Commercial printing facilities user guide for Environmental Activity and Sector Registry

This guide has been developed to provide detailed information on the use of the Environmental Activity and Sector Registry (EASR) for the printing industry and other interested members of the public. It includes specific requirements for registering activities in printing facilities.

1. Introduction

1.1 Purpose

This guide has been developed to provide detailed information on the use of the Environmental Activity and Sector Registry (EASR) for the printing industry and other interested members of the public. It includes specific requirements for registering activities in respect of printing facilities.

The Ministry of the Environment, Conservation and Parks (MECP) intends to update this guide regularly to ensure that it provides accurate information and guidance for those intending to register. Website addresses and hyperlinks in this guide were current at the time of its release.

1.2 Disclaimer

While this guide was written to provide detailed information on EASR requirements in respect of printing facilities it should not be construed as legal advice. All requirements relating to registration in the EASR are contained in Part II.2 of the Environmental Protection Act (EPA), Ontario Regulation (O. Reg.) 245/11 (Registrations Under Part II.2 of the Act – General) and O. Reg. 349/12 (Registrations Under Part II.2 of the Act – Printing). All regulations can be found on Ontario’s e-Laws website. Note that specific references to sections of O. Reg. 349/12 are made throughout this guide, and readers are recommended to have a copy of the regulation itself in order to refer to the exact legal language when reading this guide.

2. Overview of the Environmental Activity and Sector Registry (EASR) – questions and answers

This section presents general information about the EASR by providing answers to commonly asked questions.

What is the Environmental Activity and Sector Registry (EASR)?

The Environmental Activity and Sector Registry (EASR or the Registry) is an online self- registration system implemented by MECP. It replaced the previous application and review process for specific activities prescribed in regulation(s) that are considered routine, standard, and well-understood. As of November 18, 2012, certain printing facilities

Learn how to register, update or remove a business from the EASR.

How does a registration in the EASR differ from an Environmental Compliance Approval (ECA)?

In general, an ECA is required in order for a business to establish and operate a facility or equipment that may discharge a contaminant into the natural environment. Applying for an ECA may involve the submission of various forms, design reports and studies, among other documents, to the ministry. It is only after the review and issuance of an ECA by the Director that a business may establish or use the facility or equipment. In addition, the ECA may contain various conditions that will need to be followed.

However, if a business is engaging in an activity that is prescribed in regulation for the purposes of the EASR, then an ECA is not required. Instead, the business must register its activities in the EASR by filing required information relating to eligibility criteria (e.g. design limitations) and operational requirements laid out in regulation and certifying the accuracy of the information provided. The registered facility must continually be in compliance with the eligibility criteria as well as operational requirements set out in the regulation.

What happens if a printing facility meets the eligibility criteria of O. Reg. 349/12, but has an ECA?

Facilities that currently have an ECA but meet the criteria of O. Reg. 349/12 can register in the EASR. Once a confirmation of registration is received, the ECA and its conditions would automatically cease to have effect with respect to the registered activities, and the requirements of O. Reg. 349/12 would instead need to be followed.

For transitional purposes, O. Reg. 349/12 allows a printing facility to continue to operate under an existing ECA for up to five years from the day the regulation came into force. A printing facility that meets the criteria of the EASR regulation and is the subject of an ECA when O. Reg. 349/12 comes into force, therefore, would be required to register in the EASR on or before November 18, 2017 or when a change is made that would have otherwise triggered an approval amendment under the ECA process.

Is there any further action a business needs to take after registering an eligible printing facility?

After registering, a business will need to ensure that the registration information remains up-to-date and that the activity continues to meet the requirements set out in O. Reg. 349/12, including specific operational requirements. These operational requirements are described in detail in the sections that follow in this guide.

If the requirements of O. Reg. 349/12 are not being met, the ministry will take steps to bring facilities back into compliance using appropriate voluntary and mandatory compliance and enforcement actions that may include the issuance of orders. All of the current compliance tools used for enforcing conditions in ECAs can be used by an Environmental Officer to enforce the regulatory requirements under the EASR.

In cases where a business has shown itself to be in non-compliance with O. Reg. 349/12 or if the confirmation of registration was provided on the basis of mistaken, false or inaccurate information, the Director also has the ability to suspend or remove a registration through an order as provided for in section 20.23 of the Environmental Protection Act. If a registration is suspended or removed, the activity can no longer legally operate. A person engaged in a suspended activity can request that the suspension be ended, and the Director may do so if he/she believes the reason for the suspension no longer exists.

3. Summary of O. Reg. 349/12 (registrations under part II.2 of the act – printing)

3.1 Structure of O. Reg. 349/12

The EASR regulation for printing facilities (O. Reg. 349/12) is comprised of six parts which are briefly summarized below:

- Part I: Interpretation – this Part contains definitions used in the regulation and describes how setback distances from buildings for various pieces of equipment are to be determined.

- Part II: Prescribed Activities, Criteria and Requirements – this Part sets out the criteria that must be met in order for the activities at a printing facility to be registered in the EASR. Additional criteria for the specific types of printing allowed on the EASR (lithographic, screen and digital) are described in Parts III and IV. Part II also lists types of printing facilities that are not allowed to register their activities. Lastly, this section lists operating criteria (such as using inks with certain volatile organic compound (VOC) percentages).

- Part III: Digital and Screen Printing – Criteria – this Part sets out the criteria that must be met in order for activities related to digital and/or screen printing to be registered on the EASR.

