Private rural water supplies

Learn about groundwater, private water supplies and the different types of private rural water wells. This technical information is for Ontario farmers and rural residents.

ISSN 1198-712X, Published June 2021

Introduction

All Ontarians can play a role in protecting groundwater quality and quantity. This is the fourth fact sheet of seven in a series that will help Ontario’s farmers and rural residents learn more about groundwater and private water supplies. This fact sheet discusses the different types of private rural water wells that may be found on a rural property or farm.

The OMAFRA fact sheets in the groundwater series are:

- Understanding groundwater

- Managing the quantity of groundwater supplies

- Protecting the quality of groundwater supplies

- Private Rural Water Supplies

- Highly vulnerable water sources

- Disinfecting private water wells

- Testing and treating private water wells

Groundwater is a valuable resource for farm and rural families, farming (livestock watering, irrigation, wash water, etc.) and rural businesses, in some situations it may be the only water source. Understanding their type of well water supply and the factors and conditions that affect it can help well owners protect and conserve groundwater.

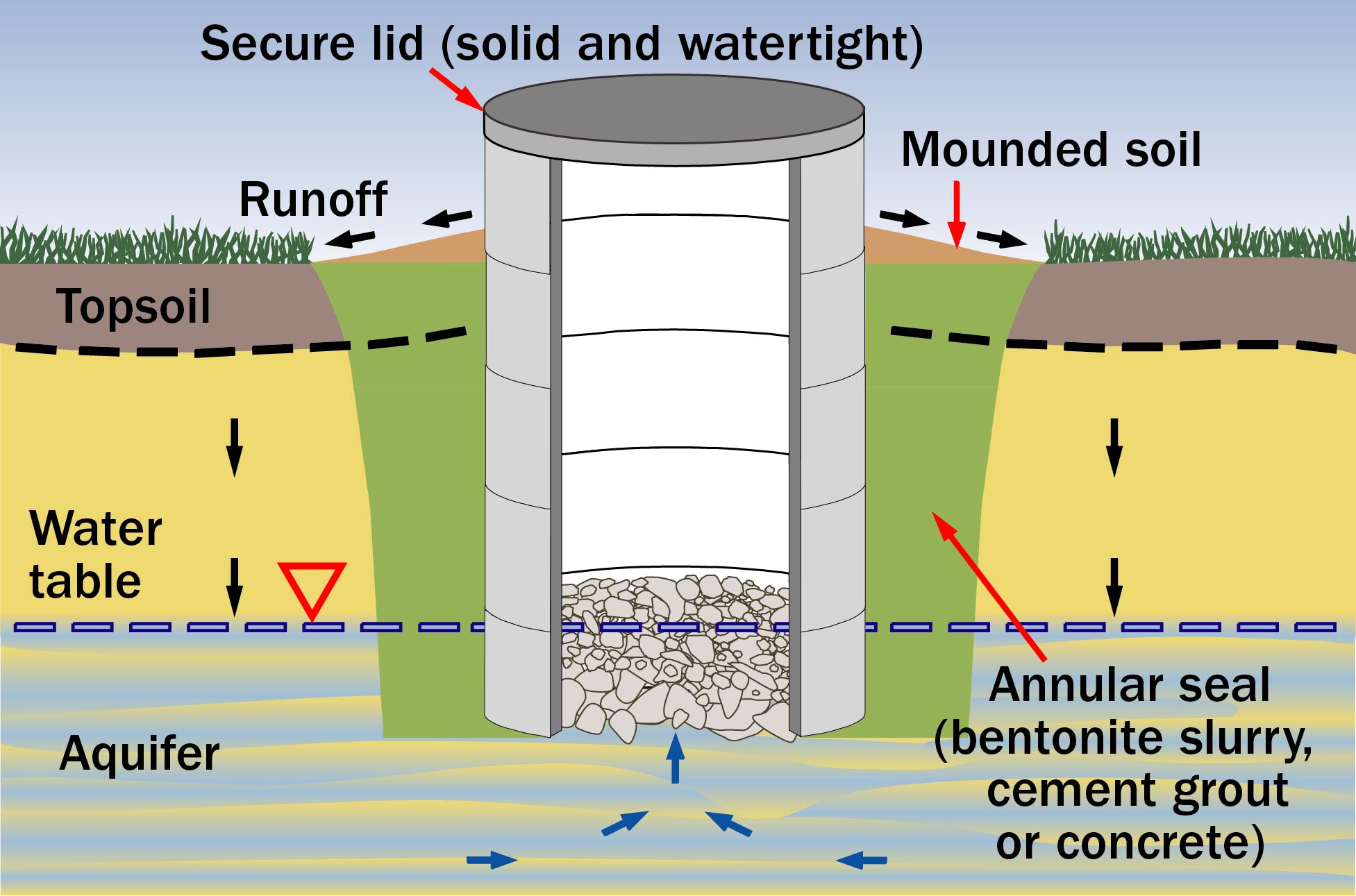

A well is designed to draw water while also keeping contaminants and surface water out. Proper well construction ensures that surface water cannot directly enter the well and will instead infiltrate and pass downward through the soil before it enters the well (Figure 1). A well casing with proper height and a secure lid prevents direct entry of surface water, dust, debris and vermin. Mounded-up soil around the wellhead directs water away from the well casing, and the watertight grout in the space around the well casing prevents surface water from easily moving down along the side of the well casing and into the groundwater.

Figure 1. A properly constructed dug or bored well keeps surface water and contaminants from the well.

In Ontario, Regulation 903 (the Wells Regulation) prescribes requirements for the construction, maintenance and abandonment of private water wells. The Wells Regulation requires that the well owner must maintain the well in a way that prevents the entry of surface water and other foreign materials into the well. Proper construction and maintenance of a well will help prevent it from becoming a pathway for surface water and contaminants to reach the groundwater. If a well is no longer used, it must be properly abandoned (plugged and sealed). The requirements for construction change periodically, and it is recommended that well owners refer to the current requirements under the Wells Regulation.

Surface water can sometimes be contaminated, and the soil will help filter and clean infiltrating water. The term “surface water” is used in a generic sense and does not distinguish between different forms. Regardless of the source, surface water can contaminate your well.

