Item 4: Processes with a risk of ignition or explosion

Overview of Item 4

When a process involves a risk of ignition or explosion that would create a condition of imminent hazard to a person’s health or safety, a PSR is required under Item 4 unless an exemption can be established. A process for the purposes of Item 4 could be as simple as heating a substance that will produce ignitable vapour that could explode, or as complex as a process at a paint manufacturing facility. There is an exemption if the process is conducted inside a spray booth.

The applicable provision of the Industrial Establishments Regulation is section 63, which applies to processes that are likely to produce a gas, vapour, dust or fume to such an extent as to be capable of forming an explosive mixture with air. Section 63 requires that these processes be carried out in areas that meet specific conditions.

A PSR would be triggered if a new process that meets the conditions for Item 4 is introduced to a workplace, or if the process is modified and new engineering controls are needed for section 63 to be complied with.

While not specific to a PSR for Item 4, sections 121 and 122 of the Industrial Establishments Regulation may affect design criteria for a hazardous room.

Out of scope

A PSR for Item 4 would not be required for the following:

- Dispensing flammable liquids covered by Item 1 of the Table.

- When a process for which a PSR was conducted has not changed. If existing process equipment and components, including associated piping, vessels, components and instrumentation are modified, the changes must be reviewed by a person with the appropriate knowledge, skill and experience to ensure that the level of process safety that existed prior to the modification is maintained or exceeded so that people and workers continue to be protected from imminent hazards to their health or safety.

- Appliances, boiler and pressure vessels and propane-fired equipment reviewed by the TSSA.

The PSR for Item 4

When a process involves a risk of ignition or explosion that creates a condition of imminent hazard to a person’s health or safety and a PSR is being undertaken to determine compliance with section 63 or measures to be taken to achieve compliance, the scope of the PSR must include the entire process, including the piping. If there are appliances such as boilers, furnaces, or other appliances that are part of a process that involves the risk of ignition or explosion and that have not been reviewed by the TSSA, the PSR must include those appliances.

The following codes, guidelines, regulations and standards should be referenced when completing the PSR.

- Ontario Building Code (O. Reg. 332/12) under the Building Code Act, 1992

- Ontario Electrical Safety Code (O. Reg. 164/99) under the Electricity Act, 1998

- Ontario Fire Code (O. Reg. 213/07) under the Fire Protection and Prevention Act, 1997

- National Fire Code of Canada (NFC), Parts 4 and 5

- Technical Standards and Safety Act, 2000 and its regulations

- Factory Mutual Systems - Handbook of Industrial Loss Prevention

- PLUS 2203 HAZLOC-94, Hazardous Locations: A Guide for the Design, Construction and Installation of Electrical Equipment in Explosive Atmospheres by John A. Bossert (Available from CSA ISBN 0-921347-39-1)

- Perry’s Chemical Engineers’ Handbook

- Standard Handbook for Electrical Engineers

- Standard Handbook for Mechanical Engineers

- Factory Mutual Global (FM Global) - Property Loss Prevention Data Sheets

- Industrial Ventilation: A Manual of Recommended Practice for Design, published by the American Conference of Governmental Industrial Hygienists (ACGIH)

- ANSI/API (American Petroleum Institute) 500: Recommended Practice for Classification of Locations of Electrical Installations at Petroleum Facilities Classified as Class I, Division 1 and Division 2

- American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) 15: Safety Standard for Refrigeration Systems

- CSA B52-13* Mechanical Refrigeration Code

- CSA B51-14* - Boiler, Pressure Vessel, and Pressure Piping Code

- CSA-B149.1-05 Natural gas and propane installation code

- Underwriters Laboratories Canada (ULC) standards

National Fire Protection Association (NFPA) standards and codes of practice

- NFPA 30: Flammable and Combustible Liquids Code

- NFPA 33*: Standard for Spray Application Using Flammable or Combustible Materials

- NFPA 34: Standard for Dipping, Coating, and Printing Processes Using Flammable or Combustible Liquids

- NFPA 68: Standard on Explosion Protection by Deflagration

- NFPA 69: Standard on Explosion Prevention Systems

- NFPA 86: Standard for Ovens and Furnaces

- NFPA 497: Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

- NFPA 499: Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

- NFPA 505: Fire Safety Standard for Powered Industrial Trucks

- NFPA 820: Standard for Fire Protection in Wastewater Treatment and Collection Facilities

- Fire Protection Handbook, published by the NFPA

Reviewer for a PSR for Item 4

A reviewer for Item 4 must be an engineer.

Exemptions for Item 4

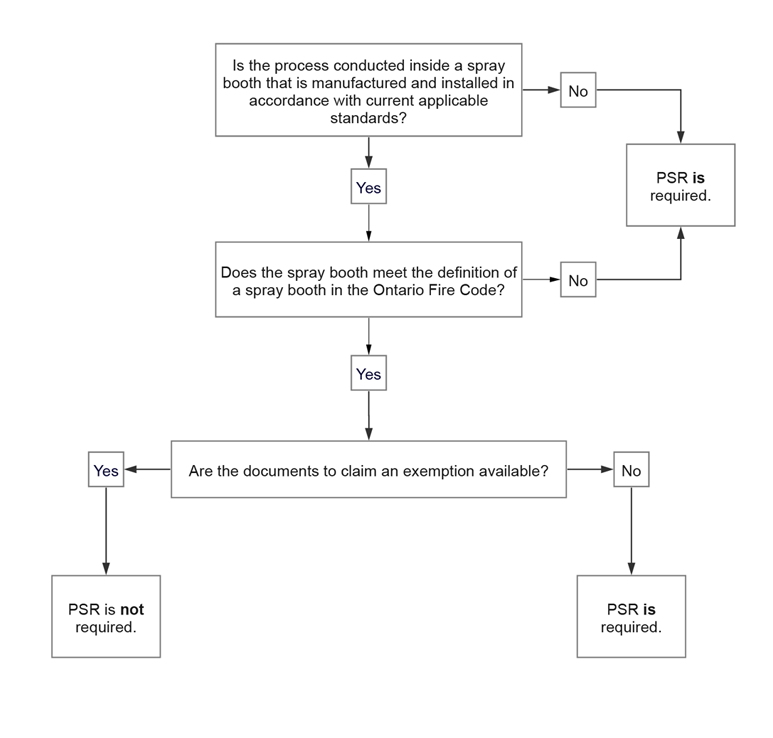

A PSR is not required if the process is conducted inside a spray booth that is manufactured and installed in accordance with current applicable standards, including NFPA 33*: Standard for Spray Application Using Flammable or Combustible Materials. Ontario’s Building Code and Fire Code must also be met.

For the purposes of section 7, a spray booth means a spray booth as defined in Ontario’s Fire Code – a power-ventilated structure that encloses or accommodates a spraying operation so that spray vapour and residue can be controlled and exhausted. This could include a self-contained powder coating unit.

The exemption for spray booths does not apply to equipment installed inside the spray booth (for examples, robots).

Documents for establishing an exemption

In establishing an exemption to Item 4, keep all the following documents:

- written documentation from the manufacturer, or certification from an accredited organization, declaring that the spray booth is manufactured to current applicable standards

- written documentation from the installer stating that the spray booth is installed in accordance with current applicable standards

Flow Chart 5 – Spray booth exemption