- Part IV: Lithographic Printing – Criteria – this Part sets out the criteria that must be met in order for activities related to lithographic printing to be registered on the EASR.

- Part V: Miscellaneous – this Part sets out various record-keeping requirements.

- Part VI: Commencement – this Part sets out the date O. Reg. 349/12 comes into force.

A more detailed description of the requirements of O. Reg. 349/12 is found throughout the rest of this guide.

3.2 Definitions used in O. Reg. 349/12

Part I, section 1 contains definitions relevant to the regulation. How specific terms used in the regulation are defined affects both the eligibility criteria that a printing facility will need to meet in order to be registered as well as the operating requirements that will need to be followed if the facility is eligible. It is recommended that persons registering their printing facility read this section first before any other parts of the regulation. Where necessary, additional guidance on specific definitions in the regulation is provided throughout this guide.

4. Confirming that a printing facility is eligible for the EASR

4.1 Introduction

The EASR is a new approval pathway for specific prescribed activities that would otherwise require an Environmental Compliance Approval (ECA). The prescribed activities set out in O. Reg. 349/12 include the use, operation, construction, alteration, extension or replacement of any structure, equipment apparatus, mechanism or thing that is used at a printing facility that meets the eligibility criteria in the regulation and may discharge or from which may be discharged a contaminant into any part of the natural environment other than water. They also include the alteration of a process or rate of production at the printing facility and the storage of chemicals used in the printing processes at the printing facility that meets the eligibility criteria in the regulation.

In general, businesses will need to determine if their printing facility meets all applicable eligibility criteria in O. Reg. 349/12. The various eligibility criteria are summarized in Categories 1 through 4 below. Category 5 highlights that O. Reg. 349/12 also contains conditions that will prevent certain printing facilities from being able to register.

- Types of eligible printing processes. To be eligible for the EASR only certain types and combinations of printing processes are allowed.

- General eligibility criteria. There are additional requirements (beyond having only certain types of printing processes) that a facility must meet in order to be eligible.

- Eligibility requirements related to noise generating equipment at the facility. The regulation limits the number and type of noise generating equipment units at a facility and requires that the units be set back minimum distances from the property boundary of noise receptors.

- Eligibility requirements related to materials usage at the facility. Air emissions are controlled by rules in the regulation that require the facility to be minimum distances from the property boundary of the printing facility based on the amounts of printing materials that are used. Additional operating requirements are prescribed in the regulation to further control emissions.

- Printing facilities not eligible to register. Certain types of printing facilities are prevented from being registered in the EASR. These facilities can be considered unique and may require more detailed analysis and site specific conditions beyond those in the EASR regulation. The printing facilities that are not able to register are described by conditions found in Part II of O. Reg. 349/12.

The sections below provide more information on each of the above categories.

If a facility cannot be registered, it still may require an Environmental Compliance Approval (ECA). For additional information about ECAs, businesses are encouraged to review the Guide to applying for an Environmental Compliance Approval or contact the ministry for further assistance.

4.2 Eligible printing processes

O. Reg. 349/12 limits the registration of printing facilities to facilities engaged in certain types of printing processes. The only types of printing processes allowed are digital, lithographic and screen printing. Therefore, if a facility has other types of printing process (e.g. letterpress, flexography or gravure printing) with or without digital, lithographic or screen printing, the facility would not be eligible for the EASR.

My facility has gravure presses as well as digital presses. Am I able to register just the digital presses and obtain an ECA for my gravure presses?

No. The regulation does not allow the registration of only the eligible printing processes at printing facilities with both eligible (i.e. digital) and non-eligible (i.e. gravure) printing processes. This has been done to ensure that a printing facility is covered by either a registration or an ECA, but not by both.

Digital printing

Digital printing has been defined in the regulation as “printing carried out for commercial purposes through the use of a digital printing press and any pre-press operations and post-press operations.”

Because digital printing has been defined as printing carried out for commercial purposes, digital printers used in home or office applications are not required to be registered in the EASR.

Definitions for digital printing, lithographic printing, and screen printing

The definitions for digital printing, lithographic printing and screen printing all refer to printing carried out for commercial purposes and also include pre-press and post-press operations.

The EASR regulation includes pre- and post-press operations to ensure that these activities (and their associated equipment) are allowed to be conducted through the registration process and do not need a separate Environmental Compliance Approval.

Examples of pre-press operations include creating printing plates, preparation of printing presses and cleaning operations. Examples of post-press operations include cutting, gluing, and binding operations as well as the compaction and temporary storage of waste paper.

For digital printing, a printing facility must use digital presses that use organic solvent based liquid inks and water based liquid inks or ultraviolet inks. However, ultraviolet inks do not need to be tracked as part of the digital ink usage limits explained later in this guide.

In addition, the Ministry understands that printing facilities may use other types of digital printers that do not use the kinds of inks listed above (e.g. photocopiers that use dry toner to print mail-outs or flyers). Therefore, section 3 (5) of the regulation allows for other types of digital printing to exist at a facility and still be eligible to be registered.

My printing facility only does digital printing, but it has digital presses that use water based liquid inks and digital presses that use a dry toner. Can I still register my facility?

Yes. O. Reg. 349/12 allows a printing facility to have other types of digital printers not captured by the definition of digital printing in the regulation. However, there are no specific requirements that need to be followed for these particular machines.

As long as the printing facility complies with the air emissions requirements, explained later in this guide, there is no restriction on the number or types of digital printing presses that a facility can have.

