Efficient lighting for swine facilities

Learn about lighting systems to reduce energy use and improve animal performance. This technical information is for Ontario swine producers.

ISSN 1198-712X, Published October 2022

Introduction

A good lighting system provides appropriate amounts of light at minimum cost with low maintenance. Efficient lighting systems in swine facilities can reduce energy use, increase light levels and improve animal performance.

While electricity use for lighting is a small portion of your cost of production, selecting efficient lighting systems will improve your bottom line.

This fact sheet summarizes lighting terminology, light level targets throughout the swine facility, design considerations when selecting lighting systems and installation considerations.

We also provide a comparison of two common light types (T8 fluorescent and LED) to illustrate the benefits and options when choosing fixture types for your facility.

Lighting terminology

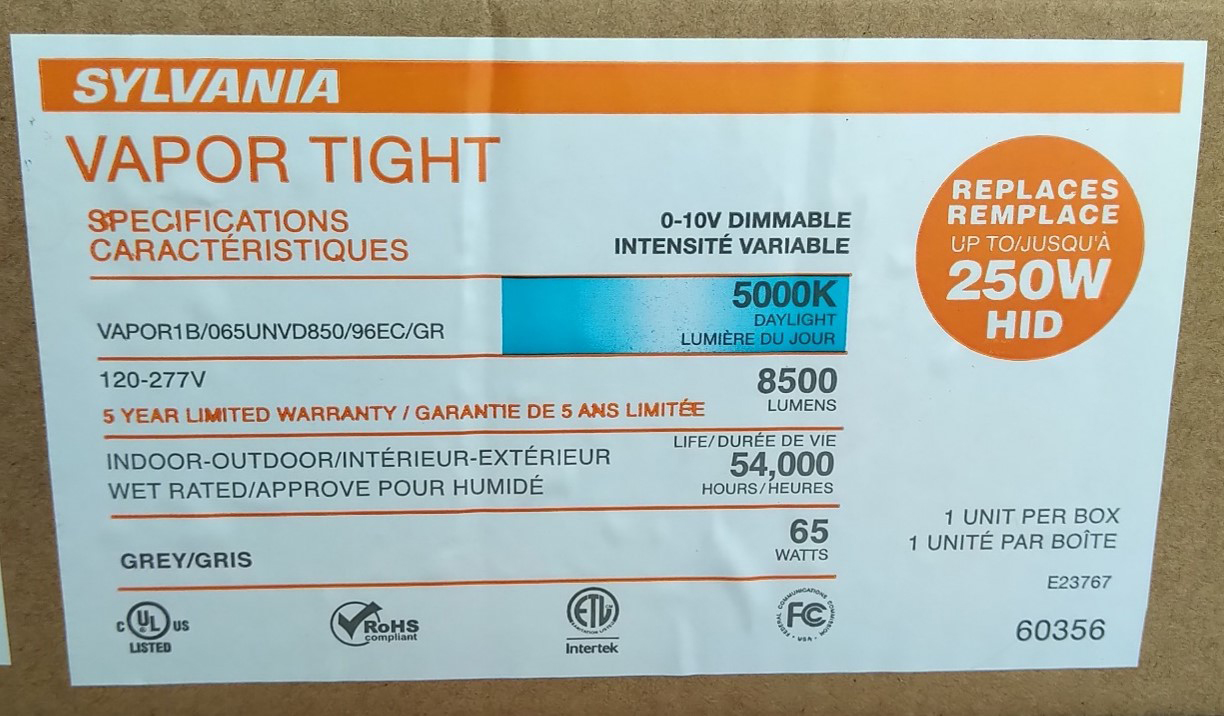

An understanding of how light is measured and the terminology used is essential when choosing your lighting system fixtures. Common information found on fixture packaging is shown in Figure 1.

Lumen: Lumen (lm) is the amount of light output from a lamp or bulb.