You can determine if your water supply is suitable for potable use (there is no significant evidence of bacterial contamination) by submitting samples to Public Health Ontario or to your local public health unit. When a well produces water that is not potable upon testing, the well owner should seek the advice of the local public health unit and take steps as directed. There are many corrective options to consider, and abandoning the well is only one option. Concerns with using surface water and highly vulnerable groundwater for water supplies are explained in more detail in the OMAFRA fact sheet, Highly vulnerable water sources.

Types of wells

It is important for well owners to know what kind of well they have, including how it was built and its basic operation. This information is summarized in a water well record that was created when the well was built. Contact the Ministry of the Environment, Conservation and Parks Wells Help Desk to obtain a copy of the water well record that was filed when the well was constructed. If the water well record is not available, there are other ways to determine the type of well. Important information for identifying your well type is summarized in Table 1.

| Casing size | Description |

|---|---|

| Small-diameter 10–20 cm (4–8 in.) | Drilled well (most locations) Note: Natural gas wells use similar-type casing. |

| Very small-diameter 2.5–5 cm (1–2 in.) | Sand-point well (if located in a shallow, sandy area) Note: Natural gas wells use similar-type casing. |

| Large-diameter 60–120 cm (24–48 in.) | Often called a bored or dug well |

The Well Regulation requires that a contractor submit a copy of the Water Well Record to the owner of a new, upgraded or abandoned well and the Ministry of the Environment, Conservation and Parks (MECP). You can contact the MECP Wells Help Desk to get a copy of the record of your well. You may want to start a log of actions and measurements that have been taken for your well and can be later retrieved for comparison purposes. See the OMAFRA fact sheet, Managing the quantity of groundwater supplies, for more information about creating actions and measurements for your well.

Natural gas wells have used narrow casing similar to very small-diameter private water wells. These often involved the inner narrow casing nested within a larger-diameter outer casing. More information on gas wells is found in the OMAFRA fact sheet, Locating Existing Water, Gas or Oil Wells.

Some wells have no visible casing. In the past, drilled and sand-point wells were sometimes buried or constructed in pits. Also, drilled wells were occasionally constructed in the bottom of large-diameter wells acting as pits.

Small-diameter wells

Drilled wells

A drilled well consists of a small-diameter casing ranging in size from 10–20 cm (4–8 in.). Drilled wells obtain water from either overburden or bedrock aquifers. Overburden wells include those constructed into overburden aquifers (the geological materials above bedrock), composed typically of sands and gravels, but also possibly of silts and clays.

