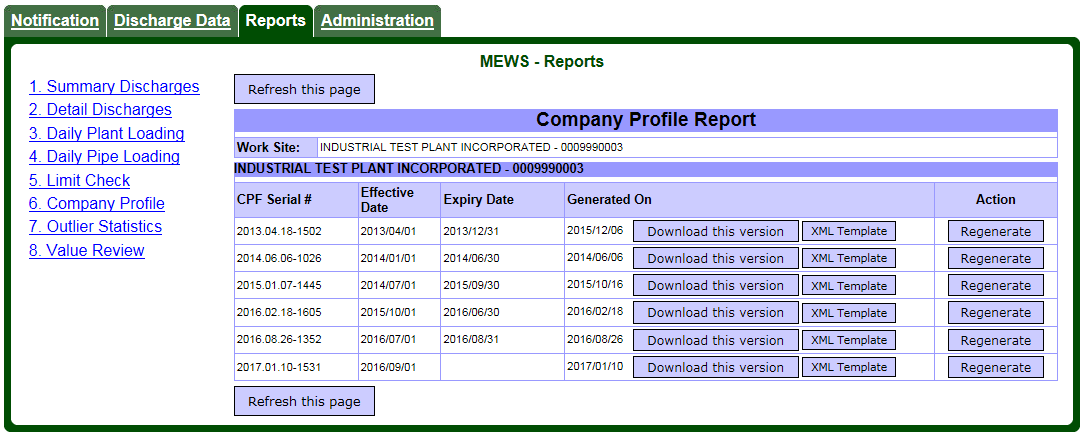

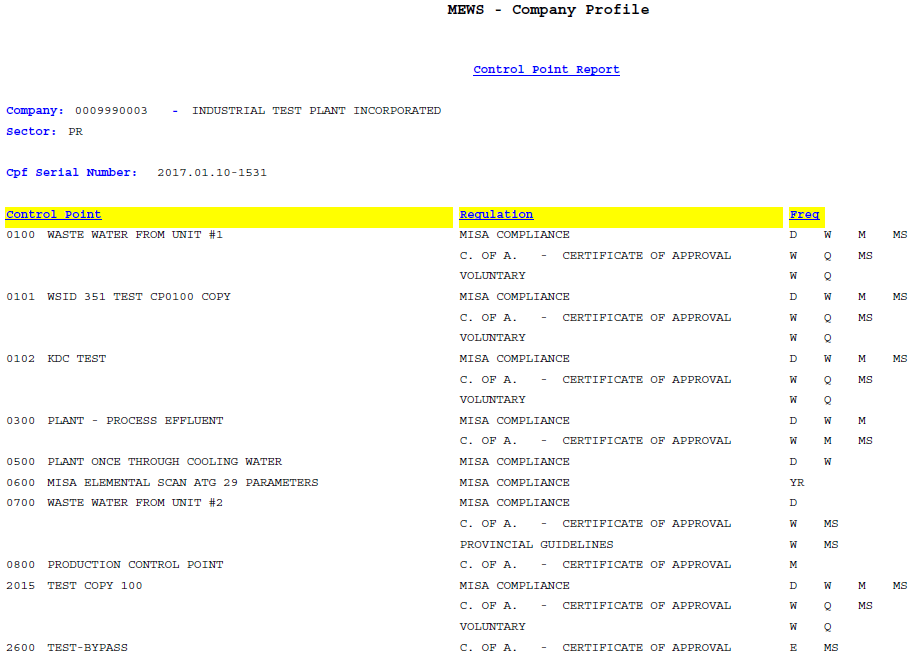

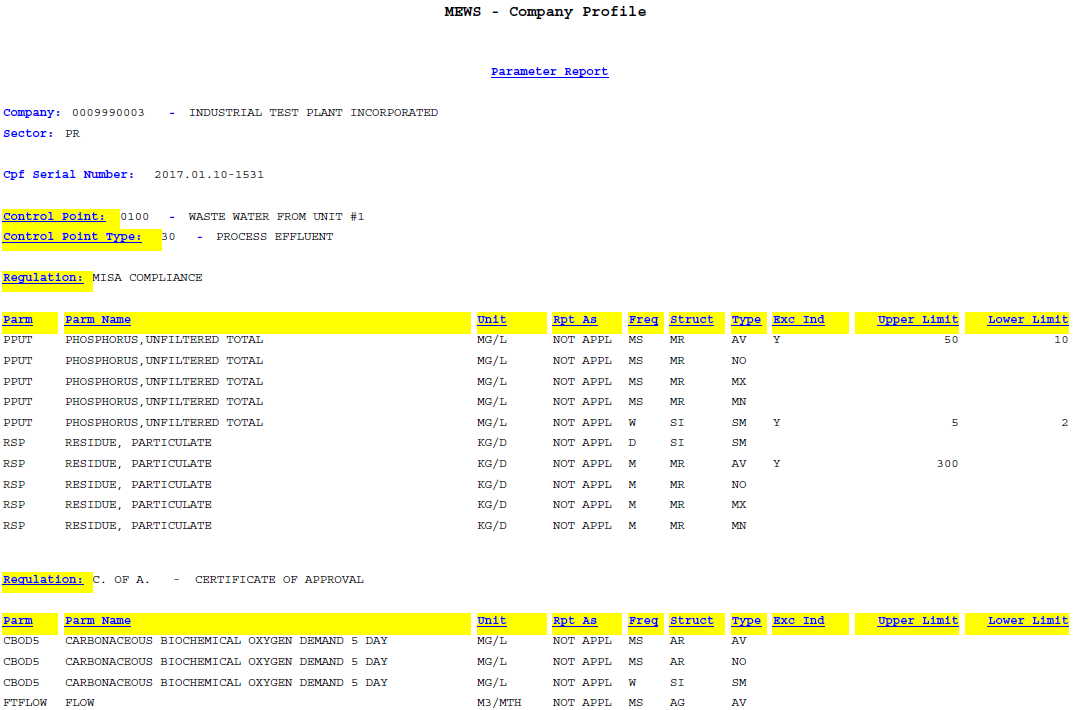

The MEWS home page contains four tabs—“Notification”, “Discharge Data”, “Reports” and “Administration”—and normally defaults to the “Notification” tab. However, when you first log in, MEWS defaults to the “Reports” tab and the Company Profile Report page; this page is also the default display following any recustomization of your Company Profile File (CPF) (see Figure 3). Review your company profile before starting (see Figure 74 for an example of a CPF), and report any errors in your CPF to your ministry District Office.

Figure 3

Note: The parameter codes and descriptions (e.g. PPUT - Phosphorus, Unfiltered Total) relate to specific parameter testing methods and analysis. Verify with your laboratory to ensure the correct testing method and analysis is being performed for each parameter.

The MEWS discharge data entry application requires that reporting parameters such as flow and chemical substances are customized in a CPF. This Company Profile is “active” for a defined period of time. The Industrial Data Entry screen is driven by the customization in the CPF. The ministry customizes the Company Profile based on the regulatory requirements (such as reporting parameters and schedules). The shortest CPF period is one calendar month and it must start on the beginning of the month. A maximum of three CPFs may be active within a given quarterly reporting period. When you enter a particular sample date, the system will search and select the appropriate CPF.

Before you begin entry of data resulting from the analysis of wastewater discharge samples, please verify that the ministry has created a valid active Company Profile for the quarterly sampling period in question. To do this, download the Company Profile Report to assist in the verification (details in Section 9g).

Note: When the ministry uploads a new CPF to MEWS, a notification is presented when you log in (see Figure 4). This notification is displayed once. To proceed, read the content and click the “I Acknowledge” button.

Figure 4

c. Choose your task

The MEWS home page contains four tabs—“Notification”, “Discharge Data”, “Reports” and “Administration”—and defaults to the “Notification” tab. You may choose any of these four tabs. Each one is explained briefly below. You can find more details of all four tabs and their modules in other sections of this guide.

Note: The MEWS system “times out” after 20 minutes of inactivity. Your session will be disconnected and the system will ask you to log in again. Any changes that were not saved prior to the time-out disconnection will be lost.

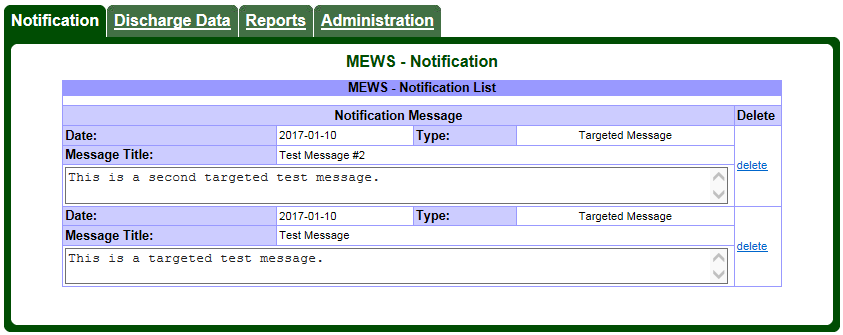

d. Notification tab

The “Notification” tab provides a listing of notices posted by the MOECC (see Figure 5). These notices are displayed in reverse chronology (latest at the top), grouped by notification message type (targeted and broadcast). The discharger should consult the notices for important information on the use of MEWS, or for reporting issues specific to your work site.

Figure 5

The following function is available:

| Function | Description |

|---|---|

| Delete | Click on “delete” beside a notice to delete the Notice after you have read it and / or saved it (see below). |

The discharger may wish to save notices for future reference. This may be accomplished by selecting the notice (use your mouse to highlight the notice) and using the browser’s Copy feature (under the Edit tab), then Paste the notice text into a separate word processing document.

A notice that is posted by the MOECC while a user is displaying the “Notification” page will not appear to this user; however, it will appear once the user has either refreshed the page (using the browser’s Refresh button) or has returned to the “Notification” page from another tab.

The “Notification” tab screen will show only the page title when a user has no messages.

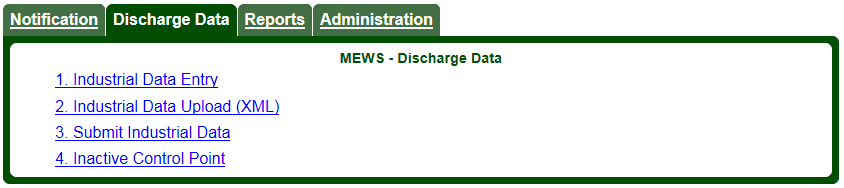

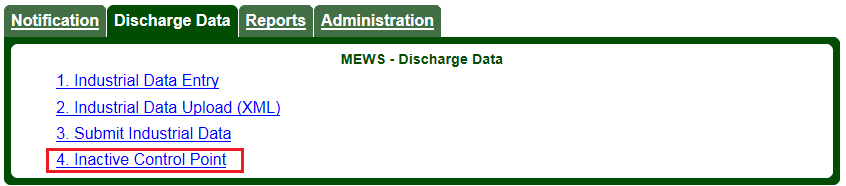

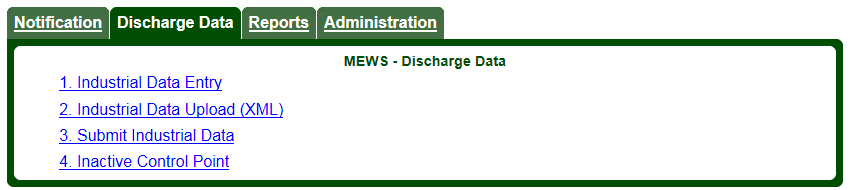

e. Use discharge data tab for day-to-day operations

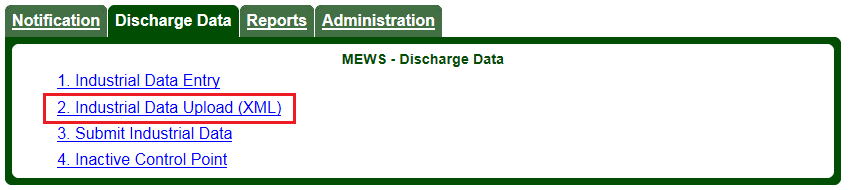

The “Discharge Data” tab provides four modules where day-to-day operations will be performed (see Figure 6). To activate a module, simply click on the module title.

Figure 6

| Number | Module | Function |

|---|---|---|

| 1 | Industrial Data Entry | To perform entry and editing of sample comments, result values, value remark codes and result comments. Find details in Section 7 of this Guide. |

| 2 | Industrial Data Upload (XML) | To upload data results through the use of the XML file format (an alternative to Industrial Data Entry). Find details in Section 8 of this Guide, as well as the current “XML Format Electronic File Transfer for industrial officers and staff” guide. |

| 3 | Inactive Control Point | To specify a period of inactivity for one or more control points. If a specific control point has a period of inactivity, this information may be entered into MEWS in this module. Find details in Section 6 of this Guide. |

| 4 | Submit Industrial Data | To submit industrial data to the ministry. After uploading and / or data entry of regulatory discharge data and verification is complete, this data is required to be submitted to the ministry. Find details in Section 10 of this Guide.

Note: The Submit Industrial Data module is only available to Industrial Officers. |