Lux: Lux is a measure of the brightness of light striking a surface. One lux is defined as 1 lumen of light striking on an area of 1 m2. Appropriate lighting levels in swine facilities are given in lux.

Watt: Watt (W) is the amount of energy required to create the light output.

Luminous efficacy: Luminous efficacy is a rating of how many lumens of light are produced per watt of energy used. It is measured in lumens per watt (lm/W).

Average rated life: The average rated life for non-LED bulbs is the time it takes for 50% of the light bulbs to fail. For LEDs, usable life (called L70) is the point in time when the LED produces only 70% of the initial light.

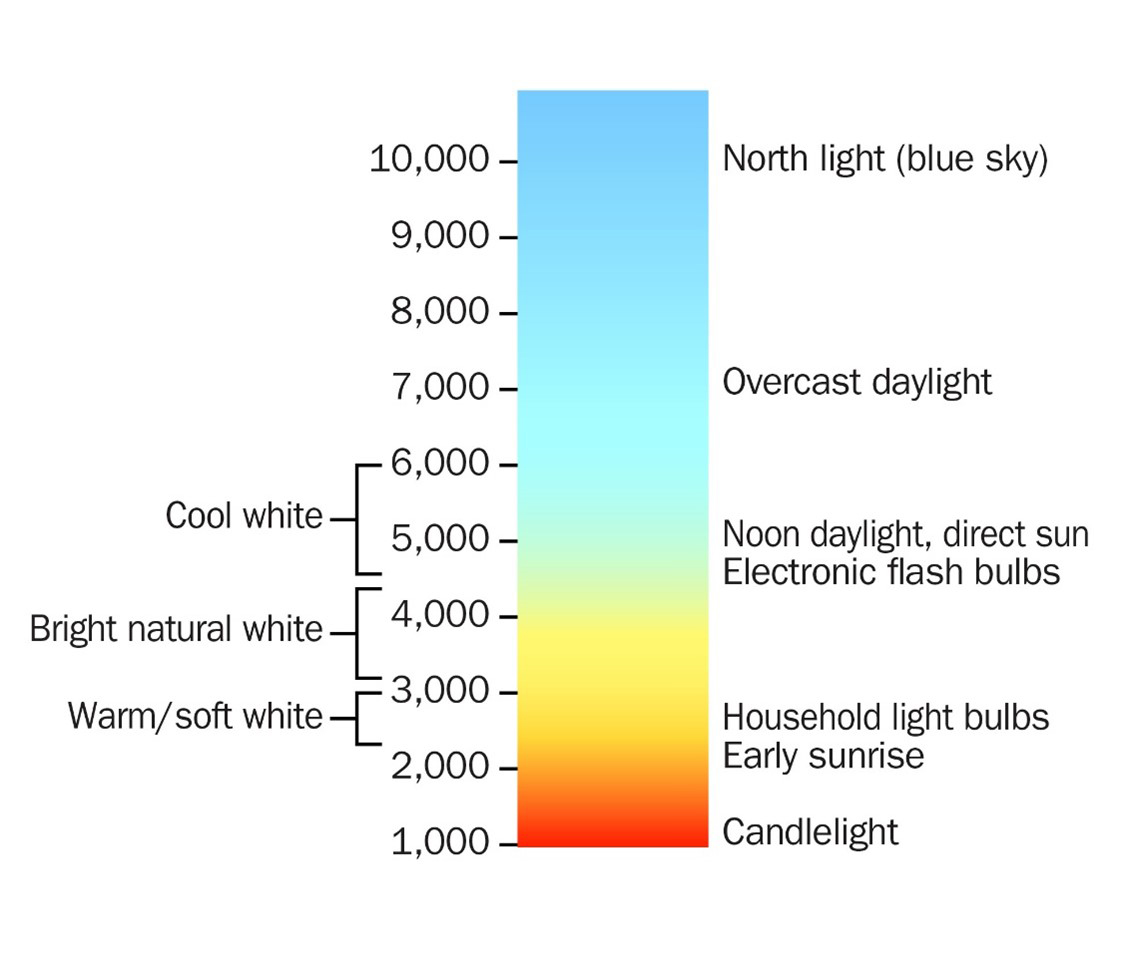

Kelvin: Kelvin (K) is a measure of the colour or appearance of the light. Warm or soft white light has a range of 2,700 to 3,000 K. Natural white light has a range of 3,000 to 4,500 K, and cool white light is 4,500 to 6,500 K.