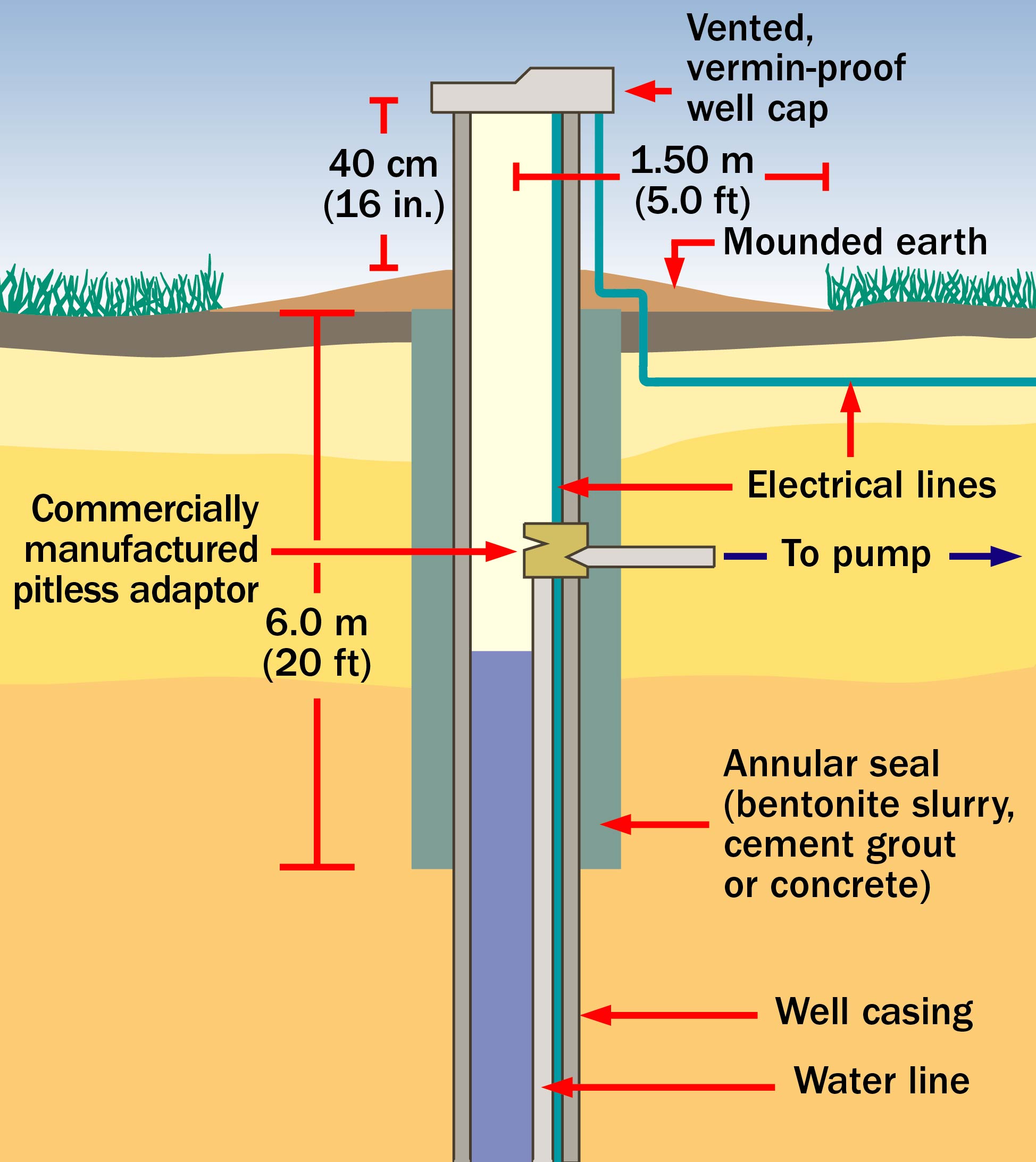

Most water wells are constructed with a well screen that allows groundwater to enter a well while keeping sand and other materials out. A properly constructed overburden well is shown in Figure 2. Well screen openings are sized carefully to allow water to flow efficiently into the well, prevent sediment from entering the well, and improve the connection between the well and the aquifer. Wells are “developed” during construction by the contractor to ensure that pumped water is sediment-free. The contractor will pump the well for an extended period by agitating water (also called surging) in the well, to remove fine-grained sediments from the area of the aquifer close to the screen.

Figure 2. Best management practices for a properly constructed, drilled overburden well.

An unscreened, poorly screened or poorly developed well is usually less efficient to operate and more difficult to maintain than a properly constructed (screened) well. Sediment can reduce pump life, affect quality of the water and in some cases plug a well.