Lithographic printing

Lithographic printing press has been defined in the regulation to mean:

- A printing production assembly comprised of,

- one or more inking systems and fountain solution dampening systems,

- a planographic printing plate roll, and

- an intermediate roll that receives images transferred from the planographic printing plate roll before the images are transferred onto the substrate, and

- Any equipment associated with the printing production assembly mentioned in (a), including ovens, dryers, chillers and equipment used in a flashoff area.

As can be seen from the above definition, the regulation only captures offset lithographic printing. However, most lithographic printing is of the offset type.

Associated equipment, such as dryers or ovens, have also been captured in the definition and do not need a separate Environmental Compliance Approval.

The regulation allows printing facilities engaged in the following types of lithographic printing to be registered in the EASR if the facility meets all relevant criteria:

- Heatset web lithographic printing

- Non-heatset web lithographic printing

- Newspaper lithographic printing

- Sheet-fed lithographic printing

Any lithographic printing involving the use of newsprint and inks designed to print on newsprint and set without the application of heat should be included under the category of newspaper lithographic printing and not under the non-heatset or sheet-fed categories.

Most combinations of the above four types of lithographic printing are allowed for the purposes of being eligible for the EASR. As with digital printing, as long as the air emissions-related requirements for lithographic printing are met, there is no restriction on the number of lithographic presses a facility can have.

Screen printing

A screen printing press has been defined as:

- A printing production assembly comprised of,

- one or more inking systems, and

- a stencilled screen with unblocked areas through which ink is squeezed to transfer an image onto the substrate, and

- Any equipment associated with the printing production assembly described in clause (a), including ovens, dryers, conveyors and equipment used in a flashoff area.

As with the other two types of printing noted above, associated equipment such as a dryer is included in the regulation and does not need a separate approval. The activity of screen reclaiming can be considered as a post-press (or pre-press) activity and therefore equipment used in the screen reclamation area also does not need a separate approval. There is also no restriction on the number of screen printing presses a facility can have.

Eligible combinations of digital, lithographic and screen printing

For the purposes of the EASR, a person can engage in any combination of digital, lithographic and screen printing at their facility except for the following combinations:

- Any type of lithographic printing and screen printing

- Newspaper lithographic printing and sheet-fed lithographic printing

- Newspaper lithographic printing and non-heatset web lithographic printing

With the exception of the three above, all combinations are acceptable but if a facility intends on engaging in more then one type of printing process they may be required to follow certain conditions related to materials used in a month under normal operation. Requirements on materials usage are discussed later in this guide.

4.3 General eligibility criteria

In addition to limiting types of printing processes, O. Reg. 349/12 also sets out the criteria described below that must be met in order for the facility to be eligible to be registered in the EASR. Reference to the applicable section in O. Reg. 349/12 has been provided.

Any wastewater generated by the facility (if any) must be handled as prescribed by the regulation (O. Reg. 349/12, paragraph 3 of subsection 3 (2)). The regulation requires that any wastewater generated by the facility is managed by one or more of the following methods:

- The wastewater is discharged to a municipal sewer.

- The wastewater is transported offsite by a waste hauling company that is approved under an Environmental Compliance Approval or has been registered in the EASR.

- The wastewater has been discharged to a sewage works that is approved under an Environmental Compliance Approval. This includes any approved sewage works at the facility itself (i.e. an approved sewage treatment plant).

The facility must comply with any permit requirements under the Niagara Escarpment Planning and Development Act (NEPDA) (O. Reg. 349/12, paragraph 4 of subsection 3 (2)). Printing facilities located in an area of development control within the Niagara Escarpment Planning Area may require a development permit (as per section 24 of the NEPDA). If a permit is required it must have been issued and the requirements of O. Reg. 349/12 must not conflict with any conditions in it in order for the printing facility to be eligible for registration.

More information on the Niagara Escarpment and permits.

4.4 Eligibility criteria related to noise generating equipment at the facility

Paragraph 2 of subsection 3 (2) of O. Reg. 349/12 sets out the noise related criteria that a facility must meet in order to be eligible for the EASR. In general, a facility must:

- Have only a certain number of exhaust stacks or specifically identified noise generating equipment units; and

- Depending on the number of exhaust stacks and/or noise generating equipment units, meet a minimum specified separation distance between the facility, stack or equipment unit and the property boundary of noise receptors in the vicinity of the facility.

Step 1: Determine number of exhaust stacks and noise generating equipment units at the facility

The first step in determining if a facility meets the criteria in paragraph 2 of subsection 3 (2) of O. Reg. 349/12 is to determine the number of exhaust stacks and/or noise generating equipment units at the facility.

Noise generating equipment unit is defined to mean a wet cooling tower, air cooled condenser, cyclone dust collector, paper waste compactor or blower for a vacuum system located at a printing facility.

For the purposes of the regulation, an exhaust stack has been defined as a stack from which contaminants captured from the use of a printing press or from equipment used in a screen reclamation area are discharged into the air.

Stacks that are used only for general ventilation of indoor air out of a building (i.e. the venting from fume hoods or press dryers do not tie into the general ventilation ductwork of the building) are not considered exhaust stacks.

Stacks that are associated with the noise generating equipment units identified above are also not considered to be exhaust stacks.