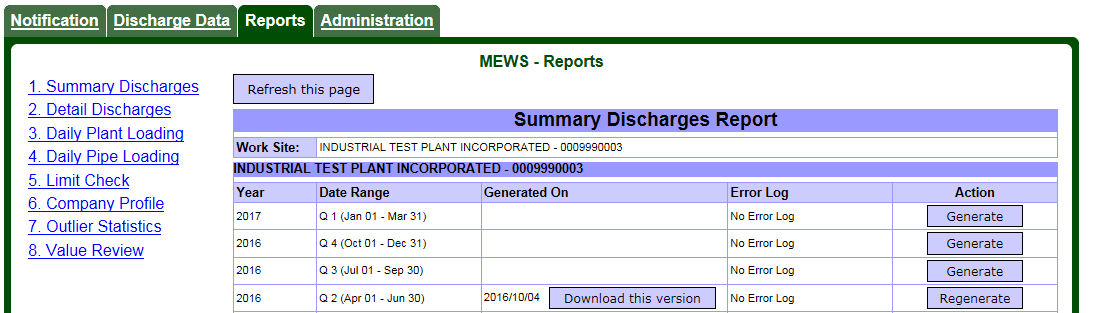

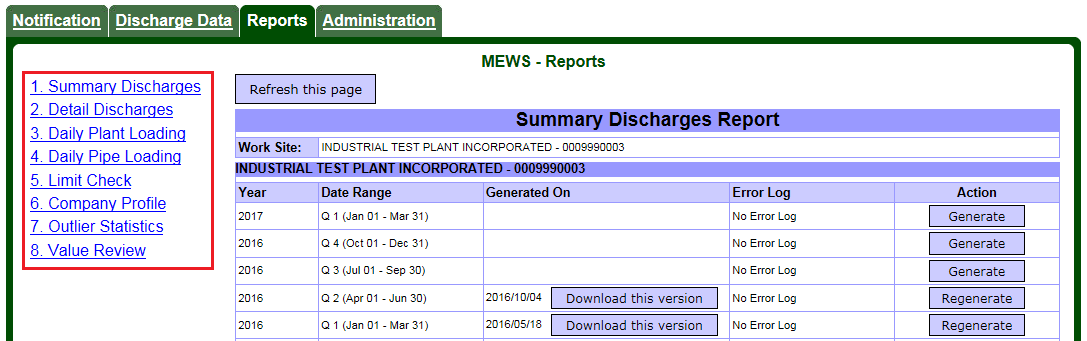

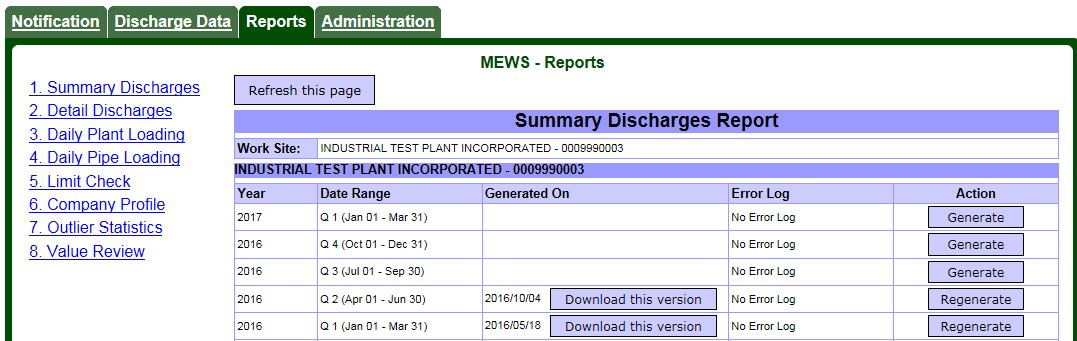

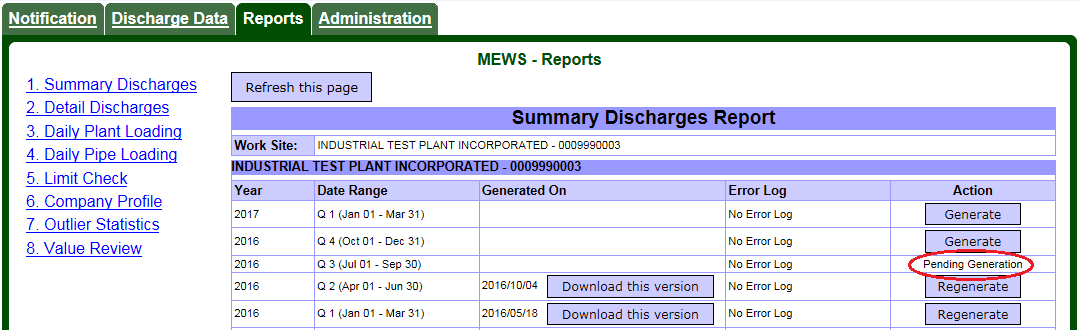

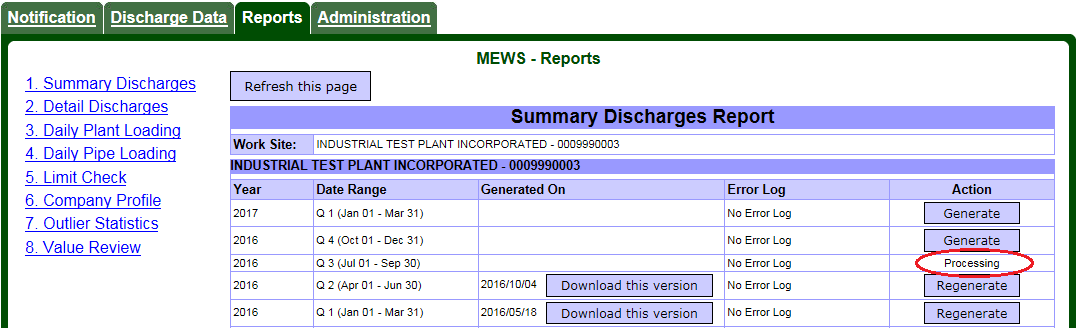

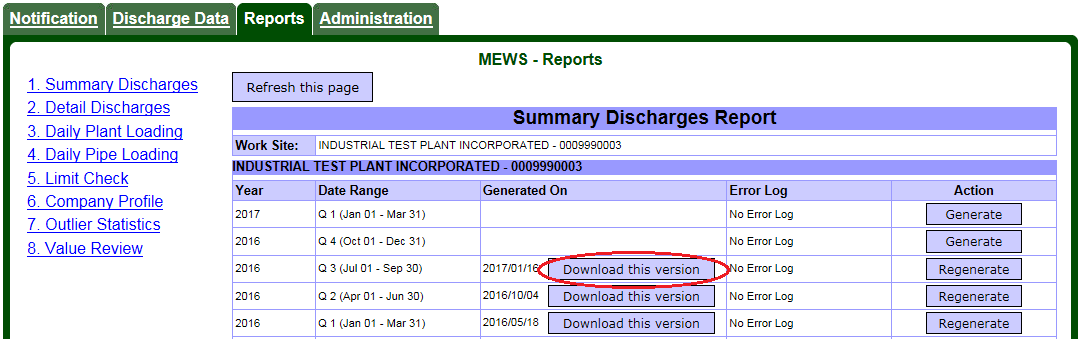

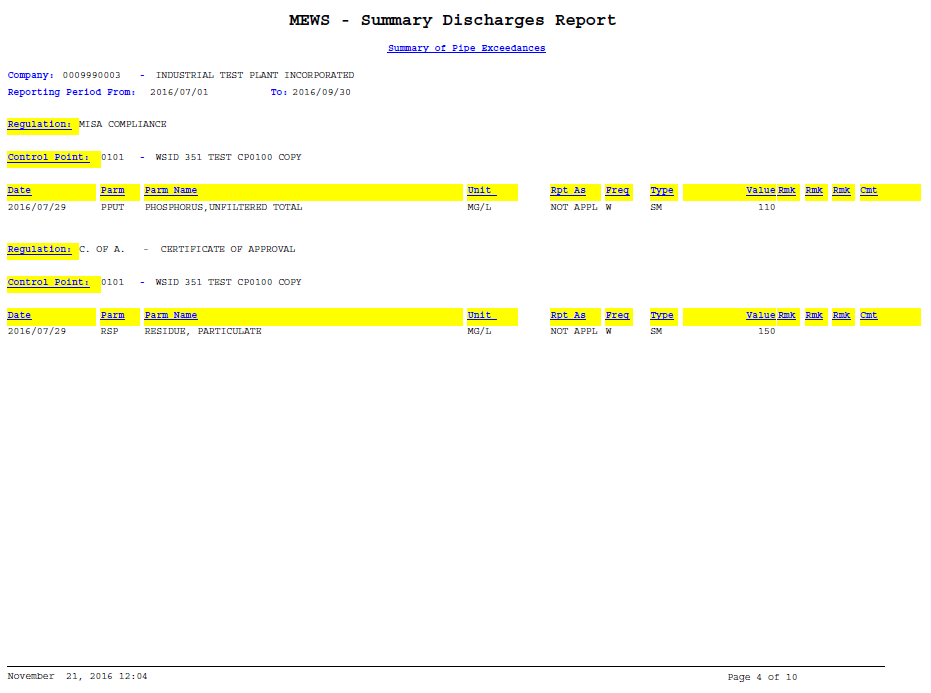

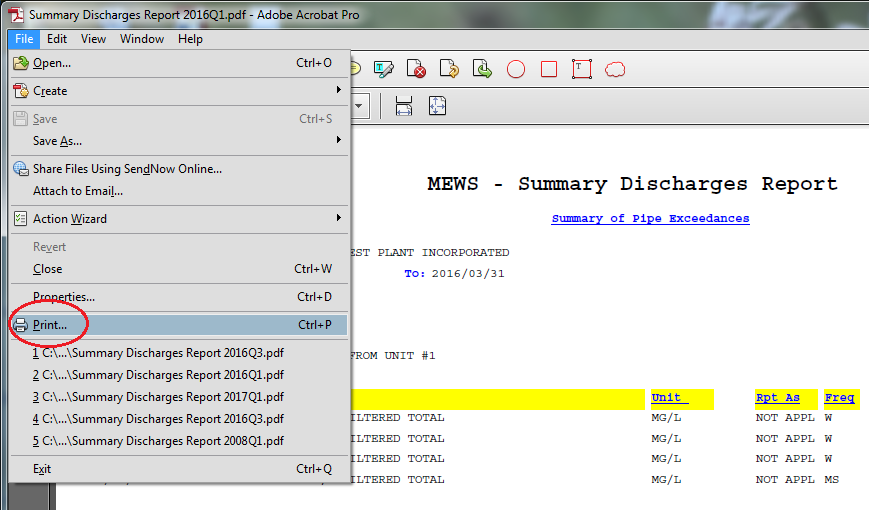

f. Use reports tab to generate reports

The “Reports” tab (see Figure 7) provides eight online discharges reports:

Figure 7

| Number | Report | Function |

|---|---|---|

| 1 | Summary Discharges | Lists all summary values calculated by MEWS, based on the sample result values you entered. |

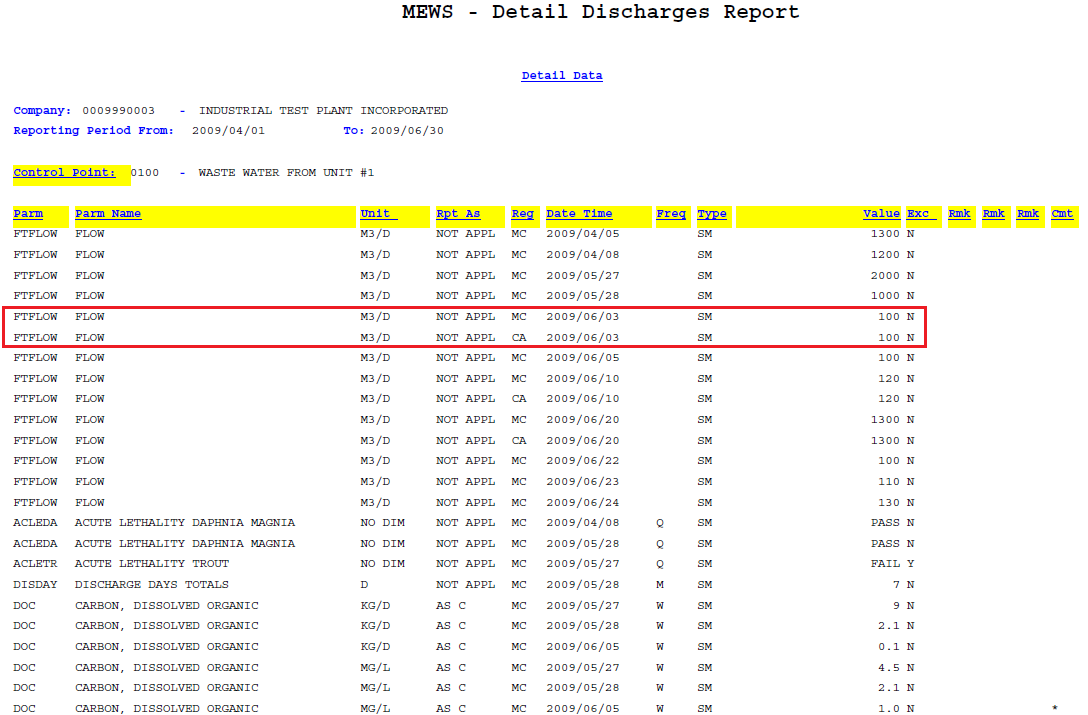

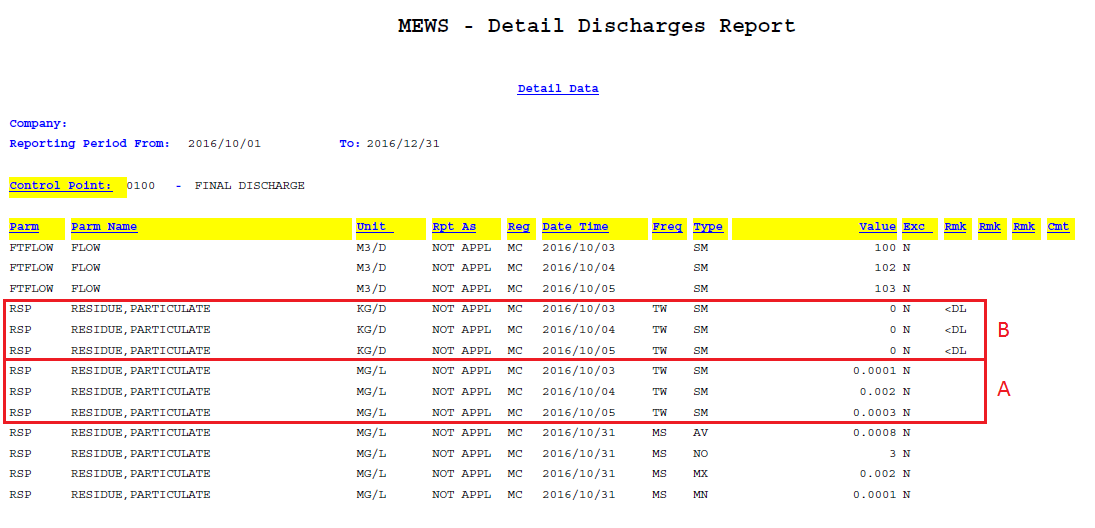

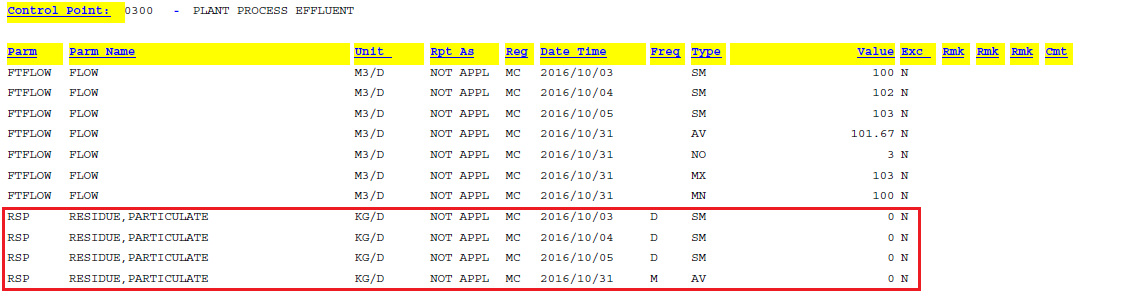

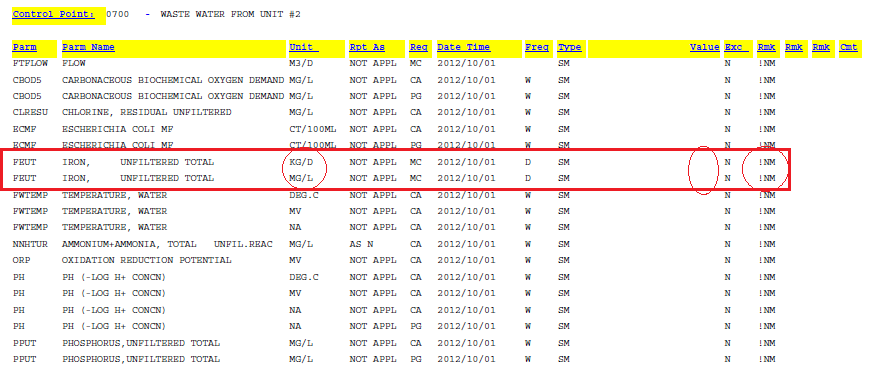

| 2 | Detail Discharges | Lists all values you entered and all values calculated by MEWS. |

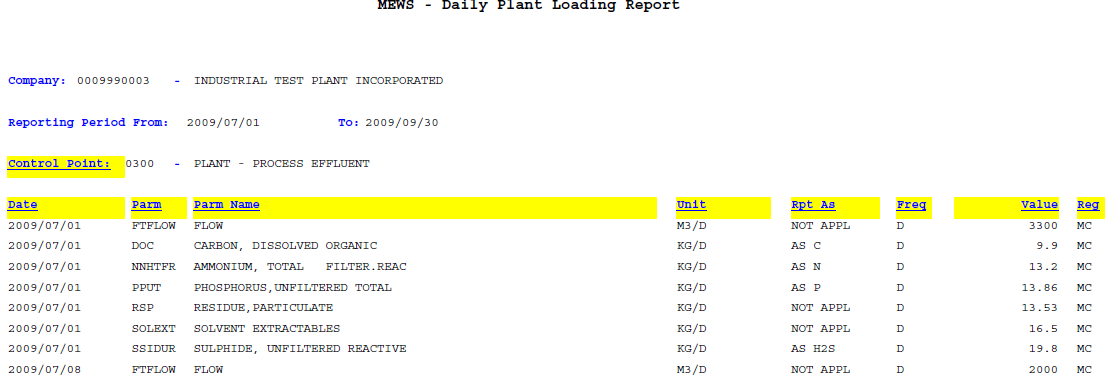

| 3 | Daily Plant Loading | Lists all loading values calculated by MEWS for the plant. |

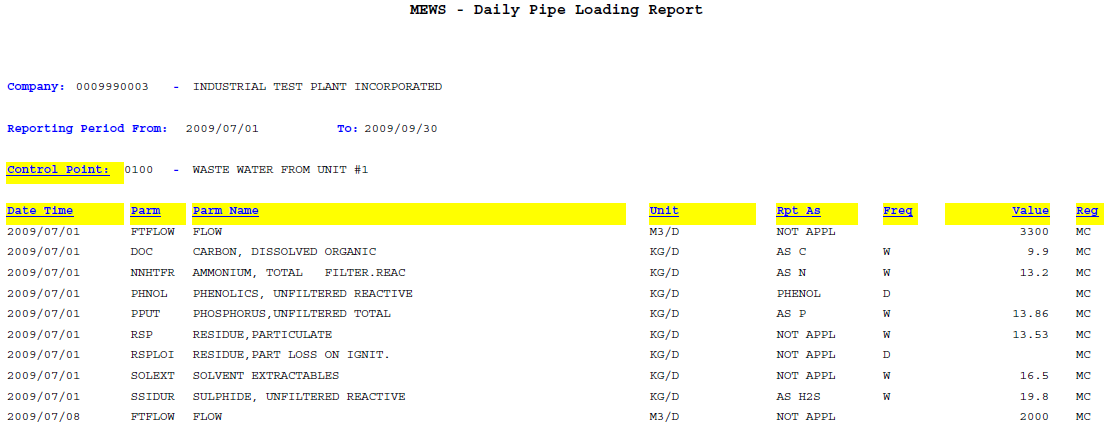

| 4 | Daily Pipe Loading | Lists all loading values calculated by MEWS for each sample location (pipe). |

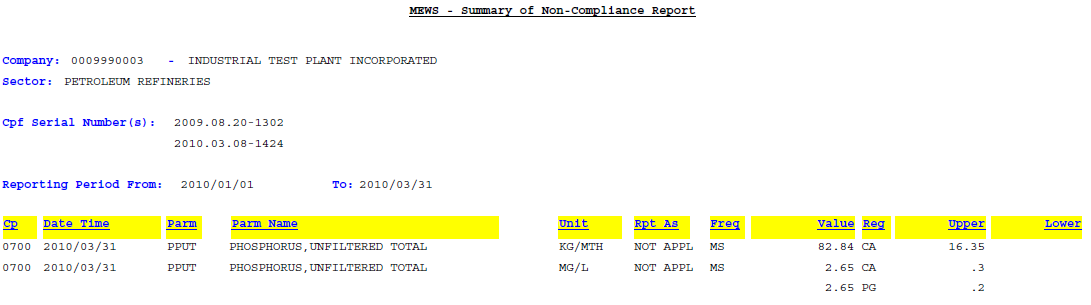

| 5 | Limit Check | Also called the “Summary of Non-Compliance Report”, lists values in non-compliance with ministry requirements. Limit exceedances must be reported as soon as reasonably possible to your local ministry District Office. |

| 6 | Company Profile | Provides details of the work site sample locations and monitoring and reporting requirements. |

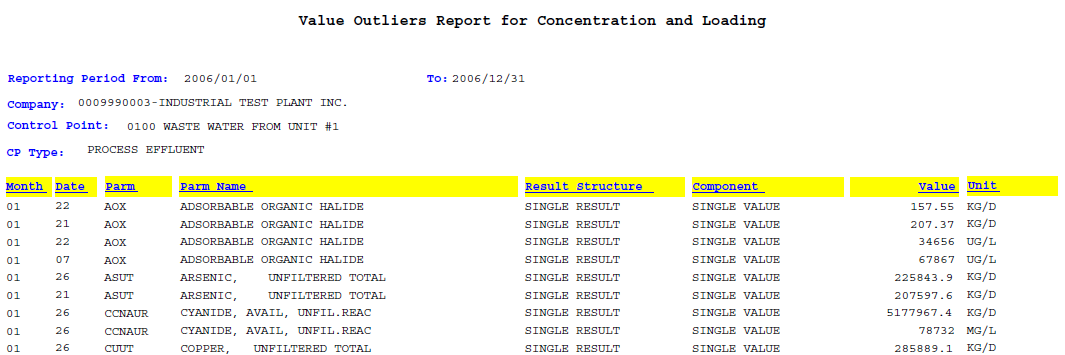

| 7 | Outlier Statistics | Also called the “Value Outliers Report for Concentration and Loading”, lists sample result values that fall outside the normal expected results—for data quality review only. |

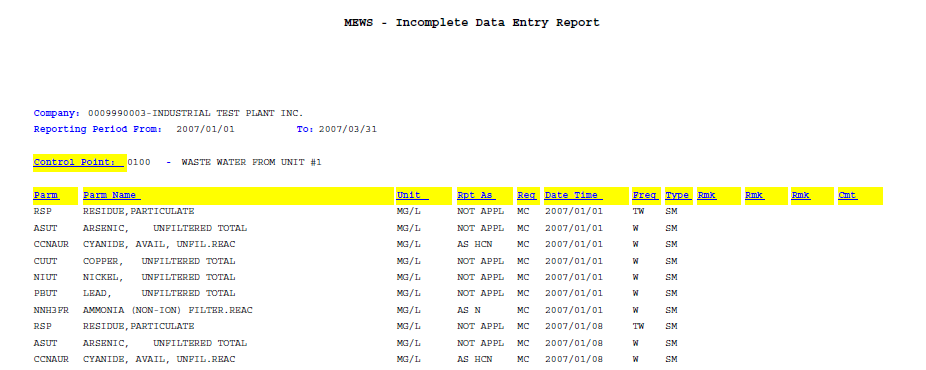

| 8 | Value Review | Also called the “Incomplete Data Entry Report”, lists all parameters not reported for each day that a sample is required—for data quality review only. |

To select a report, simply click on the report name. Details of these reports are in Section 9 of this guide.