Bedrock wells are drilled down through any overlying overburden (such as soils and sediments) and into the bedrock. The portion of the casing that extends from the ground surface to the top of the bedrock is often cemented around the exterior at the bedrock to ensure a good seal and avoid leakage of water from the overburden into the well. A well screen may or may not be used where bedrock is stable but may be installed to stabilize the drill hole if the rock is highly fractured or unstable and likely to cave in. Drilled bedrock wells, like drilled overburden wells, are developed during construction to ensure sediment-free water.

A properly constructed and maintained drilled well should prevent the entry into the well casing of any foreign substance that might impair water quality. When a well is drilled, a bore hole is created into which the well casing is placed. The annular space, which is the space between the casing and the outside of the borehole, should be sealed with a suitable sealant. The casing should be watertight, made from approved materials, and the joints should be welded or properly sealed. This watertight method of construction (using the best management practices shown in Figure 2) makes drilled wells less vulnerable to contamination than other types of wells.

Existing drilled wells that do not meet the specifications in Figure 2 can be upgraded in a number of ways:

- Extend the well casing above finished ground surface by at least 40 cm (16 in.). Where a drilled well is located in a well pit, remove the well pit casing (concrete tile), extend the casing above the ground surface, and backfill and seal the old pit.

- Mound soil around the well casing above normal ground level and slope it away from the casing to prevent ponding and direct surface water away from the well.

- Cover the top of the casing with a commercially manufactured, vermin-proof well cap.

A complete well maintenance checklist including these, and other best management practices is provided in the OMAFRA fact sheet, Protecting the quality of groundwater supplies. These best management practices either meet or exceed the requirements of the Wells Regulation.