In addition to the previous two paragraphs, the only exhaust stacks that need to be counted are those that have a volumetric flow rate that is greater than 0.472 cubic metres per second (approximately 1,000 ft3/min.) as specified at 20 degrees Celsius and 101.3 kilopascals. Stacks that have a flow rate less than this are not considered to be dominant sources of noise and do not need to be considered

How can I determine the flow rate of my exhaust stacks?

Manufacturer specifications for the equipment associated with the exhaust stack should contain flow rate information. The flowrate from the stack could also be measured directly using equipment such as a vane anemometer which can be rented or purchased from businesses that provide meteorological instrumentation.

In order to be eligible for the EASR, a printing facility can have no more than six (6) exhaust stacks and no more than three (3) noise generating equipment units.

Example: counting exhaust stacks

A printing facility has three exhaust stacks that meet the flow rate requirement of 0.472 m3/s. One of the three exhaust stack serves only the general ventilation system for the building. The other two exhaust stacks are for pollution control equipment on the facility’s heatset web lithographic presses.

In the above example, all three exhaust stacks have flow rates larger than the minimum flow rate needed in order to be counted. However, the ventilation exhaust does not need to be considered because the ventilation system is only being used for general ventilation.

Therefore, in this example the facility has a total of two exhaust stacks for the purposes of the regulation.

In determining the number of noise generating equipment units at the facility, a business only needs to count the number of the following types of units:

- Wet cooling towers

- Air cooled condensers

- Cyclone dust collectors

- Paper waste compactors

- Blowers used for a vacuum system

If a facility has more than one of the above type units, then each individual unit needs to be counted. For example, a facility that has a dust collection system made up of two cyclone dust collectors would count each dust collector for a total of two noise generating equipment units.

Step 2: Determine exhaust stack and noise generating equipment unit distances from property boundary of noise receptors

Once the number of exhaust stacks and noise generating equipment units have been determined, the next step is to determine how far each stack or unit is from the property boundaries of noise receptors and whether this distance meets the requirements in the regulation.

The required distance to be met depends on the number of exhaust stacks and/or noise generating equipment units at the facility. The distances are listed in the table below.

| Number of exhaust stacks | Number of noise generating equipment units | Distance(m) |

|---|---|---|

| 1 or 2 | 0 | 55 |

| 3 or 4 | 0 | 75 |

| 5 or 6 | 0 | 80 |

| ≥ 0 | 1 | 85 |

| ≥ 0 | 2 | 170 |

| ≥ 0 | 3 | 180 |

For the purposes of registering in the EASR, a noise receptor is defined as a:

- Permanent or seasonal residence

- Hotel/motel

- Long-term care home/retirement home

- Hospital

- Campground

- Child care facility

- Educational facility

- Place of worship

A printing facility has two exhaust stacks and a waste compactor. What is the required distance that the stacks and compactor have to meet?

Since the facility has one noise generating equipment unit (the compactor) the required distance, as per row four in the table, is 85 m.

Note that each stack and the compactor all have to meet the distance of 85 m.

When measuring the distance between exhaust stacks or noise generating equipment units and the property boundary of a noise receptor, the following rules are to be followed:

- If the exhaust stack or noise generating equipment unit lies within the building envelope of the printing facility, then the distance from the point on the exterior wall of the building closest to the noise receptor to the closest point on the property boundary of the noise receptor must be measured.

- If the noise generating equipment unit extends beyond the wall of the building, then the distance from the edge of the equipment to the closest point on the property boundary of the noise receptor must be measured.

- If the exhaust stack extends beyond the wall of the building, then the distance from the centre of the stack at the point of discharge to the closest point on the property boundary of the noise receptor must be measured.

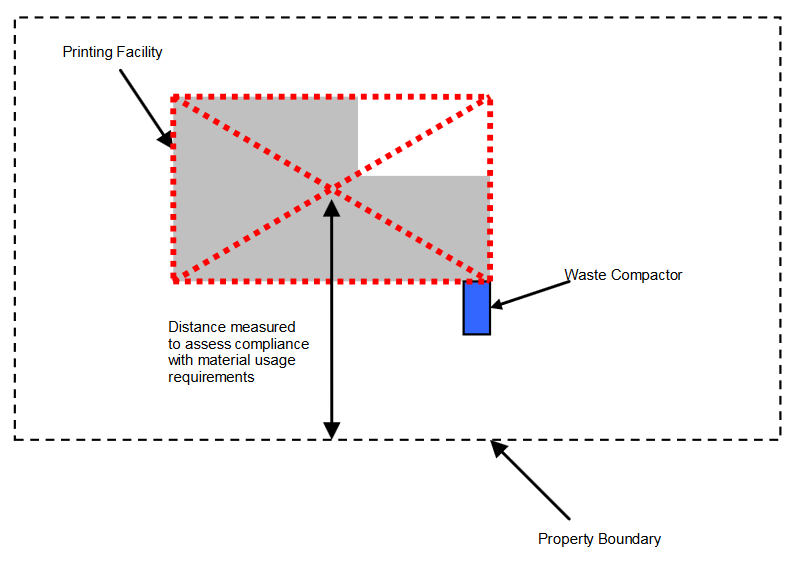

The figure below illustrates how distances are to be determined. Since the exhaust stacks are within the building envelope, measurement between the closest exterior wall of the facility to the closest property boundary of the noise receptor needs to be taken.

In this example, the waste compactor is located outside the building. To determine its distance from the property boundary, the measurement starting point is the edge of the waste compactor that is closest to the boundary of the neighbouring property.