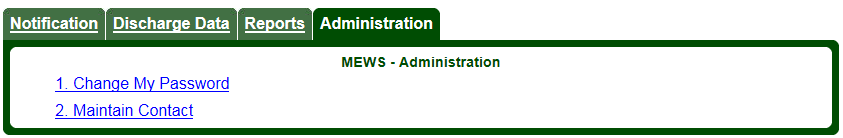

g. Use administration tab for contact information

The “Administration” tab (see Figure 8) has two modules that allow you to change your password and manage contact information. To activate a module, simply click on the title.

Figure 8

| Number | Module | Function |

|---|---|---|

| 1 | Change My Password | Allows you to change your MEWS website log-in password as required. |

| 2 | Maintain Contact | Work Site and Ministry contact information is maintained here. The work site contact entered here will be used as defaults for the quarterly industrial data submission to the ministry. |

For details on the “Administration” tab, see Section 5 of this guide.

5. Managing your account

Before getting started with MEWS business, you need to change your password and check your contact information with the ministry. You do this through the “Administration” tab, which has two modules: Change My Password and Maintain Contact (see Figure 9)

Figure 9

a. Changing your password

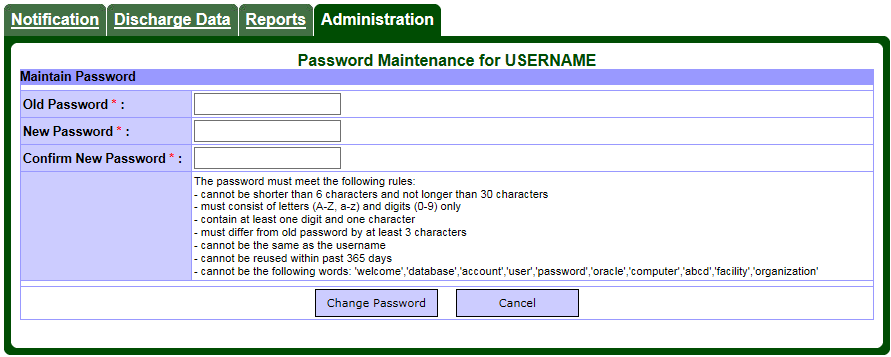

You will be provided with an initial user name and password by the ministry. It is highly recommended that you change your password the first time you log on. After you click on the Change My Password module from the MEWS “Administration” tab, the Password Maintenance page appears (see Figure 10).

Figure 10

Entering old and new passwords

To change your password:

- Enter your current (“old”) password in the first field.

- Enter a “new” password in the second field.

- Confirm the new password by entering it again in the third field.

The data entry section contains the following fields:

| Field | Description | Editable? |

|---|---|---|

| Old Password | Enter your old password for security check. | Yes |

| New Password | Enter your new password. | Yes |

| Confirm New Password | Re-enter your new password for confirmation | Yes |

All fields are mandatory. The new password must meet the following rules:

- Cannot be shorter than 6 characters and not longer than 30 characters.

- Must consist of letters (A to Z, a to z) and digits (0 to 9) only.

- Contain at least one digit and one character.

- Must differ from old password by at least 3 characters.

- Cannot be the same as the username.

- Cannot be reused within past 365 days.

- Cannot be the following words: ‘welcome’, ‘database’, ‘account’, ‘user’, ‘password’, ‘oracle’, ‘computer’, ‘abcd’, ‘facility’, ‘organization’.

The following buttons are available:

| Button | Description |

|---|---|

| Change Password | Saves the new password. |

| Cancel | Exits the current page without saving any changes, and returns to Administration tab page. |

Saving a new password

Click the ‘Change Password’ button to save the new password. The following validation message may appear:

| Validation message | Meaning |

|---|---|

| “Old Password is incorrect.” | Re-enter old password in the Old Password field. |

| “Invalid New Password.” | Make sure the new password adheres to the rules as listed on the change password page. |

| “New Password and Confirm Password do not match.” | Make sure that the New Password field and the Confirm Password field contain the same password. |

After the password has been successfully changed a message will be displayed: “Success! Password has been changed.”

You may continue working in MEWS but the next time you log in, use your new password.

Note: If you have forgotten your password and need to have the password reset, please contact the MEWS Program Officer. A new temporary password will be provided. It is highly recommended that you change the temporary password immediately.

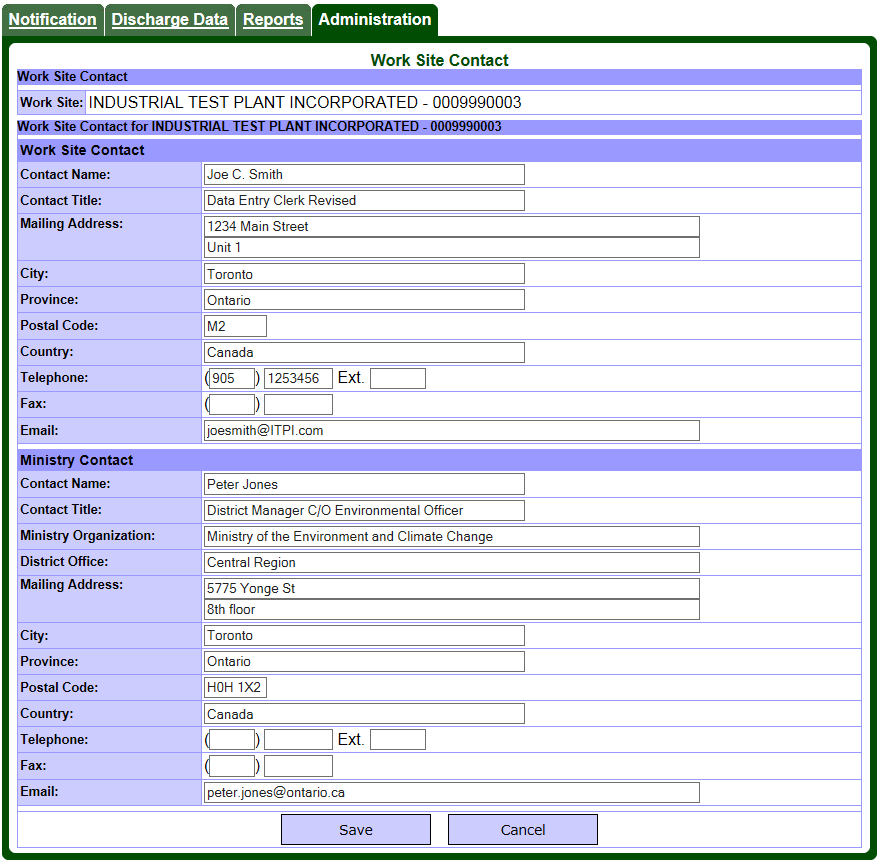

b. Maintaining contact information for the ministry

You can manage the contact information that the ministry needs for your data submissions in the Maintain Contact module. When you select this module in the “Administration” tab, the Work Site Contact page appears (see Figure 11).

Figure 11

There are 2 types of contact information required for the work site:

| Number | Contact Type | Where contact information is used |

|---|---|---|

| 1. | Work Site Contact | The work site contact information is used to automatically populate the appropriate submission information fields on the “Data Submission” page (explained in Section 10) on which you enter information when performing data submissions. |

| 2. | Ministry Contact | The ministry contact information will provide you with details to allow you to directly contact your District Officer. This information also appears on the Transmittal Sheet. |

Important Note: The data submission Transmittal Sheet will not include all the required components unless the work site contact (including the ministry contact) data are completed.

The work site contact should be an employee of the discharger, who has been assigned a MEWS user account, preferably with the role of Industrial Officer. The work site contact details must relate to the same discharger for whom the user is logged in; the company name of the discharger is automatically populated in the Work Site field. The regulatory requirement is for the Transmittal Sheet to be signed by the discharger, who is defined as being “the owner or person in occupation or having the charge, management or control of a plant”. While the Transmittal Sheet is populated with the work site contact details (Figure 81), since the person signing may not necessarily be the same person listed as being the Work Site Contact person, the Transmittal Sheet must be completed/revised manually in the format provided.

For the Ministry Contact information, the Contact Name field should be the District Manager care of (“C/O”) your Environmental Officer, and the Contact Title field should be “District Manager”. The Transmittal Sheet is populated with this information (Figure 81); the regulatory requirement is for the discharger to make their data submissions to the “Director”, who is defined as the District Manager. The remainder of the Ministry Contact information should relate to the Environmental Officer.

You may perform any of the following tasks on the Work Site Contact page:

- retrieve the contact information

- edit the contact information

- save contact information modifications

- cancel contact information modifications

Retrieving the contact information

MEWS will automatically retrieve existing contact information. You may proceed with editing. Note that upon entering the Work Site Contact page for the first time, the data entry fields will be blank.

Editing the contact information

The retrieved contact information is displayed in the data entry section. You can edit the contact information on this page. To modify contact information, move the cursor to the desired contact field and enter the new information. The data entry section contains the following fields:

| Field | Description | Editable? |

|---|---|---|

| Work Site | Defaults to your work site. | No |

| Work Site Contact | ||

| Contact Name | Name of the work site contact person. | Yes |

| Contact Title | Title of the work site contact person. | Yes |

| Mailing Address | Mailing address of the work site contact; can include street number and name, postal box number, suite number, rural route number, etc. | Yes |

| City | City of the mailing address. | Yes |

| Province | Province of the mailing address. | Yes |

| Postal Code | Postal Code of the mailing address. | Yes |

| Country | Country of the mailing address. | Yes |

| Telephone | Area Code (3-digit), telephone number (7-digit) and extension (4-characters, if applicable) of the work site contact. | Yes |

| Fax | Area Code (3-digit) and fax number (7-digit) of the work site contact. | Yes |

| Email address of the work site contact. | Yes | |

| Ministry Contact | ||

| Contact Name | Name of the ministry contact person—enter the name of the District Manager, care of (“C/O”), and the name of your Environmental Officer. The regulatory requirement is for the discharger to make their data submissions to the “Director”, who is defined as the District Manager. | Yes |

| Contact Title | Title of the ministry contact person—should be “District Manager”. The remainder of the Ministry Contact information should relate to the Environmental Officer identified in the Contact Name field. | Yes |

| Ministry Organization | Defaulted to “Ministry of the Environment and Climate Change”. | Yes |

| District Office | Name of the ministry District Office. | Yes |

| Mailing Address | Mailing address of the ministry contact; can include street number and name, postal box number, suite number, etc. | Yes |

| City | City of the mailing address. | Yes |

| Province | Province of the mailing address. | Yes |

| Postal Code | Postal Code of the mailing address. | Yes |

| Country | Country of the mailing address. | Yes |

| Telephone | Area Code (3-digit), telephone number (7-digit) and extension (4-characters, if applicable) of the ministry contact. | Yes |

| Fax | Area Code (3-digit) and fax number (7-digit) of the ministry contact. | Yes |

| Email address of the ministry contact, which is typically firstname.lastname@ontario.ca. | Yes |

Note: MEWS does not validate the contact information entered. However, the telephone numbers, fax numbers and email addresses must be in the appropriate formats.

The following buttons are available:

| Button | Description |

|---|---|

| Save | Saves all modifications and returns to previous screen. |

| Cancel | Exits the current page without saving any changes, and returns to previous page. |

Saving contact information modifications

To save changes you have made to the contact information during your editing, click on the ‘Save’ button at the bottom of the page.

Note: When the ‘Save’ button is clicked, the data will be saved and the system will return to the “Administration” tab page.

Canceling modifications to contact information

If you want to cancel your changes, simply click on the ‘Cancel’ button.

Note: When the ‘Cancel’ button is clicked, the system will return to the “Administration” tab page, without saving any of the changes that you have made.

c. Removing a work site from MEWS

A work site can be removed from the MEWS system. The discharger must contact the MEWS Program Officer to confirm why the work site should be removed from the MEWS system and the final day of discharge from work site. The work site will then be end-dated in the MEWS system and related MEWS accounts will be removed.

Alternately, an MOECC Environmental Officer may notify the MEWS Program Officer of a work site status (e.g. company out of business), and the MOECC will proceed with end-dating the work site and removing all related MEWS accounts from the system.

Note: A work site should be removed from MEWS when there is no longer any discharge of wastewater effluent directly to Ontario waterways from any control point, and when there is no expectation of any such discharge in the future. Examples include: permanent site closure, diversion of all discharge to sanitary sewer, and wholesale change of operations. This is not the same as designating control points as being Inactive—see Section 6.

6. Specifying an inactive control point

There will be occasions when a work site has no discharge from one or more control points for a significant (week or more) amount of time. In these cases, it is important that you let the ministry know that there was no discharge from the control point(s).

This can be easily accomplished by designating a control point as inactive. Below are the steps one should take in ensuring that there are no errors and the information is accurately submitted to the ministry.

a. Specifying an inactive control point

This section features a function that allows you to enter a start and end date where no effluent has passed the sample location over an extended time period. Examples of no discharge over an extended time period include:

- The sample location is shut down for maintenance.

- The discharge is rerouted from one control point to another for a defined period of time (overflow effluent discharge).

- The discharge facility is temporarily shut down (e.g., seasonal, work stoppage)—see Section 6d, Submitting quarterly data with all control points inactive.

The remark code “!NM” will automatically be added for each entire month for which no discharge is entered using the Inactive Control Point module. You should enter the reason for no discharge in the Comments field provided in the “Data Submission Form” (see Section 10, Submitting industrial data) prior to submitting the quarterly Industrial Data.

“Inactive” is defined as a period of time during which no effluent was discharged for listed control point(s).

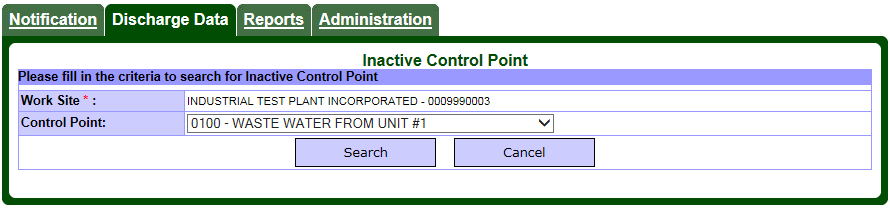

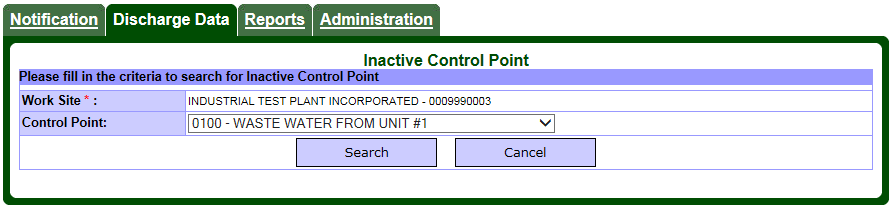

Select module #4 from the “Discharge Data” tab (see Figure 12).

Figure 12

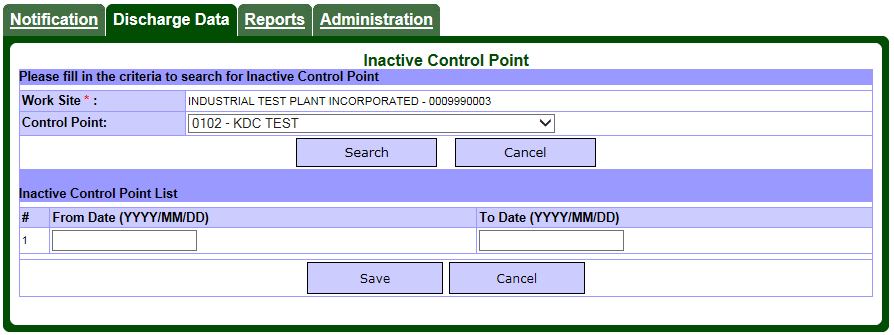

You must first identify the control point that is inactive. To do this, select the control point from the pick list (see Figure 13).

Figure 13

The following table identifies the criteria:

| Field | Description | What to do |

|---|---|---|

| Work Site | Name and number of the work site. | This field is pre-populated. |

| Control Point | Name and number of the control point within the work site. | Select a control point from the pick list. |

Hint: If a control point is no longer being used, you must inform the ministry to change your Company Profile File (CPF).