Colour rendering index: Colour rendering index (CRI) is a measure of the accuracy of the colour perceived under the light as compared to the colour perceived under natural light (or sunlight). A lower CRI value indicates that some colours may appear unnatural. A CRI value of 100 represents the maximum value and indicates that colours appear natural.

An efficient lighting system will provide the appropriate lux for the task or area, maximize the luminous efficacy, rated life and CRI, and minimize the lifetime costs of the system.

Light level targets

The amount of light at the working surface, or lux, will vary for each part of the swine facility. The appropriate amount of light is required to:

- allow good inspection of animals for husbandry practices

- provide sufficient light for pigs to find food, water and interact

- allow tasks to be completed safely and efficiently (handling, repairs)

- allow good lighting for office tasks

- stimulate natural behaviours of sows for breeding, gestation and farrowing

The 2014 Code of Practice for the Care and Handling of Pigs requires a minimum light level of 50 lux be provided for a minimum photoperiod of 8 hours each day for all pigs. Also, a period of darkness (light level of less than 5 lux) for at least 6 consecutive hours per day is specified.

Pigs are highly adaptable and tolerant to artificial light. However, very bright lights can cause eye damage and weight loss. Constant bright light increases stress levels and can cause disruptive behaviour and productivity issues. Table 1 provides recommended light levels for various parts of the swine facility.

Increasing farrowing room lighting photoperiod to 15 to 18 hours per day may promote piglet suckling. Farrowing rooms that do not use heat lamps should provide 24 hours per day of light. However, light levels should be reduced to less than 5 lux at nighttime.

Nursery pigs should be provided with low levels of light (<5 lux) 24 hours per day, with higher levels during the daytime, such that piglets can find feed, water and interact.

Increasing day length in finishing can promote feed intake and growth.

| Type of housing, area | Light levels | Photoperiod | Comments |

|---|---|---|---|

| Breeding | 100–150 lux | 14–16 hours per day | Necessary for estrus cycling |

| Gestation | 100–150 lux | 14–16 hours per day | To assist in missed cycles and bring on estrus again |

| Farrowing | 50–150 lux | 8–12 hours per day | <5 lux minimum for overnight lighting |

| Nursery | 50–100 lux | 8–12 hours per day | <5 lux minimum for overnight lighting |

| Finishing | 50 lux | 8–12 hours per day | N/A |

| Handling/shipping | 150–200 lux | As needed | N/A |

| Office maintenance areas | 500 lux | As needed | For general work: up to 1,000 lux for specific task lighting |

| Washroom/shower, feed room | 200–300 lux | As needed | N/A |

Design and installation considerations

Consider the following points when choosing a lighting system:

- Choose NEMA 4X or IP66 rated fixtures as high pressure washing, water vapour and corrosive gases found inside swine facilities are detrimental to electrical equipment. These fixtures are vapour-tight and wet-rated with gasketed polycarbonate housings or similar. Additional information is found in the OMAFRA fact sheet, Electrical systems in barns, Section 22 of the Ontario Electrical Safety Code and Electrical Safety Authority (ESA) Bulletin 22-3-5 for more information.

- All electrical equipment must be Underwriters Laboratory (Canada) (ULC) or Canadian Standards Association (CSA) approved and bear a certification sticker or stamp.