4.5 Eligibility requirements related to materials usage at the facility

Parts III and IV [of O. Reg. 349/12 set out the materials usage related requirements that a facility must meet in order to be eligible to be registered in the EASR. In general, a facility must:

- Meet monthly materials usage limits under normal operation specific to the type(s) of printing undertaken; and

- Meet the distance that correlates to the amounts and types of materials used.

Part III contains the usage and setback distance requirements for digital and screen printing processes. Similarly, Part IV of the regulation contains the usage and distance requirements for lithographic printing processes.

Step 1: Determine setback distance of the facility

The first step to determine if a facility meets the requirements in Parts III and IV of the regulation is to determine the facility’s distance from its property boundary (also referred to as a setback distance).

This distance is determined by measuring from the centre of the facility to the closest point on the property boundary of facility. The centre of the facility is determined by finding the centre of the smallest rectangle that can be drawn around the perimeter of the building, as demonstrated in the example below.

Figure 4.2: Example of measuring from centre of a building to its property boundary

- All buildings that contain printing presses need to be considered (buildings that do not have printing presses, such as a warehouse or vehicle garage, do not need to be taken into account); and

- Determining the centre of the building only needs to take the exterior walls of the building into account (for example, the drawing above does not take the waste compactor into account when drawing the rectangle around the building).

Step 2: Determine the monthly usage of printing materials

Once the setback distance to the facility’s property boundary is known, the next step is to determine the facility’s monthly usage of printing materials under normal operation.

For each printing type, the following table provides a list of the printing materials that must be considered when determining a facility’s monthly usage under normal operation:

| Printing Type | What needs to be taken into account | What does not need to be taken into account |

|---|---|---|

| Digital printing |

Note: for the purposes of the regulation, organic solvent based liquid inks are inks with a water content less than 60% by weight. |

|

| Screen printing |

|

|

| Lithographic printing |

|

|

Once both the facility’s setback distance and monthly printing materials usage under normal operation is known, the appropriate table or tables in the regulation need to be consulted to determine whether the facility meets the applicable eligibility criteria. The usage tables are also provided in Appendix A of this guide.

If a facility engages in more than one type of printing (e.g. digital and lithographic) and if more than one setback distance is required to be met, the greater of the setback distances that must be met applies to all buildings at the facility that have printing presses in them (see Example 2 in the box below).

Examples of printing facilities that meet the distance and usage requirements

Example 1:

A digital printing facility’s presses only use water based liquid inks. The facility’s owner determines that the centre of the building containing the presses is 35 m away from the property line. He also determines that the facility normally uses about 1,200 L of ink in a month.

According to the usage table for digital printing in section 6 of O. Reg. 349/12, the centre of the building needs to be at least 20 m from the property boundary. In the example above, the centre of the building is greater than 20 m and, therefore, the facility meets the eligibility requirements related to materials usage.

Example 2:

A printing facility has both digital presses that use water based liquid inks and sheet fed lithographic presses all contained in a single building. The digital presses use 1,000 L of ink per month. The lithographic presses use a combined total of all inks, reducers, fountain solutions, cleaning solutions, coatings and adhesives in the amount of 800 L per month. The centre of the building is 58 m away from the property boundary.

In this example two sections of the regulation must be consulted: section 6 for digital printing and section 14 for sheet fed lithographic printing.

The table in section 6 of the regulation shows that a setback distance of 20 m is required for a digital water based ink usage of 1,000 L/month. The table in section 14 shows that a setback distance of 50 m is required for a sheet fed lithographic printing materials usage of 800 L/month. The setback distance requirement for lithographic printing is greater than for digital printing and, therefore, the 50 m requirement applies to all buildings with either digital and/or lithographic presses at the facility.

Because the distance between the centre of the building and its property boundary is greater than 50 m, the facility would meet the eligibility requirements related to materials usage.

Examples of printing facilities that do not meet the distance and usage requirements

Example 3:

A printing facility has both solvent and water based digital presses that use 300 L and 1,000 L of inks per month, respectively. The centre of the building that houses the presses is 25 m from the property line.

The facility is required to meet the distance and usage requirements for both types of digital printing. According to section 6 of the regulation, a monthly usage of 300 L of solvent based inks requires a distance of 30 m and a monthly usage of water based inks requires a distances of 20 m. The facility meets the distance requirement for the water based ink usage but does not meet the distance requirement for the solvent based inks. Therefore, the facility does not meet this eligibility requirement and cannot register in the EASR.

Example 4:

A printing facility has heatset lithographic presses. The presses use 2,000 L of lithographic printing materials per month. The centre of the building is 150 m from its property boundary.

The distance and usage limits for heatset lithographic printing are located in section 9 of the regulation. Even though the facility has an ample setback distance its lithographic printing materials usage limit exceeds the maximum allowable limit in the regulation (1,830 L/month). Therefore, the facility above does not meet the usage related eligibility requirements and cannot register for the EASR.

As can be seen from the tables in Appendix A determining whether a facility meets setback distance requirements for certain types of printing processes may require considering more than one category of materials used in a month under normal operation. For example, the setback distance required for a printing facility engaged in only screen printing needs to be determined considering (1), the amount of screen printing materials used at the facility in a month and then (2) the amount of cleaning solutions used at the facility in a month. Be aware that cleaning solutions are also included in the screen printing materials definition. Both setback distances must be met in order to satisfy the eligibility requirement.

Screen printing example

A screen printing facility uses a total of 400 L of inks, cleaning solutions (including screen reclaiming products), and coatings per month. Of the 400 L, 100 L is from the cleaning solutions.