The following buttons are available:

| Button | Description |

|---|---|

| Search | Retrieves the period of inactivity for a control point. Also, refreshes the screen and removes any incorrectly entered dates / record. |

| Cancel | Exits the current page and returns to the Discharge Data tab. |

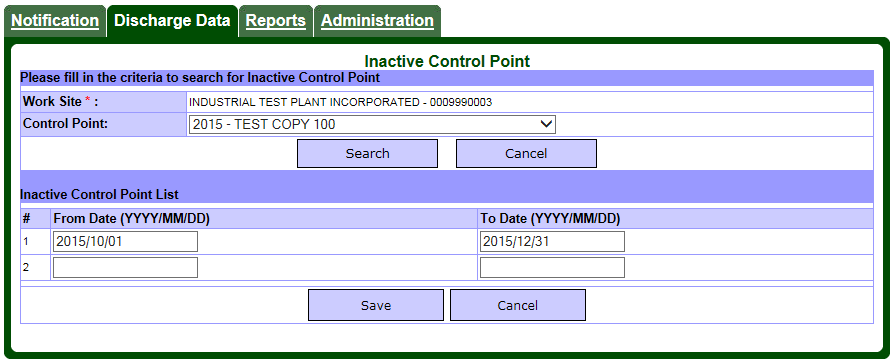

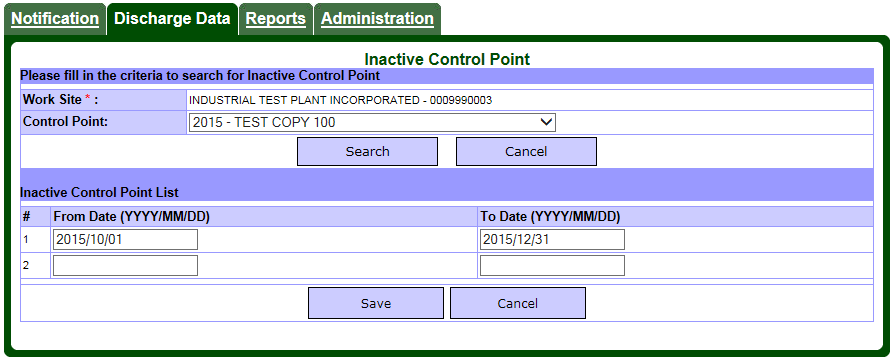

Once you click Search, the application will search for dates already entered for the selected control point. If no data is found, a blank record will appear for entry of dates by the user (see Figure 14). If data is found, the dates for which the control point is inactive will be listed.

Figure 14

Enter the “From Date” and the “To Date” (in yyyy/mm/dd format) for the period of time during which there is no discharge for this control point. The start and end dates of periods of control point inactivity must be within the reporting period, and are inclusive. The following table identifies the data entry fields:

| Field | Description | What to do |

|---|---|---|

| From Date | The beginning of the period of time during which there is no discharge for this control point. | Enter the beginning date of the inactive control point in yyyy/mm/dd format (must be within the reporting period). |

| To Date | The end of the period of time during which there is no discharge for this control point. | Enter the end date of the inactive control point in yyyy/mm/dd format (must be within the same reporting period as the From Date). |

The following buttons are available:

| Button | Description |

|---|---|

| Save | Saves the control point inactive information to the database and adds a second line with blank date range fields for the same control point. |

| Cancel | Exits the current page (without saving any changes), and returns to the Discharge Data tab page. |

The following validation message may appear:

| Validation message | Meaning/button |

|---|---|

| Input value must be in (YYYY/MM/DD) format. | The dates entered in the “From Date” or “To Date” field are invalid. This error message will supersede the “To Date and From Date cannot span more than a quarter” error message if both errors are present. |

| To Date and From Date cannot span more than a quarter. | The period identified by a From Date and To Date is more than a calendar quarter (i.e., one of the 4 three-month periods within each calendar year). Old entries may be validated as new ones are entered; check all inactive date entries for the control point and revise. |

| Data exists for Inactive control point period specified. Please delete data from YYYY/MM/DD to YYYY/MM/DD. | Data cannot be entered or exist for an inactive control point period. The data should be removed or the inactive control point information revised. |

If you change the Control Point, click the “Search” button again.

Once you have saved one set of dates, a second line will appear with blank fields for entry of another date range for the same control point, if required (see Figure 15).

Figure 15

Enter the next set of dates and click “Save.” If there are no other periods to be entered for this control point, click “Cancel” to return to the “Discharge Data” tab page. Or select another control point from the control point pick list and click the “Search” button. Repeat the above steps to enter the inactive period information for the control point.

Hint: You may provide additional information regarding the inactive control point. Enter this information in the Comments field provided in the “Data Submission Form” (see Section 10, Submitting industrial data) prior to submitting the quarterly Industrial Data.

Note: Inactive control point periods, “From” and “To” dates, can only be entered through this website module. Inactive “From” and “To” dates cannot be entered via XML file uploads.

b. Editing an inactive control point time period

Select module #4 from the “Discharge Data” tab (see Figure 12).

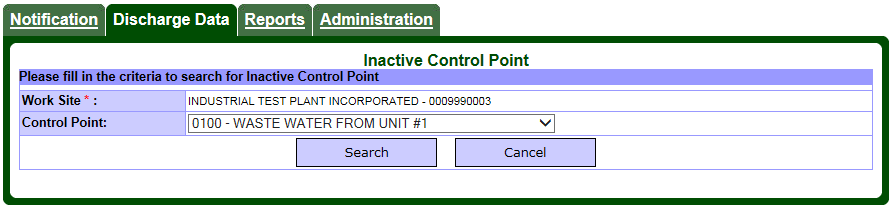

You must first identify the control point that requires the inactive period to be edited. To do this, select the control point from the pick list in the criteria section of the page (see Figure 16).

Figure 16

The following table identifies the criteria:

| Field | Description | What to do |

|---|---|---|

| Work Site | Name and umber of the work site. | This field is pre-populated. |

| Control Point | Name and number of the control point within the work site. | Select a control point from the pick list. |

The following buttons are available:

| Button | Description |

|---|---|

| Search | Retrieves the period of inactivity for a control point. |

| Cancel | Exits the current page (not saving any changes), and returns to MEWS Discharge Data tab page. |

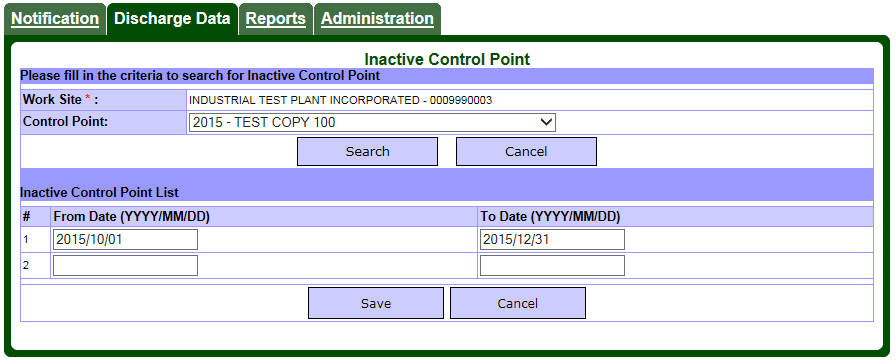

Once you click Search, the application will search for the selected control point. If no data is found, a blank record will appear for entry of dates by the user. If data is found, the dates for which the control point is inactive will be listed (see Figure 17).

Figure 17

To edit an existing from/to date period, place the cursor in the appropriate field and change the date. Click the ‘Save’ button.

c. Deleting an inactive control point time period

Select module #4 from the “Discharge Data” tab (see Figure 12). You must first identify the control point that has an inactive period to be deleted. To do this, select the control point from the pick list (see Figure 18).

Figure 18

The following table identifies the criteria:

| Field | Description | What to do |

|---|---|---|

| Work Site | Name and number of the work site. | This field is pre-populated. |

| Control Point | Name and number of the control point within the work site. | Select a control point from the pick list. |

The following buttons are available:

| Button | Description |

|---|---|

| Search | Retrieves the period of inactivity for a control point. |

| Cancel | Exits the current page (not saving any changes), and returns to the MEWS Discharge Data tab page. |

Once you click Search, the application will search for the selected control point. If no data is found, a blank record will appear for entry of dates by the user. If data is found, the dates for which the control point is inactive will be listed (see Figure 19).

Figure 19

To delete an inactive date period record, highlight the date and delete the values in each of the “From Date” and “To Date” fields. Click the ‘Save’ button.

Important Note: If all sample dates for a quarter are deleted, as described in Section 7d, the inactive control point periods must also be deleted to clear all information for the quarter.

d. Submitting quarterly data with inactive control points

The discharger is reminded that even if all control points are indicated as being inactive for an entire reporting period (i.e. the full quarter), the discharger is obligated to submit a Detail Discharges Report to the MOECC for this quarter.

The discharger is further reminded that the start date and end date of periods of control point inactivity must be within the reporting period.

Important Note: The discharger should complete a Detail Submission (see Section 10) and submit a Detail Discharges Report (section 9c) if any or all control points are inactive for any period greater than a month.

7. Discharge data: Entering sample results

The second tab is the “Discharge Data” tab (see Figure 20). Four modules appear in this tab:

- Industrial Data Entry

- Industrial Data Upload (XML)

- Submit Industrial Data

- Inactive Control Point

Figure 20

“Discharge Data” entry is the primary front-end tool for wastewater discharge reporting. It provides an easy-to-use interface for entering and editing sample results for industrial wastewater discharge. You can create a new discharge sample and save it, you can edit existing discharge data, or you can delete an entire sample.

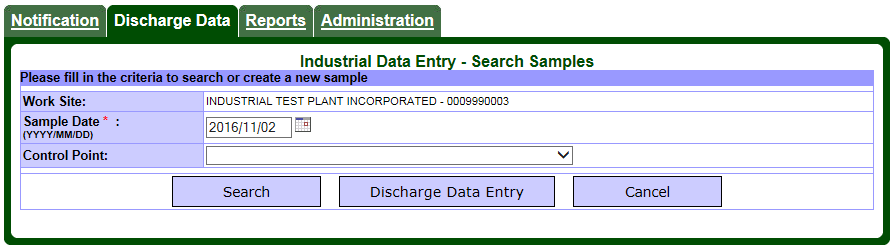

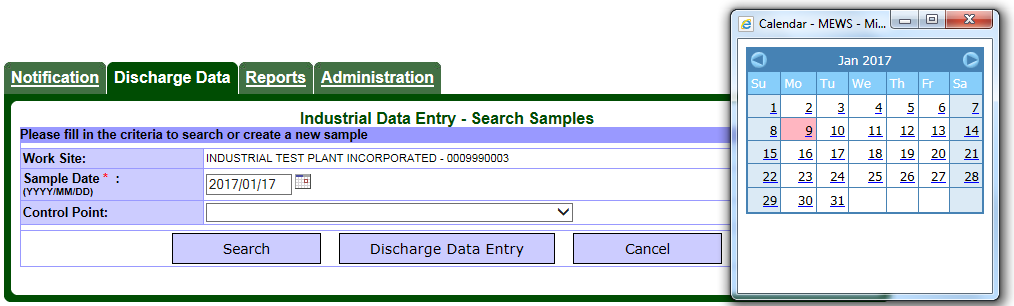

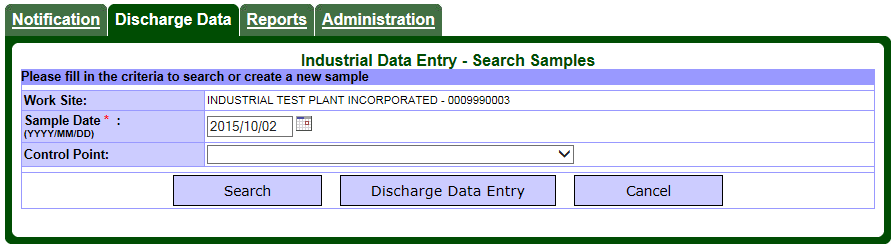

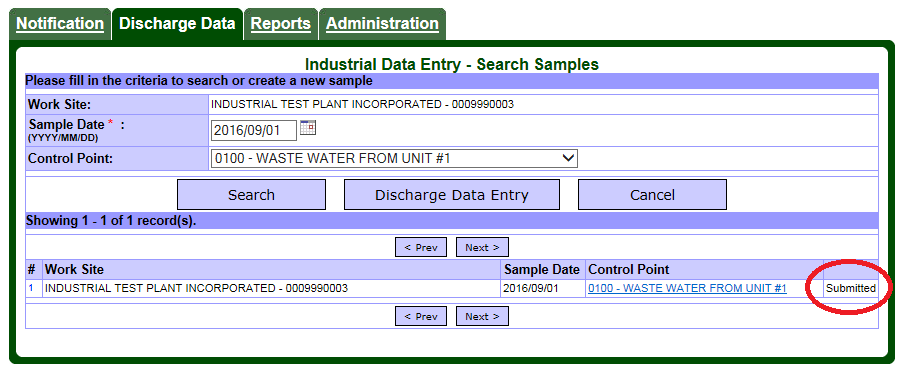

On the “Discharge Data” tab, click on module #1, Industrial Data Entry. The Industrial Data Entry - Search Samples page appears (see Figure 21). Use this page to enter or edit discharge data.

Figure 21

The following table describes the fields and buttons found in the Industrial Data Entry module:

| Field / Button | Description | What to do |

|---|---|---|

| Work Site | Your company name will appear in this field. | This field is pre-populated; however, if the company name has changed, the discharger must advise the MOECC and the Company Profile File must be updated. The company name must include the legal name of the company, followed by the work site company name if it is different than the legal name. |

| Sample Date | Date the discharge sample is taken. Defaults to today’s date. | Enter a valid date to identify when the sample was taken. The default format is yyyy/mm/dd, such as 2017/01/19.

Type the date or click on the calendar icon to select the sample date by calendar. When you select a date in the calendar, it will appear in the sample date field, as in Figure 22 below. |

| Control Point | Provides a drop down pick list of pipe-level control points that are active at the above work site and sampling date. This pick list is dynamically populated based on the company profile and the above specified work site and sampling date. | Select the pipe-level control point of interest. |

| Search | Provides a list of existing sample results based on criteria such as sample date and control point. | Use only if discharge data is already entered and you want to review or edit the information. |

| Discharge Data Entry | Opens the Industrial Data Entry Discharge Data Sample Results page. | Click when you have entered the sample date and control point and you are ready to enter new discharge data. |

| Cancel | Exits the current page without saving any changes, and returns to Discharge Data tab page. | Click to cancel anything you have entered and return to the “Discharge Data” tab page. |

First, enter the date (see Figure 22).

Figure 22

Hint: Certain dates on the calendar appear in red. At least one sample has been created on those dates, for at least one control point.

Important Note: After the sample date is entered, MEWS searches the appropriate company profile for the sample date. The system will pop up a “Please Wait” window. Allow the system to refresh the screen before continuing.

Note: The calendar pop-up window may continue to appear on the screen or be active after the search is completed; in this case, click on the X to close the calendar window.

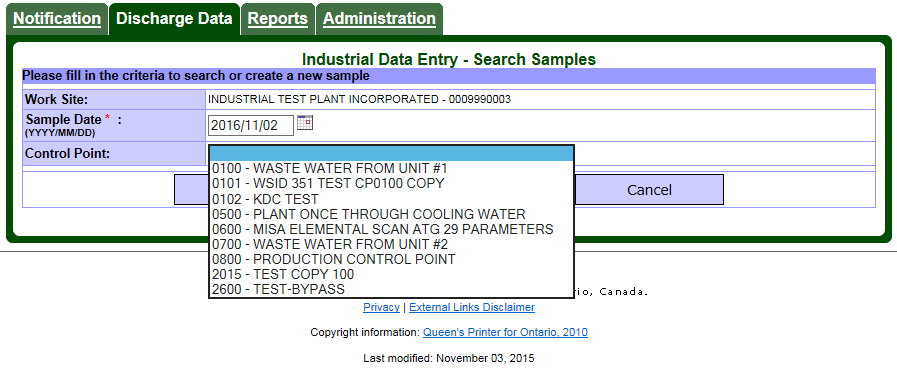

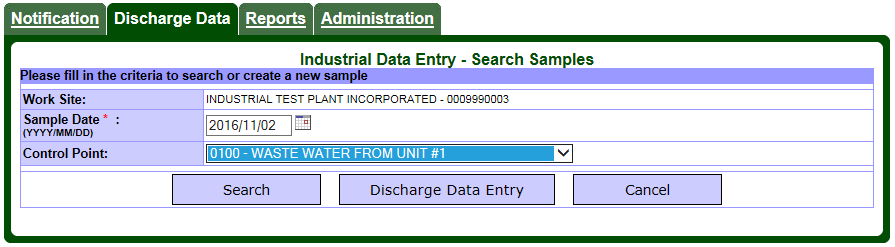

Next, select a control point from the drop-down list (see Figure 23 and Figure 24).

Figure 23

Figure 24

Now you are ready to enter the discharge sample result values. Click the Discharge Data Entry button at the bottom of the page.