Well points

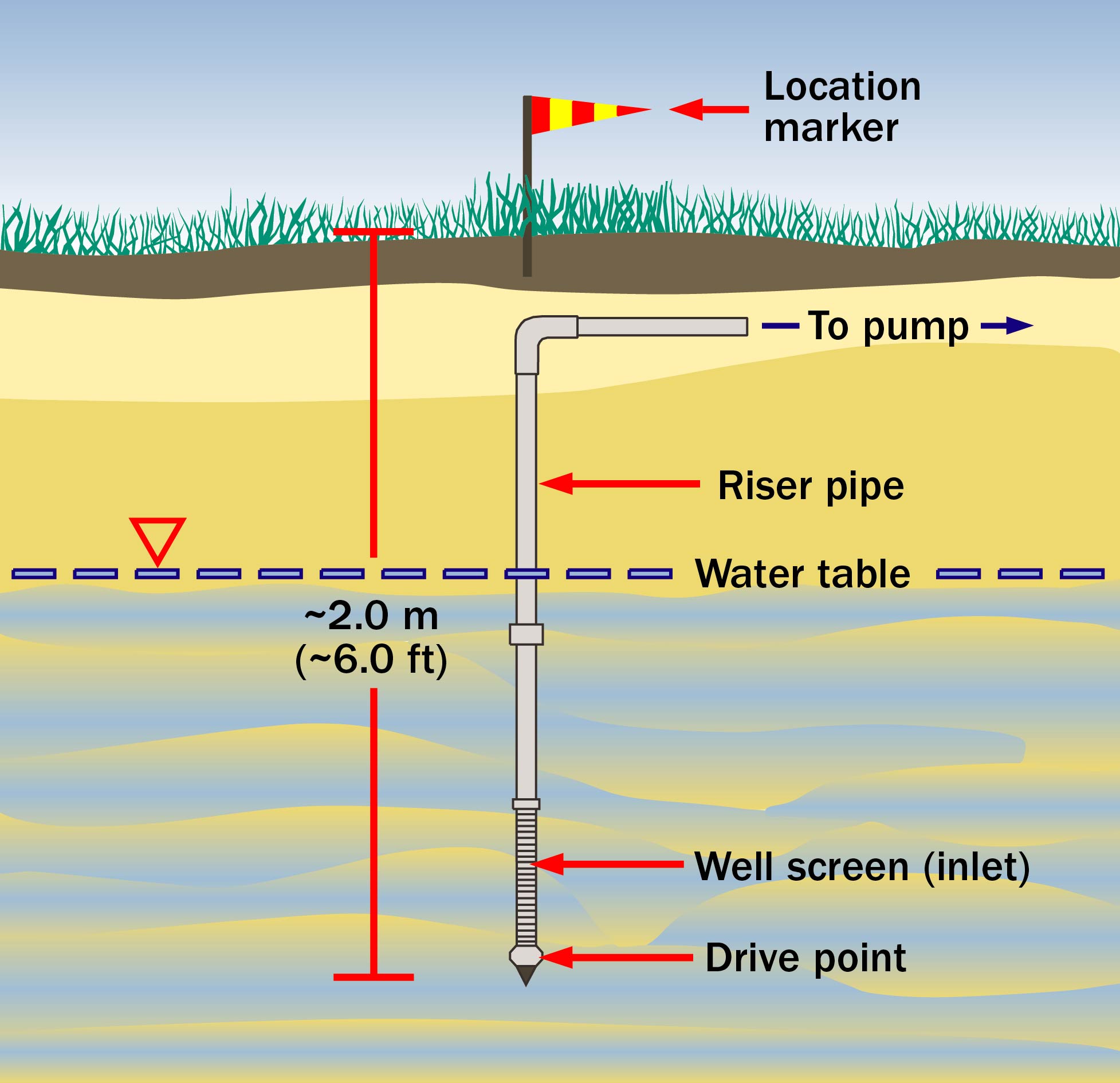

Well points, sand-point or driven-point wells consist of a small-diameter casing (usually) ranging in size from 2.5–5 cm (1–2 in.). Well points are constructed in sand and gravel aquifers and are either driven or jetted (inserted using high-pressure water) into the ground. Well points are usually only installed where the aquifer has a shallow water table and contains few or no stones.

Figure 3 shows the construction of a typical well point. Because of the type of construction (driven or jetted into place) and the type of aquifer (unconfined, shallow, sand or gravel), well points are considered highly vulnerable to contamination. Contaminants on the ground surface have only a short distance to travel before reaching the water table and the well inlet. They are also very susceptible to seasonal low water conditions and may not be able provide the required amount of water when needed.

Figure 3. Example of a well point installation.