For a total screen printing materials usage rate of 400 L/month, the table in section 7 of the regulation specifies that the minimum distance the centre of the building has to be from the property boundary is 20 m. However, a cleaning solution usage rate of 100 L/month requires a minimum distance of 50 m. Therefore, in order for the facility to be eligible, it must meet the 50 m distance requirement.

Note: As per the definition of “cleaning solution” in the regulation, only a cleaning solution that contains organic solvent needs to be considered when determining usage limits. This applies to all printing types where cleaning solutions are required to be tracked.

Lastly, it is important to remember that the regulation may require certain types of printing materials. such as inks and adhesives, to meet specific VOC limits. These are shown in the Operating Requirements section of this guide.

4.6 Printing facilities not eligible to register

The following section describes the criteria in O. Reg. 349/12 the prevents a printing facility from being eligible for the EASR – even if they satisfy the criteria described earlier in sections 5.2 to 5.4.

A printing facility cannot be located on the same property as another facility that requires an ECA under either the Environmental Protection Act or the Ontario Water Resources Act (O. Reg. 349/12, paragraph 1 of subsection 3 (4)).

Examples that illustrate O. Reg. 349/12 subsection 3 (4), paragraph 1

Example 1: Acme Printing Inc. leases space in a large factory that also contains a furniture manufacturing business. Due to emissions from its equipment, the furniture manufacturer requires an ECA. In this example, even if Acme Printing Inc. met all other eligibility criteria it would not be able to register because it is co-located with another business that needs an ECA.

Example 2: A metal fabrication business has various equipment for the production of various types of machine parts. It also has a small screen printing facility for printing on the machine parts it produces. The business in this example would not be allowed to register its screen printing operations because it requires an ECA for other processes not related to the screen printing facility. This example illustrates what is sometimes referred to as ‘in plant’ printing operations.

Important: ‘In-plant’ printing operations are not allowed to be registered in the EASR.

A printing facility located on a property adjacent to another property on which is located another facility that requires an approval – where the printing facility and the other facility share raw materials, products or services, – is not eligible for the EASR (O. Reg. 349/12, paragraph 2 of subsection 3 (4)).

Example that illustrates O. Reg. 349/12 subsection 3 (4), paragraph 2

Acme Printing Inc. is located on property that is adjacent to a property on which a T-shirt manufacturing business that requires an ECA is located. Finished T-shirts are sent by the shirt manufacturer to Acme Printing Inc. to have various patterns and images printed on them.

Because Acme Printing Inc. and the shirt manufacturer are located on adjacent properties and sharing products and services, Acme Printing Inc. would not be eligible for the EASR.

The reason why printing facilities that mirror this example are excluded is due to requirements in Ontario’s Local Air Quality Regulation (O. Reg. 419/05) that may require adjacent properties to look at their combined emissions.

Note that two properties are adjacent to each other if the boundary of one touches the other or were it not for an intervening highway, road allowance, railway line, railway allowance or utility corridor, would touch each other.

Printing facilities located in multi-tenant buildings are not eligible for the EASR (O. Reg. 349/12, paragraph 3 of subsection 3 (4)). Printing facilities that are located in buildings comprised of several individual units where each unit can have different business cannot register. Examples of this include strip malls or multi-tenant office building where each unit in the mall or all or part of a floor in the building can have unique mailing addresses. This condition is intended to exclude facilities where same structure contamination may be an issue.

Printing facilities that are considered to be a Business Service Centre, Photo Finishing Laboratory or a One-Hour Photo Finishing establishment are not eligible for the EASR (O. Reg. 349/12, paragraph 8 of subsection 3 (4)). In general, these types of facilities do not normally require an ECA and, therefore, have not been required to be registered in the EASR. The regulation relies on the descriptions of these types of facilities provided in the North American Industry Classification System (NAICS) maintained for Canada by Statistics Canada. The associated NAICS codes are provide below:

- 561430 – Business service centres

- 812921 – Photo finishing laboratories (except one-hour)

- 812922 – One-hour photo finishing

Descriptions can be found by visiting the Statistics Canada website.

The regulation does not apply to businesses that manufacture equipment or materials used in a printing facility (O. Reg. 349/12. subsection 3 (3)). The regulation is intended to apply to certain facilities engaging in commercial printing. It is not intended to apply to businesses that manufacture equipment used at a printing facility (e.g. print presses, plate makers, companies that manufacture paper, inks, fountain solutions or other materials used at a commercial printer). These types of operations will need an ECA if one is otherwise required.

5. Operating requirements for eligible printing facilities

Operating requirements are found in two main sections of the regulation: section 5 and section 16.

5.1 Registering the printing facility

One key mandatory requirement for all EASR-eligible activities is that the business register the activity in the EASR. This requirement is from clause (a) of subsection 20.20 (1) of the Environmental Protection Act.

The registration process involves setting up a business profile with contact information and confirming eligibility by answering questions about the printing facility. Questions are also posed to the business for the purpose of collecting additional information about the facility that may assist the ministry in auditing registrations or conducting other compliance enforcement activities. The information also benefits the public who may locate information in the EASR through a search of the ministry’s Access Environment website.

Once registered, the business must ensure that the information filed in the Registry remains complete and accurate. If any information submitted at the time of registration changes the registrant must update this information within 30 days after the day the person becomes aware that the information is no longer complete or accurate. This requirement is from subsection 3 (1) of O. Reg. 245/11 under the Environmental Protection Act.