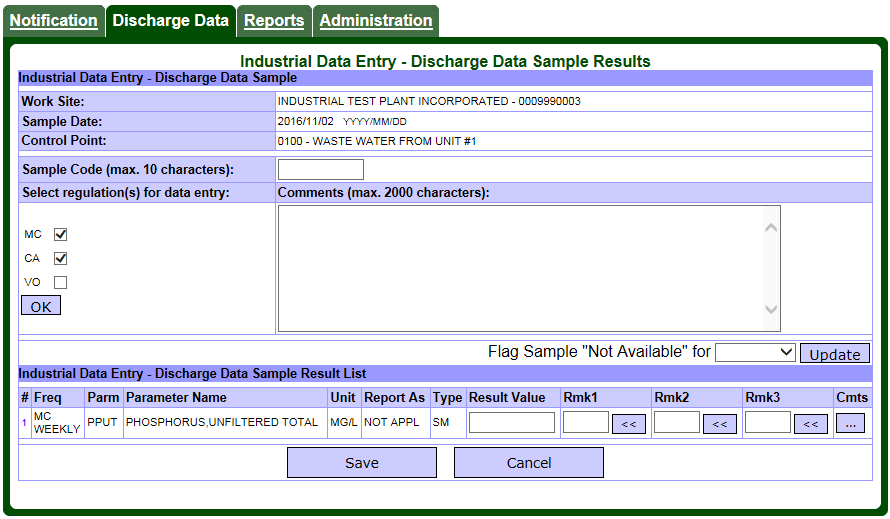

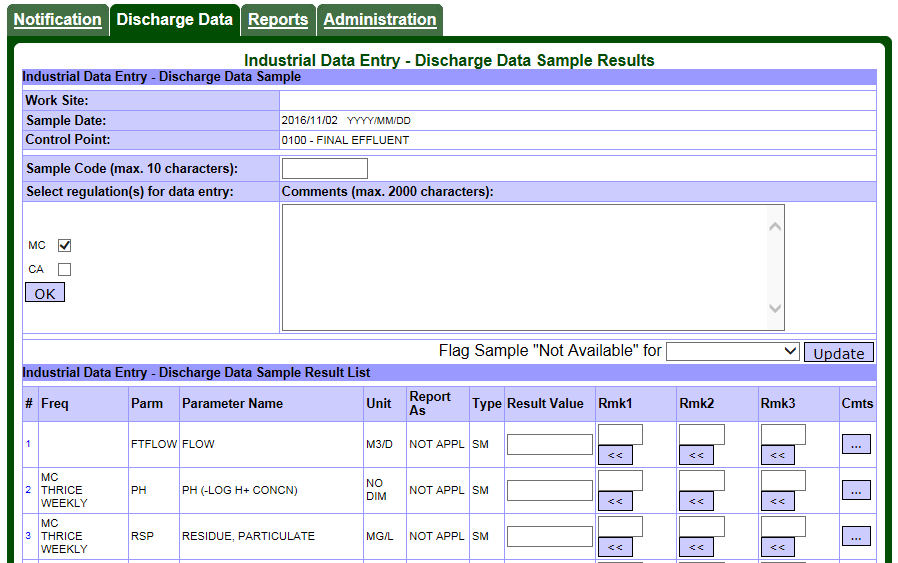

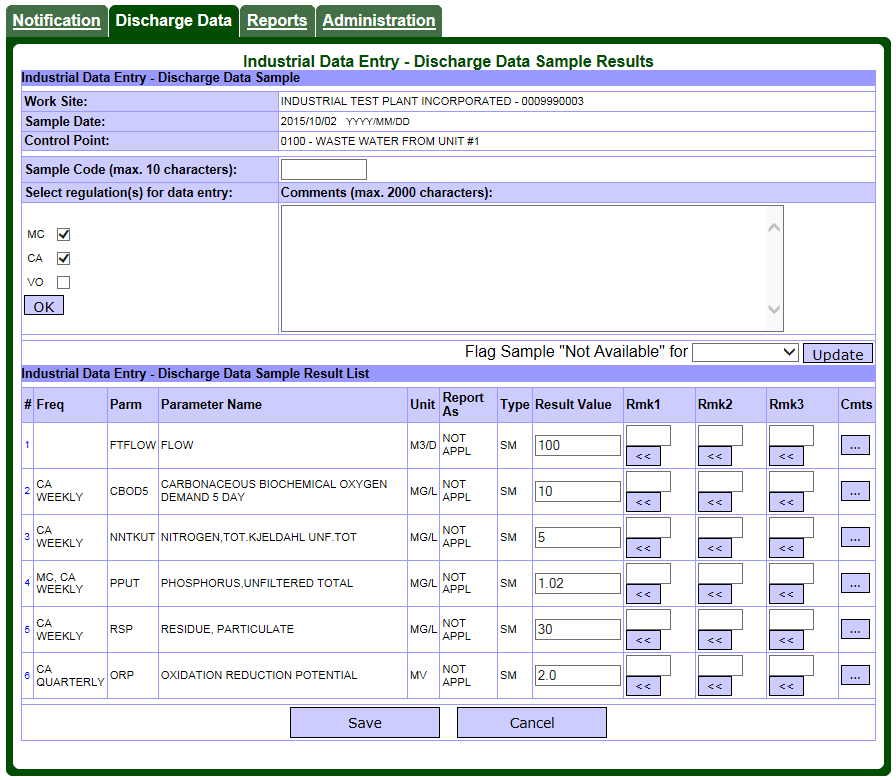

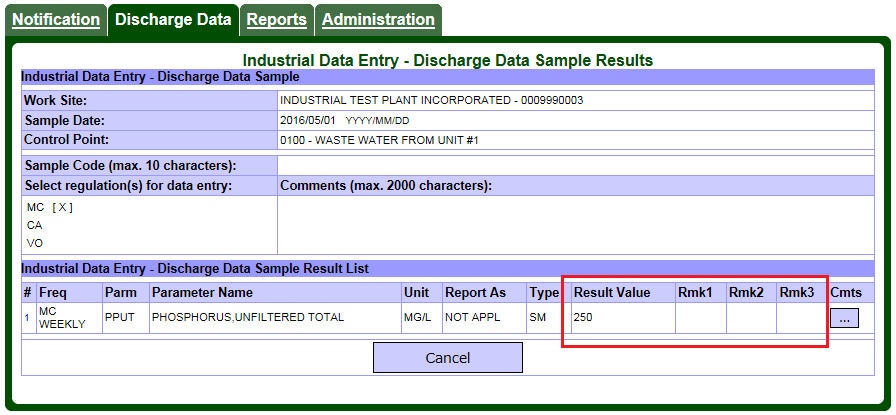

The page similar to the example below will appear (see Figure 25). The number and type of parameters will reflect your work site specific CPF.

Figure 25

a. Understanding the discharge data sample results page

Before you enter new information about discharge samples, make sure you understand everything on this page. It provides access to pipe-level “detailed data” (such as flows and concentration values). Other categories of data, such as statistical (monthly plant-level maximum, minimum and averages) and derived data (such as daily loading), are generated by the Summary Calculation function (discussed in Section 9a, “Tips for retrieving reports”).

The Discharge Data Sample Results page contains the following fields:

| Field | Description | Editable? |

|---|---|---|

| Work Site | The company name and unique IMIS number of the discharger’s work site. | No |

| Sample Date | The chosen date of the discharge sample for data entering and/or editing. | No |

| Control Point | The chosen control point of the discharge sample for data entering and/or editing. Control points are typically located at the end of a discharge pipe, and are prescribed by a legal instrument. | No |

| Sample Code | An identifier to be associated with the discharge sample as a whole. This field is optional, free-text, and can include up to 10 alphanumeric characters. Dischargers may use this field to document their own sample numbering system. However, it does not appear on any reports. | Yes |

| Select Regulation | Available modules for the different ministry regulations. Refer to section 7b, “Entering new discharge data,” for more details. See full name descriptions in your CPF. | Yes |

| Comment | A comment to be associated with the discharge sample as a whole. This field is optional, free-text, and can include up to 2000 alphanumeric characters. This comment will appear on the Detail Discharges Report. This comment will appear on the Summary Discharges Report, provided at least one result value or remark has been entered for the sample. | Yes |

| Flag Sample “Not Available” for | Refer to section 7b, “Entering new discharge data,” for more details. | Yes |

The discharge sample parameters are displayed in tabular format. Each row represents a reporting-for-time (frequency) and parameter that have been customized in the “active” company profile. The following field items are presented in a tabular fashion:

| Field | Description | Editable? |

|---|---|---|

| # | A unique row number for each reporting parameter in the current data entry screen. | No |

| Freq | The reporting frequency of the parameter, also known as “Reporting-For-Time”. | No |

| Parm | The code of the parameter being reported. | No |

| Parameter Name | The name of the parameter being reported. | No |

| Unit | The abbreviation of the unit of measure of the parameter. | No |

| Report As | An abbreviation of an alternative way that the parameter will be reported. For example, the parameter BOD5 is reported as oxygen (“as O”). | No |

| Type | The type of the component of the result structure that applies to the parameter. For example, “SM” means “single measurement”, whereas “T3” means “time 3”. | No |

| Result Value | The value of the result of the analysis of the sample for the given control point, date, parameter, and unit of measure. Typically the result value is a number representing a concentration, but it could also refer to a value for time, acidity, conductivity, the number of days, or a toxicity exceedance, among others. Some parameters require the value to be chosen from a pick list. The result value must be left blank if none is required on the given sample date (see Note below). | Yes |

| Rmk 1, Rmk 2, Rmk 3, | A remark represented by a code, to be associated with the result value. All remark codes must be chosen from a pick list. | Yes |

| Cmt | A comment to be associated with the result value. This field is optional, free-text, and can include up to 2000 alphanumeric characters. This comment will appear on the Detail Discharges Report only. | Yes |

Hint: All fields bolded in the chart above are generated from your Company Profile File (CPF).

The reporting parameters are listed, with flow parameter appearing at the top of the list. The rest of the reporting parameters follow Flow, and are listed alphabetically by:

- frequency of reporting

- parameter code

- unit abbreviation

- type of result structure component

Note: During data entry, you don’t need to enter result values for all parameters. For a given sample, only parameters required for that day need to be entered.

For example, if the discharge control point is customized for daily, weekly and monthly reporting of various parameters, result values (or remarks) for daily parameters must be reported every day, for weekly parameters must be reported once per week, and for monthly parameters must be reported once per month.

Consult the regulatory requirements that apply to your work site. For each sample location and parameter, the monitoring and reporting periods are also listed in your Company Profile File (CPF).

Note: If no result value is available on a required sample date, a Remark Code (and optionally a Comment) should be entered to explain why a result value has not been entered (see Section 7b, “Entering new discharge data”).

Hint: You can use the short-cut Ctrl+F to search for alphanumeric characters to find a word or value on the page.

b. Entering new discharge data

Notice that there are four different buttons on this page. Use these buttons to enter new information about your discharge data.

| Button | Description |

|---|---|

| ok | To confirm the selected regulation. All of the applicable regulations must be selected (checked) for the specified sample date before entering any data; otherwise some data may be lost. Click the ok button prior to entering any data. |

| Update | To populate the “!NM” remark code in the remark field for parameter records of a frequency selected in the drop down ‘Flag Sample “Not Available” for’ field. The Update button applying the Flag must be clicked prior to entering data for all parameters with the selected frequency, otherwise the result values and / or remarks entered for all such parameters will be deleted and replaced by the remark code “!NM” (“no effluent - no sample available”). |

| Save | Saves all modifications since the last cancel or save. The system will return to the “Industrial Data Entry - Search Samples” page. |

| Cancel | Exits the current page without saving any changes, and returns to “Industrial Data Entry - Search Samples” page. |

Note: Please ensure that your CPF contains your monitoring and reporting requirements. See Section 4b for details.

Note: Individual reporting parameters cannot be inserted during discharge sample editing. If there are missing reporting parameters for the control point selected, you must notify the ministry to modify your Company Profile File.

Note: In the Industrial Data Entry module, don’t use the back button in the Browser toolbar. Use the “Save” and “Cancel” buttons on the MEWS page.

Selecting available regulation

You can select one regulation or a combination of several regulations. The example below (see Figure 26) shows two possible selections: MC (MISA Compliance) and CA (Certificate of Approval/Environmental Compliance Approval).

Figure 26

The default selection is “MC” if MC is in the Company Profile—all customization of the parameters required under MISA/EMEL Compliance will automatically appear. If other parameters are required for the same sample date under different regulations, you will need to also select the regulation that applies for that sample date, and then press the ‘ok’ button. The page will refresh with the appropriate parameters to be reported for the selected regulations and sample date.

Important Note: All of the applicable regulations must be selected (checked) prior to entering any data. Click the ‘ok’ button. Once the ‘ok’ button is clicked, this page will refresh with the parameters customized for the selected regulation(s). When you come back for further editing for the specified sample date, you must select the same regulation(s) entered in the previous session for the same sample date. If not, data will be lost.

For example, you select regulations MC and CA for a specified sample date, complete data entry and save the data. You then return to the same specified sample date and select only regulation CA to edit result values. You then save the data: MEWS saves only the CA data for that day, and will delete data previously entered for MC, as it will assume that the user intended that only the CA regulation requirements applied for that date. You must always select the same regulations for the specified sample date.

Conversely, only those regulations that are applicable must be selected (checked) prior to clicking the ‘ok’ button and entering any data. The discharger must not select a regulation for which data is not required for the specified date. Doing so may result in Error Logs and report generation failure.

If you de-select the default regulation or fail to select any regulation and then select the ‘ok’ button, no parameters are shown and an error message “Please select at least one regulation” will appear.

Note: If data entry has been completed and the ‘Save’ button is not clicked, data will not be saved.

Following is the default display order of the commonly used regulations:

| Regulations | Abbreviations |

|---|---|

| MISA/EMEL Compliance | MC |

| C. OF A. - Certificate Of Approval / ECA – Environmental Compliance Approval | CA |

| Control Order | CO |

| Provincial Guidelines | PG |

| Provincial Regulations | PR |

| Federal Requirements | FR |

Entering the sample code

The sample code field is optional. This field may be comprised of up to 10 alphanumeric characters. This code is used for your internal reference and sample identification purposes only. This code does not appear on any report.

Entering the sample comments

The sample comment field is optional. This field may be comprised of up to 2000 alphanumeric characters. This comment will appear on the Detail Discharges Report. This comment will appear on the Summary Discharges Report, provided at least one result value or remark has been entered for the sample.

Entering result values

To enter a result value, move the cursor to the desired result value field and enter the new result value. For some parameters, a value and/or result (such as pass/fail) must be selected from the drop-down pick list.

The result value can be blank—simply skip over a result value that is intentionally left blank; do not enter a “null” value such as a space, and do not enter a zero. The result value of all parameters for which the frequency does not apply for the date selected must be blank.

Results that are less than one and greater than zero must be entered with a leading zero (“0.002”, not “.002”), otherwise the value is not recognized as a number.

Scientific E notation (e.g. 3.2 million = 3,200,000 = 3.2 × 106 = 3.2E6) may not be used in data entry or XML file uploads.

Leading blank spaces do not affect the recognition by MEWS of the actual result value—no Error Log will be generated due to leading blanks in a result value.

Trailing blank spaces do not affect the recognition by MEWS of the actual result value—no Error Log will be generated due to trailing blanks in a result value.

Significant digits

The following guidelines should be used to determine the appropriate number of significant digits to report in the result value:

- There are a minimum number of two significant digits when determining compliance.

- Legislated limits containing more than the minimum number of two significant digits are assumed to have an appropriate number of significant digits.

- Reported result values should contain as many significant digits as the method detection limit allows for the type of analytical equipment used.

- All digits in excess of the appropriate number of (or default two) significant digits will be ignored when determining compliance—i.e., no rounding occurs; however, MEWS calculations will use all significant digits as input by the user, when determining a derived value.

- Significant digits start with the first non-zero from the left; however, three significant digits are preferable if the first digit on the left is a "1".

- The Result Value field in MEWS has a restriction of 20 digits, including the decimal point (if any); therefore, the number of significant digits cannot be over 20, and will be less if the numerical result value includes a decimal.

Note: You are required to enter data only for the sample date, regulation and frequencies that apply. Result values may not need to be entered for all parameters.

For a given sample day only parameters required for that day need to be entered. For example, if the discharge control point is customized for daily, weekly and monthly reporting of various parameters, result values (or remarks) for daily parameters must be reported every day, for weekly parameters need only be entered once per week, and for monthly parameters need only be entered once per month.

If the “Flag Sample ‘Not Available’” button is selected for the day, then of course no result value or remark need be entered for all parameters—see the section “Flagging all parameters when no effluent is discharged”.

Note: The parameter value measured using a given method must be recorded as measured and that value must be used to determine compliance with the regulated limits

Note: The purpose of regulating accuracies of monitoring equipment is to ensure that sufficiently accurate equipment is used and to allow enforcement of the use of such equipment. It is not meant to provide variance to compliance with regulated effluent discharge limits.

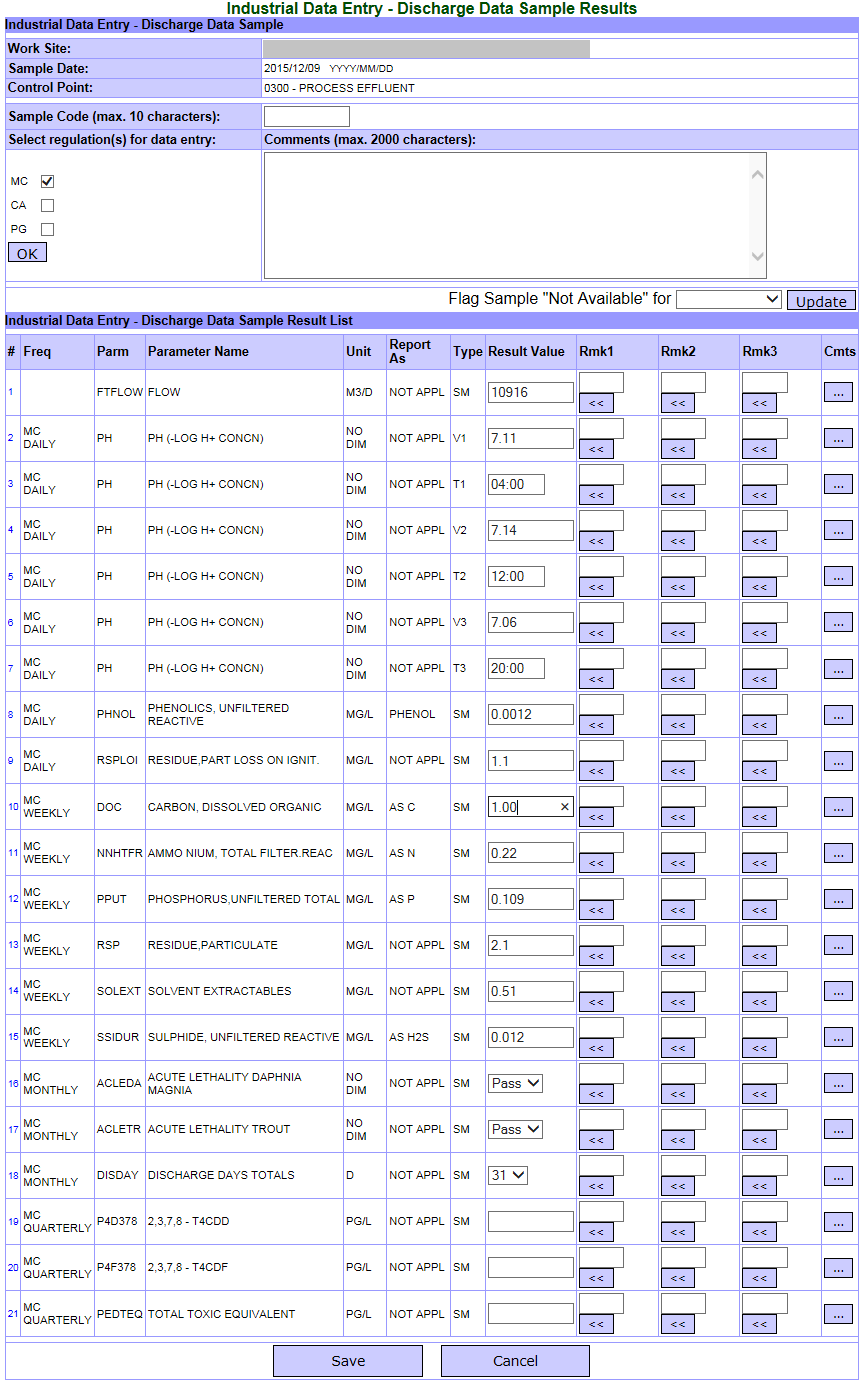

See Figure 27 for an example of properly entered data.