Large-diameter wells

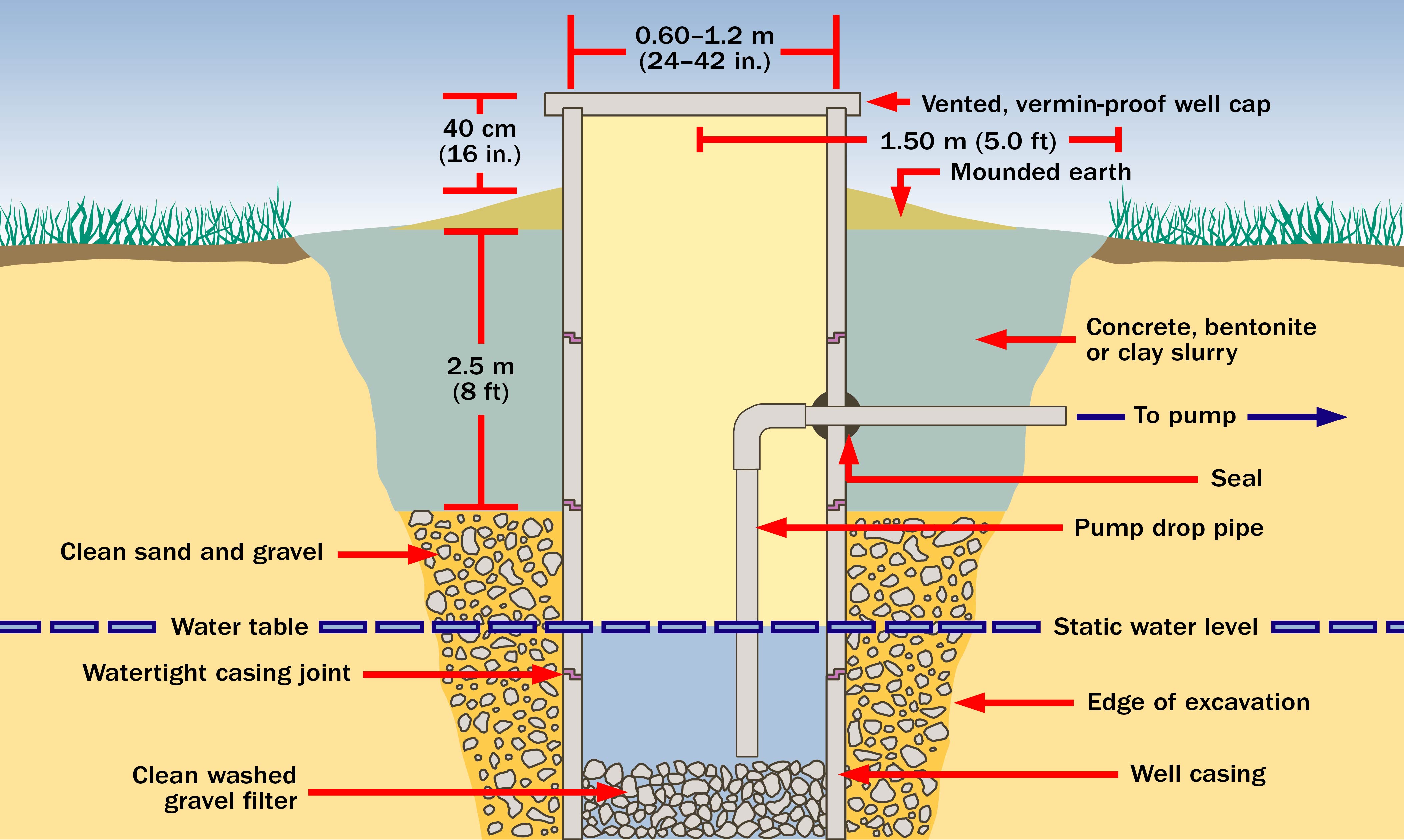

Large-diameter wells are constructed with prefabricated concrete tile or corrugated galvanized steel pipe ranging in diameter from 60–120 cm (24–48 in.) (Figure 4). Older wells may be constructed of brick, stone or even wood cribbing and are very susceptible to undesirable surface‑water seepage through the portion of the casing located above the water table.

Figure 4. A properly constructed large diameter well

Dug wells, which were often hand-dug in the past, are now constructed primarily with excavation equipment. They are usually no more than 9 m (30 ft) deep.

Bored wells are now constructed with the use of a boring machine. The average depth of bored wells is 15 m (50 ft), but some are 30 m (100 ft) deep. An example of a properly constructed large-diameter well is shown in Figure 4.

Large-diameter wells can now be made of metal or approved plastic casing, where the joints are made watertight by welding or sealing with a waterproof material (Figure 4). Large-diameter wells in general are more vulnerable to contamination than drilled wells because of potential leaks in the casing joints and the difficulty of grouting the well’s annular space properly.

All large-diameter wells must be capped with a safe cover to prevent unwanted access by water, vermin or other contaminants to the well’s interior.

Extremely shallow large-diameter wells (less than 3 m (10 ft) deep) may experience the added problem of low water levels during extended periods of low precipitation. The result can be a reduction in the amount of water that a well can provide, or the well may go dry. More information about managing private wells during times of low precipitation is presented in the OMAFRA fact sheet, Managing the quantity of groundwater supplies.

Extremely shallow large-diameter wells may also be more prone to water quality issues. More Information on these and other highly vulnerable water sources Is provided In the OMAFRA fact sheet, Highly vulnerable water sources.

Unused wells

Unused or improperly abandoned wells are a significant potential source of groundwater contamination.

In Ontario, all wells, whether used or not used, must be maintained, according to the Wells Regulation. If not maintained, the well must be properly abandoned (plugged and sealed to protect the aquifer from the direct entry of surface water and contaminants). When considering upgrading, replacing or abandoning a well, consult a licensed well technician who also holds a valid well contractor licence or works for the holder of a valid well contractor licence. Properly abandoning a well also prevents the movement of water and contaminants between aquifers, or between an aquifer and the ground surface, and eliminates a safety hazard to humans and animals.

This fact sheet is consistent with, but does not reflect the full detail, of the Wells Regulation. For assistance with the Regulation, seek advice from the Ontario Ministry of the Environment, Conservation and Parks (MECP) through the Wells Help Desk. Call

Resources

Ontario Ministry of the Environment, Conservation and Parks:

- Water Supply Wells: Requirements and Best Practices

- Well Maintenance — Well Maintenance

- Technical Bulletin — Well Repairs and Other Alterations

- Technical Bulletin — Well Abandonment: How to Plug and Seal a Well

Ontario Soil and Crop Association:

- Information on different actions that can be taken to protect the quality of groundwater and your drinking water supply is provided in the Canada-Ontario Environmental Farm Plan workbook and associated Infosheets.

This fact sheet was updated by Dr. Hugh Simpson, program analyst (retired), OMAFRA; Jim Myslik, JPM consulting and Brewster Conant, Jr. It was reviewed by John Warbick, engineer, crop systems & environment, OMAFRA.