5.2 Activity requirements

For any printing facility, regardless of the type(s) of printing processes engaged in, the following operating rules must be followed:

- The following items are used, operated and maintained in a way recommended by the manufacturer:

- A printing production assembly that is part of a printing press.

- Equipment used or operated in a screen reclamation area.

- Noise generating equipment unit.

- Equipment used or operated to control the discharge of contaminants from a printing press.

- Equipment used or operated to control the discharge of contaminants from a printing press.

- Cyclone dust collectors and paper waste compactors shall be operated between the hours of 7 a.m. and 7 p.m.

- Any doors and windows to the exterior of the building from the area where the printing process is engaged in must be kept closed while the printing process equipment is being used except for the normal ingress and egress of staff, equipment and materials.

- If the operator of the facility receives a complaint about the facility that relates to the natural environment, the district manager of the Ministry must be notified of the complaint no later than two business days after the complaint is received.

The following rules must also be followed for the identified printing process:

Heatset web lithographic printing

- Any fountain solution used shall have a volatile organic compound concentration that is less than 30% by weight, as specified by the manufacturer of the fountain solution.

- Any ink used after the addition of any reducers shall have a volatile organic compound concentration that is less than 40% by weight.

- Any coating used shall have a volatile organic compound concentration that is less than 40% by weight, as specified by the manufacturer of the coating.

- Any adhesive used shall have a volatile organic compound concentration that is less than 40% by weight, as specified by the manufacturer of the adhesive.

- Press dryers are used or operated so that the vacuum at the web slot of the dryer is at least 1.3 mm of water relative to the press room, or so that the average capture velocity of the air entering the dryer ports is at least 1 m/s.

- Press dryers exhaust to equipment that is designed to control the discharge of contaminants and is specified by the manufacturer of the equipment as having a minimum emissions reduction efficiency of 95%.

- The exhaust stacks associated with the equipment (described in 6 above) shall be oriented vertically and shall be free of any impediments that would prevent the flow of emissions.

Newspaper lithographic printing

- Any fountain solution used shall have a volatile organic compound concentration that is less than 15% by weight, as specified by the manufacturer of the fountain solution.

- Any ink used shall have a volatile organic compound concentration that is less than 5% by weight, as specified by the manufacturer of the ink.

Non-heatset web or sheet-fed lithographic printing

- Any fountain solution used shall have a volatile organic compound concentration that is less than 15% by weight, as specified by the manufacturer of the fountain solution.

- Any ink used after the addition of any reducers shall have a volatile organic compound concentration that is less than 15% by weight.

- Any coating used shall have a volatile organic compound concentration that is less than 15% by weight, as specified by the manufacturer of the coating.

- Any adhesive used shall have a volatile organic compound concentration that is less than 15% by weight, as specified by the manufacturer of the adhesive.

Screen printing

- The exhaust stacks associated with a screen reclamation area or dryer shall be oriented vertically and shall be free of any impediments that would prevent the flow of emissions.

- Any organic solvent based liquid ink used shall have a volatile organic compound concentration that is less than or equal to 400 g/L.

For all printing types, the regulation requires that the amounts of materials (identified in the various tables in Parts III and IV of O. Reg. 349/12) used do not exceed the maximum amount of materials that can be used in a printing processes at the facility based on the setback distance to the property boundary of the facility.

For example, if a facility that engaged in digital printing using water based liquid inks has a 20 m setback, the facility would be out of compliance with the regulation if they used greater than 1,850 L of water based liquid inks in any month. Because the required setback distances are based on monthly usages under normal operation, an exceedence would not necessarily mean that the facility is ineligible to register in the EASR, although compliance action may be taken with respect to the non-compliance with the operating requirement. Frequent exceedence of monthly material usage limits may result in the facility being considered ineligible for the EASR.

5.3 Documentation requirements

Certain EASR-related records must be retained. Records must be available for inspection, upon request by a provincial officer. The requirements for these documents are outlined in section 16 of O. Reg. 349/12 and are summarized below:

| Type of Record | Description | Retention Period |

|---|---|---|

| Material Usage Record | Records must include the following information:

|

Minimum of 5 years from the day record was created. |

| Inspection, Maintenance and Repairs | Inspection and maintenance records must be kept for the following equipment:

See paragraphs 2 and 3 of subsection 16 (1) of O. Reg. 349/12. |

Minimum of 5 years from the day record was created. |

| Complaints | Complaints received by a facility that are related to the natural environment must be retained and contain the following information:

|

Minimum of 5 years from the day records were created. |

| Equipment Information | The following information related to specific equipment at the facility must be retained:

|

Until such time that the equipment is removed from the facility or replaced or retired from service. |

| Spill prevention and management plan | A spill prevention and management plan that contains at a minimum the following information must be retained:

|

For the life of the facility. |

Appendix A: printing materials usage tables

| Distance(Metres) | Organic solvent based liquid inks (litres) | Water based liquid inks (litres) |

|---|---|---|

| 20 | ≤ 230 | ≤ 1,850 |

| 30 | > 230 to ≤ 290 | > 1,850 to ≤ 2,300 |

| 50 | > 290 to ≤ 650 | > 2,320 to ≤ 5,200 |

| 100 | > 650 to ≤ 1,780 | > 5,200 to ≤ 14,280 |

| Distance(metres) | Screen printing materials (litres) | Cleaning solutions (litres) |