Figure 27

The reporting parameters are listed with flow parameter appearing at the top of the list. The rest of the reporting parameters follow, sorted by Frequency, Parameter test code, Unit Abbreviation, and Structure Component Type.

To easily navigate the Industrial Data Entry screen you may use one or a combination of the following methods:

- Click the scroll bar to move the page up and down.

- Place mouse pointer and click left mouse button to place cursor in the desired field.

- Tab key – to move the cursor to the next field.

- Shift + Tab key – to move the cursor to the previous field

Entering flow value

FTFLOW is customized in the Company Profile File (CPF) for every monitoring frequency that requires a loading calculation and/or a monthly summary calculation for flow, and / or for when flow data by itself is required.

The Flow parameter (FTFLOW) always appears at the top of the Results Table. There is no “Freq” (frequency, or reporting-for-time) displayed with the FTFLOW.

Refer to your regulatory requirements for your flow data entry. If there is no flow for that day:

- Flag “Sample not available for”.

- Click drop down list.

- Select the appropriate frequency as customized in the company profile.

- Click the “Update” button — see the section “Flagging all parameters when no effluent is discharged” for more details.

Entering values with multiple components (like pH)

A Result Structure with multiple components allows for data entry of more than one result value for the reporting parameter (as customized for the parameter) on a given day. The parameter “pH” usually has 6 components customized in its Result Structure. They are:

| Component | Type | Description |

|---|---|---|

| Value 1 | V1 | The numeric value of the first sample result. |

| Time 1 | T1 | The time when the first sample result value was obtained. Enter time as “HH:MM” in 24-hour clock. |

| Value 2 | V2 | The numeric value of the second sample result. |

| Time 2 | T2 | The time when the second sample result value was obtained. Enter time as “HH:MM” in 24-hour clock. |

| Value 3 | V3 | The numeric value of the third sample result. |

| Time 3 | T3 | The time when the third sample result value was obtained. Enter time as “HH:MM” in 24-hour clock. |

Hint: When entering a time value with no minutes, you may skip the minute portion (defaulted to “00”). For example, if the time value is “03:00,” you can simply enter “3” into the Result value. MEWS converts the time value to the HH:MM format, such as 03:00.

For any Value / Time combination, a remark may be entered for that time period only. For example, the on-line analyzer was off-line during only one of these three periods; enter the appropriate remark for that time period.

Other parameters may have a similar Result Structure, including Specific Conductance (Conductivity, or CNDVTY). Some parameters may be customized with a Result Structure requiring the entry of six result values and times on a given day.

Entering results over two days

Some parameters require samples to be taken several times a day with specified periods in between (4 hours, 8 hours, etc.), within the 24-hour period beginning at the first sample. Typically, this is for Daily sampling of the parameters pH, Conductivity, or Temperature. MEWS has no special provision for entering results over two days—the discharger should enter the result values on the day and time of the sampling as usual. For example, result values for the parameter pH customized for 3 result values within a 24-hour period beginning at 14:00 (2:00 PM) with an 8-hour separation, would consist of:

- For the first calendar day, a Remark Code (such as AR) entered instead of a value for V1 at T1 (06:00), a value entered for V2 at T2 (14:00), and a value entered for V3 at T3 (22:00).

- For all subsequent calendar days, a value entered for V1 at T1 (06:00), a value entered for V2 at T2 (14:00), and a value entered for V3 at T3 (22:00).

- For the last calendar day required to be reported, a value entered for V1 at T1 (06:00), a Remark Code (such as AR) entered instead of a value for V2 at T2 (14:00), and a Remark Code (such as AR) entered instead of a value for V3 at T3 (22:00).

The 24-hour period result values reviewed for compliance purposes would then be V2, V3 and V1 over two consecutive calendar days.

Entering pass or fail for acute lethality

You can report pass or fail for acute lethality (toxicity) parameters. You simply:

- Go to the acute lethality parameter at the specified frequency.

- Select either “Pass” or “Fail” or blank in the pick list. “Fail” indicates that toxicity test of the sample obtained from the effluent exceeded the regulatory requirements.

A Remark Code of NL (non-lethal, all organisms survived) is not required in addition to a Pass result value; the Pass result value is sufficient.

| Validation message | Meaning |

|---|---|

| “Invalid Pass/Fail Value. Verify that the value is either "Pass" or "Fail". | The value entered does not match one of the three appropriate entries. The result can only be “ ” (blank), “pass” or “fail” (all capitals letters). |

Note: Please leave the pick list blank if a result is not being reported. This may be the case if the frequency of reporting has been reduced from monthly to quarterly, and the company profile file has not been updated. Notification to the Director may be required for frequency changes; consult applicable regulations for details.

Note: The only parameters that you are required to enter a pass or fail of the regulatory limit exceedance are these toxicity parameters—MEWS calculates regulatory limit exceedances for all other parameters. While toxicity analysis results may be a reportable item, usually only the status of the results exceeding the allowable limit is reportable.

Entering DISDAY value

You can report the number of days in a calendar month that discharge flows past a control point by using the DISDAY parameter. For each month that discharge flows past a control point, on the last day of the month that discharge flowed past the control point, you simply:

- Go to the DISDAY parameter (they all should have a frequency of Monthly).

- Select a number from 1 to 31 in the pick list

The result value for the parameter DISDAY must be blank if:

- There was no discharge flowing past the control point for all days of the month, or

- It is not the last day of the month that discharge flowed past the control point.

For example, a discharger would enter “31” on July 31 for the month of July during which discharge flowed past the control point on all days in the month. A discharger would enter “22” on July 22 for the month of July during which discharge flowed past the control point on the first 22 days only in the month. A discharger would enter “22” on July 31 for the month of July during which discharge flowed past the control point on the last 22 days only in the month.

Note: Two sectors of the MISA/EMEL regulations, Petroleum Sector and Industrial Minerals Sector, are not explicitly required to report the parameter DISDAY at the pipe level. The system currently does not allow DISDAY to be customized at the plant level; therefore, any customization for reporting of DISDAY must be customized at the pipe level. This requires an interpretation of these two regulations to have the same meaning as the other regulations, which require reporting DISDAY at the pipe level.

If there is no flow for a full month, the DISDAY result value should remain blank (do not enter zero). In addition, a remark code is not required if the DISDAY result value is blank.

Low level data reporting

For low-level and “less than” data recording, refer to the ministry publication “Protocol for the Sampling and Analysis of Industrial/Municipal Wastewater,” as amended from time to time (available on the ministry website).

There is no minimum volume for reporting of Flow—i.e., all measured values of flow are to be reported. The discharger must determine if the level of flow is such that sampling cannot be conducted as per the MISA/EMEL Sampling Protocol, and indicate either a flow result value or an inactive control point.

The following table, based on the “Protocol for the Sampling and Analysis of Industrial/Municipal Wastewater,” lists the data entry of low level result values and codes:

| If the Measured Result Value is | Numeric value to be entered | Remark code to be entered |

|---|---|---|

| Equal to or greater than the RMDL | measured value | valid code if required |

| Less than the RMDL and equal to or greater than the LMDL | measured value | <T |

| Less than the LMDL and equal to or greater than the SRI | measured value | <DL |

| Less than the SRI, and the SRI is equal to or greater than the one-tenth the RMDL | measured valueIf a measured value is not available then the SRI value must be recorded. | <W |

| Less than one-tenth the RMDL | measured value | <W |

| Not available due to interference with the sampling | estimated value | > or < |

| Not available for reasons given in a separate report | Leave blank | ! |

Where:

SRI

Smallest Recording Increment

LMDL

Laboratory Method Detection Limit

RMDL

Regulation Method Detection Limit

Note: A discharger using a Laboratory for their sample analysis must obtain a result value from the Laboratory, and the value should be entered in MEWS along with an appropriate Remark Code.

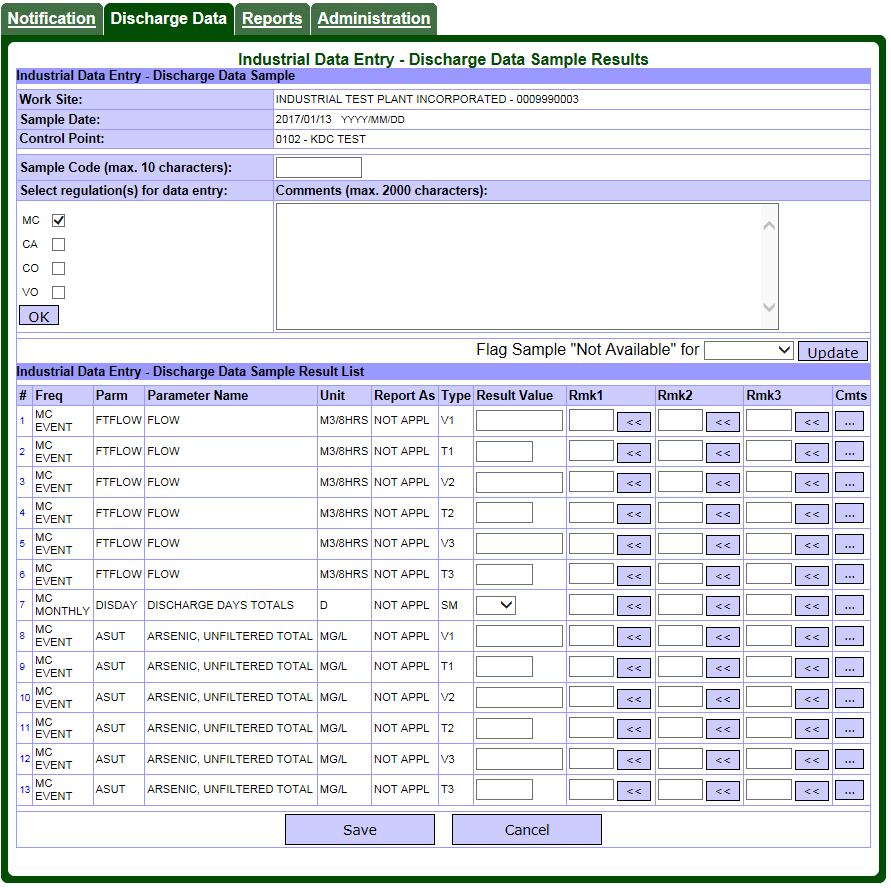

Other direct wastewater: metal mining sector

Companies under the Metal Mining Sector may have overflow effluent sample locations. The Ministry Control Point Type is Type 44, “Other Direct Wastewater”. This CP Type has unique flow and loading calculation requirements. The reporting-for-time period is Event, and the discharger is required for the period of discharge to take a sample during each eight-hour period.

The discharger is also required to report on the volume of effluent that has passed the sample point during the eight-hour period. The flow is reported as the unit of measure cubic meters per eight-hours, or m3/8Hrs.

The discharger is also required to calculate overflow effluent stream loading for the same eight-hour period. The load is reported as the unit of measure kilograms per eight-hours, or kg/8Hrs.

For CP Type 44, the customization for data entry and reporting in MEWS is now as follows:

- Reporting-for-time is Event.

- Result Structure is P3 (three sample result values and times per day) for flow, concentration and loading.

Figure 28 shows the customized data entry page for this control point type.

Figure 28

Entering remarks for result value

In some cases, a remark may be entered instead of entering a result value. For instance, if there is no flow on the date a sample is required, a remark such as “!NM” should be entered and the result value field remains blank. If there is no flow for extended periods of time at a sample location, refer to Section 6 for inactive control points. In other cases, such as for low-level result values, both a remark and a result value must be entered. See Section 6 of the "Protocol for the Sampling and Analysis of Industrial/Municipal Wastewater".

Sample locations and/or parameters with the sampling frequency as “Event” are expected to have infrequent flows or sample under specific conditions set out in applicable regulations. A result is expected to be entered only when a flow event occurs or the conditions warrant sampling. The “!NM” remark code is not required to indicate no flow when the sampling frequency as “Event”.

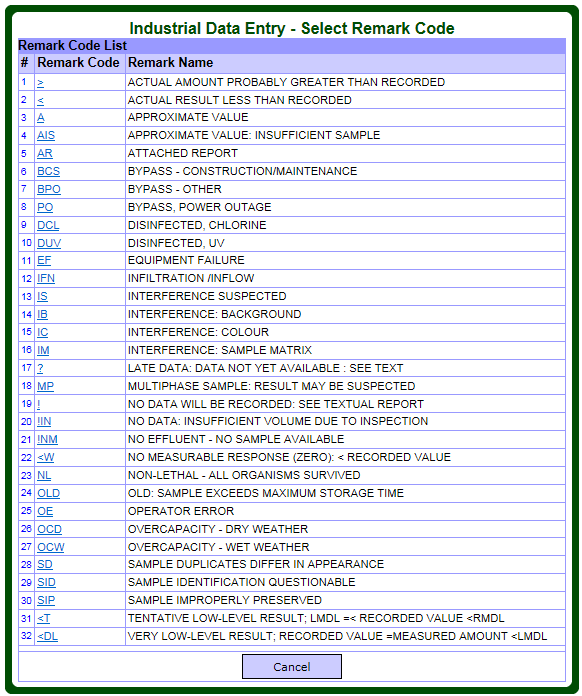

Each result value can have up to 3 remarks. Simply enter a valid remark code in the ‘Rmk1’, ‘Rmk2’ and ‘Rmk3’ fields. Alternatively, click on the double arrow button to display the list of remark codes (see Figure 29)

Figure 29

Select the desired remark by clicking on the “Remark Code” beside the “Remark Name” to associate a remark with the result value. Only one can be chosen at any one time. Once a Code has been selected, it will populate the Remark field for the parameter, and the Remark Code dialog box will close. The “Cancel” button will close the “List of Remark Codes” dialog box.

A Remark Code must be entered in the order of ‘Rmk1’ field, ‘Rmk2’ field (if a second Remark Code is required), and ‘Rmk3’ field (if a third Remark Code is required).

The following validation message will appear if a remark code not listed above is used and if “Rmk” fields are blank.

| Validation message | Meaning |

|---|---|

| “Invalid Remark Code “*” for Rmk* on row *.” | The value remark code is invalid. Verify that the value remark code is valid or select the remark code from the List of Codes. |

| “Remark code 1 (and/or 2) cannot be blank when remark code 2 (or 3) is specified on row *.” | The remark codes must be entered in the order of Rmk1, Rmk2 and Rmk3 fields. Add the first remark code to Rmk1, the second remark code to Rmk2 and the third remark code to Rmk3. |

Result Value Remark Codes will appear on the Detail Discharges Report; they will not appear on the Summary Discharges Report.

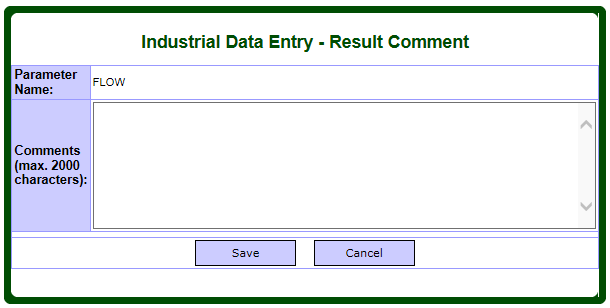

Entering a comment for a result

Each reporting parameter result value can have an associated comment. Simply click on the square in the “Cmts” column to display the Result Comment dialog box. Enter the result comment (maximum of 2000 alphanumeric characters) and press ‘Save’, or ‘Cancel’ to exit (see Figure 30).

Note that a comment for a result will only appear in the Detail Discharges Report.

Figure 30

Note: The comment is associated with the result and not the individual result value of a multiple components reporting structure. (For example, the result comment of a pH reporting parameter is associated with all the result components V1, T1, V2, T2, V3 and T3.) A result or remark must be entered.

The following validation message may appear:

| Validation message | Meaning |

|---|---|

| “Error on row xx. Comment cannot be saved without a valid value or remark.” | You need to complete the result value field and/or choose a remark code. |

Hint: To close the Result Comment box, click on ‘Cancel’ or the X in the top right corner.

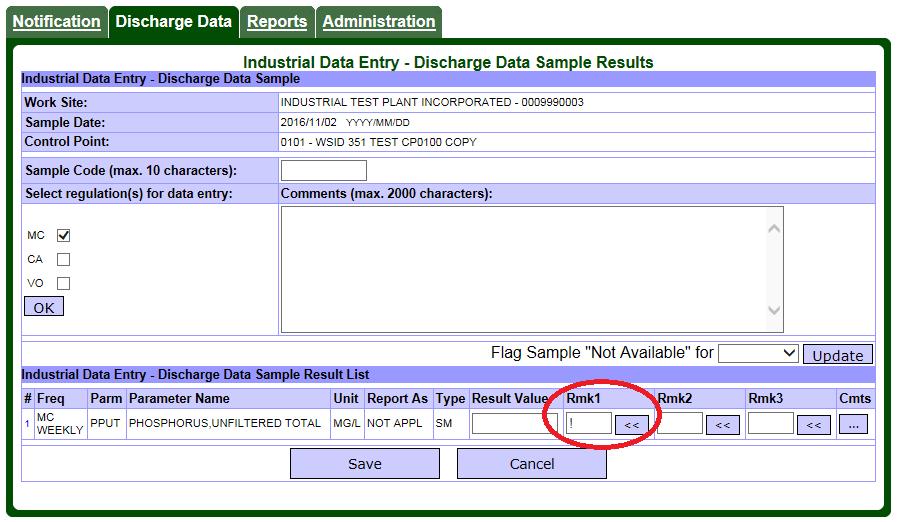

Tagging parameters as no data recorded

For situations where effluent is discharged but no data will be recorded for a parameter for a single day or for short periods, enter “!” in the valid remark code field of the parameter (see Figure 31). For situations where no effluent is discharged and therefore no data is collected, use the NM! remark code described below.

