Item 3: Racks and stacking structures

Overview of Item 3

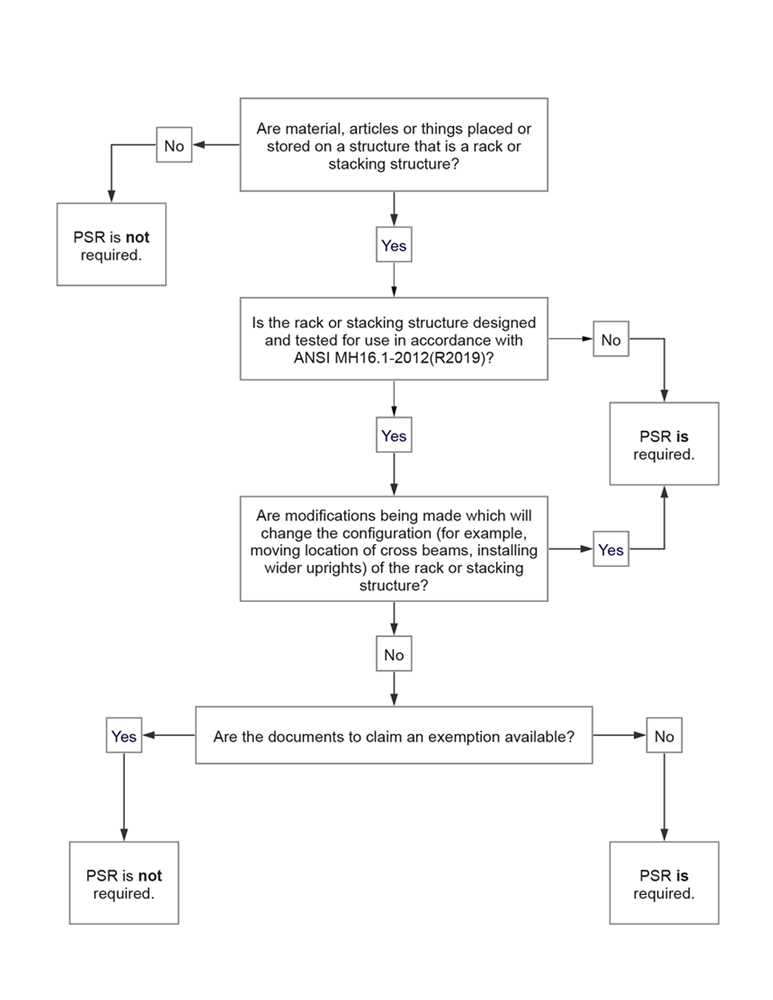

When materials, articles or things are to be placed or stored on a rack or stacking structure, a PSR is required under Item 3 unless an exemption can be established.

For the purpose of Item 3, racks or stacking structures are structures designed so that mechanical lifting devices, typically lift trucks, are used to place loads onto them. These racks could be made of steel, wood, aluminum or concrete structural members.

These structures may be referred to as:

- industrial pallet racks

- stacker racks

- drive-in and drive-through racks

- cantilever racks

- push-back racks

- selective racks

The applicable provision of the Industrial Establishments Regulation is clause 45(b), which requires that materials, articles or things be transported, placed or stored so that the material, article or thing will not tip, collapse or fall. In addition, the regulation requires these items be removed or withdrawn without endangering the safety of any worker.

The PSR requirement would be triggered when a new rack or stacking structure is to be installed in a factory or an existing rack or stacking structure is to be modified. Other modifications that may trigger a PSR would include changing the kind of lift trucks used to load materials onto the rack or the type or weight of the loads to be stored on the rack or stacking structure deviate from their original design parameters.

The material that is to be stored should be reviewed to determine if the material introduces a hazard, for example, the storage of flammable or corrosive materials.

A building permit may be required for racks and stacking structures, but this does not override the requirement to complete a PSR or to establish an exemption. However, the documentation used for the purposes of a permit could form part of a PSR report or could be used to support an exemption.

Out of scope

A PSR for Item 3 would not be required for the following:

- Shelving units that are intended for low-weight storage and that will be loaded by hand from the ground, such as shelving units for spare parts or small racks for storage that are purchased from a hardware store.