|---|---|---|

| 20 | ≤ 460 | ≤ 50 |

| 30 | > 460 to ≤ 590 | > 50 to ≤ 60 |

| 50 | > 590 to ≤ 1,120 | > 60 to ≤ 320 |

| 100 | > 1,120 to ≤ 3,400 | > 320 to ≤ 580 |

| Distance (metres) | Organic solvent based liquid inks used in digital printing (litres) | Water based liquid inks used in digital printing (litres) | Cleaning solutions used in screen printing (litres) | Organic solvent based liquid inks used in digital printing and screen printing materials used in screen printing (litres) |

|---|---|---|---|---|

| 20 | ≤ 230 | ≤ 1,850 | ≤ 50 | ≤ 460 |

| 30 | > 230 to ≤ 290 | > 1,850 to ≤ 2,320 | > 50 to ≤ 60 | > 460 to ≤ 590 |

| 50 | > 290 to ≤ 650 | > 2,320 to ≤ 5,200 | > 60 to ≤ 320 | > 590 to ≤ 1,120 |

| 100 | > 650 to ≤ 1,780 | > 5,200 to ≤ 14,280 | > 320 to ≤ 580 | > 1,120 to ≤ 3,400 |

Note: If a facility engages in both digital and screen printing then they must follow the limits in Table A3 (O. Reg. 349/12, section 8). They do not use Table A1 or A2.

| Distance (metres) | Lithographic printing materials (litres) |

|---|---|

| 30 | ≤ 330 |

| 50 | > 330 to ≤ 670 |

| 100 | > 670 to ≤ 1,830 |

| Distance (metres) | Lithographic printing materials (litres) |

|---|---|

| 20 | ≤ 1,070 |

| 30 | > 1,070 to ≤ 1,430 |

| 50 | > 1,430 to ≤ 3,710 |

| 100 | > 3,710 to ≤ 8,790 |

Note:

- ‘high VOC fountain solution’ means a fountain solution that has a volatile organic compound concentration that is greater than or equal to five per cent by weight

- ‘high VOC ink’ means an ink that has a volatile organic compound concentration that is greater than or equal to three per cent by weight

| Distance (metres) | Lithographic printing materials (litres) |

|---|---|

| 20 | ≤ 2,670 |

| 30 | > 2,670 to ≤ 3,870 |

| 50 | > 3,870 to ≤ 8,690 |

| 100 | > 8,690 to ≤ 23,880 |

Note:

- a ‘low VOC fountain solution’ means a fountain solution that has a volatile organic compound concentration that is less than five percent by weight

- a ‘low VOC ink’ means an ink that has a volatile organic compound concentration that is less than three per cent by weight

| Distance (metres) | Inks used in heatset web lithographic printing (litres) | Lithographic printing materials (litres) |

|---|---|---|

| 30 | ≤ 60 | ≤ 1,160 |

| 50 | > 60 to ≤ 120 | > 1,160 to ≤ 2,440 |

| 100 | > 120 to ≤ 390 | > 2,440 to ≤ 7,790 |

| Distance (metres) | Inks used in heatset web lithographic printing (litres) | Lithographic printing materials (litres) |

|---|---|---|

| 30 | ≤ 50 | ≤ 2,460 |

| 50 | > 50 to ≤ 100 | > 2,460 to ≤ 5,110 |

| 100 | > 100 to ≤ 330 | > 5,110 to ≤ 16,700 |

| Distance (metres) | Lithographic printing materials (litres) |

|---|---|

| 20 | ≤ 500 |

| 30 | > 500 to ≤ 680 |

| 50 | > 680 to ≤ 1,420 |

| 100 | > 1,420 to ≤ 3,890 |

| Distance (metres) | Inks used in heatset web lithographic printing (litres) | Lithographic printing materials (litres) |

|---|---|---|

| 30 | ≤ 50 | ≤ 540 |

| 50 | > 50 to ≤ 110 | > 540 to ≤ 1,110 |

| 100 | > 110 to ≤ 330 | > 1,110 to ≤ 3,270 |

Appendix B: monthly material usage tracking sheet sample template

Notes:

- List brand name or supplier’s (manufacturer’s) identification number from MSDS.

- Methods to determine material usage: 1) Record usage on a job-by-job basis and total at the end of the month 2) Beginning monthly inventory minus final monthly inventory plus purchases minus any amount of product that returned to suppliers minus amounts of product lost due to spills or upset conditions.

- Check product MSDS or supplier information for VOC content. Note VOC limits as per O. Reg. 349/12 may apply.

Appendix C: printing equipment information sheet sample template

Notes:

- For example: water-based digital, heatset web, sheet fed etc.

Appendix D: complaint record sample template

Notes:

- Use this sheet to record complaints related to the natural environment as required by O. Reg. 349/12.

- The District Office Manager must be notified no later than two businesses after the complaint was received.

- While not a regulatory requirement, contacting complainant after measures have been taken is recommended to ensure that the complaint has been resolved.

Footnotes

- footnote[1] Back to paragraph The act and O. Reg. 349/12 require a person who is engaging in activities set out in the regulation at a printing facility that meets the criteria set out in the regulation to register those activities in the EASR. In this guide ‘registering a printing facility’ is intended to refer to the registration of activities associated with that printing facility such as the use, operation, construction or alteration of equipment like a printing press. A reference to ‘a business’ is intended to be a reference to a person engaging in the activities set out in O. Reg. 349/12.