Figure 31

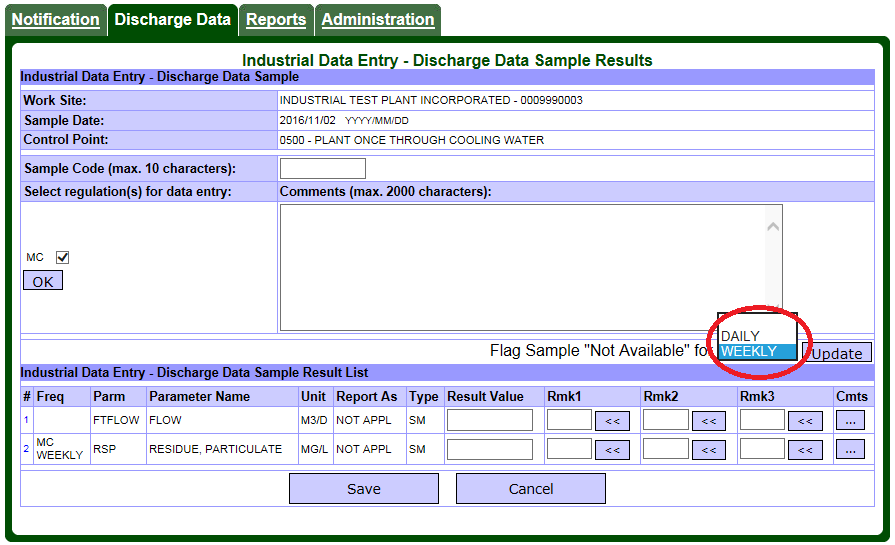

Flagging all parameters when no effluent is discharged

To identify that a sample is not available for a Reporting-for-Time (Frequency) code, you are required to identify each parameter result value in the specified Reporting-for-Time code as “no effluent - no sample available.”

There are two methods to flag these parameters if no effluent is discharged over a short time period: manually enter the remark code for each parameter, or use the ‘Flag Sample “Not Available” for’ function.

If no effluent is discharged over a longer period, use the Inactive Control Point module (refer to Section 6).

To manually enter the remark code, complete the following procedure to flag a parameter for a selected Reporting-for-Time code as “No Effluent – No Sample Available”:

- Go to the first parameter of the specific Reporting-for-Time.

- Enter “!NM” in the first remark code field. The “!NM” stands for “No effluent - no sample available.”

- Go to the next parameter of the specific Reporting-for-Time.

- Repeat steps 2 and 3.

Note: The result value, remark code 2 and remark code 3 fields should be blank for those parameters tagged no effluent “!NM”.

Alternatively, use the ‘Flag Sample “Not Available” for’ function to automatically populate the first remark code of each parameter in a specific reporting-for-time as “No Effluent - No Sample Available” (see Figure 32).

Figure 32

To use this function:

- Go to the ‘Flag Sample “Not Available” for’ pick list.

- Select the Reporting-for-Time in the pick list.

- Click the ‘Update’ button beside the pick list.

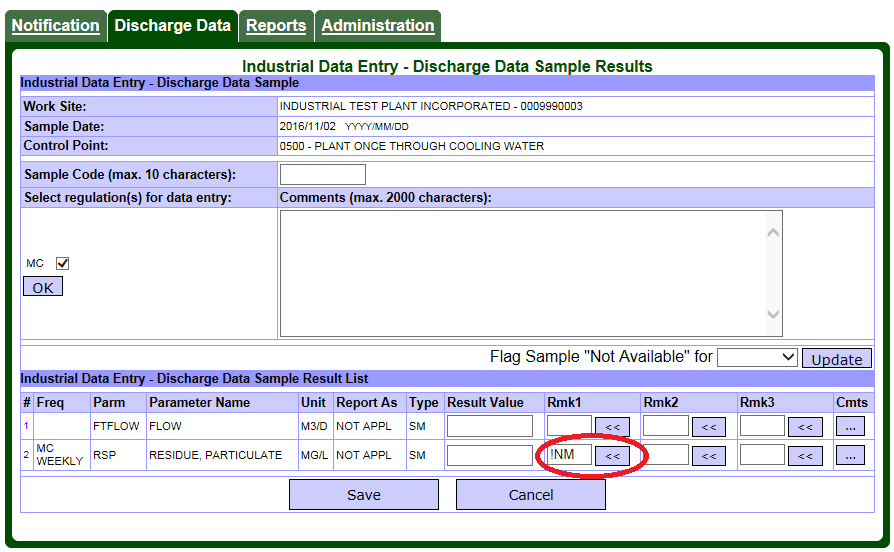

All reporting parameters in the chosen reporting-for-time (Frequency) will be assigned a blank Result Value and a “!NM” code in the first Remark Code field (see Figure 33).

Figure 33

Note: Do not use the “No Effluent - No Sample Available” remark to flag results that are not required for reporting. The “No Effluent - No Sample Available” remark only applies when there is no discharge passing by the sampling point.

Saving result values to the sample discharge record

Save data entries of result values to the sample discharge record once you have completed your data entry by clicking on the ‘Save’ button.

The following validation message may appear:

| Validation message | Meaning |

|---|---|

| “Invalid Result Value “*” on row *. Verify that the value is a number.” | Alpha numbering such as the letter “O” used instead of a zero (0) or the word “two” instead of “2” won’t work. In addition, if you enter a decimal you need to add the zero (enter “0.25” instead of “.25”). |

| “Invalid pH Value “*” on row *. Verify that the value is not outside 1 and 14.” | The result value is not a valid pH value. Verify that the value is between 1 and 14. |

| “Error: Invalid time. Time format is HH:MM.” | The result value is not a valid Time value. Verify that the value is between 00:00 and 23:59. Be aware that the time format used in MEWS is a 24-hour format, so “12:00” means 1200 hours, or noon, while “00:00” means 0000 hours or midnight. Values under 10:00 should have a leading zero—MEWS will add a leading zero if one is missing (“5:00” will appear as”05:00”). |

| “Report currently generating. This information cannot be edited/entered. Please wait for report generation to complete.” | If a report is in the process of generating, the corresponding data cannot be edited. Once the report generation is complete, the data can be edited. |

Note: Whenever the ‘Save’ button is clicked, the data will be saved and the system will return to the Data Entry Search page.

Hint: After entering or editing a sample record, the ‘Save’ button must be clicked. Using the ‘Back’ button on the tool bar of the Browser or clicking on the ‘Cancel’ button on the screen will not save data.

Canceling data entry

If you wish to cancel your data entry without saving, click on the ‘Cancel’ button.

Note: Whenever the ‘Cancel’ button is clicked, the system will return to the Industrial Data Entry - Search Samples page without saving any changes.

Deleting result values

A Reporting-for-Time (Frequency) and result value is considered as “not required for reporting” when it’s Result Value, Remark 1, Remark 2 and Remark 3 fields are all blank.

If a Result Value, Remark 1, Remark 2 and / or Remark 3 for a parameter was entered in error, use the following procedure to “delete” the result value and / or remark(s) for each parameter:

- Go to the first reported parameter of the specific Reporting-for-Time to be deleted.

- Clear the content in the Result Value and Remark(s) fields.

- Clear the content of the comment for the parameter (if any).

- Go to the next reported parameter of the specific Reporting-for-Time to be deleted.

- Repeat steps 2 and 3.

- Save the changes by clicking the “Save” button.

Note: This is not the same as “No Data Recorded” (“!”) which stands for “No data will be recorded: see textual report”.

Note: This feature is typically used for “deleting” individual result values. To delete an entire sample record for a specific day, refer to Section 7.d.

c. Editing sample results

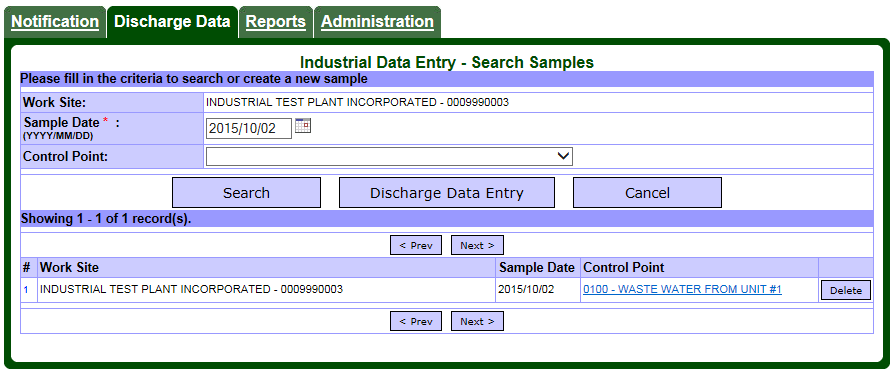

Once the discharge sample record has been created, you may check it to edit or delete it. Back in the Industrial Data Entry - Search Samples page, you have the option of clicking the “Search” button to retrieve sample results you have already entered (see Figure 34).

Figure 34

When you have entered the date and (if you wish) a control point, click the “Search” button (see Figure 35).

Figure 35

One of 3 scenarios may occur when you click on the “Search” button:

| Scenario | What will happen |

|---|---|

| No sample data exists for the specified criteria | No matching records are found. Try new search criteria. |

| Sample data exists for the specified criteria and has not been submitted | Data entry section appears with existing sample and result data. Data may be edited or deleted. |

| Sample data exists for the specified criteria and has been submitted | Data entry section appears with existing sample and result data. Submitted data cannot be edited. Message appears at the top. |

Note: The control point and sample date together is the unique key for a sample. There can only be one sample for a particular control point and sample date.

Click a control point link to open the sample for editing (see Figure 36).

Figure 36

Once the discharge sample has been retrieved, you may proceed with editing.

Note: Data that has already been submitted to the ministry is locked and cannot be edited here. See section 10d, “Requesting resubmission of data,” to unlock the data.

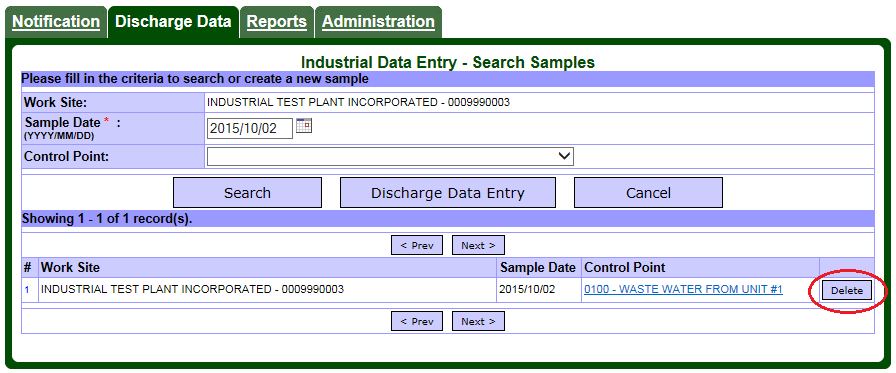

d. Deleting an existing sample discharge record

If you retrieve an existing discharge sample record and you want to delete it, simply click on the ‘Delete’ button beside the record (see Figure 37).

The delete function is used for permanent removal of a discharge sample from the database. You may want to use this function when you have accidentally created an incorrect discharge sample (the incorrect criteria such as date was used).

Figure 37

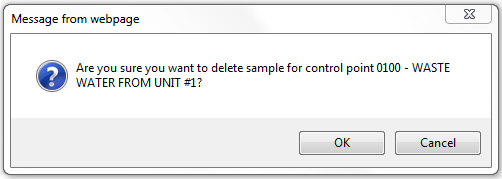

The application will prompt for confirmation. A dialog box will appear (see Figure 38).

Figure 38

| Button | Description |

|---|---|

| ok | Permanently removes current discharge sample (all reporting-for-time and parameters). If you click ok the deletion of the sample will be complete. The screen will then return to the Industrial Data Entry – Search Samples page. |

| Cancel | Cancels action to delete selected discharges sample, closes dialogue box and returns to the Industrial Data Entry – Search Samples page. |

Note: Even after all the result values and all the remarks for all parameters in a sample that were previously entered have been cleared from the Data Entry page, a discharge sample record will still exist.

To ensure that a discharge sample record is properly deleted, use the method above.

8. Industrial Data Upload (XML)

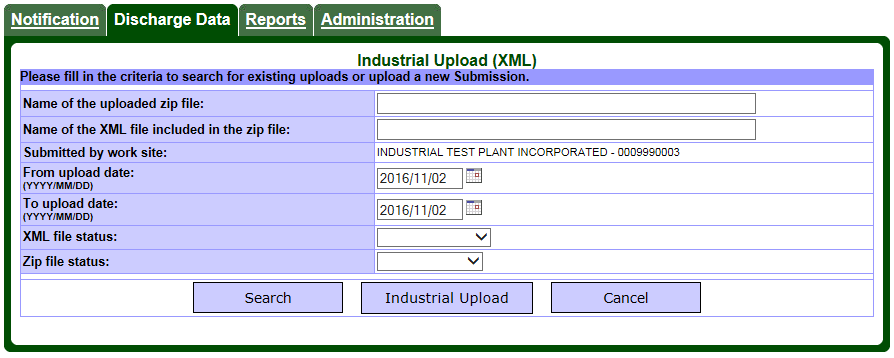

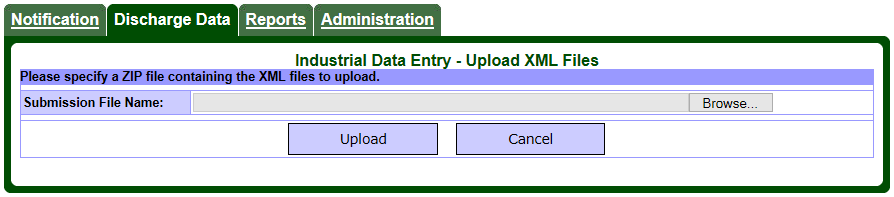

Industrial Data Upload (XML) is an alternative method of sample data entry to MEWS instead of completing the manual data entry as detailed in Section 7. The XML file content is shown in Appendix B. The ministry has created a guidance document, “XML Format Electronic File Transfer for Industrial Officers and Staff” to assist you in creating the XML file.

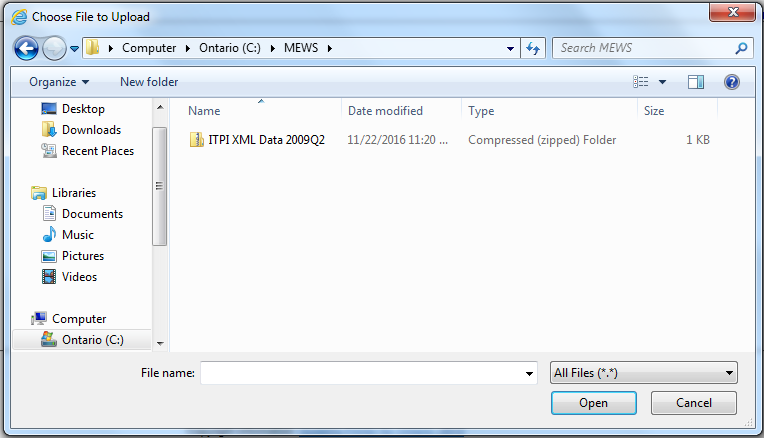

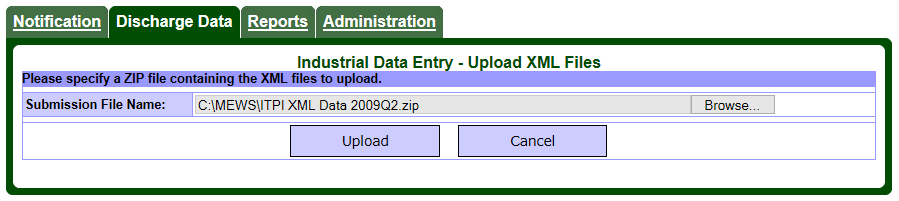

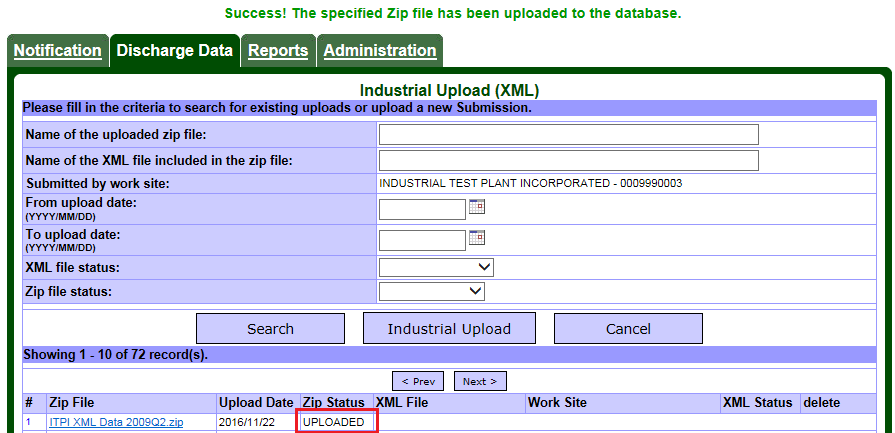

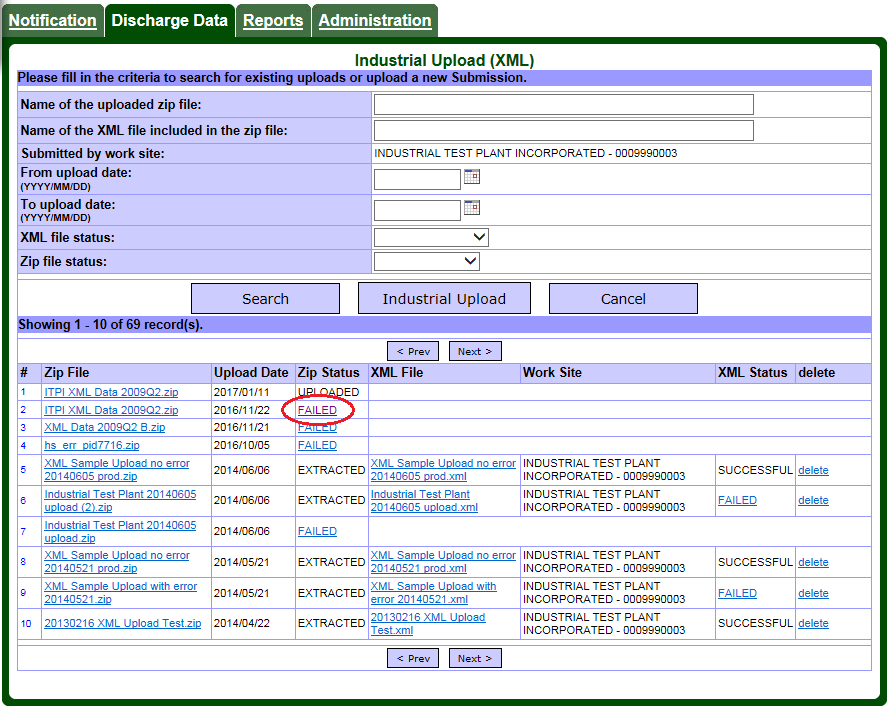

Prior to uploading the XML files to MEWS, they must be compressed (zipped) file format. Multiple XML files can be included in the compressed file. Therefore, you can upload many XML files for different control points and sample dates in a single upload.