- Have your supplier use a lighting design program to confirm the proposed fixture layout will provide the required light levels. Pay particular attention to light level uniformity in the space, reduction of shadows and glare.

- Select a CRI greater than 85.

- Use surge and voltage protection on the lighting system to ensure ballasts and drivers are not damaged by lighting or high/low voltage fluctuations.

- Choose a modular design for the lighting system to allow for easier maintenance or expansion/upgrade of the system.

- Choose components with good warranties — 1 year for drivers and ballasts, 5 years or more for fixtures.

- If planning to use dimmers, ensure all components are compatible and choose dimming ballasts and drivers.

- Check with the local utility for energy saving incentives.

- Consider remote or centralized lighting controls to ensure appropriate photoperiods for animals and promote energy savings for you.

Efficient light types

Most swine facilities use T8 fluorescent or LED linear lighting. These types of lights offer energy cost savings of up to 85% when compared to older incandescent lights. While there are other suitable styles of fluorescent and LED lighting, the following information is limited to T8 and LED linear fixtures.

T8 fluorescent and LED linear fixtures are very similar:

- Lumen output per fixture is very comparable.

- CRI values range from 70 to 95 for T8 fixtures and from 70 to 90 for LED fixtures.

- Both have a useful colour temperature in the range of 2,700 K to 6,500 K. LEDs are generally available up to 7,000 K (Figure 2).

- With appropriately chosen electronic ballasts, T8 fixtures are dimmable with little to no flicker. Dimmable LED fixtures with proper drivers are fully dimmable.

- With proper ballast type, T8 fixtures are almost instant-on and can have good cold-start properties. LED fixtures are instant-on and have excellent hot and cold temperature performance.

LED linear fixtures do have some significant advantages over T8 fluorescent fixtures:

- LED lights are directional, meaning all the light produced is directed within a 180° arc (Figure 3). Fluorescent bulbs are omni-directional, producing light in all directions. For this reason, all fluorescent fixtures must have an efficient reflector and lens to re-direct the light towards the working surface. Reflectors and lenses are never perfect, so some light produced by fluorescents is wasted.

- LED fixtures have an average rated life of 25,000 to 100,000 hours. T8 fixtures have an average rated life of 15,000 to 25,000 hours. The cost of bulbs and labour to replace T8 bulbs will be higher over the lifetime of the fixtures.

- With current technology, LED fixtures have up to 20% higher luminous efficacy than comparable T8 fixtures. Combined with the directionality of LED lights, it takes less energy to operate LED lights.

- LED fixtures are a solid-state technology, making them more physically durable (Figure 4). Fluorescent bulbs are fragile.

- Because LED fixtures last longer, there is less waste when bulbs are changed compared to T8 fixtures. Also, fluorescent bulbs contain small amounts of mercury, which presents an environmental challenge when disposing of bulbs.

- LED technology is not affected by the hot or cold temperatures that are typical of swine facilities. Fluorescent light output is highly affected by cold and hot temperatures.

- LED fixtures are generally more expensive to purchase than comparable T8 fixtures. However, if the lifetime cost of the fixture includes the initial purchase price, cost of energy usage, replacement bulb costs and labour, then the lifetime cost of LED fixtures is lower than that of comparable T8 fixtures.

Conclusion

While LED and T8 linear fixtures are good choices for swine facilities, LED technology is the clear winner in both lifetime cost and features.

Give careful attention to the design and installation considerations presented when building or upgrading your lighting system.

Choose the efficient lighting system that:

- works for your facility

- provides the necessary amount of light for your pigs and your workers

- improves your bottom line

Resources

ASABE EP344.4 Jan2014 (R2019) Lighting Systems for Agricultural Facilities.

This fact sheet was updated by Steve Beadle, P. Eng., Engineering specialist, swine and sheep housing and equipment, OMAFRA, and reviewed by Dan Ward, P. Eng., engineering specialist, poultry and other livestock housing and equipment, OMAFRA.