- Shelf and rack storage systems that are regulated by Ontario’s Building Code. These are self-contained structural systems within a building, with one or more elevated platforms or walkway levels for personnel access, which may also support conveyors and other material handling, storage and distribution equipment. They must be designed by an engineer.

- Component replacement or repair that does not alter the configuration of the rack or stacking structure and the replacement/repaired component is identical to the original component.

- Component replacement or repair if there is documentation from the manufacturer or an engineer stating that the replaced/repaired component sufficiently maintains or restores the original capacity of the rack or stacking structure.

- Structural adequacy of the floor supporting the rack or stacking structure. However, a floor must be able to safely support the racks or stacking structures and the loads that will be placed on them. See clause 25(1)(e) of the OHSA and Ontario’s Building Code for details.

- Damage to existing racks or stacking structures. However, damage can adversely affect the capacity of a rack or stacking structure, sometimes severely. Under the OHSA an employer must maintain equipment in good condition, which would include inspecting racks for damage and repairing them appropriately.

PSR for Item 3

A PSR for Item 3 must include details of the measures that must be taken to comply with clause 45(b) as well as details of the structural adequacy of the rack or stacking structure. Most manufacturers or suppliers will provide a PSR with their racking systems.

The PSR should include information about the design standards and loading conditions used to design and manufacture the rack or stacking structure, its maximum capacity, anchorage, erection tolerances, installation instructions, etc. The author of the PSR should take into account the equipment to be used to place and withdraw the materials, articles or things. Review of this equipment could include the capacity, turning radius, and vertical and horizontal reach.

A review of actual pallet loads is not required for a PSR. The PSR would focus on the parameters and/or type of load the rack or stacking structure is designed to support. It would be the responsibility of the employer to ensure the pallet loads are stable and conform to the specified parameters.

The following codes, guidelines, regulations and standards should be referenced when carrying out a PSR for Item 3:

- Ontario Building Code (O. Reg. 332/12) under the Building Code Act, 1992

- Ontario Fire Code (O. Reg. 213/07) under the Fire Protection and Prevention Act, 1997

- Code of Practice for the Design of Static Racking, published by the Storage Equipment Manufacturers Association (SEMA)

- The Civil Engineering Handbook, editors: W.F. Chen, J.Y. Richard Liew, CRC Press 2002, 2nd. Edition.

- CSA S16, Design of Steel Structures

- CSA-S136, Cold Formed Steel Structural Members

- CSA-S157, Strength Design in Aluminum

- ANSI MH16.1-2012(R2019)* Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks

Reviewer for a PSR for Item 3

A reviewer for Item 3 must be an engineer.

Exemptions for Item 3

When a workplace can establish through documentation that a rack or stacking structure is designed and tested for use in accordance with ANSI MH16.1-2012 (R2019)* Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks, the owner, lessee or employer may claim an exemption from conducting a PSR.

If the load limits set out by the manufacturer of the rack will be exceeded, then a PSR will be required to assess whether the structure has the capacity to support the additional loading.

Documents for establishing an exemption

To establish an exemption to Item 3, the following documents from the manufacturer, supplier or vendor of the rack or stacking structure would be acceptable:

- a statement that the rack or stacking structure is designed and tested for use in accordance with ANSI MH16.1-2012(R2019) Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks

- capacity tables, capacity charts, or a written statement specifying the capacity

- structural drawings, identification of all components and how they must be assembled, and

- instructions for the safe installation and use of the rack or stacking structure

Each component provided by the manufacturer must be tested to the standard to validate the design. Once a component has been tested and validated, it becomes acceptable for use.

A rack or racking system that is assembled using components (for example, beams and upright frames) that have been designed and tested for use in accordance with ANSI MH16.1-2012(R2019)* Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks may still require a PSR if there is no documentation that clearly states that the rack or stacking structure as a whole is designed to the above listed current applicable standard.

The installation of a racking system should only be carried out by workers who have received adequate training and are familiar with rack assembly procedures. The installation should be carried out in accordance with instructions from the manufacturer or an engineer licensed in Ontario.

Flow Chart 4 – Racks and stacking structures exemption