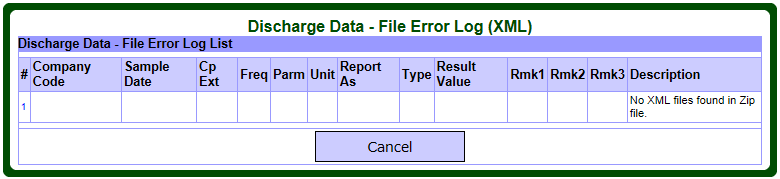

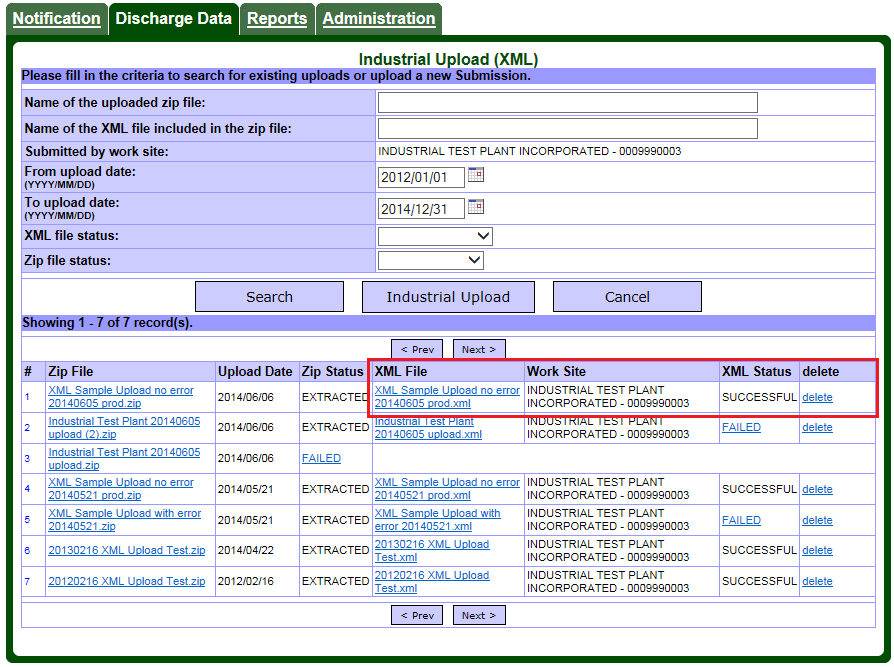

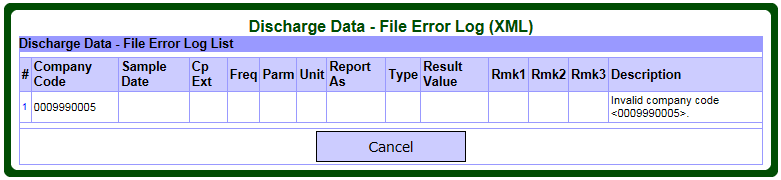

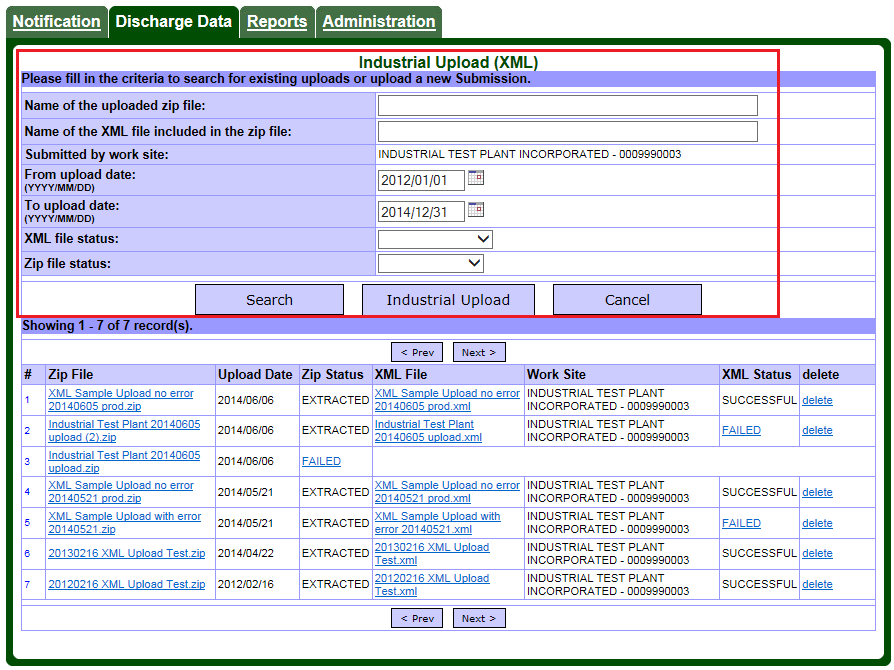

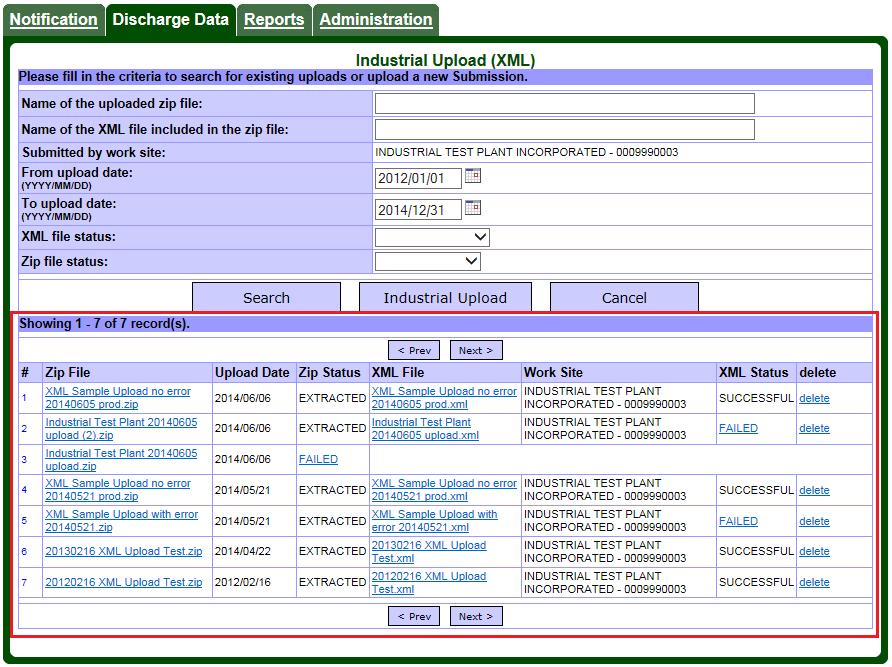

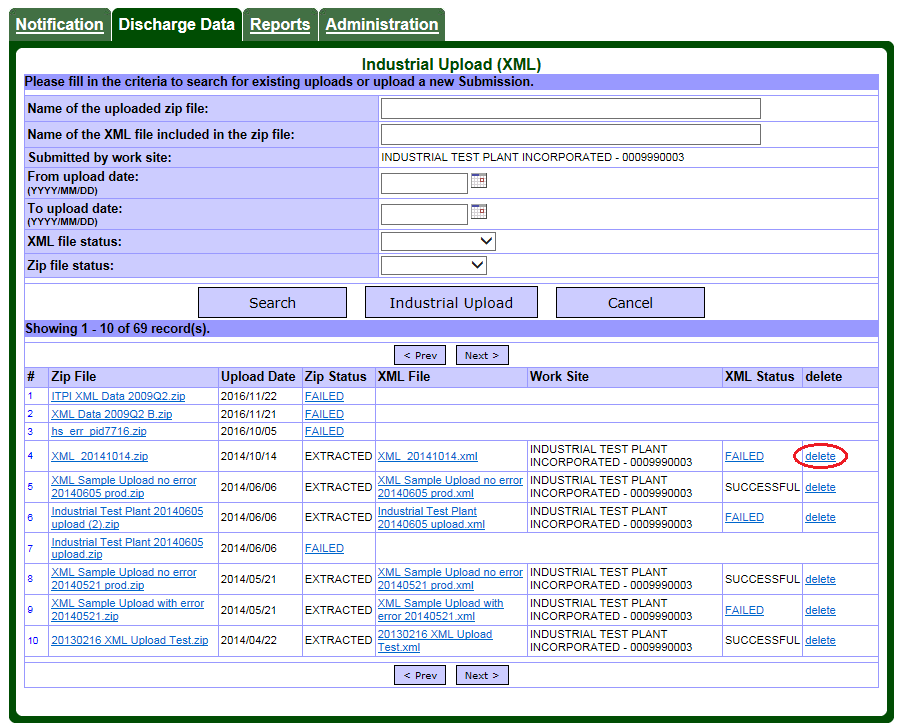

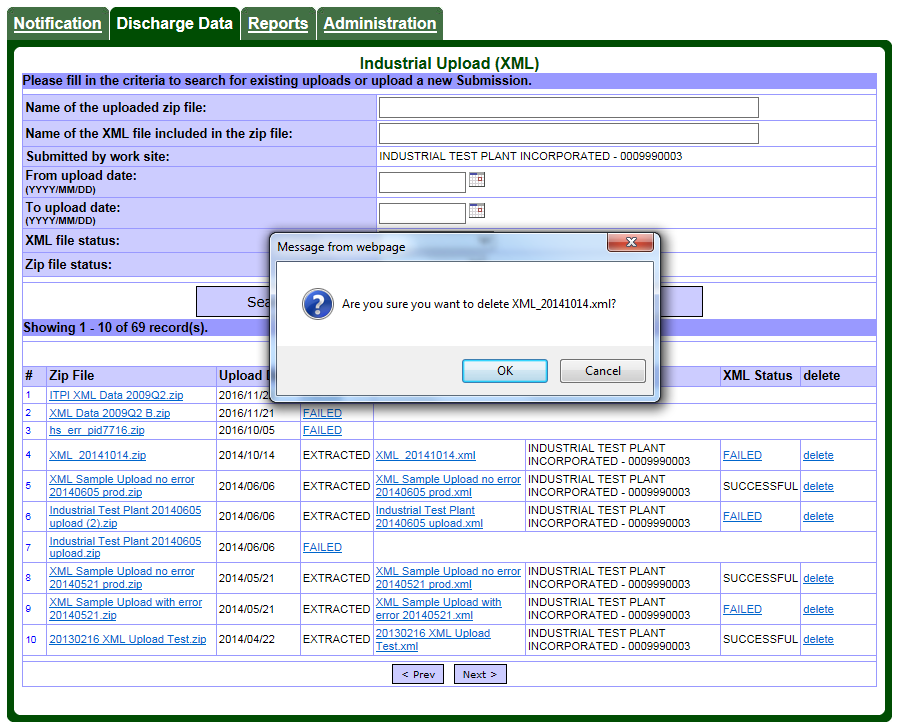

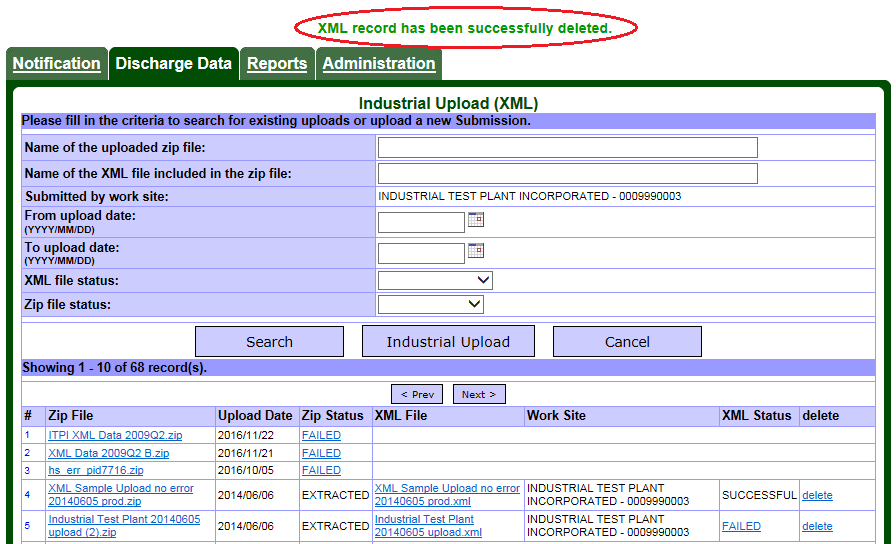

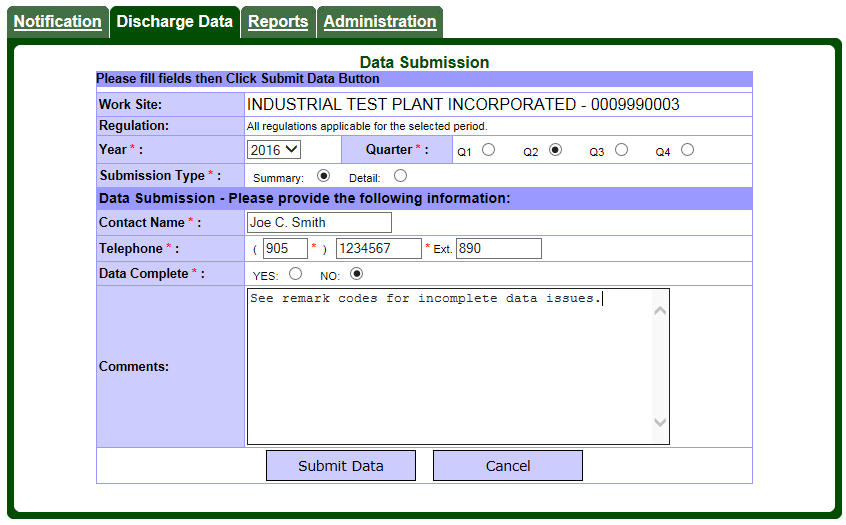

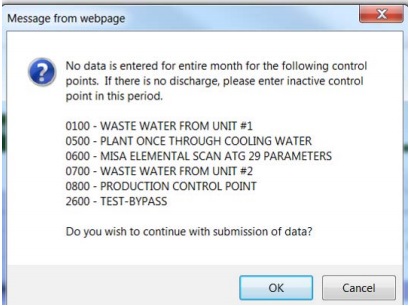

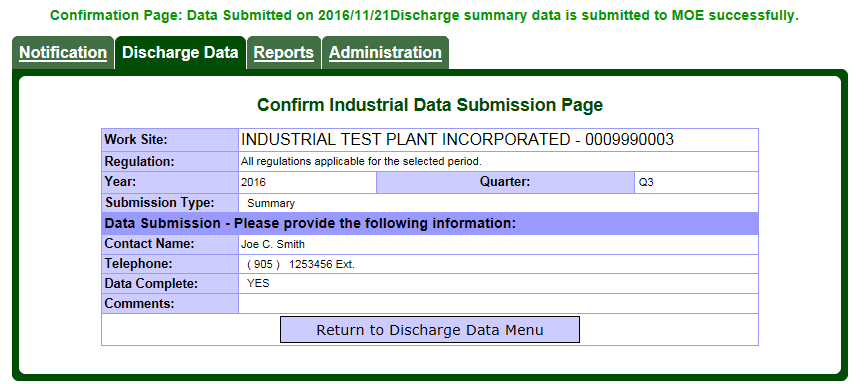

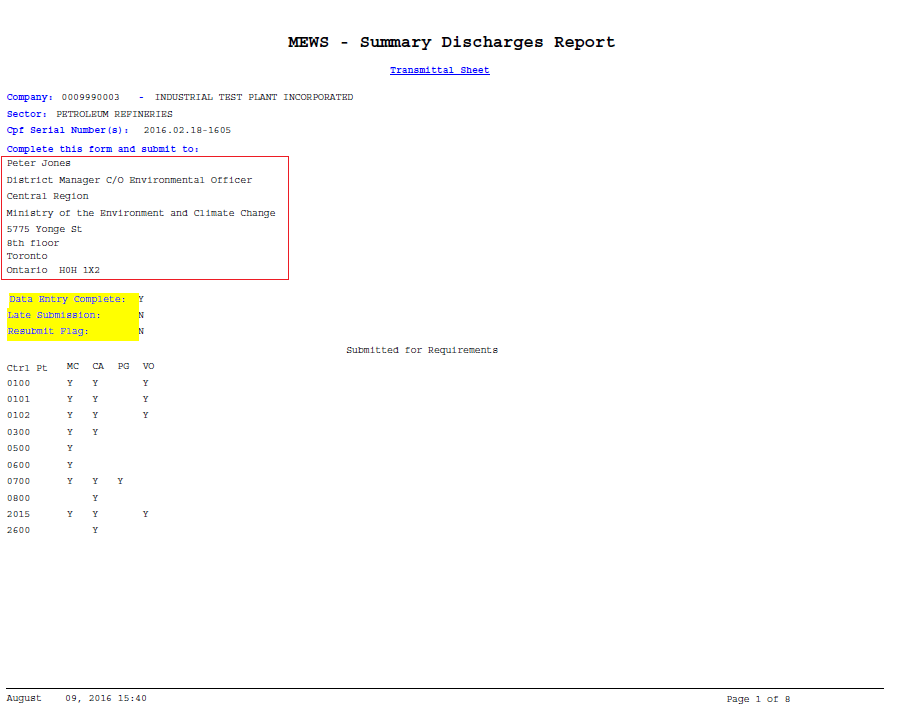

Q: What is an XML file?